Press release

Chemical Mechanical Planarization (CMP) Slurry Market Outlook 2026: Industry Share, Trends, and Future Forecast - 2035

"The Chemical Mechanical Planarization (CMP) slurry market is experiencing significant growth, primarily driven by the escalating demand for advanced semiconductor devices, the increasing complexity of integrated circuits, and the rising adoption of optical and photovoltaic technologies. CMP is a crucial process in the manufacturing of these devices, ensuring surface planarity and defect reduction, which are vital for enhancing performance and reliability. Technological advancements in semiconductor manufacturing, particularly the move towards smaller feature sizes and higher chip densities, necessitate the use of CMP slurries with superior polishing capabilities. Furthermore, government policies promoting the growth of the semiconductor industry and investments in research and development are creating a favorable environment for market expansion. The CMP slurry market plays a pivotal role in addressing global challenges related to efficient energy consumption, advanced computing, and sustainable manufacturing practices. By enabling the production of more efficient solar cells and high-performance electronic devices, CMP technology contributes to a greener and more technologically advanced future. The market's ability to adapt to evolving industry needs, such as the development of specialized slurries for new materials and processes, will be crucial for sustaining its growth trajectory.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/1188

Market Size:

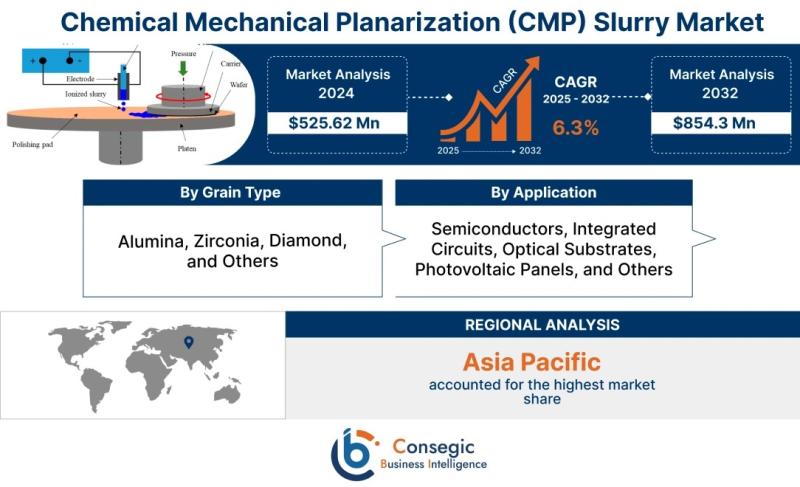

Consegic Business Intelligence analyzes that the Chemical Mechanical Planarization (CMP) Slurry Market size is estimated to reach over USD 854.3 Million by 2032 from a value of USD 525.62 Million in 2024 and is projected to grow by USD 549.15 Million in 2025, growing at a CAGR of 6.3 % from 2025 to 2032.

Definition of Market:

The Chemical Mechanical Planarization (CMP) slurry market encompasses the production, distribution, and application of specialized chemical solutions used in the CMP process. CMP is a polishing technique employed to flatten surfaces of semiconductor wafers, integrated circuits, optical substrates, and photovoltaic panels.

Key components of this market include:

CMP Slurries: These are the core products, consisting of abrasive particles (e.g., alumina, silica, ceria, diamond, zirconia) suspended in a chemical solution. The chemical solution etches or modifies the surface while the abrasive particles mechanically remove the material. The composition of the slurry is tailored to the specific material being polished and the desired surface finish.

Abrasive Particles: The type and size of the abrasive particles are critical to the CMP process. Different materials, like alumina, zirconia, diamond, and others, offer varying degrees of hardness and polishing efficiency.

Chemical Additives: These are added to the slurry to control the chemical etching rate, prevent corrosion, and improve the stability and dispersion of the abrasive particles.

CMP Equipment: While not directly part of the slurry market, CMP equipment (polishers, pads, and endpoint detection systems) are essential for the CMP process and closely linked to the slurry's performance.

Key terms related to the CMP slurry market include:

Planarization: The process of creating a flat surface.

Defect Reduction: Minimizing surface imperfections and irregularities.

Etch Rate: The speed at which the chemical solution removes material from the surface.

Removal Rate: The overall rate at which material is removed during the CMP process.

Surface Finish: The quality and smoothness of the polished surface.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/1188

Market Scope and Overview:

The CMP slurry market's scope spans a wide range of technologies, applications, and industries. It primarily serves the semiconductor industry, where CMP is indispensable for manufacturing microchips and integrated circuits. Beyond semiconductors, CMP slurries are used in the production of optical components (lenses, mirrors), hard disk drives, photovoltaic panels, and other advanced materials requiring ultra-smooth surfaces. The technologies involved include the development of novel abrasive particles, chemical formulations, and slurry delivery systems. The market also encompasses the services related to slurry testing, optimization, and disposal.

The CMP slurry market is crucial within the context of global technological trends. The increasing demand for smaller, faster, and more energy-efficient electronic devices fuels the need for advanced CMP techniques. The semiconductor industry's constant push towards miniaturization, driven by Moore's Law and beyond, requires CMP slurries capable of achieving atomic-level precision. Furthermore, the growth of renewable energy sources, such as solar power, relies on the efficient production of photovoltaic panels, where CMP plays a vital role in enhancing cell performance. The CMP slurry market is also influenced by environmental concerns, leading to the development of more sustainable and eco-friendly slurry formulations.

Top Key Players in this Market

Hitachi, Ltd., Fujifilm Corporation, Cabot Microelectronics Corporation, Fujimi Corporation, Merck KGaA, DuPont, Saint-Gobain Ceramics & Plastics, Inc., BASF SE, Showa Denko Materials Co. Ltd, and AGC Inc.

Market Segmentation:

The CMP slurry market is segmented based on several key factors.

By Grain Type: This includes Alumina, Zirconia, Diamond, and Others. Alumina slurries are widely used for general polishing applications, while Zirconia slurries offer higher removal rates. Diamond slurries are utilized for extremely precise polishing.

By Application: This includes Semiconductors, Integrated Circuits, Optical Substrates, Photovoltaic Panels, and Others. Semiconductors and integrated circuits represent the largest application segment due to the extensive use of CMP in microchip manufacturing. Optical substrates and photovoltaic panels are also significant contributors, driven by the demand for high-quality optical components and efficient solar cells.

Market Drivers:

Technological Advancements in Semiconductor Manufacturing: The move towards smaller feature sizes and higher chip densities requires CMP slurries with superior polishing capabilities.

Increasing Demand for Advanced Electronic Devices: The growing adoption of smartphones, tablets, and other electronic devices drives the need for high-performance semiconductors, which rely on CMP technology.

Rising Adoption of Optical and Photovoltaic Technologies: The expansion of the optical and solar energy industries creates demand for CMP slurries used in manufacturing optical components and photovoltaic panels.

Government Policies and Investments: Government initiatives promoting the growth of the semiconductor industry and investments in research and development contribute to market expansion.

Growing Demand for Miniaturization: The need for smaller, more efficient electronic components drives the demand for advanced CMP slurries.

Market Key Trends:

Development of Novel Abrasive Particles: Research and development efforts are focused on creating new abrasive particles with improved polishing performance and selectivity.

Formulation of Eco-Friendly Slurries: There is a growing trend towards developing environmentally friendly CMP slurries that minimize waste and reduce the use of hazardous chemicals.

Integration of Advanced Monitoring and Control Systems: The use of real-time monitoring and control systems to optimize the CMP process and improve slurry performance is increasing.

Customization of Slurries: CMP slurry vendors are increasingly offering customized slurry solutions tailored to specific customer needs and applications.

Market Opportunities:

Expansion into Emerging Markets: The growing semiconductor industries in developing countries offer significant growth opportunities for CMP slurry vendors.

Development of Specialized Slurries: The development of CMP slurries for new materials and processes, such as 3D NAND flash memory and advanced packaging technologies, presents a promising avenue for growth.

Product Innovation: Continuous innovation in slurry formulations, abrasive particles, and delivery systems can drive market expansion and enhance competitiveness.

Collaborations and Partnerships: Strategic partnerships between CMP slurry vendors, equipment manufacturers, and end-users can foster innovation and market development.

Growing Semiconductor Fab Capacity: Expanding semiconductor production facilities globally boost CMP slurry demand.

Market Restraints:

High Initial Costs: The cost of developing and manufacturing CMP slurries can be substantial, particularly for advanced formulations.

Technical Challenges: Achieving the desired surface finish and removal rates while minimizing defects can be technically challenging.

Environmental Regulations: Stringent environmental regulations regarding the disposal of CMP waste and the use of hazardous chemicals can pose a restraint on market growth.

Economic Slowdowns: Economic downturns can reduce demand for electronic devices and semiconductors, impacting the CMP slurry market.

Supply Chain Disruptions: Disruptions in the supply chain for raw materials and components can affect the availability and cost of CMP slurries.

Market Challenges:

The Chemical Mechanical Planarization (CMP) slurry market faces several complex challenges that require innovative solutions and strategic adaptations. One significant challenge is the increasing demand for higher precision and performance in CMP processes. As semiconductor devices continue to shrink in size and increase in complexity, the requirements for surface planarity and defect control become increasingly stringent. This necessitates the development of CMP slurries with advanced abrasive particles, chemical additives, and delivery systems capable of achieving atomic-level precision. However, formulating such slurries is a complex and time-consuming process, requiring extensive research and development efforts.

Another challenge is the growing concern over the environmental impact of CMP processes. Traditional CMP slurries often contain hazardous chemicals and generate significant waste streams, posing environmental risks. The increasing scrutiny from regulatory agencies and environmental organizations is driving the need for more sustainable and eco-friendly slurry formulations. Developing such formulations requires the use of less toxic chemicals, the reduction of waste generation, and the implementation of efficient recycling and disposal methods. However, balancing environmental sustainability with performance requirements can be a significant challenge.

The CMP slurry market also faces challenges related to cost pressures and competition. The semiconductor industry is highly competitive, and manufacturers are constantly seeking ways to reduce costs and improve efficiency. This puts pressure on CMP slurry vendors to offer cost-effective solutions without compromising performance. In addition, the CMP slurry market is characterized by a large number of players, ranging from established multinational corporations to smaller, specialized companies. This intense competition can drive down prices and erode profit margins, making it difficult for companies to invest in research and development and maintain a competitive edge. The limited number of manufacturers for specific and critical components is a big concern as well.

Furthermore, the CMP slurry market is vulnerable to fluctuations in the semiconductor industry. Economic downturns or shifts in consumer demand can significantly impact semiconductor production, which in turn affects the demand for CMP slurries. This cyclical nature of the semiconductor industry poses a challenge for CMP slurry vendors, who must carefully manage their production capacity and inventory levels to avoid oversupply or undersupply.

Finally, the CMP slurry market faces technical challenges related to the integration of new materials and processes. The semiconductor industry is constantly evolving, with new materials and processes being introduced to improve device performance. CMP slurries must be adapted to these new materials and processes to ensure optimal polishing performance. This requires ongoing research and development efforts and close collaboration between CMP slurry vendors and semiconductor manufacturers. It also often demands significant investment in analytical tools to correctly measure and access the performance metrics in the slurry being used.

Market Regional Analysis:

The CMP slurry market exhibits diverse dynamics across different regions, primarily influenced by the presence of semiconductor manufacturing facilities and the level of technological development. Asia-Pacific currently dominates the market, driven by the concentration of semiconductor fabrication plants in countries like Taiwan, South Korea, China, and Japan. These countries are investing heavily in expanding their semiconductor manufacturing capabilities, leading to a significant demand for CMP slurries. North America, particularly the United States, also holds a substantial share of the market, driven by the presence of leading semiconductor companies and research institutions.

Europe represents a smaller but growing market for CMP slurries, with a focus on specialty applications and research and development. The region is home to several leading research institutions and semiconductor equipment manufacturers, which are driving innovation in CMP technology. The market growth in different countries of LATAM and MEA also hold potential due to increasing investments into the electronics industry. However, each of these regions face unique challenges in the form of economic and social.

Frequently Asked Questions:

What is the projected growth of the CMP slurry market?

The CMP slurry market is projected to grow at a CAGR of 6.3% from 2025 to 2032, reaching over USD 854.3 Million by 2032 from a value of USD 525.62 Million in 2024.

What are the key trends in the CMP slurry market?

Key trends include the development of novel abrasive particles, formulation of eco-friendly slurries, integration of advanced monitoring and control systems, and customization of slurries.

What are the most popular CMP slurry types?

Alumina slurries are the most widely used for general polishing applications, followed by Zirconia and Diamond slurries for higher performance needs.

"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Chemical Mechanical Planarization (CMP) Slurry Market Outlook 2026: Industry Share, Trends, and Future Forecast - 2035 here

News-ID: 4049612 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for CMP

CMP Materials for Semiconductor Market Share Driven by CMP Slurry and Widespread …

CMP Materials for Semiconductor Market Size

The global market for CMP Materials for Semiconductor was valued at US$ 3701 million in the year 2024 and is projected to reach a revised size of US$ 5657 million by 2031, growing at a CAGR of 6.3% during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-14V14904/Global_CMP_Materials_for_Semiconductor_Market_Research_Report_2023

The CMP (Chemical Mechanical Planarization) Materials for Semiconductor market is witnessing consistent growth as global chip manufacturers pursue higher precision and yield…

Global CMP Pads Conditioning Disk Market Size by Application, Type, and Geograph …

According to Market Research Intellect, the global CMP Pads Conditioning Disk market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

Due to rising demand in the semiconductor production industry, the market for CMP (Chemical Mechanical Planarization)…

Colloidal Silica For CMP Slurry Market

Colloidal Silica For CMP Slurry Market analysis report has recently added which helps to make informed business decisions. This research report further identifies the market segmentation along with their sub-types. The Global Colloidal Silica For CMP Slurry Market is expected to reach at a huge CAGR during the forecast period. Various factors are responsible for the market's growth, which are studied in detail in this research report.

The report envelops a…

SiC CMP Slurry Market 2022 | Detailed Report

This report offers a detailed view about the challenging landscape of the international market. The exact and innovative information gave through this report helps organizations with getting mindful of the kinds of consumers, buyer's demand and preferences, their perspective, their purchasing aims, their reaction to a specific item, and their different tastes about the certain item already prevailing in the SiC CMP Slurry market. It includes a point-by-point illustration of…

CMP Slurry Filters Market Competitive Insights with Global Outlook 2021-2027|Pal …

Los Angeles United States: The global CMP Slurry Filters market is researched with great precision and in a comprehensive manner to help you identify hidden opportunities and become informed about unpredictable challenges in the industry. The authors of the report have brought to light crucial growth factors, restraints, and trends of the global CMP Slurry Filters market. The research study offers complete analysis of critical aspects of the global CMP Slurry…

CMP Slurry Market Forecast to 2026- Analysis of CMP Slurry Industry by Manufactu …

CMP Slurry market report provides key insights about industry including market drivers, restraints, opportunities, new product launches or approval, market trends, regional outlook, and competitive strategy adopted by key players. CMP Slurry market report explains potential revenue opportunities across different segments, sub segments and explains attractive investment proposition matrices for the market.

Chemical mechanical polishing (CMP) is a process of smoothing surfaces with the combination of chemical and mechanical forces. It…