Press release

Polyolefin Catalyst Market Size to Reach USD 3.8 Billion by 2033 | With a 3.9% CAGR

Market Overview:The polyolefin catalyst market is experiencing rapid growth, driven by increasing demand for polyolefins across diverse end-use industries, technological advancements in catalyst systems, and growing emphasis on sustainability and circular economy initiatives. According to IMARC Group's latest research publication, "Polyolefin Catalyst Market Report by Type (Ziegler-Natta Catalyst, Single Site Catalyst, Chromium Catalyst, and Others), Classification (Polypropylene, Polyethylene, and Others), Application (Injection Molding, Blow Molding, Films, Fibers, and Others), End Use Industry (Automobile, Construction, Healthcare, Electronics, Packaging, and Others), and Region 2025-2033", The global polyolefin catalyst market size reached USD 2.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.8 Billion by 2033, exhibiting a growth rate (CAGR) of 3.9% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Download a sample PDF of this report: https://www.imarcgroup.com/polyolefin-catalyst-market/requestsample

Our report includes:

● Market Dynamics

● Market Trends And Market Outlook

● Competitive Analysis

● Industry Segmentation

● Strategic Recommendations

Growth Factors in the Polyolefin Catalyst Market

● Increasing Demand for Polyolefins Across Diverse End-Use Industries:

A key factor driving the polyolefin catalyst market is the rising demand for polyolefins. These materials, like polyethylene (PE) and polypropylene (PP), are among the most common plastics. They are used in packaging, automotive parts, construction, consumer goods, and textiles. For example, the packaging industry needs lightweight, durable, and moisture-resistant materials. This boosts demand for polyolefins in films, bags, and containers. In the automotive sector, polyolefins are increasingly used for both interior and exterior parts. This helps reduce vehicle weight and improve fuel efficiency. The growing use of polyolefins in various industries drives a steady demand for the catalysts that make them.

● Technological Advancements in Catalyst Systems:

Technological advancements in polyolefin catalyst systems drive growth. Ongoing research aims to create efficient, selective, and versatile catalysts. These catalysts produce polyolefins with better properties and specific features. Innovations include Ziegler-Natta catalysts, still popular for bulk production. Newer options like metallocene and single-site catalysts are also emerging. These technologies improve control over polymer microstructure, molecular weight distribution, and comonomer incorporation. So, manufacturers can make high-performance polyolefins. These have improved mechanical strength, clear optics, and better chemical resistance. Such innovations help meet strict performance requirements for specialized applications. This expansion grows the market for advanced catalyst solutions.

● Growing Emphasis on Sustainability and Circular Economy Initiatives:

The global push for sustainability and the move to a circular economy drive the polyolefin catalyst market. Industries want to cut their environmental impact and promote responsible consumption. This increases the need for catalysts. They help produce sustainable polyolefins and recycle plastic waste. Creating catalysts that use raw materials and energy better during polymerization is essential. New recycling methods are being tested. They aim to turn polyolefin waste into useful fuels or chemical feedstocks. This emphasis on green chemistry and circularity spurs the creation and use of new catalyst technologies. These advancements aim to make the polyolefin industry more environmentally friendly and resource-efficient.

Key Trends in the Polyolefin Catalyst Market

● Rise of Metallocene and Single-Site Catalysts for Specialized Applications:

A prominent trend shaping the polyolefin catalyst market is the increasing shift towards and adoption of metallocene and other single-site catalysts, particularly for specialized and high-performance polyolefin applications. While traditional Ziegler-Natta catalysts still dominate bulk production, metallocene catalysts offer superior control over the polymerization process, allowing for the creation of polymers with very narrow molecular weight distributions, precise comonomer incorporation, and tailored microstructures. This enables the production of polyolefins with enhanced properties such as improved clarity, impact resistance, and strength, which are highly desirable in sectors like high-end packaging, medical devices, and automotive applications. The ability of these advanced catalysts to produce polymers with specific, high-value characteristics is driving their growing market share.

● Focus on Catalyst Optimization for Enhanced Productivity and Efficiency:

The polyolefin catalyst industry is witnessing a strong trend focused on continuously optimizing catalyst performance to achieve enhanced productivity and operational efficiency in polyolefin production. Manufacturers are investing in research and development to improve catalyst activity, increase polymerization yields, and extend catalyst lifespan. This optimization aims to reduce overall production costs, minimize waste generation, and improve process stability for polyolefin producers. Innovations include refinements in catalyst support materials, modifications to active sites, and the development of new activation methods that allow for more precise control over the polymerization reaction. This relentless pursuit of higher efficiency and better performance is a key driver for technological advancement within the polyolefin catalyst market.

● Growing Demand for Tailored Polyolefins and Custom Formulations:

A significant trend in the polyolefin catalyst market is the increasing demand for tailored polyolefins and custom formulations to meet specific application requirements. End-use industries are seeking polymers with precise combinations of properties, such as specific melt flow rates, rigidity, flexibility, or optical characteristics. This necessitates the development of specialized catalysts that can fine-tune the molecular structure of polyolefins to achieve these desired attributes. Catalyst manufacturers are increasingly collaborating with polymer producers to develop bespoke catalyst solutions that enable the creation of highly customized polyolefin grades. This trend moves away from a "one-size-fits-all" approach, leading to a more segmented and specialized catalyst market driven by the need for high-performance, application-specific polymer solutions.

Buy Full Report: https://www.imarcgroup.com/checkout?id=4514&method=1670

Leading Companies Operating in the Global Polyolefin Catalyst Industry:

● Albemarle Corporation

● Clariant AG

● Honeywell International Inc.

● INEOS Capital Limited

● Japan Polypropylene Corporation (Mitsubishi Chemical Corporation)

● LyondellBasell Industries N.V.

● Mitsui Chemicals Inc.

● Nova Chemicals Corporation

● Sinopec Catalyst Co. Ltd. (China Petroleum & Chemical Corporation)

● Toho Titanium Co. Ltd. (JX Nippon Mining & Metals Corporation)

● W. R. Grace and Company

● Zeochem AG

Polyolefin Catalyst Market Report Segmentation:

By Type:

● Ziegler-Natta Catalyst

● Single Site Catalyst

● Chromium Catalyst

● Others

Ziegler-Natta catalyst represents the largest segment as it improves polymerization processes by providing high polymerization rates and enhanced control over molecular weight distribution.

By Classification:

● Polypropylene

● Polyethylene

● Others

Polyethylene holds the biggest market share on account of its flexible and lightweight nature.

By Application:

● Injection Molding

● Blow Molding

● Films

● Fibers

● Others

Films account for the largest market share due to the rising focus on enhancing product visibility and branding.

By End Use Industry:

● Automobile

● Construction

● Healthcare

● Electronics

● Packaging

● Others

Packaging exhibits a clear dominance in the market, driven by the increasing need to preserve the quality and freshness of various packaged products.

Regional Insights:

● North America (United States, Canada)

● Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

● Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

● Latin America (Brazil, Mexico, Others)

● Middle East and Africa

Asia Pacific enjoys a leading position in the polyolefin catalyst market, which can be attributed to the rising focus on sustainability in the plastics industry.

Ask Analyst for Sample Report: https://www.imarcgroup.com/request?type=report&id=4514&flag=C

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polyolefin Catalyst Market Size to Reach USD 3.8 Billion by 2033 | With a 3.9% CAGR here

News-ID: 4065989 • Views: …

More Releases from IMARC Group

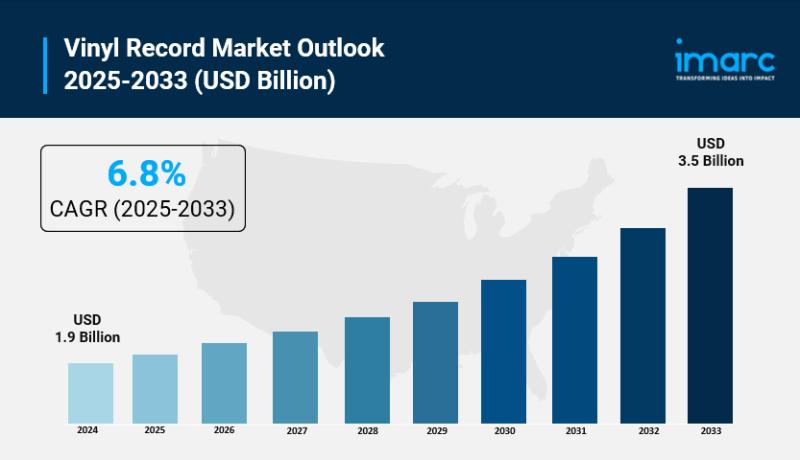

Vinyl Record Market Size to Reach USD 3.5 Billion by 2033 | With a 6.8% CAGR

Market Overview:

According to IMARC Group's latest research publication, "Vinyl Record Market Report by Product (LP/EP Vinyl Records, Single Vinyl Records), Feature (Colored, Gatefold, Picture), Gender (Men, Women), Age Group (13-17, 18-25, 26-35, 36-50, Above 50), Application (Private, Commercial), Distribution Channel (Supermarkets and Hypermarkets, Independent Retailers, Online Stores, and Others), and Region 2025-2033", The global vinyl record market size reached USD 1.9 Billion in 2024. Looking forward, IMARC Group expects the…

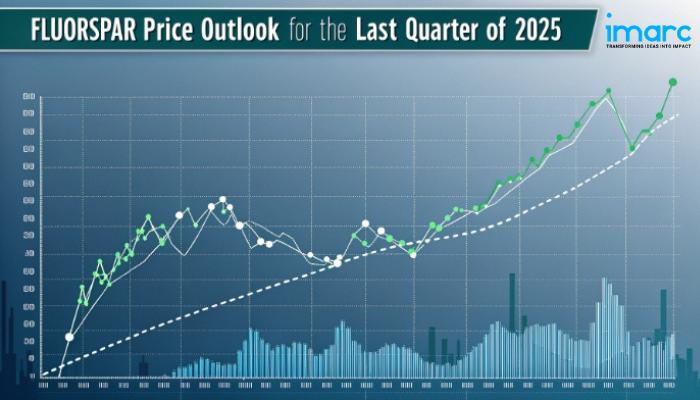

North America Fluorspar Prices Rise in Q4 2025: USA at USD 484/MT, Canada Peaks …

North America Fluorspar Prices Movement Q4 2025:

Fluorspar Prices in USA:

In Q4 2025, fluorspar prices in the USA averaged USD 484 per metric ton. Stable demand from aluminum production and chemical manufacturing supported price levels. Domestic mining operations maintained consistent output, while transportation and energy costs influenced overall supply. Moderate industrial activity and inventory management helped prevent significant price fluctuations across the regional market.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/fluorspar-pricing-report/requestsample

Note: The analysis…

Brazil Hybrid Electric Vehicle Market: Growth Dynamics, Consumer Shifts, and Com …

The Brazil hybrid electric vehicle market size was 348.75 Thousand Units in 2025 and is forecasted to reach 2,551.74 Thousand Units by 2034, reflecting a CAGR of 24.75% during 2026-2034. This robust expansion is fueled by increasing environmental awareness, rising fuel costs, and government policies aimed at emission reduction. Advances in battery technology and flex-fuel hybrid variants leveraging Brazil's ethanol resources also contribute to market growth.

Sample Request Link: https://www.imarcgroup.com/brazil-hybrid-electric-vehicle-market/requestsample

Study Assumption…

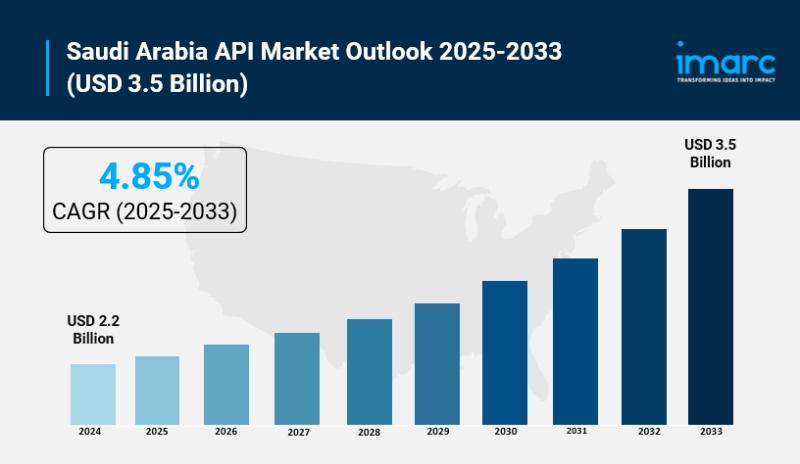

Saudi Arabia API Market Size to Expand USD 3.5 Billion by 2033 at a CAGR of 4.85 …

Saudi Arabia API Market Overview

Market Size in 2024: USD 2.2 Billion

Market Forecast in 2033: USD 3.5 Billion

Market Growth Rate 2025-2033: 4.85%

According to IMARC Group's latest research publication, "Saudi Arabia API Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Saudi Arabia API market size reached USD 2.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.5 Billion by 2033, exhibiting a growth rate…

More Releases for Catalyst

Cr-based Alkanes Dehydrogenation Catalyst Market 2025: Innovations, Trends, and …

Los Angeles-United State: QY Research has recently published a research report titled, "Cr-based Alkanes Dehydrogenation Catalyst - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031" assessing various factors impacting its trajectory. The market research report is a perfect tool for digging deep into critical aspects of the global Cr-based Alkanes Dehydrogenation Catalyst market and closely understanding factors that influence its growth. Our research analysts are experienced enough…

Catalyst Market Economic Drivers Factors Influencing Catalyst Market Expansion - …

In recent years, the global Catalyst Market has witnessed a dynamic shift, influenced by changing consumer preferences, technological advancements, and a growing emphasis on sustainability. The Research report on Catalyst Market presents a complete judgment of the market through strategic insights on future trends, growth factors, supplier landscape, demand landscape, Y-o-Y growth rate, CAGR, pricing analysis. It also provides and a lot of business matrices including Porters Five Forces Analysis,…

Diesel Engine Catalyst Market Report 2024 - Diesel Catalyst Market Size And Grow …

"The Business Research Company recently released a comprehensive report on the Global Diesel Engine Catalyst Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive…

Continuous Catalyst Regeneration (CCR) Catalyst Market Segmentation & Analysis, …

Los Angeles, USA: QY Research has recently unveiled a comprehensive report titled, "Global Continuous Catalyst Regeneration (CCR) Catalyst Market Report: Insights, Forecast to 2030." This detailed analysis examines the multiple elements shaping the future of the global Continuous Catalyst Regeneration (CCR) Catalyst market.

The Continuous Catalyst Regeneration (CCR) Catalyst report serves as an invaluable resource for industry players, providing precise and extensive research insights necessary for strategic decision-making. The analysts have…

Refinery Catalyst Market: Refinery Catalyst Market Projections: Innovations and …

Market Overview:

Refinery catalysts are used in petroleum refining operations to facilitate and accelerate chemical reactions for conversion of crude oil into useful petroleum products like gasoline, diesel, jet fuel etc. Without catalysts, refining processes would be inefficient or not commercially viable.

Get Sample Report with Global Industry Analysis @ https://www.coherentmarketinsights.com/insight/request-sample/736

Major Players Are:

✤ BP Global and Royal Dutch Shell. Other key industry participants include YARA International

✤ Foster Wheeler AG

✤ OXEA GmbH

✤ W…

Global Homogeneous Catalyst Market, Global Homogeneous Catalyst Industry, Covid- …

Homogeneous catalysts such as transition metal complexes have been utilized for the chemical reactions on the biopolymers. Homogeneous catalysts were the catalysts of choice in the early days of metathesis reactions. They entailed of a transition metal compound and a non-transition metal compound, primarily organometallic as cocatalysts. Although, the homogeneous catalysts have high probable to speed up the reaction rate, augment selectivity, conversion rate, and diminish side reactions, they cannot…