Press release

UPVC and CPVC Pipe Manufacturing Plant Project Report 2025: Machinery and Raw Materials

UPVC (Unplasticized Polyvinyl Chloride) pipes are rigid, durable pipes commonly used for cold-water distribution, drainage, and sewage systems. They offer excellent chemical resistance, corrosion-free performance, and long service life, making them ideal for plumbing and irrigation. CPVC (Chlorinated Polyvinyl Chloride) pipes are similar but chlorinated to withstand higher temperatures, making them suitable for hot-water supply and industrial fluid handling. Both types provide easy installation, cost-effectiveness, and reliability in residential, commercial, and industrial applications.The UPVC and CPVC pipe market is driven by rapid urbanization, rising construction activities, and increasing replacement of metal pipes due to corrosion concerns. Growing adoption of cost-effective, leak-proof, and low-maintenance plumbing solutions in residential and commercial buildings contributes significantly to demand. Additionally, government investments in water supply, sanitation, and infrastructure modernization are fueling market growth. The shift toward safer, hygienic, and environmentally friendly piping materials supports wider acceptance, while technological improvements in extrusion processes and material formulations enhance pipe strength and performance. Expanding industrial applications, including chemical processing and hot-water systems, further strengthen the market outlook.

IMARC Group's report, titled "UPVC and CPVC Pipe Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up an UPVC and CPVC pipe manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

UPVC and CPVC Pipe Industry Outlook 2025

The UPVC and CPVC pipe industry is projected to experience robust growth in 2025, driven by expanding urbanization, infrastructure development, water supply and sanitation projects, affordable housing initiatives, and replacement of aging metal pipe networks globally. Government investments in smart cities, Jal Jeevan Mission-type programs, irrigation modernization, and building construction fuel demand. CPVC gains market share in plumbing applications due to superior hot water handling and fire safety properties. Asia-Pacific, Middle East, Africa, and Latin America show strongest growth, while developed markets focus on infrastructure renewal. Manufacturers invest in larger diameter capabilities, multilayer pipe technologies, lead-free formulations, recycled content integration, and automation to improve productivity. The industry benefits from plastic pipes' advantages over metal alternatives in corrosion resistance, installation ease, and lifecycle costs.

Request for a Sample Report: https://www.imarcgroup.com/upvc-cpvc-pipe-manufacturing-plant-project-report/requestsample

Key Insights for setting up an UPVC and CPVC Pipe Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up an UPVC and CPVC Pipe Manufacturing Plant

• Land acquisition with adequate space for multiple production lines and storage

• Factory building construction with proper ventilation and equipment foundations

• Raw material procurement (UPVC resin or CPVC resin, heat stabilizers, impact modifiers, processing aids, lubricants, calcium carbonate, titanium dioxide pigments)

• Conical twin-screw extruders or parallel twin-screw extruders (separate for UPVC and CPVC)

• Extrusion dies and mandrels for various pipe diameters

• Vacuum calibration tanks with sizing sleeves

• Spray cooling tanks or immersion cooling systems

• Haul-off units with caterpillar puller systems

• Planetary cutting machines or flying cutters

• Socketing/belling machines for creating joints

• Printing equipment for pipe marking and branding.

Economic Trends Influencing UPVC and CPVC Pipe Plant Setup Costs 2025

• PVC and CPVC resin price volatility linked to crude oil and chlorine costs

• Rising electricity costs significantly impacting extrusion operations

• Government infrastructure spending on water supply and housing projects

• Urbanization driving plumbing and drainage system demand

• Import duties on resins, additives, and machinery

• Currency exchange rates affecting resin procurement costs (often imported)

• Competition from HDPE, PPR, and other plastic pipe alternatives

• Investment in automation reducing labor dependency

• Environmental regulations on lead stabilizers requiring calcium-zinc alternatives

• Green building certifications driving CPVC adoption for fire safety.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=28005&flag=C

Challenges and Considerations for Investors

• High initial capital investment for extruders and auxiliary equipment ($1-5 million per line)

• Heavy dependency on imported PVC/CPVC resin with price volatility

• CPVC resin significantly more expensive than UPVC (2-3x cost) affecting margins

• Intense competition from established manufacturers and unorganized sector

• Multiple pipe sizes requiring different dies, calibrators, and tooling

• Significant electricity consumption affecting production economics

• Quality consistency challenges impacting pressure ratings and durability

• Working capital requirements for resin inventory (30-60 days stock)

• Separate production lines needed for UPVC and CPVC (cannot mix resins)

• Compliance with stringent quality standards and testing requirements.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release UPVC and CPVC Pipe Manufacturing Plant Project Report 2025: Machinery and Raw Materials here

News-ID: 4271305 • Views: …

More Releases from IMARC Group

Saudi Arabia Event Management Market Size to Hit USD 19,561.3 Million by 2033 at …

Saudi Arabia Event Management Market Overview

Market Size in 2024: USD 9,450.2 Million

Market Size in 2033: USD 19,561.3 Million

Market Growth Rate 2025-2033: 8.42%

According to IMARC Group's latest research publication, "Saudi Arabia Event Management Market Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", the Saudi Arabia event management market was valued at USD 9,450.2 Million in 2024 and is projected to reach USD 19,561.3 Million by 2033, growing at a CAGR…

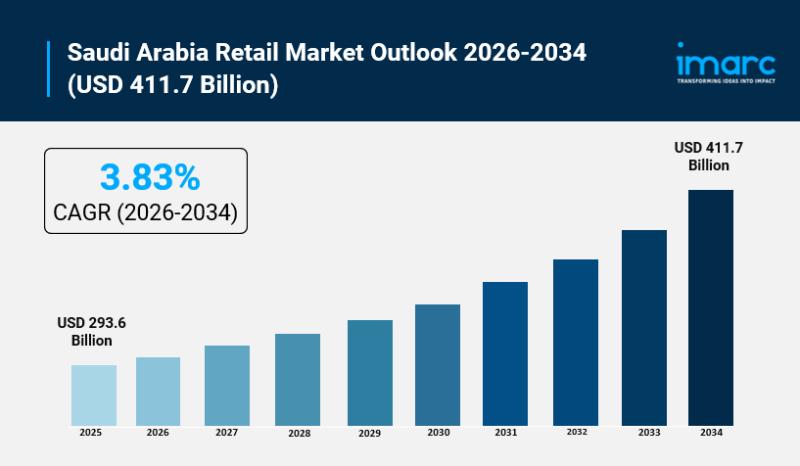

Saudi Arabia Retail Market Size to Surge to USD 411.7 Billion by 2034 | CAGR of …

Saudi Arabia Retail Market Overview

Market Size in 2025: USD 293.6 Billion

Market Size in 2034: USD 411.7 Billion

Market Growth Rate 2026-2034: 3.83%

According to IMARC Group's latest research publication, "Saudi Arabia Retail Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Saudi Arabia retail market size was valued at USD 293.6 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 411.7 Billion by 2034, exhibiting a…

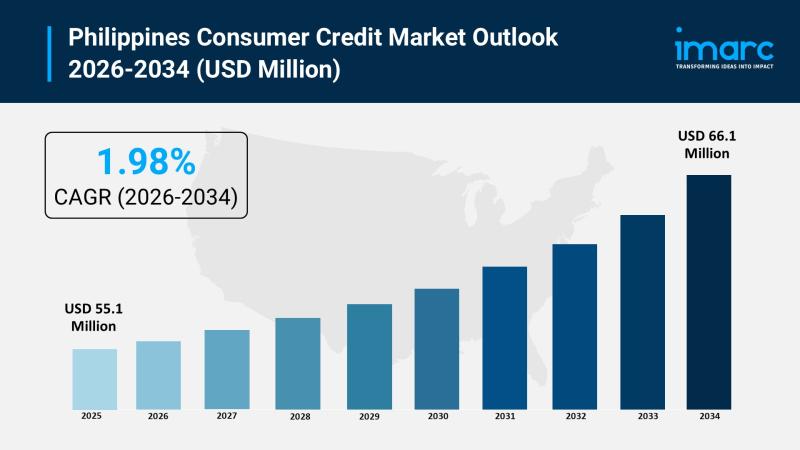

Philippines Consumer Credit Market 2026 | Worth USD 66.1 Million by 2034

Philippines Consumer Credit Market Overview:

The Philippines consumer credit market size reached USD 55.1 Million in 2025. The market is projected to reach USD 66.1 Million by 2034, exhibiting a growth rate (CAGR) of 1.98% during 2026-2034. The market is expanding steadily as rising financial inclusion, mobile-first lending platforms, and Buy Now Pay Later adoption bring formal credit to previously underserved Filipinos. Fintech innovation, neobank growth, and supportive BSP regulatory frameworks…

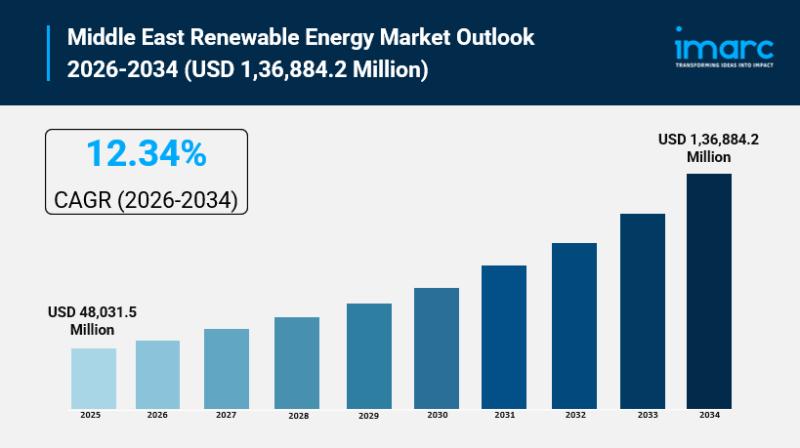

Middle East Renewable Energy Market Size to Hit USD 1,36,884.2 Million by 2034 | …

Middle East Renewable Energy Market Overview

Market Size in 2025: USD 48,031.5 Million

Market Size in 2034: USD 1,36,884.2 Million

Market Growth Rate 2026-2034: 12.34%

According to IMARC Group's latest research publication, "Middle East Renewable Energy Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", the Middle East renewable energy market size was valued at USD 48,031.5 Million in 2025. Looking forward, IMARC Group estimates the market to reach USD 1,36,884.2 Million by…

More Releases for PVC

PVC Coated Fabrics Market Accelerates at 5.3% CAGR as Transportation, Infrastruc …

The PVC coated fabrics market reached USD million in 2022 and is projected to witness lucrative growth by reaching up to USD million by 2031. The market is growing at a CAGR of 5.3% from 2024 to 2031.

Market growth is fueled by surging demand for durable, waterproof materials in transportation, marine, and construction sectors, alongside rising infrastructure projects and automotive upholstery needs. Key drivers include advancements in eco-friendly PVC formulations…

PVC Foam Profiles Market Outlook 2034: Global Valuation to Reach USD 4.8 Billion …

The global PVC foam profiles market was valued at US$ 2.9 Bn in 2023. As industries continue to adopt lightweight, moisture-resistant, and dimensionally stable materials, PVC foam profiles are witnessing growing integration into construction, automotive, marine, and furniture manufacturing applications. According to current projections, the market is set to expand at a CAGR of 4.2% from 2024 to 2034, ultimately reaching US$ 4.8 Bn by 2034. This sustained growth reflects…

The Growing PVC Window Market

New York, US, - [01-December- 2025] - The PVC window market is experiencing significant growth, driven by increasing demand for energy-efficient and sustainable building materials. As consumers and builders alike prioritize durability, cost-effectiveness, and environmental impact, PVC (polyvinyl chloride) windows have emerged as a preferred choice in residential and commercial construction. This press release provides an overview of the current state of the PVC window market, key trends, and future…

New PVC External Lubricant Improves Performance

Shandong HTX New Material Co., Ltd. is a newly established company that has already made a significant impact in the industry. Since its inception in March 2021, the company has been focused on producing high-quality PVC External Lubricant [https://www.htxchem.com/lubricant-manufacture-price-product/] and other related products. HTX is a comprehensive enterprise that not only specializes in PVC processing aids but also involves itself in research and development, production, and sales.

The product range offered…

PVC Pipes Market to See Major Growth by 2026 | Bow Plastics, Royal PVC, Tulsi Ex …

Latest released the research study on Global PVC Pipes Market, offers a detailed overview of the factors influencing the global business scope. PVC Pipes Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the PVC Pipes

The study covers emerging player’s data, including: competitive…

Global Polyvinyl Chloride (PVC) Market 2017 -

Worldwide Polyvinyl Chloride (PVC) 2017 Research Report presents a professional and complete analysis of Global Polyvinyl Chloride (PVC) Market on the current situation.

In the first part, the report provides a general overview of the Polyvinyl Chloride (PVC) industry 2017 including definitions, classifications, Polyvinyl Chloride (PVC) market analysis, a wide range of applications and Polyvinyl Chloride (PVC) industry chain structure. The 2017's report on Polyvinyl Chloride (PVC) industry offers the global…