Press release

Metal Injection Molding Market 2025 Edition: Industry to Reach USD 9.5 Billion by 2033, CAGR of 8.21%

IMARC Group's latest research report, titled "Metal Injection Molding Market Report by Material Type (Stainless Steel, Low Alloy Steel, Soft Magnetic Material, and Others), End Use Industry (Electrical and Electronics, Automotive, Medical and Orthodontics, Consumer Products, Firearms and Defense, and Others), and Region 2025-2033," offers a comprehensive analysis of the metal injection molding market. The report also includes competitor and regional analysis, along with a breakdown of segments within the industry. the global metal injection molding market size was valued at USD 4.6 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 9.5 Billion by 2033, exhibiting a CAGR of 8.21% from 2025-2033. In 2024, United States accounted for 83.38% of the metal injection modeling market share in North America. The market is growing rapidly due to the increasing requirement for miniaturized components in electronics and healthcare sectors, rising demand for lightweight parts in the automotive industry, expanding need in medical and dental applications, heightened awareness about the technique's cost-efficiency in mass production, and rapid advancements in material science.Get free Sample Copy of Report at - https://www.imarcgroup.com/metal-injection-molding-market/requestsample

Latest Trends Shaping the Metal Injection Molding Market:

The metal injection molding (MIM) market is witnessing significant transformation, fueled by a convergence of technological innovations, material advancements, and increasing industry-specific applications. One of the most prominent trends is the rising integration of MIM components into high-precision industries such as medical devices, aerospace, automotive, and consumer electronics. These sectors demand compact, complex, and high-performance parts, which MIM can efficiently deliver due to its unique ability to combine the design flexibility of plastic injection molding with the strength of metallic materials. In recent years, manufacturers have increasingly adopted advanced feedstock formulations that offer enhanced sintering capabilities, dimensional accuracy, and material strength. This evolution is not only improving product quality but also optimizing production efficiency and reducing waste. Furthermore, there is a growing emphasis on miniaturization and the development of micro-sized MIM components, particularly for medical implants and electronic devices, where conventional manufacturing methods struggle to deliver cost-effective precision. Sustainability is also influencing market direction, with stakeholders investing in greener manufacturing processes, recyclable raw materials, and energy-efficient sintering technologies. Additionally, the emergence of AI and machine learning tools for process optimization and defect prediction is driving greater consistency and reliability in MIM part production. The shift toward Industry 4.0 practices-such as real-time monitoring, smart automation, and data analytics-is also gaining traction, helping manufacturers enhance scalability and meet evolving customer requirements. These trends collectively underscore the market's dynamic evolution, positioning MIM as a key enabler in high-precision, high-volume manufacturing.

Growth Factors Propelling the Metal Injection Molding Market:

The metal injection molding market is experiencing robust and sustained growth, supported by increasing demand across a diverse array of industries and advancements in manufacturing technologies. One of the primary drivers of growth is the expanding application base of MIM components in sectors that require intricate geometries and high-strength materials, such as the defense, dental, and industrial machinery segments. These industries are actively transitioning from traditional machining methods to MIM due to its cost-effectiveness in producing complex parts at scale. The medical sector, in particular, is fueling significant demand, as MIM is ideal for producing biocompatible components like surgical instruments and orthopedic implants with exceptional precision. Similarly, the automotive industry's shift toward lightweighting and compact engine systems has resulted in a higher adoption of MIM for engine components, turbocharger parts, and sensors. Additionally, consumer electronics manufacturers are leveraging MIM for fabricating miniaturized connectors, phone parts, and wearable device components, driven by a surge in global electronics consumption. From a geographic perspective, the Asia-Pacific region continues to dominate market expansion due to rapid industrialization, a strong manufacturing base, and increasing R&D investments by regional players. Moreover, the growing affordability of MIM technologies-helped by economies of scale and advancements in feedstock production-has lowered entry barriers for small and medium-sized enterprises. The availability of customized solutions and quick turnaround times further makes MIM an attractive choice for clients seeking both performance and economic efficiency. Overall, these diverse growth factors are consolidating MIM's role as a preferred manufacturing solution in today's highly competitive industrial landscape.

Future Demand Outlook for the Metal Injection Molding Market:

The future demand for metal injection molding is expected to rise steadily, underpinned by the evolving requirements of precision-driven industries and the continuous shift toward high-efficiency manufacturing processes. As product designs become increasingly intricate and compact across sectors like aerospace, electronics, and medical technology, MIM is uniquely positioned to meet these demands through its ability to produce near-net-shape components with minimal secondary operations. Future demand will also be influenced by the increasing call for lightweight, high-strength materials in next-generation vehicles, electric mobility systems, and energy-efficient consumer products. The rise of electric vehicles (EVs) is particularly noteworthy, with MIM components being used in battery systems, drive units, and thermal management solutions, where space efficiency and thermal conductivity are critical. The adoption of smart factories and digital twin technologies is set to enhance the scalability and quality control of MIM processes, making it easier for manufacturers to meet growing global demand while ensuring product consistency and traceability. Furthermore, advancements in binder systems and sintering techniques will allow the use of more exotic metals and alloys, expanding the scope of applications and pushing the boundaries of what MIM can achieve. The growing interest in additive manufacturing and hybrid technologies may also complement MIM in producing tailored solutions for niche markets. As global manufacturing becomes more data-driven and consumer-centric, the ability of MIM to offer both customization and scalability will be pivotal. These factors collectively point to a strong and sustained demand outlook for the MIM market, supported by innovation, sustainability, and market responsiveness.

Leading Key Players Operating in the Metal Injection Molding Industry:

• Amphenol Corporation

• ARC Group Worldwide Inc

• ATW Companies Inc

• CMG Technologies

• CN Innovations Ltd.

• Dean Group International Ltd

• Ernst Reiner GmbH & Co. KG

• Metal Powder Products LLC

• Parmaco Metal Injection Molding AG

• Sintex a/s

• Smith Metal Products

• Tanfel Metal

Metal Injection Molding Market Trends:

The metal injection molding market is undergoing a significant transformation, characterized by a shift toward advanced applications, material innovation, and digital integration. One of the most influential trends is the diversification of end-use industries. Sectors such as medical, automotive, aerospace, and consumer electronics are increasingly turning to MIM for its ability to produce complex, high-strength components in large volumes at competitive costs. This is leading to a broadening of MIM applications, with manufacturers exploring new opportunities in electric mobility, smart devices, and wearable technologies. Another key trend is the emphasis on sustainable production, with companies focusing on reducing material waste, enhancing energy efficiency, and utilizing recyclable feedstock materials to align with global environmental goals.

The adoption of Industry 4.0 practices is also revolutionizing the MIM manufacturing landscape. Real-time data analytics, AI-driven quality control systems, and automation technologies are being implemented to enhance process stability, reduce lead times, and improve product consistency. Additionally, innovations in binder and sintering technologies are allowing for greater material flexibility, enabling the use of titanium, cobalt-chrome, and other high-performance alloys previously considered challenging for injection molding. This is opening doors to high-value markets where precision and material properties are non-negotiable. The rising demand for miniaturized components, especially in the fields of electronics and medical devices, is further pushing the development of micro-MIM capabilities. As a result, manufacturers are investing in R&D and upgrading their production facilities to stay competitive and meet evolving customer expectations. These emerging trends signal a strong and adaptable market, capable of addressing the complex challenges of modern manufacturing while maintaining a focus on efficiency, innovation, and sustainability.

Do you know more information, Contact to our analyst at- https://www.imarcgroup.com/metal-injection-molding-market

Key Market Segmentation:

Breakup by Material Type:

• Stainless Steel

• Low Alloy Steel

• Soft Magnetic Material

• Others

Stainless steel leads due to its corrosion resistance and high strength, suiting a broad range of intricate part applications.

Breakup by End Use Industry:

• Electrical and Electronics

• Automotive

• Medical and Orthodontics

• Consumer Products

• Firearms and Defense

• Others

The electrical & electronics sector dominates as metal injection molding (MIM) meets the demand for miniaturized, complex components in electronic devices.

Breakup by Region:

• North America (United States, Canada)

• Asia Pacific (China, Japan, India, Australia, Indonesia, Korea, Others)

• Europe (Germany, France, United Kingdom, Italy, Spain, Others)

• Latin America (Brazil, Mexico, Others)

• Middle East and Africa (United Arab Emirates, Saudi Arabia, Qatar, Iraq, Other)

Asia Pacific holds the largest market share with its extensive manufacturing base and increased adoption of MIM across diverse industries.

Key Highlights of the Report:

• Market Performance (2019-2024)

• Market Outlook (2025-2033)

• Porter's Five Forces Analysis

• Market Drivers and Success Factors

• SWOT Analysis

• Value Chain

• Comprehensive Mapping of the Competitive Landscape

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Who we are:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Injection Molding Market 2025 Edition: Industry to Reach USD 9.5 Billion by 2033, CAGR of 8.21% here

News-ID: 4016870 • Views: …

More Releases from IMARC Group

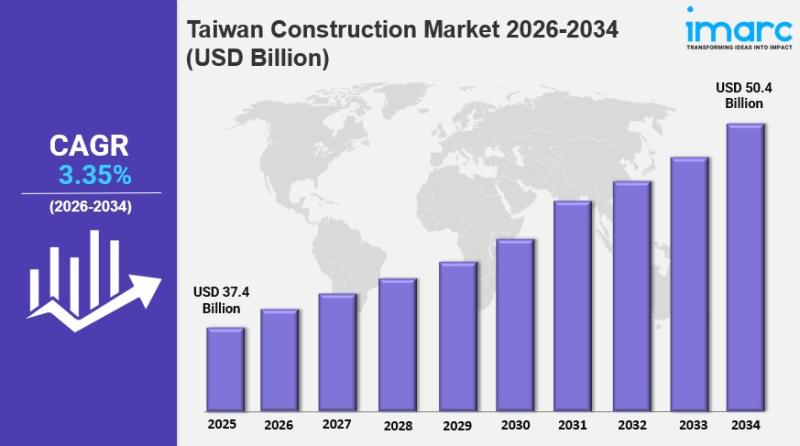

Taiwan Construction Market Size, Share, In-Depth Insights, Trends and Forecast 2 …

IMARC Group has recently released a new research study titled "Taiwan Construction Market Report by Sector (Residential, Commercial, Industrial, Infrastructure (Transportation), Energy and Utilities Construction), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Taiwan construction market size reached USD 37.4 Billion in 2025 and is projected to grow to USD 50.4…

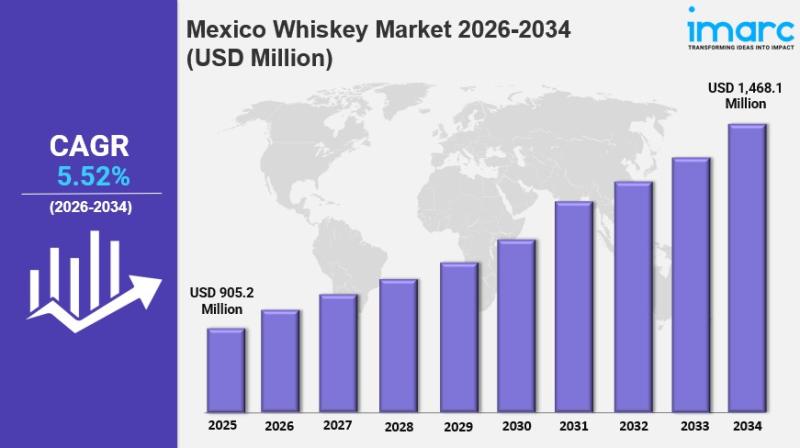

Mexico Whiskey Market Size to Hit USD 1,468.1 Million by 2034: Trends & Forecast

IMARC Group has recently released a new research study titled "Mexico Whiskey Market Size, Share, Trends and Forecast by Product Type, Quality, Distribution Channel, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico whiskey market size reached USD 905.2 Million in 2025. It is projected to grow to USD 1,468.1 Million…

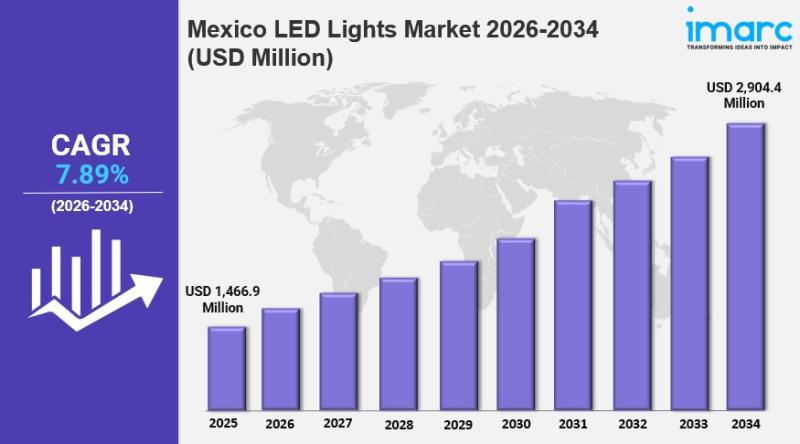

Mexico LED Lights Market 2026 : Industry Size to Reach USD 2,904.4 Million by 20 …

IMARC Group has recently released a new research study titled "Mexico LED Lights Market Size, Share, Trends and Forecast by Product Type, Application, Import and Domestic Manufacturing, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico LED lights market was valued at USD 1,466.9 million in 2025 and is projected to…

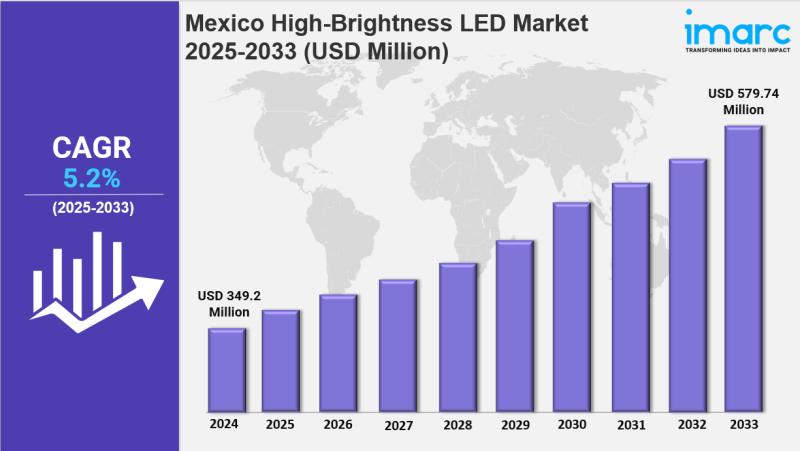

Mexico High-Brightness LED Market Size, Share, Latest Insights and Forecast 2025 …

IMARC Group has recently released a new research study titled "Mexico High-Brightness LED Market Size, Share, Trends and Forecast by Application, Distribution Channel, Indoor and Outdoor Application, End-Use Sector, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico high-brightness LED market size reached USD 349.2 Million in 2024 and is…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…