Press release

Engineering Polymers Market to Hit USD 211.8 Bn by 2031, Growing at 5.7% CAGR

The global engineering polymers market was valued at USD 129.8 billion in 2022 and is projected to reach USD 211.8 billion by the end of 2031. This growth reflects a compound annual growth rate (CAGR) of 5.7% from 2023 to 2031. The market expansion is driven by increasing demand from automotive, electronics, aerospace, and industrial sectors due to the superior mechanical, thermal, and chemical properties of engineering polymers compared to conventional plastics.Surge in focus on reducing vehicle weight, improving fuel efficiency, and meeting emission standards is anticipated to offer lucrative opportunities for vendors in the global engineering polymers industry. Rise in adoption of Electric Vehicles (EVs) is boosting the need for lightweight and thermally resistant materials for battery components and electric motors.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85839

Market Segmentation

The engineering polymers market can be segmented based on various factors:

By Compound Type:

Polycarbonate (PC): Known for its high impact strength and optical clarity, widely used in automotive and electronics.

Polyamide (PA) / Nylon: Versatile, offering high strength, stiffness, and heat resistance, used in automotive, electrical, and industrial applications. Demand for polyamide in 3D printing is also increasing.

Polymethyl Methacrylate (PMMA): Valued for its transparency and weather resistance.

Polyacetal/Polyoxymethylene (POM): Offers excellent stiffness, low friction, and dimensional stability.

Polyethylene Terephthalate (PET): Primarily used in packaging (bottles and containers) due to its recyclability, cost-effectiveness, and clarity.

Polybutylene Terephthalate (PBT): Offers good electrical properties and chemical resistance.

Polyphenylene Oxide (PPO/PPE Blends): Known for heat resistance and dimensional stability.

Fluoropolymers (PTFE & Other FPs): Renowned for their heat stability, electrical properties, non-adhesive, and low-friction characteristics.

Polyphenylene Sulfide (PPS): High-performance thermoplastic with excellent chemical and heat resistance.

Acrylonitrile Butadiene Styrene (ABS): Popular for its low production cost, impact resistance, and aesthetic appeal, often used in injection molding applications.

Styrene Copolymers (ABS and SAN): Held the largest share of 33.7% in 2023.

Liquid Crystal Polymer (LCP): Emerging as the fastest-growing segment due to exceptional properties for electronic components and miniaturization.

Thermoplastic Elastomers (TPEs): Including Styrenic Block Copolymers, Thermoplastic Polyolefin Elastomers, Thermoplastic Vulcanizates, Thermoplastic Polyurethanes, Thermoplastic Copolyesters, and Thermoplastic Polyamides.

By Application/End-Use Industry:

Automotive & Transportation: The largest segment, driven by demand for lightweight automobiles to improve fuel efficiency and reduce emissions.

Engineering plastics are used in interior and exterior furnishings, engine parts, electrical components, and under-the-hood items.

Electrical & Electronics: Significant growth driven by increasing demand for consumer electronics (computers, communication equipment, appliances), wires, cables, sockets, and circuit breakers.

Industrial & Machinery: Fastest-growing segment due to the superior properties of engineering plastics in industrial components.

Consumer Goods & Appliances: Used in a wide range of products from televisions to refrigerators.

Packaging: Extensive use in various packaging formats due to properties like clarity, strength, and recyclability.

Medical: Growing demand for medical-grade polymers in surgical instruments, disposable devices, wellness, and wearable devices.

Building & Construction: Utilized in pipes, tubes, and other structural components.

Aerospace: High-performance plastics are increasingly used in structural components, insulation, and seals due to their lightweight and strength properties.

By Sourcing Type (Not explicitly detailed in provided info but a relevant segmentation):

Virgin Polymers

Recycled Polymers

Bio-based Polymers

By Service Type (Not explicitly detailed in provided info but a relevant segmentation):

Compounding

Fabrication

Molding

Others

By Region:

Asia Pacific: Expected to hold the largest market share and be the fastest-growing region from 2023 to 2031. Rapid industrialization, increasing automotive production, expanding electronics sector, and a focus on material innovation in countries like China, India, and Japan are key drivers.

North America: Major consumer of polyamide, PC, PET, PPO/PS blends, and POM, driven by expansion in electrical & electronics sector and innovations in high-performance formulations.

Europe: Similar to North America, with strong demand from automotive and electronics sectors.

Latin America: Moderate growth expected.

Middle East & Africa: Growth anticipated due to ongoing infrastructure projects requiring engineering plastic products.

Regional Analysis

Asia Pacific continues to dominate the engineering polymers market, fueled by robust manufacturing activities, particularly in the automotive and electrical & electronics industries. Countries like China and India are experiencing significant growth in demand for lightweight vehicles and electronic products.

North America and Europe are mature markets with a strong focus on high-performance applications and continuous innovation in polymer formulations. The demand for medical-grade polymers and advanced automotive components contributes significantly to their market share.

Market Drivers and Challenges

Market Drivers:

Growth in End-Use Industries: The flourishing automotive & transportation, electrical & electronics, industrial & machinery, packaging, and consumer appliances sectors are the primary demand drivers.

Demand for Lightweight Materials: In the automotive and aerospace industries, the need for lighter components to improve fuel efficiency and reduce emissions is a key driver for engineering polymers as metal replacements.

Technological Advancements: Innovations in material science, manufacturing processes (e.g., 3D printing), and machinery are continuously enhancing the properties and applications of engineering polymers.

Miniaturization of Electronics: The increasing complexity and smaller size of electronic devices necessitate high-performance, durable, and lightweight materials.

Urbanization and Industrialization: Rapid urban and industrial growth, particularly in emerging economies, fuels demand across various applications.

Market Challenges:

High Costs Compared to Commodity Plastics: Engineering polymers often have a higher price point, limiting their widespread adoption in cost-sensitive applications.

Competition from Other Polymers: Engineering plastics face competition from commodity polymers (e.g., polypropylene) in certain lower-end applications, especially where cost is a major factor.

Price Volatility of Raw Materials: Fluctuations in crude oil prices and supply chain disruptions can impact the cost of petrochemical-based raw materials.

Environmental Concerns and Regulations: Growing awareness of plastic waste and environmental impact is leading to stricter regulations and a push for sustainable and recyclable alternatives.

Lack of Skilled Workforce: In some developing regions, a shortage of skilled labor and adequate testing facilities can hinder market growth.

Market Trends

Sustainability and Circular Economy: Increasing focus on developing eco-friendly, bio-based, and recyclable engineering polymers to address environmental concerns. Companies are investing in research for bio-based adipic acid (for nylon 66) and exploring conversion of plastic waste into fuel.

Additive Manufacturing (3D Printing): Engineering polymers are crucial for 3D printing, enabling the creation of complex geometries and customized products across various industries, including medical and automotive.

High-Performance Thermoplastics: Continued development of thermoplastics with enhanced properties like transparency, chemical resistance, and heat stability for demanding applications.

Smart and Functional Materials: Research and development in polymers that can respond to external stimuli (light, heat, moisture) for applications in robotics, medical devices, and wearable tech.

Automation in Manufacturing: Increased adoption of automation in plastic manufacturing to improve efficiency, reduce costs, and address labor scarcity.

Electrification and Digitalization: These macro trends are driving demand for specific engineering polymers in electrical wiring, cables, and components for electric vehicles (EVs).

Future Outlook

The future of the engineering polymers market appears promising, driven by ongoing innovation and increasing demand across critical sectors. The emphasis will be on developing more sustainable, high-performance, and cost-effective solutions. The shift towards a circular economy, with increased recycling and the development of bio-based alternatives, will be a defining characteristic of the market. Continued advancements in additive manufacturing and smart materials will also open up new application avenues.

Key Market Study Points

In-depth analysis of compound types and their specific applications.

Detailed understanding of market drivers, restraints, and opportunities.

Regional market dynamics and growth potential.

Impact of technological advancements and sustainability initiatives.

Competitive strategies and recent developments by key players.

Pricing trends and cost structures across different polymer types.

Competitive Landscape

The engineering polymers market is characterized by the presence of several global and regional players. Key companies are focusing on strategic initiatives such as research and development, product innovation (including bio-based and recycled materials), capacity expansion, and mergers & acquisitions to strengthen their market position.

Prominent Industry Players include:

BASF SE

Covestro AG

Celanese Corporation

Asahi Kasei Corporation

DuPont de Nemours Inc.

LG Chem Ltd.

Mitsubishi Chemical Corporation

Saudi Basic Industries Corporation (SABIC)

Solvay S.A.

Toray Industries, Inc.

Victrex Plc.

Lanxess AG

Daicel Polymer Ltd.

Kawasaki Sanko Kasei Co., Ltd.

AKRO-PLASTIC GmbH

RadiciGroup

These companies are actively engaged in product development and strategic partnerships to cater to the evolving demands of end-use industries.

Recent Developments

February 2023: Covestro AG introduced Makrolon 3638 polycarbonate for healthcare and life sciences applications, including wearable devices and drug delivery.

April 2023: BASF launched a high-performance thermoplastic elastomer for electrical and electronics applications, offering flexibility, dielectric properties, and flame retardancy.

May 2023: Borealis AG announced the launch of a new class of engineering polymer, Stelora.

November 2023: Celanese Corp. commercially launched Frianyl PA W-Series and Celanyl PA B3 GF30 E, new polyamide compounds for electric vehicle (EV) powertrain components and batteries.

January 2023: Bertone Inc. introduced the GB110 hypercar, powered by plastic waste, showcasing a novel application of plastics.

August 2022: Toray Industries, Inc. developed the first fully bio-based adipic acid, a component of nylon 66, from non-edible feedstock.

May 2022: RadiciGroup acquired Ester Industries Ltd.'s engineering plastics business to expand its presence in the Indian market.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=85839<ype=S

These developments underscore the continuous innovation and strategic growth observed in the engineering polymers market, positioning it for significant expansion in the coming years.

Explore Latest Research Reports by Transparency Market Research:

Engineering Polymers Market - https://www.transparencymarketresearch.com/engineering-polymers-market.html

Below-slab Vapor Barrier Market - https://www.transparencymarketresearch.com/below-slab-vapor-barrier-market.html

Medium Voltage Electric Cables Market - https://www.transparencymarketresearch.com/medium-voltage-electric-cable-market.html

Green Polypropylene Market - https://www.transparencymarketresearch.com/green-polypropylene-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Want to know more? Get in touch now. -https://www.transparencymarketresearch.com/contact-us.html

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Engineering Polymers Market to Hit USD 211.8 Bn by 2031, Growing at 5.7% CAGR here

News-ID: 4066475 • Views: …

More Releases from transparencymarketresearch

Air Fryer Market to Reach USD 2,343.9 Mn by 2036 Driven by Health-Focused Cookin …

The global air fryer market was valued at USD 1,103.4 Mn in 2025 and is projected to reach USD 2,343.9 Mn by 2036, expanding at a CAGR of 7.8% from 2026 to 2036. Market growth is primarily driven by rising health consciousness and increasing demand for low-oil cooking appliances among consumers. Busy urban lifestyles, compact kitchen trends, and the growing preference for convenient home-cooking solutions are further supporting adoption. Additionally,…

Global Yeast Market to Reach US$ 16.9 Bn by 2036 Driven by Bakery and Beverage D …

The global yeast market was valued at USD 9.7 Bn in 2025 and is projected to reach USD 16.9 Bn by 2036, expanding at a CAGR of 5.1% from 2026 to 2036. Market growth is primarily driven by increasing demand from the bakery and food processing industries, along with the steady expansion of alcoholic and non-alcoholic beverage production. Rising consumption of convenience foods and fermented products continues to support sustained…

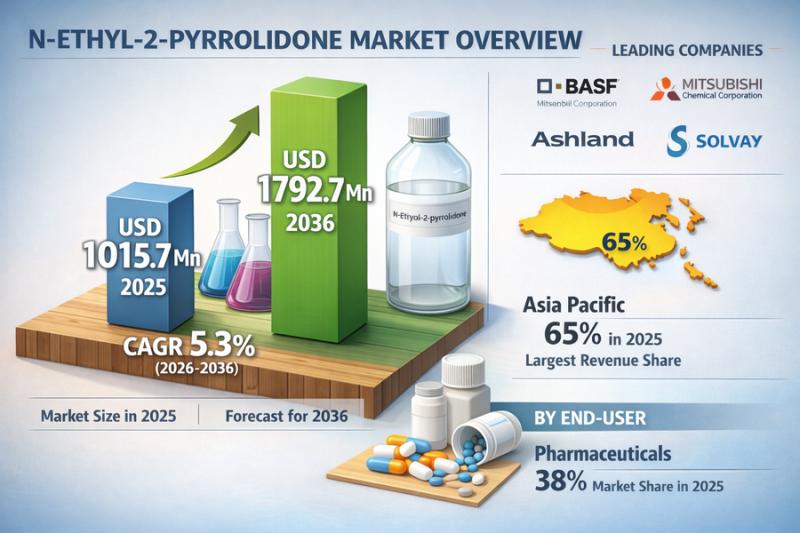

N-Ethyl-2-pyrrolidone Market to Reach USD 1,792.7 Million by 2036 at 5.3% CAGR

The N-Ethyl-2-pyrrolidone market was valued at USD 1,015.7 million in 2025 and is projected to reach USD 1,792.7 million by 2036. The industry is expected to grow at a CAGR of 5.3% from 2026 to 2036, supported by increasing demand across pharmaceuticals, electronics, petrochemicals, and industrial cleaning applications.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85529

Market Overview

N-Ethyl-2-pyrrolidone (NEP) is a colorless to yellowish liquid with a characteristic odor. It…

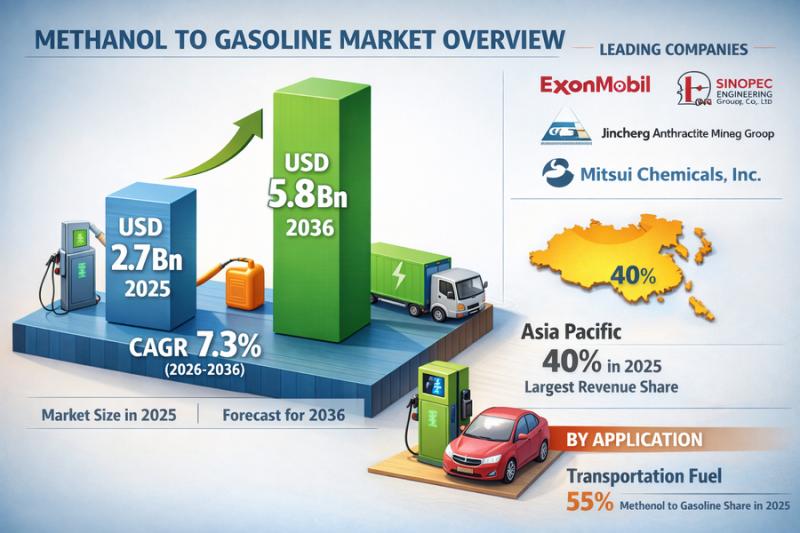

Methanol to Gasoline Market to Reach USD 5.8 Billion by 2036 at 7.3% CAGR

The methanol to gasoline market was valued at USD 2.7 billion in 2025 and is projected to reach USD 5.8 billion by 2036. The industry is expected to expand at a CAGR of 7.3% from 2026 to 2036, driven by growing interest in alternative fuels, efforts to enhance energy security, and increasing investments in methanol-to-fuel conversion technologies.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85466

Market Overview

Methanol to Gasoline (MTG)…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…