Press release

Europe Ultrasonic NDT Equipment Market Size, Share, Growth Trends, and Forecast 2025 to 2032

"The Ultrasonic Non-Destructive Testing (NDT) Equipment market is experiencing significant growth, driven by the increasing demand for reliable and efficient inspection methods across various industries. This market plays a crucial role in ensuring the safety, reliability, and longevity of critical infrastructure and manufactured components. Key drivers include the rising adoption of NDT techniques in sectors like aerospace, automotive, oil & gas, and power generation, coupled with stringent safety regulations and quality control standards. Technological advancements in ultrasonic testing, such as phased array, time-of-flight diffraction (TOFD), and automated systems, are further fueling market expansion by offering enhanced accuracy, speed, and portability. Moreover, the growing emphasis on predictive maintenance and the need to minimize downtime are encouraging industries to invest in advanced ultrasonic NDT equipment. As industries globally prioritize infrastructure integrity and product quality, the ultrasonic NDT equipment market becomes increasingly important in addressing global challenges related to safety, sustainability, and efficiency. Advancements continue to improve the sensitivity and resolution of these technologies, allowing for the detection of smaller defects and more comprehensive assessments of material properties. This is critical in applications ranging from identifying micro-cracks in aircraft components to monitoring corrosion in pipelines, ensuring that potential failures are identified and addressed before they lead to catastrophic consequences. The market's growth is also supported by the development of user-friendly software and interfaces, making ultrasonic NDT equipment more accessible to a wider range of technicians and engineers. Furthermore, the integration of artificial intelligence and machine learning into ultrasonic testing systems is enhancing data analysis and defect recognition capabilities, enabling faster and more accurate inspections.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/1255

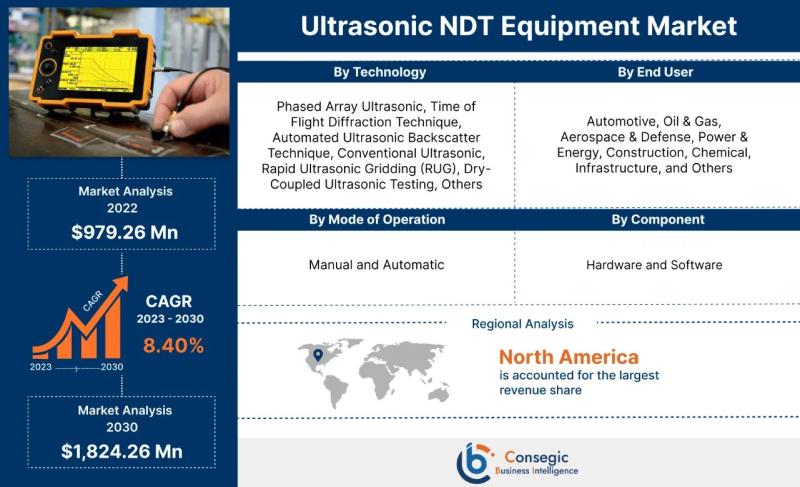

Market Size:

The Ultrasonic NDT Equipment Market size is estimated to reach over USD 1,824.26 Million by 2030 from a value of USD 979.26 Million in 2022, growing at a CAGR of 8.40% from 2023 to 2030.

Definition of Market:

The Ultrasonic NDT Equipment Market encompasses the range of instruments, systems, and services used to evaluate the properties of a material or component without causing damage. This non-destructive approach relies on the principles of sound wave propagation to detect internal flaws, measure thickness, and characterize material properties. Key components of the market include:

Ultrasonic Transducers: Devices that generate and receive ultrasonic waves.

Pulser-Receivers: Electronic units that drive the transducers and process the returning signals.

Display and Analysis Units: Software and hardware used to visualize and interpret the data collected by the ultrasonic sensors.

Automated Scanning Systems: Robotic or mechanical systems that move the transducer across the surface of the inspected object.

Key terms related to this market include:

A-scan, B-scan, C-scan: Different display modes for representing ultrasonic data.

Phased Array: An advanced technique that uses multiple transducers to steer and focus the ultrasonic beam.

TOFD (Time-of-Flight Diffraction): A technique that measures the time it takes for ultrasonic waves to diffract around the edges of a defect.

Couplant: A fluid or gel used to improve the transmission of ultrasonic waves between the transducer and the test object.

These components and techniques are essential for ensuring the reliability and safety of various industrial assets and products.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/1255

Market Scope and Overview:

The scope of the Ultrasonic NDT Equipment Market covers a wide array of technologies, applications, and industries. The technologies involved include conventional ultrasonic testing (UT), phased array UT (PAUT), time-of-flight diffraction (TOFD), automated ultrasonic backscatter technique (AUBT), rapid ultrasonic gridding (RUG), and dry-coupled ultrasonic testing, among others. These technologies are applied across various industries, including automotive, oil & gas, aerospace & defense, power & energy, construction, chemical, and infrastructure, to inspect components, structures, and materials for defects, corrosion, and other anomalies.

The importance of the Ultrasonic NDT Equipment Market in the context of global trends is underscored by the increasing emphasis on safety, quality control, and sustainability. As industries strive to minimize risks, improve efficiency, and extend the lifespan of assets, the demand for reliable and accurate NDT solutions continues to grow. The market also aligns with the broader trend of digitalization and automation, with the integration of advanced software, robotics, and data analytics enabling more sophisticated and efficient inspection processes. Furthermore, the market contributes to the global efforts towards sustainable development by enabling the early detection and prevention of failures, reducing the need for costly repairs and replacements. Therefore, the Ultrasonic NDT Equipment Market plays a vital role in supporting economic growth, environmental protection, and societal well-being.

Top Key Players in this Market

Nanjing BKN Automation System Co., LTD., Magnetic Analysis Corporation, Unique Group, EVIDENT, Modsonic Instruments Mfg. Co. (P) Ltd., Instrumart, Honesdom International (HK) Limited, OKOndt GROUP, TWI Ltd., Baker Hughes Company, Sonatest, and Aimil Ltd.

Market Segmentation:

The Ultrasonic NDT Equipment Market is segmented based on several factors:

By Component: Hardware and Software. Hardware includes transducers, pulser-receivers, and scanning systems, while software involves data acquisition, analysis, and reporting tools.

By Mode of Operation: Manual and Automatic. Manual operation involves direct human control, while automatic operation utilizes automated systems for increased efficiency.

By Technology: Phased Array Ultrasonic, Time of Flight Diffraction Technique, Automated Ultrasonic Backscatter Technique, Conventional Ultrasonic, Rapid Ultrasonic Gridding (RUG), Dry-Coupled Ultrasonic Testing, and Others. Each technology offers specific advantages for different inspection needs.

By End Use: Automotive, Oil & Gas, Aerospace & Defense, Power & Energy, Construction, Chemical, Infrastructure, and Others. Each sector requires specific NDT solutions tailored to its unique challenges and regulatory requirements.

Each segment contributes uniquely to the market's overall growth. For instance, advancements in phased array technology are driving adoption in critical industries like aerospace and oil & gas, while the increasing demand for automated systems is boosting efficiency in high-volume manufacturing environments.

Market Drivers:

Technological Advancements: Innovations in ultrasonic testing methods, such as phased array and TOFD, are improving accuracy and efficiency, driving market growth.

Stringent Regulations: Government policies and industry standards mandating regular inspections in sectors like aerospace, oil & gas, and power generation are increasing the demand for NDT equipment.

Increasing Demand for Safety: The growing emphasis on preventing failures and ensuring the safety of critical infrastructure and manufactured components is fueling the adoption of ultrasonic NDT solutions.

Aging Infrastructure: The need to inspect and maintain aging infrastructure, such as pipelines, bridges, and power plants, is creating opportunities for the market.

Growing Automotive Industry: the increased demand for ultrasonic NDT equipment for the development and quality control in the automotive sector is a major driving force for the market.

Market Key Trends:

Integration of AI and Machine Learning: The incorporation of AI and machine learning algorithms into ultrasonic NDT systems is enhancing data analysis and defect recognition capabilities.

Development of Portable and Wireless Devices: The emergence of portable and wireless ultrasonic NDT equipment is enabling more convenient and efficient on-site inspections.

Focus on User-Friendly Software: The development of intuitive software interfaces is making ultrasonic NDT equipment more accessible to a wider range of users.

Rise of Automated Inspection Systems: The increasing adoption of robotic and automated systems is improving inspection speed and consistency.

Cloud-Based Data Management: Cloud platforms for storing and analyzing inspection data are gaining popularity, enabling better collaboration and decision-making.

Market Opportunities:

Emerging Markets: Untapped potential in developing countries with growing infrastructure and industrialization.

Retrofitting Aging Infrastructure: Opportunities to deploy advanced NDT solutions for inspecting and maintaining aging infrastructure in developed countries.

Aerospace and Defense: Continued growth in the aerospace and defense sectors, driven by increasing air travel and defense spending.

Renewable Energy: Opportunities in the inspection and maintenance of wind turbines, solar panels, and other renewable energy infrastructure.

Innovations:

Developments in Robotics and Automation: The combination of robotics and ultrasonic technology offers the ability to remotely or automatically inspect parts and equipment, making inspections in hard-to-reach areas feasible.

Dry-Coupled Ultrasonic Transducers: These remove the need for a couplant liquid, enabling simpler, cleaner, and potentially faster inspections.

Market Restraints:

High Initial Costs: The cost of advanced ultrasonic NDT equipment can be a barrier to entry for smaller companies.

Lack of Trained Personnel: The need for skilled technicians to operate and interpret data from ultrasonic NDT systems can limit adoption.

Limitations in Certain Materials: Some materials, such as highly attenuating materials, can be challenging to inspect with ultrasonic methods.

Geographic Limitations: Accessibility and logistical challenges in remote locations can hinder the deployment of ultrasonic NDT equipment.

Standardization Challenges: Lack of universal standards for ultrasonic NDT can lead to inconsistencies in inspection results.

Market Challenges:

The Ultrasonic NDT Equipment Market faces several complex challenges that could impact its growth trajectory. One significant challenge is the need for highly skilled personnel to operate and interpret the results from advanced ultrasonic NDT systems. While technological advancements have made equipment more user-friendly, accurate interpretation of the data still requires specialized training and experience. This skills gap can be a barrier to entry for smaller companies and limit the widespread adoption of advanced NDT techniques. Addressing this challenge requires investments in training programs, educational initiatives, and certification processes to ensure a sufficient supply of qualified technicians.

Another major challenge is the cost associated with advanced ultrasonic NDT equipment, especially phased array and TOFD systems. The high initial investment can be prohibitive for many organizations, particularly small and medium-sized enterprises (SMEs). This challenge is exacerbated by the fact that NDT equipment often requires regular maintenance and calibration to ensure accuracy and reliability, adding to the overall cost of ownership. To overcome this hurdle, equipment manufacturers may need to offer flexible financing options, leasing programs, or subscription-based models to make advanced NDT technology more accessible to a wider range of customers.

Furthermore, the limitations of ultrasonic NDT techniques in certain materials and applications pose a challenge to the market. While ultrasonic testing is effective for detecting flaws in many materials, it can be less reliable for inspecting highly attenuating materials, such as some composites and coarse-grained metals. In addition, the accuracy of ultrasonic testing can be affected by surface roughness, geometry, and other factors. Overcoming these limitations requires ongoing research and development efforts to improve ultrasonic testing techniques and develop new methods for inspecting challenging materials and geometries. This could involve exploring alternative ultrasonic modalities, such as guided wave testing or nonlinear ultrasonics, or combining ultrasonic testing with other NDT methods, such as radiography or eddy current testing, to provide a more comprehensive assessment of material integrity.

Finally, the lack of standardized procedures and acceptance criteria for ultrasonic NDT can create inconsistencies in inspection results and hinder the widespread adoption of the technology. Different industries and regulatory bodies may have varying requirements for ultrasonic testing, making it difficult to compare results across different applications. To address this challenge, it is essential to develop and promote standardized procedures and acceptance criteria for ultrasonic NDT, based on best practices and scientific evidence. This will help to ensure the reliability and consistency of inspection results and facilitate the adoption of ultrasonic NDT technology across a wider range of industries.

Market Regional Analysis:

The Ultrasonic NDT Equipment Market exhibits varying dynamics across different regions. North America and Europe have traditionally been the leading markets, driven by stringent safety regulations, advanced industrial infrastructure, and a high level of technological adoption. These regions are characterized by a strong focus on quality control and predictive maintenance, fueling the demand for advanced ultrasonic NDT solutions.

The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, infrastructure development, and increasing investments in manufacturing. Countries like China, India, and Japan are experiencing a surge in demand for ultrasonic NDT equipment across various sectors, including automotive, aerospace, and energy. The Middle East and Africa also present significant opportunities, particularly in the oil & gas and construction sectors, due to the need for inspecting and maintaining critical infrastructure.

Latin America is another region with promising growth prospects, driven by increasing investments in infrastructure and manufacturing. However, the market in this region faces challenges such as limited access to advanced technology and a shortage of skilled personnel. Overall, the Ultrasonic NDT Equipment Market is characterized by a diverse range of regional dynamics, with each region presenting unique opportunities and challenges for market players.

Frequently Asked Questions:

What is the growth projection for the Ultrasonic NDT Equipment Market?

The market is projected to grow at a CAGR of 8.40% from 2023 to 2030, reaching over USD 1,824.26 Million by 2030.

What are the key trends in the market?

Key trends include the integration of AI and machine learning, the development of portable and wireless devices, and the rise of automated inspection systems.

Which Market types are most popular?

Phased Array Ultrasonic and Time of Flight Diffraction Technique are among the most popular market types due to their advanced capabilities and accuracy.

"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Europe Ultrasonic NDT Equipment Market Size, Share, Growth Trends, and Forecast 2025 to 2032 here

News-ID: 4051751 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for NDT

Seamless Digital RT Workflow with DRIVE NDT and D-Tect X from DÜRR NDT

For an optimal digital workflow in radiographic testing (RT), the X-ray inspection software D-Tect X can be integrated with the NDT management software DRIVE NDT. The closely meshed interaction between DRIVE NDT and D-Tect X means that a large part of the process takes place automatically. This not only saves time, but the automatic exchange of data also minimizes the possibility of human error. As all the steps and processes…

Rapid CUI Inspection with the DRA 3543 NDT Flat Panel Detector from DÜRR NDT

NDE Solutions Pty Ltd, located in Adelaide, South Australia with a team of over 60 employees provides non-destructive testing and inspection solutions to the oil and gas, defence, power, and mining industries.

NDE Solutions has been using the DÜRR NDT DRA 3543 digital flat panel since 2021 in combination with Iridium-192 radiation sources to perform Corrosion-Under-Insulation (CUI) radiography for confirming pipe wall loss in oil and gas plants and refineries. The…

DRIVE NDT enables DEKRA to increase its efficiency with digital NDT workflow man …

DEKRA has approximately 48,000 employees and ranks as one of the foremost testing companies worldwide. A pioneering team is introducing the innovative DRIVE NDT to organize non-destructive testing and its peripheral processes at the BAYERNOIL site in Neustadt.

Digital processes are firmly embedded in all industrial fields these days. The resulting advantages are clearly seen by all companies and industries and their potential is also increasingly recognized for non-destructive testing. Benjamin…

Corrosion-Under-Insulation Inspection Made Easy with the CR 35 NDT from DÜRR ND …

Stork Technical Services, located in Kwinana, Western Australia with a team of over 30 employees provides asset integrity and fabric maintenance services to the oil and gas, chemical, power and mining industries.

Stork Technical Services has been using the CR 35 NDT Computed Radiography scanner since 2019 and uses it with Iridium-192 in combination with high-sensitivity white imaging plates to perform Corrosion-Under-Insulation (CUI) radiography and digital gap shots which are…

Applus+ Entrusts DRIVE NDT with Digitization of NDT Workflow

Applus+ Germany is one of the largest providers of non-destructive testing (NDT) services in Germany and with more than 20,000 employees in over 70 countries is one of the largest companies in the industry worldwide.

In order to cement its leading position over the longer term, Applus+ is investing in future technologies. One of the key challenges of the future is the digitalization of all NDT processes. "A key promise is…

HD-CR 35 NDT from DÜRR NDT Increases Efficiency of Oil & Gas RT Inspection Task …

ENOD S.R.L is an NDT service company based in Buenos Aires, serving the energy sector in Argentina since August 1980.

ENOD is one of the largest service providers in Argentina, offering a wide range of inspection methods to fit their customers' needs. They have largely invested in the latest technologies to be one of the pioneers in their local market. A few years ago, they stepped into digital radiography to replace…