Press release

Industrial Furnace Market Insights: Emerging Opportunities, Size Estimation & Forecast to 2032

"The industrial furnace market is a critical component of various manufacturing and processing industries globally. These furnaces are essential for heating materials to high temperatures for processes such as heat treatment, melting, calcination, and drying. The market's growth is primarily driven by the increasing demand for high-quality materials across automotive, aerospace, metallurgy, and chemical sectors. Technological advancements in furnace design, including energy-efficient systems and automated controls, further fuel market expansion. The increasing adoption of Industry 4.0 principles and the integration of smart technologies into furnace operations are also contributing to growth. Furthermore, stringent environmental regulations and the need for sustainable manufacturing practices are pushing manufacturers to adopt advanced, eco-friendly furnaces, promoting innovation and efficiency. The industrial furnace market plays a vital role in addressing global challenges related to material processing, energy efficiency, and environmental sustainability. It enables industries to enhance productivity, reduce carbon emissions, and improve the overall quality of their products, thereby contributing to economic growth and environmental preservation.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2579

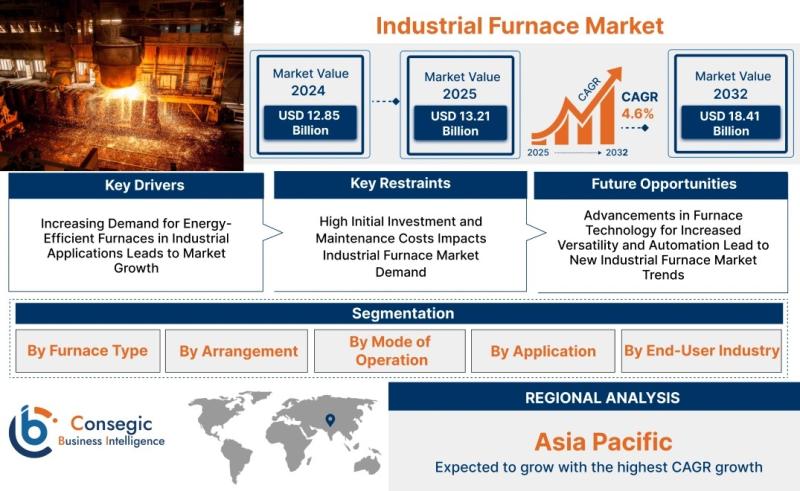

Market Size:

The Industrial Furnace Market size is estimated to reach over USD 18.41 Billion by 2032 from a value of USD 12.85 Billion in 2024 and is projected to grow by USD 13.21 Billion in 2025, growing at a CAGR of 4.6% from 2025 to 2032.

Definition of Market:

The Industrial Furnace Market encompasses the design, manufacturing, sales, and services related to heating equipment used in industrial settings. These furnaces are employed to heat materials to extremely high temperatures to facilitate various processes such as heat treatment, melting, drying, and chemical reactions.

Key Terms:

*Heat Treatment: A process where materials are heated and cooled to achieve desired mechanical properties.

*Melting: The process of converting a solid material into a liquid state through the application of heat.

*Calcination: The process of heating solid materials to high temperatures to drive off volatile substances or to cause thermal decomposition.

*Drying: The process of removing moisture from materials using heat.

*Atmosphere Control: The regulation of gases inside the furnace to prevent oxidation or unwanted reactions.

*Energy Efficiency: The ability of a furnace to perform its function while minimizing energy consumption.

*Automation: The use of automated systems to control and monitor furnace operations.

The market includes various types of furnaces, such as electric furnaces, gas/burner-operated furnaces, vacuum furnaces, and atmosphere furnaces, each designed to meet specific industrial needs. Services include installation, maintenance, repair, and upgrades to existing furnace systems. The market also includes components like burners, heating elements, temperature controllers, and insulation materials.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2579

Market Scope and Overview:

The scope of the industrial furnace market extends across numerous technologies, applications, and industries. Technologies include advanced heating mechanisms, control systems, and energy-efficient designs. The market serves a wide range of industries, including automotive manufacturing, oil and gas, metallurgy, steel and iron production, and food processing. These furnaces are utilized in processes that require precise temperature control, uniform heating, and atmosphere management.

The importance of the industrial furnace market is underscored by its critical role in enabling industries to produce high-quality materials and products. In the context of global trends, the market supports sustainable manufacturing practices by offering energy-efficient solutions that reduce carbon emissions and minimize waste. The increasing adoption of Industry 4.0 technologies, such as IoT and AI, in furnace operations is driving further innovation and efficiency. The demand for advanced materials and the need for cost-effective and environmentally friendly manufacturing processes are expected to continue to propel the growth of the industrial furnace market. Moreover, the market facilitates the advancement of research and development in various sectors, including materials science and engineering, by providing the necessary equipment for high-temperature experimentation and processing.

Top Key Players in this Market

Inductotherm Corp. (United States) Lindberg/MPH (United States) SECO/WARWICK S.A. (Poland) Tenova S.p.A. (Italy) Fives Group (France) Cicada Industrial Furnace Co., Ltd. (China) L&L Special Furnace Co., Inc. (United States) Elexxion GmbH (Germany) ANDRITZ AG (Austria) Erdemir Group (Turkey)

Market Segmentation:

The industrial furnace market can be segmented based on several factors:

By Furnace Type: Includes Electric Furnaces and Gas/Burner-Operated Furnaces. Electric furnaces offer precise temperature control and are often used in applications requiring clean energy, while gas/burner-operated furnaces are commonly used for high-volume heating applications.

By Arrangement: Includes Box Type, Tube or Clamshell Type, and Car Bottom Type furnaces. Box type furnaces are general-purpose furnaces suitable for various applications, tube or clamshell type furnaces are used for heating cylindrical objects, and car bottom type furnaces are designed for handling heavy loads.

By Mode of Operation: Includes Batch Type and Continuous Type furnaces. Batch type furnaces process materials in discrete batches, whereas continuous type furnaces are designed for continuous production processes.

By Application: Includes Atmosphere and Vacuum furnaces. Atmosphere furnaces control the gas composition within the furnace to prevent oxidation or other reactions, while vacuum furnaces operate under vacuum to eliminate atmospheric gases.

By End-User Industry: Includes Automotive Manufacturing, Oil and Gas, Metallurgy, Steel and Iron Production, and Food Processing. Each industry utilizes furnaces for specific applications, such as heat treatment of automotive components, processing of petroleum products, and heat treatment of metals.

Market Drivers:

Technological Advancements: Innovations in furnace design, control systems, and energy efficiency technologies drive market growth.

Government Policies: Regulations promoting energy efficiency and emission reduction encourage the adoption of advanced furnace technologies.

Increasing Demand for Sustainability: The growing emphasis on sustainable manufacturing practices drives demand for energy-efficient and eco-friendly furnaces.

Growth in End-User Industries: Expansion in automotive, aerospace, metallurgy, and other industries increases the demand for industrial furnaces.

Adoption of Industry 4.0: Integration of IoT and AI in furnace operations enhances efficiency and productivity.

Market Key Trends:

Energy-Efficient Furnaces: Focus on developing and adopting furnaces that minimize energy consumption.

Smart Furnace Technologies: Integration of IoT, AI, and automation in furnace operations for improved control and monitoring.

Customization and Flexibility: Demand for furnaces tailored to specific industrial needs and capable of handling diverse materials.

Additive Manufacturing Integration: Use of furnaces in additive manufacturing processes for sintering and heat treatment of 3D-printed parts.

Focus on Emissions Reduction: Development of technologies to reduce emissions from industrial furnaces.

Market Opportunities:

Retrofitting Existing Furnaces: Upgrading older furnaces with advanced technologies to improve efficiency and reduce emissions.

Development of Advanced Materials: Creating furnaces capable of processing advanced materials for aerospace, defense, and other high-tech industries.

Expansion in Emerging Markets: Growth opportunities in developing countries with increasing industrialization.

Service and Maintenance: Providing maintenance, repair, and upgrade services for existing furnace systems.

Integration with Renewable Energy: Designing furnaces that can be powered by renewable energy sources like solar and wind power.

Innovations: Advanced Materials research and Development, Focus on Sustainable Manufacturing Practices, and Smart Furnace Technologies.

Market Restraints:

High Initial Costs: The significant upfront investment required for purchasing advanced industrial furnaces can be a barrier.

Geographic Limitations: Some regions may lack the infrastructure or skilled workforce needed to operate and maintain advanced furnace systems.

Technical Complexity: The complexity of advanced furnace technologies may require specialized expertise for operation and maintenance.

Economic Uncertainty: Economic downturns can reduce investment in industrial equipment.

Regulatory Compliance: Stringent environmental regulations can increase the cost of compliance for furnace operators.

Market Challenges:

The industrial furnace market faces several significant challenges that impact its growth and sustainability. One of the primary challenges is the high energy consumption associated with industrial furnaces. The intense heat generation required for various industrial processes leads to substantial energy costs and contributes to greenhouse gas emissions. Developing and implementing energy-efficient technologies and practices is crucial to mitigating this challenge, but it requires significant investment in research and development.

Another challenge is the need for precise temperature control and uniformity. Many industrial processes, such as heat treatment and sintering, demand precise temperature control to achieve the desired material properties. Ensuring uniform heating across the furnace chamber is essential to prevent defects and inconsistencies in the final product. However, achieving this level of precision can be technically challenging and may require advanced control systems and furnace designs.

Environmental regulations also pose a significant challenge. Stringent environmental regulations regarding emissions and waste disposal require furnace operators to adopt cleaner technologies and practices. Compliance with these regulations can be costly and may necessitate significant changes to furnace operations. However, non-compliance can result in severe penalties and reputational damage.

The integration of advanced technologies, such as IoT and AI, also presents challenges. While these technologies offer significant benefits in terms of efficiency and control, their implementation requires expertise in data analytics, cybersecurity, and systems integration. Furthermore, ensuring the compatibility and interoperability of different systems can be complex and may require significant investment in training and infrastructure.

Finally, the availability of skilled labor is a critical challenge. Operating and maintaining advanced industrial furnaces requires skilled technicians and engineers who understand the complexities of the equipment and the processes involved. The shortage of skilled labor in some regions can limit the adoption of advanced furnace technologies and hinder the growth of the market.

Market Regional Analysis:

The industrial furnace market exhibits varying dynamics across different regions. North America and Europe are characterized by mature markets with a strong emphasis on energy efficiency and environmental sustainability. These regions have stringent regulations that drive the adoption of advanced furnace technologies. Asia-Pacific is experiencing rapid growth due to increasing industrialization and infrastructure development in countries like China and India. The demand for industrial furnaces in this region is driven by expanding manufacturing sectors and growing investments in infrastructure projects.

Latin America and the Middle East are also showing growth potential, driven by increasing investments in oil and gas, mining, and manufacturing industries. However, these regions may face challenges related to infrastructure development, regulatory compliance, and economic stability. Africa represents a nascent market with significant growth opportunities due to its vast natural resources and increasing industrialization. However, the African market faces challenges related to infrastructure development, political stability, and access to financing.

Each region's market dynamics are influenced by factors such as economic conditions, regulatory frameworks, industrial development, and technological advancements. Understanding these regional nuances is crucial for companies seeking to expand their presence in the industrial furnace market.

Frequently Asked Questions:

Q: What is the projected growth rate of the industrial furnace market?

A: The industrial furnace market is projected to grow at a CAGR of 4.6% from 2025 to 2032.

Q: What are the key trends in the industrial furnace market?

A: Key trends include energy-efficient furnaces, smart furnace technologies, customization, integration with additive manufacturing, and a focus on emissions reduction.

Q: Which are the most popular industrial furnace types?

A: Electric furnaces and gas/burner-operated furnaces are among the most popular types, each suited for different industrial applications.

Follow us on:

https://www.linkedin.com/company/techflux-reports/

https://www.linkedin.com/company/insight-burst24/

https://www.linkedin.com/company/tech-savvy-solutions-pvt/

https://www.linkedin.com/company/innovation-chronicles/

https://www.linkedin.com/company/knowledge-evolution24/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial Furnace Market Insights: Emerging Opportunities, Size Estimation & Forecast to 2032 here

News-ID: 4064181 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Furnace

Oil Furnace Market Size, Growth, Key Trends to 2033 Irving, Carrier, Armstrong F …

An oil furnace is a type of heating system that uses oil as a fuel source to generate heat. It works by burning oil in a combustion chamber, which heats a heat exchanger. The heated air or water is then circulated throughout the building to maintain a comfortable temperature. Oil furnaces are particularly useful in areas without access to natural gas and are known for their ability to provide consistent…

Metal Melting Furnace Market Future Trends Landscape 2031 || Meta Therm Furnace …

The metal melting furnace market is essential for various industries, including automotive, aerospace, construction, and manufacturing. These furnaces are used to melt different types of metals such as iron, steel, aluminum, and copper, playing a critical role in the production of metal products. The market for metal melting furnaces is driven by increasing demand for metals in various applications and technological advancements in furnace design and efficiency.

Market Size and Growth

The…

Semiconductor Monocrystalline Silicon Furnace Market: High-Precision Furnace for …

Global Semiconductor Monocrystalline Silicon Furnace Market Overview:

The Semiconductor Monocrystalline Silicon Furnace market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Semiconductor Monocrystalline Silicon Furnace market has experienced significant growth, driven by factors such as increasing consumer demand, technological advancements, and…

Induction Furnace Melting Aluminum

The induction melting furnace working principle is that the power supply device converts the power frequency 50HZ alternating current into the medium frequency (from 300HZ to 1000HZ), converts the three-phase power frequency alternating current into the direct current after rectification, and then converts the direct current into the adjustable medium frequency current, supplies the medium frequency alternating current flowing through the capacitor and the induction coil, generates high-density magnetic lines…

Muffle furnace Market Future Growth Outlook: ThermoFisher Scientific, Brother Fu …

A new statistical surveying study titled Muffle furnace Market investigates a few critical features identified with Muffle furnace Market covering industry condition, division examination, and focused scene. Down to earth ideas of the market are referenced in a straightforward and unassuming way in this report. A far-reaching and exhaustive essential investigation report features various actualities, for example, improvement factors, business upgrade systems, measurable development, monetary benefit or misfortune to support…

Induction Furnace Market Foraying into Emerging Economies 2018 to 2028(Based on …

Induction Furnace Market: Introduction

Induction furnace is an electrical furnace in which the heat is generated by induction heat of the metal. Induction capacities range from less than one kilogram to one hundred tonnes, and widely used to melt iron, steel, copper, aluminium and precious metal. The main advantage of the induction furnace is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting.

Induction Furnace Market:…