Press release

Checkweigher Machine Market is Expected to Grow at a CAGR 2.6% by 2034 | Fact.MR

The checkweigher machine market is expected to be valued at US$ 629.2 million in 2024. With a projected compound annual growth rate (CAGR) of 2.6% over the next decade, the market is set to grow steadily, reaching an estimated valuation of US$ 813.3 million by 2034.For More Insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9706

Market Overview

Checkweigher machines have become essential tools for modern manufacturing and packaging operations. Designed to ensure the weight of products falls within specified tolerances, these systems help prevent underfilling and overfilling, thereby maintaining product consistency, reducing material waste, and meeting regulatory requirements. As industries place greater emphasis on precision and compliance, demand for reliable and automated checkweighing solutions continues to grow.

Key Market Drivers

1. Rise in Automated Quality Control Systems

Industries are rapidly transitioning to automated solutions to streamline operations and reduce human error. Checkweigher machines serve as a frontline solution in automated quality control, offering real-time feedback and system integration capabilities that help maintain product integrity across production lines.

2. Regulatory Compliance Pressures

Governments and regulatory bodies across the globe have introduced stricter guidelines on product labeling and weight standards, especially in sectors like food and beverages, pharmaceuticals, and cosmetics. Companies are turning to advanced checkweighers to ensure compliance and avoid costly penalties, recalls, or damaged brand reputation.

3. Growth in E-commerce and Retail Logistics

With the surge in e-commerce and increasing parcel volumes, accurate product weights have become more critical than ever for logistics, shipping, and fulfillment. This trend is particularly influential in driving adoption across warehousing and third-party logistics providers.

4. Technological Innovations

Recent technological advancements, including high-speed electromagnetic force restoration (EMFR) sensors, digital interfaces, and IoT connectivity, have made checkweighers smarter and more efficient. Many systems now offer predictive maintenance alerts, integration with MES/ERP platforms, and improved accuracy at high speeds, increasing their value to manufacturers.

Market Segmentation Insights

By Weight Capacity

The 12 to 60 kg segment is expected to dominate, accounting for nearly half of the total market share in 2024. This weight range offers the most flexibility across diverse industries including processed food, beverages, chemicals, and personal care.

By End-Use Industry

The food and beverage sector continues to be the leading consumer of checkweigher machines, representing an estimated 45.2% market share in 2024. With food safety standards becoming more rigorous and global food exports rising, manufacturers are heavily investing in automated weighing technologies.

By Technology Type

Strain gauge-based systems and EMFR technology are the two primary mechanisms in modern checkweighers. EMFR systems, though typically more expensive, are growing in popularity due to their high accuracy, particularly for small and fast-moving packaged products.

Regional Market Analysis

East Asia

This region is forecasted to lead the global checkweigher machine market, with an estimated 38% market share in 2024. China and Japan remain the powerhouses, driven by robust manufacturing sectors and growing domestic demand for automation in packaging.

North America

Holding an expected 29.2% share in 2024, North America's market is shaped by advanced manufacturing ecosystems and tight regulatory standards in pharmaceuticals, food, and consumer goods.

Europe

The European market remains strong, with Germany, the United Kingdom, and France at the forefront. Investments in Industry 4.0 and smart factory initiatives are helping boost the regional demand for next-generation checkweigher systems.

Competitive Landscape

The global checkweigher machine market is moderately consolidated, with several key players focusing on innovation, regional expansion, and strategic partnerships. Prominent manufacturers are consistently improving product reliability, digital integration, and operational speed to gain competitive advantages.

Leading companies include:

Thermo Fisher Scientific Inc.; Mettler Toledo; R.S. Bilance S.r.l.; SF Engineering; VBS, Inc.; VARPE CONTROL DE PESO S.A.; Soc. Coop. Bilanciai Campogalliano; Teraoka Seiko Co., Ltd.; ACG; Anritsu; Bizerba; Cassel Inspection; Dibal; Espera-Werke; Idecon; iXAPACK GLOBAL; LOMA SYSTEM; Marel; Minebea Intec; NEMESIS; OCS-WIPOTEC; Packital S.R.L.; Prisma Industriale; Mettler Toledo

These companies are focused on enhancing operational throughput, minimizing system downtime, and developing industry-specific models for pharmaceuticals, dairy, bakery, and high-speed logistics sectors.

Challenges and Restraints

Despite promising growth, the market faces certain limitations:

High Initial Costs:

Advanced checkweigher systems, especially those with EMFR technology and multi-lane setups, require substantial capital investment, which can deter small and medium manufacturers.

Complex Integration:

Integrating modern checkweighers into legacy systems can be technically challenging, particularly in older manufacturing facilities with outdated automation infrastructure.

Maintenance Requirements:

Regular calibration, cleaning, and sensor upkeep are necessary to maintain accuracy, which may increase operational downtime in facilities without proper technical support.

Browse Full Report: https://www.factmr.com/report/checkweigher-machine-market

Future Outlook

The future of the checkweigher machine market looks promising, with strong demand anticipated across traditional and emerging industries. Innovations such as AI-driven inspection systems, cloud-connected monitoring, and fully integrated end-of-line automation will likely reshape market dynamics in the coming years.

Manufacturers are expected to continue investing in hybrid systems that combine checkweighing with metal detection, X-ray inspection, and vision verification-all within a single unit. This trend reflects growing demand for multifunctional packaging line solutions in space-constrained facilities.

Moreover, as sustainability becomes a priority, checkweighers will play a key role in minimizing material waste and supporting zero-defect manufacturing processes, especially in sectors committed to circular economy principles.

Check out More Related Studies Published by Fact.MR:

Automatic Checkweigher Market : https://www.factmr.com/report/automatic-checkweigher-market

Logistics Robot Market: https://www.factmr.com/report/logistics-robot-market

Barge Transportation Market: https://www.factmr.com/report/2485/barge-transportation-market

Truck Refrigeration Unit Market: https://www.factmr.com/report/3245/truck-refrigeration-unit-market

Contact:

US Sales Office

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583, +353-1-4434-232

Email: sales@factmr.com

About Fact.MR

We are a trusted research partner of 80% of fortune 1000 companies across the globe. We are consistently growing in the field of market research with more than 1000 reports published every year. The dedicated team of 400-plus analysts and consultants is committed to achieving the utmost level of our client's satisfaction.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Checkweigher Machine Market is Expected to Grow at a CAGR 2.6% by 2034 | Fact.MR here

News-ID: 4049394 • Views: …

More Releases from Fact.MR

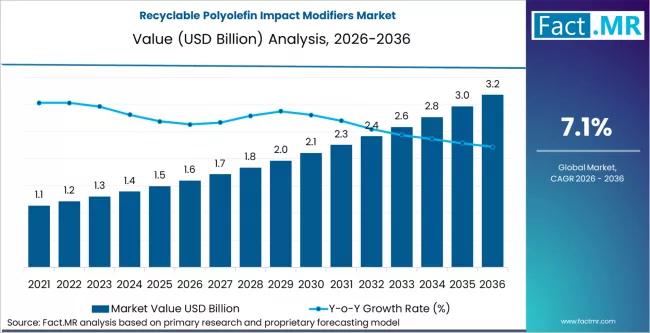

Recyclable Polyolefin Impact Modifiers Market Forecast 2026-2036: Global Market …

The global recyclable polyolefin impact modifiers market is entering a phase of rapid industrial adoption, with its valuation projected to rise from USD 1.6 billion in 2026 to approximately USD 3.1 billion by 2036. This growth reflects an absolute increase of USD 1.5 billion over the forecast period, expanding at a compound annual growth rate (CAGR) of 7.1%. As global manufacturers prioritize circularity, these modifiers have become critical for restoring…

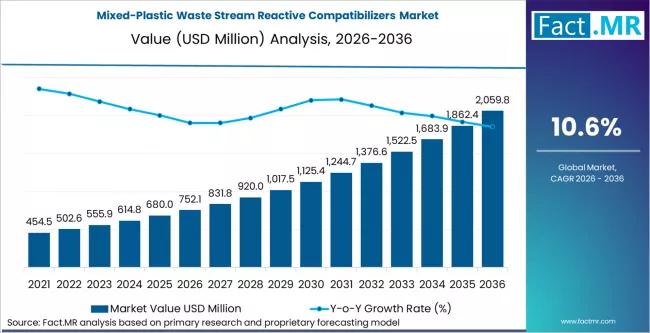

Mixed Plastic Waste Stream Reactive Compatibilizers Market Growth Outlook 2026-2 …

The global mixed plastic waste stream reactive compatibilizers market is projected to grow from USD 515.2 million in 2026 to approximately USD 943.4 million by 2036. This expansion represents an absolute increase of USD 428.2 million over the forecast period, with the market set to expand at a compound annual growth rate (CAGR) of 6.2% between 2026 and 2036. As the global transition toward a circular economy intensifies, these specialized…

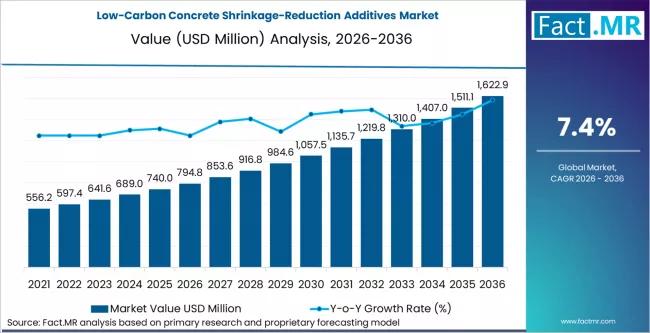

Low-Carbon Concrete Shrinkage Reduction Additives Market Forecast 2026-2036: Glo …

The global Low-Carbon Concrete Shrinkage Reduction Additives Market is projected to register robust growth over the next decade as green construction practices, stringent environmental regulations, and demand for durable infrastructure drive adoption of sustainable concrete technologies. Industry analysts estimate that the market, valued at approximately USD 1.6 billion in 2025, will grow to nearly USD 3.2 billion by 2035, expanding at a compound annual growth rate (CAGR) of about 7.2%…

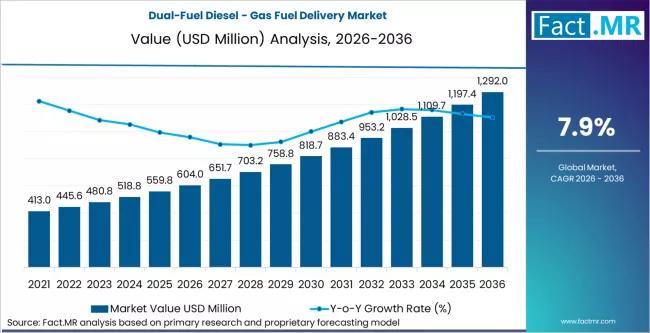

Hydrogen Fuel Rail and Pressure Regulators Market Analysis 2026-2036: Rising Hyd …

The global hydrogen fuel rail and pressure regulators market is entering a pivotal growth phase, with its valuation projected to rise from USD 385.4 million in 2026 to approximately USD 1,483.2 million by 2036. This expansion represents an absolute increase of USD 1,097.8 million over the forecast period, reflecting a robust compound annual growth rate (CAGR) of 14.4%. As the transportation sector pivots toward zero-emission solutions, high-precision hydrogen handling components…

More Releases for Checkweigher

SHIGAN Ultra-High-Speed Checkweigher Launches

SHIGAN's ultra-high-speed checkweigher is available today, capable of weighing products at astonishing speeds, up to 600 pcs/min, to meet the needs of industries that demand precision and speed in the fast-paced world of manufacturing and production. Ultra-high-speed checkweigher is designed to meet the stringent demands of modern production lines. Designed to improve operational efficiency while maintaining the highest quality control standards.

Image: https://ecdn6.globalso.com/upload/p/658/image_other/2024-08/sg-150hh-checkweigher.jpg

One of the standout features of Ultra-high-speed checkweigher is…

Selecting a Professional Checkweigher Manufacturer: Vital Importance

In the fast-paced world of manufacturing and packaging, accuracy and efficiency are key factors in ensuring product quality. One important tool that plays a key role in this process is the dynamic industrial checkweigher [https://www.sgcheckweigher.com/]. These machines are designed to accurately measure the weight of a product during the packaging process, ensuring it meets specified weight requirements. When investing in a packaging checkweigher, it is crucial to choose a professional…

How to Select a Professional Checkweigher Manufacturer

In the fast-paced world of manufacturing and packaging, accuracy and efficiency are key factors in ensuring product quality. One important tool that plays a key role in this process is the dynamic industrial checkweigher [https://www.sgcheckweigher.com/]. These machines are designed to accurately measure the weight of a product during the packaging process, ensuring it meets specified weight requirements. When investing in a packaging checkweigher, it is crucial to choose a professional…

Why Should One Get An Inline Checkweigher System?

An inline checkweigher system [https://www.sgcheckweigher.com/checkweigher-1/] is a crucial investment for any production line due to its ability to provide real-time, accurate weight measurements of products as they move through the line. inline checkweigher systems [https://www.sgcheckweigher.com/checkweigher-1/] are designed to check the weight of your products directly in your production lines without having to stop them. They present many advantages for the control of prepackaged goods, missing products and tolerance checks. Here…

What is a checkweigher in the food industry?

A checkweigher [https://www.sgcheckweigher.com/checkweigher-1/] is an essential piece of equipment in the food industry, ensuring that products meet specific weight requirements and comply with regulations. This dynamic checkweigher is designed to accurately measure the weight of food products as they move along the production line, helping manufacturers maintain consistency and quality in their offerings. With the increasing demand for high-speed production and stringent quality control, the use of a high-speed checkweigher…

Checkweigher Machines: Innovations in Automated Weight Verification

In the ever-evolving landscape of industrial automation, the demand for precision and efficiency continues to drive innovation. Checkweigher machines, pivotal in ensuring accurate weight measurements across various industries, have witnessed a significant transformation with the emergence of advanced technologies. Infinity Automated Solutions, a leading player in this domain, has unveiled a range of checkweigher machines tailored to meet the diverse needs of businesses across different weight ranges.

Request a Quote: https://infinitysols.com/request-a-quote/…