Press release

Warehouse Robotics Market Size Surges to USD 16.0 Billion by 2033, Driven by E-Commerce Boom and Automation

IMARC Group's latest research report, titled "Warehouse Robotics Market Report by Type (Articulated, Gantry, Automated Storage and Retrieval System (ASRS), Mobile, and Others), Function (Storage, Trans-shipments, Packaging, and Others), End User (Food and Beverages, Automotive, Retail, Electronics and Electrical, Pharmaceuticals, and Others), and Region 2025-2033," offers a comprehensive analysis of the warehouse robotics market. The report also includes competitor and regional analysis, along with a breakdown of segments within the industry. the global warehouse robotics market size reached USD 7.0 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 16.0 Billion by 2033, exhibiting a growth rate (CAGR) of 9.72% during 2025-2033. The market is experiencing strong growth driven by the increasing demand for automation to enhance operational efficiency, the rising labor costs, and the need for faster order fulfillment in the e-commerce sector across the globe.Get Free Sample Copy of Report at - https://www.imarcgroup.com/warehouse-robotics-market/requestsample

Technological Innovation and AI Driven Automation:

The warehouse robotics market is witnessing an unprecedented acceleration in technological innovation, driven by advances in artificial intelligence, machine learning, and sensor technologies that enable autonomous operations and real time decision making. Next generation mobile robots equipped with 3D vision, lidar mapping, and simultaneous localization and mapping (SLAM) capabilities can navigate complex warehouse layouts, avoid dynamic obstacles, and collaborate safely alongside human workers. Meanwhile, robotic arms and automated picking systems leverage deep learning-powered vision algorithms to identify, grasp, and manipulate a diverse array of products-ranging from irregularly shaped bulk items to delicate packaged goods-with precision rates exceeding 99%. Integration of edge computing reduces latency and dependence on centralized servers, allowing robots to process sensory inputs and adjust their behavior instantaneously. Software platforms have evolved from siloed controller interfaces to cloud native orchestration suites that unify fleet management, inventory tracking, and predictive maintenance under a single dashboard. These platforms employ analytics to optimize picking routes, balance workloads, and forecast peak period demands, thereby boosting throughput and minimizing idle time.

Furthermore, modular robotics-characterized by swappable end effectors, scalable payload configurations, and plug and play sensor packages-enables rapid redeployment across seasonal or mission critical tasks without extensive reprogramming. Innovations in collaborative robot ("cobot") design incorporate compliant joints, force torque sensing, and intuitive human machine interfaces, fostering safe shared workspaces where automation augments human dexterity rather than replacing it. As 5G connectivity proliferates, ultra reliable low latency communication will empower real time swarm coordination and remote monitoring, unlocking new possibilities for distributed order fulfillment models. Collectively, these technological breakthroughs not only elevate operational efficiency and accuracy but also reduce total cost of ownership by extending maintenance intervals and enabling seamless software updates. For warehouse operators seeking to maintain competitive advantage, partnering with robotics providers that demonstrate robust R&D pipelines, strong intellectual property protection, and open architecture integration frameworks has become a strategic imperative.

E Commerce Expansion and Supply Chain Resilience:

Rapid growth in e commerce, omnichannel retailing, and just in time supply chain strategies is exerting intense pressure on warehouses to process higher order volumes with ever shorter lead times, making robotic automation a business critical solution. As consumer expectations for same day and next day delivery become the norm, companies are redesigning distribution centers to incorporate high density storage systems and multi shuttle robots capable of 24/7 operations. Autonomous mobile robots (AMRs) are increasingly deployed in cross dock and sortation areas to dynamically allocate carton flows, reducing manual handling and bottlenecks during peak shopping seasons. Simultaneously, yard management robots automate trailer loading and unloading, accelerating turnaround times and optimizing yard space utilization. In response to unprecedented supply chain disruptions-from port congestions to geopolitical events-warehouse operators are adopting hybrid human robot teams to introduce agility and redundancy into their networks. Robots can be rapidly reconfigured to handle emergent product lines or to support regional e fulfillment hubs, minimizing downtime and inventory risk.

Data driven simulation models guide warehouse layout redesigns, allowing operators to test robot fleet sizes, storage configurations, and throughput thresholds before capital investment. Furthermore, integration with Transportation Management Systems (TMS) and Warehouse Management Systems (WMS) ensures end to end visibility, enabling algorithms to prioritize high value orders and batch similar SKUs for robotic picking. In verticals such as pharmaceuticals and cold chain logistics, specialized robots with temperature controlled enclosures and sanitized surfaces guarantee product integrity and regulatory compliance. As sustainability becomes a boardroom priority, energy efficient robots-featuring regenerative braking, optimized travel paths, and smart charging schedules-contribute to green warehouse certifications. Ultimately, the synergy between e commerce expansion and supply chain resilience is reshaping warehouse operations, elevating robotics from pilot projects to mission critical pillars of modern logistics.

Capital Investment, Partnerships, and Ecosystem Development:

Significant capital investment and strategic partnerships are catalyzing the maturation of the warehouse robotics ecosystem, as venture capital firms, private equity investors, and corporate backers channel funds into startups and established players alike. Over the past few years, funding rounds have targeted companies developing AI centric vision systems, modular end effectors, and fleet orchestration software, reflecting investor confidence in scalable, high margin robotics solutions. Concurrently, global robotics vendors are forging alliances with logistics integrators, WMS providers, and system integration specialists to deliver turnkey automation packages that mitigate deployment risks and streamline implementation timelines. These collaborations facilitate shared knowledge transfer, standardized communication protocols (such as ROS based frameworks), and joint go to market strategies that accelerate adoption across diverse warehouse environments. Public-private partnerships, underwritten by government grants and infrastructure incentives, are underwriting pilot programs in smart city logistics corridors and inland ports to demonstrate robotics powered efficiency gains and emissions reductions.

At the same time, academic research consortia and industry associations are co developing interoperability standards, safety guidelines, and training curricula to address workforce upskilling and regulatory compliance. As return on investment (ROI) case studies proliferate-demonstrating payback periods as short as 12 to 18 months-capital expenditure committees are increasingly earmarking budgets for mid sized and even small business warehouse automation projects. Secondary markets for refurbished robots and robotics as a service (RaaS) models further democratize access, allowing organizations to scale capacity without prohibitive upfront costs. Financing innovations, such as leasing arrangements tied to performance based payments, align vendor incentives with operational outcomes and foster long term partnerships. The convergence of robust investment flows, strategic alliances, and ecosystem development is thus propelling the warehouse robotics market from niche applications to widespread, sustainable adoption-laying a solid foundation for future growth.

Leading Key Players Operating in the Warehouse Robotics Industry:

• ABB Ltd

• Amazon.com Inc

• Fanuc Corp

• Fetch Robotics Inc

• Honeywell International Inc

• Kuka AG

• Locus Robotics

• Omron Corporation

• Siemens AG

• Yamaha Motor Co. Ltd

• Yaskawa Electric Corp

Warehouse Robotics Market Trends:

Current trends underscore a shift toward highly flexible, data driven, and human centric automation solutions. On the hardware front, modular robotic platforms allow swift reconfiguration for seasonal SKUs, promotional campaigns, or rapidly evolving product assortments-eliminating expensive forklift or conveyor overhauls. Advanced analytics engines deliver actionable insights by harmonizing data from robots, inventory systems, and facility sensors to predict maintenance needs, balance workloads, and continuously refine picking algorithms. Moreover, the interplay between robots and human operators is evolving: augmented reality (AR) assisted picking and wearable haptic feedback devices guide workers to optimal pick locations, while robots handle repetitive, ergonomically challenging tasks-boosting throughput, reducing errors, and improving workplace safety. Sustainability considerations drive the adoption of energy harvesting floors and smart charging stations that leverage off peak electricity, aligning warehouse operations with corporate environmental goals.

Meanwhile, user friendly programming interfaces and low code/no code automation tools empower operations teams to define and deploy new workflows without extensive IT involvement. Cybersecurity measures, including end to end encryption and anomaly detection protocols, are now integral design criteria to safeguard critical logistics assets against cyber threats. Finally, as digital twins of warehouse facilities become more sophisticated, operators can simulate "what if" scenarios-from labor shortage contingencies to sudden demand spikes-ensuring resilient, high performance operations. These convergent trends highlight a market that prizes adaptability, intelligence, and seamless human robot collaboration as essential drivers of competitive advantage.

Ask Analyst for Instant Discount and Download Full Report with TOC & List of Figure: https://www.imarcgroup.com/warehouse-robotics-market

Key Market Segmentation:

Breakup by Type:

• Articulated

• Gantry

• Automated Storage and Retrieval System (ASRS)

• Mobile

• Others

Breakup by Function:

• Storage

• Trans-shipments

• Packaging

• Others

Breakup by End User:

• Food and Beverages

• Automotive

• Retail

• Electronics and Electrical

• Pharmaceuticals

• Others

Breakup by Region:

• North America (United States, Canada)

• Europe (Germany, France, United Kingdom, Italy, Spain, Others)

• Asia Pacific (China, Japan, India, Australia, Indonesia, Korea, Others)

• Latin America (Brazil, Mexico, Others)

• Middle East and Africa (United Arab Emirates, Saudi Arabia, Qatar, Iraq, Other)

Key Highlights of the Report:

• Market Performance (2019-2024)

• Market Outlook (2025-2033)

• Porter's Five Forces Analysis

• Market Drivers and Success Factors

• SWOT Analysis

• Value Chain

• Comprehensive Mapping of the Competitive Landscape

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Warehouse Robotics Market Size Surges to USD 16.0 Billion by 2033, Driven by E-Commerce Boom and Automation here

News-ID: 4055979 • Views: …

More Releases from IMARC Group

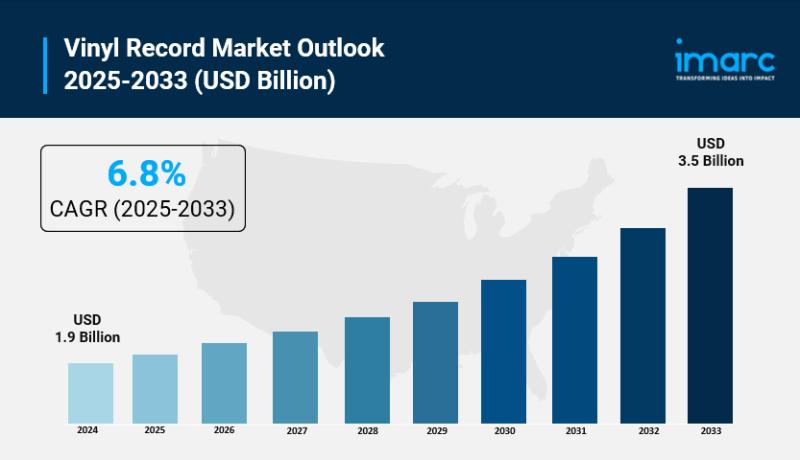

Vinyl Record Market Size to Reach USD 3.5 Billion by 2033 | With a 6.8% CAGR

Market Overview:

According to IMARC Group's latest research publication, "Vinyl Record Market Report by Product (LP/EP Vinyl Records, Single Vinyl Records), Feature (Colored, Gatefold, Picture), Gender (Men, Women), Age Group (13-17, 18-25, 26-35, 36-50, Above 50), Application (Private, Commercial), Distribution Channel (Supermarkets and Hypermarkets, Independent Retailers, Online Stores, and Others), and Region 2025-2033", The global vinyl record market size reached USD 1.9 Billion in 2024. Looking forward, IMARC Group expects the…

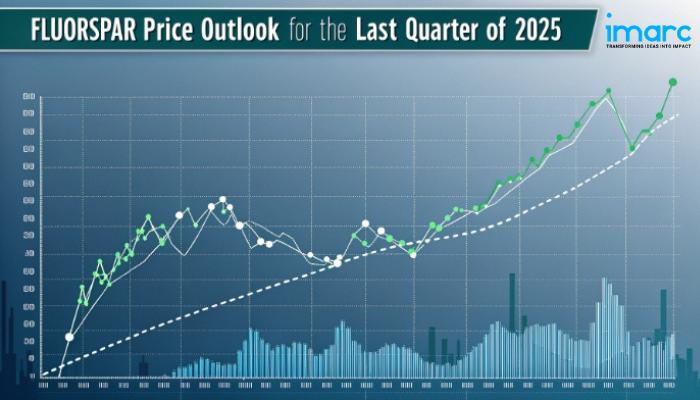

North America Fluorspar Prices Rise in Q4 2025: USA at USD 484/MT, Canada Peaks …

North America Fluorspar Prices Movement Q4 2025:

Fluorspar Prices in USA:

In Q4 2025, fluorspar prices in the USA averaged USD 484 per metric ton. Stable demand from aluminum production and chemical manufacturing supported price levels. Domestic mining operations maintained consistent output, while transportation and energy costs influenced overall supply. Moderate industrial activity and inventory management helped prevent significant price fluctuations across the regional market.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/fluorspar-pricing-report/requestsample

Note: The analysis…

Brazil Hybrid Electric Vehicle Market: Growth Dynamics, Consumer Shifts, and Com …

The Brazil hybrid electric vehicle market size was 348.75 Thousand Units in 2025 and is forecasted to reach 2,551.74 Thousand Units by 2034, reflecting a CAGR of 24.75% during 2026-2034. This robust expansion is fueled by increasing environmental awareness, rising fuel costs, and government policies aimed at emission reduction. Advances in battery technology and flex-fuel hybrid variants leveraging Brazil's ethanol resources also contribute to market growth.

Sample Request Link: https://www.imarcgroup.com/brazil-hybrid-electric-vehicle-market/requestsample

Study Assumption…

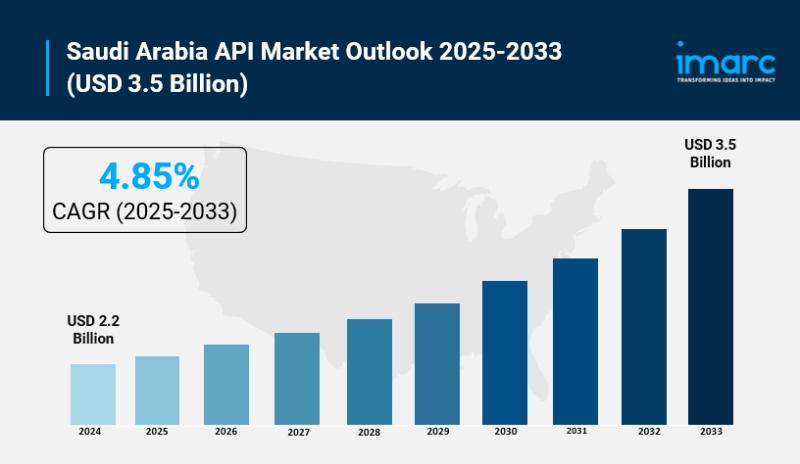

Saudi Arabia API Market Size to Expand USD 3.5 Billion by 2033 at a CAGR of 4.85 …

Saudi Arabia API Market Overview

Market Size in 2024: USD 2.2 Billion

Market Forecast in 2033: USD 3.5 Billion

Market Growth Rate 2025-2033: 4.85%

According to IMARC Group's latest research publication, "Saudi Arabia API Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Saudi Arabia API market size reached USD 2.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.5 Billion by 2033, exhibiting a growth rate…

More Releases for Robotics

Humanoid Robot Market Top Companies Study- SoftBank Robotics, ROBOTIS, Agility R …

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the " Humanoid Robot Market - (By Component (Hardware (Sensors (Gyroscopes, Microphones, Accelerometers, Tilt sensors, Force/Torque sensors, Position sensors, Vision/Image sensors, Others), Actuators (Electrical, Pneumatic, Hydraulic, Piezoelectric, Ultrasonic), Power Sources, Control Systems/Controllers, Others), Software), By Motion Type (Biped, Wheel drive), By Application (Research and Space Exploration, Education and Entertainment, Personal Assistance and Caregiving, Search and Rescue, Public…

Edible Soft Robotics Market Worth Observing Growth | Rethink Robotics, ReWalk Ro …

Advance Market Analytics published a new research publication on "Edible Soft Robotics Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Edible Soft Robotics market was mainly driven by the increasing R&D spending across the world.

Get inside Scoop of the…

Humanoid Robot Market Top Players - SoftBank Robotics, ROBOTIS, Agility Robotics …

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the " Humanoid Robot Market - (By Component (Hardware (Sensors (Gyroscopes, Microphones, Accelerometers, Tilt sensors, Force/Torque sensors, Position sensors, Vision/Image sensors, Others), Actuators (Electrical, Pneumatic, Hydraulic, Piezoelectric, Ultrasonic), Power Sources, Control Systems/Controllers, Others), Software), By Motion Type (Biped, Wheel drive), By Application (Research and Space Exploration, Education and Entertainment, Personal Assistance and Caregiving, Search and Rescue, Public…

Robotics Software Platforms Market 2023 | Futuristic Technology- RoboDK, KUKA, F …

The Robotics Software Platforms research report combines vital data incorporating the competitive landscape, global, regional, and country-specific market size, market growth analysis, market share, recent developments, and market growth in segmentation. Furthermore, the Robotics Software Platforms research report offers information and thoughtful facts like share, revenue, historical data, and global market share. It also highlights vital aspects like opportunities, driving, product scope, market overview, and driving force.

Download FREE Sample Report…

Edible Soft Robotics Market is Booming Worldwide with Rethink Robotics, ReWalk R …

Latest released Global Edible Soft Robotics Market Research Report provides detailed assessment about Key and emerging Players highlighting profiles, product portfolio, market price, and sales revenue to better derive market size estimation. With this evaluation the aim is to throw lights on Future trends, Growth Factors, opinions and facts derived from industry executives with statistically supported and validated market data. Furthermore, a clear explanation of How or Why this market…

Rehabilitation Robotics Market 2025 - Kinova Robotics, Rehab-Robotics Company, T …

Rehabilitation Robotics market is evaluated based on two segments i.e., by type and application and covers essential statistics and details for current and future market scenarios. The report actively includes informative aspects relating to product developments, launches, and trends, to assist market players, shareholders, and investors in strategic decision making.

Check for the sample here - https://www.premiummarketinsights.com/sample/TIP00000795 …