Press release

Ammonium Nitrate Production Cost Report 2025: Plant Setup Economics and Financial Outlook

Setting up a ammonium nitrate production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Ammonium Nitrate Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a ammonium nitrate production plant, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/ammonium-nitrate-manufacturing-plant-project-report/requestsample

What is Ammonium nitrate?

Ammonium nitrate manufacturing involves producing a highly soluble, nitrogen-rich compound commonly used in fertilizers and industrial explosives. The process begins with the controlled reaction of ammonia and nitric acid, forming an ammonium nitrate solution that is then concentrated through evaporation. This solution is transformed into solid prills or granules using specialized equipment, followed by drying, cooling, and packaging. Strict quality control, temperature monitoring, and safety systems are essential throughout the process due to the compound's oxidizing nature. Manufacturing facilities must also comply with regulatory standards for environmental protection, safe storage, and controlled distribution to ensure product integrity and safety.

What is Driving the Ammonium Nitrate Market?

The ammonium nitrate market is primarily driven by rising global demand for high-performance fertilizers that support increased agricultural productivity and crop yields. Growing populations, expanding food requirements, and the need for efficient soil nutrients are strengthening fertilizer consumption. Additionally, the mining, quarrying, and construction sectors significantly contribute to market growth, as ammonium nitrate is a key component in industrial explosives used for blasting operations. Infrastructure development across developing economies further boosts demand. Technological advancements, improved mining efficiency, and supportive government policies for agricultural enhancement also stimulate market expansion, although regulatory scrutiny and safety concerns remain important influencing factors.

Buy Now: https://www.imarcgroup.com/checkout?id=7859&method=1911

Key Steps Required to Set Up an Ammonium Nitrate Production Plant

1. Market Analysis

The report provides insights into the landscape of the ammonium nitrate industry at the global level. The report also provides a segment-wise and region-wise breakup of the global ammonium nitrate industry. Additionally, it also provides the price analysis of feedstocks used in the production of ammonium nitrate, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the ammonium nitrate production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for the ammonium nitrate production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for ammonium nitrate production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up an ammonium nitrate production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7859&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales{@}imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ammonium Nitrate Production Cost Report 2025: Plant Setup Economics and Financial Outlook here

News-ID: 4292479 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

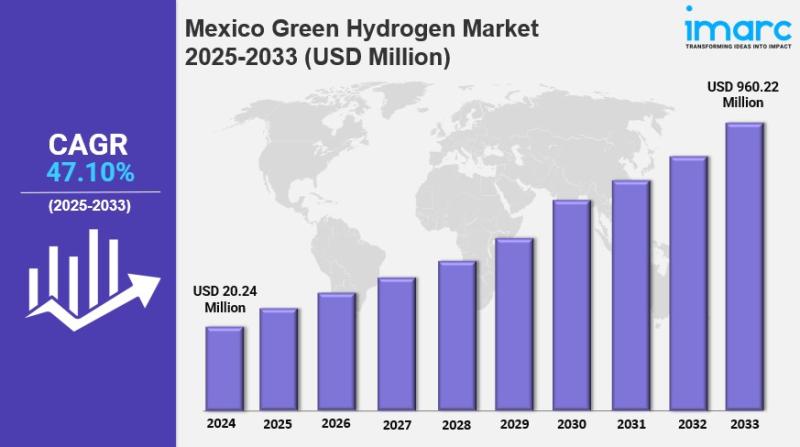

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Ammonium

Ammonium Nitrate Production Cost Analysis

Ammonium nitrate is a widely used inorganic chemical compound with significant applications in fertilizers, explosives, mining, construction, and industrial blasting. Due to its high nitrogen content and strong oxidizing properties, ammonium nitrate plays a crucial role in global agriculture and industrial development. Understanding the ammonium nitrate production cost structure is essential for manufacturers, investors, and procurement professionals operating in fertilizer and chemical markets.

Request a Free Sample:- https://www.procurementresource.com/production-cost-report-store/ammonium-nitrate/request-sample

This article provides a…

Ammonium Nitrate Production Cost Analysis

Ammonium nitrate is a critical inorganic chemical widely used in fertilizers, explosives, mining, construction, and industrial applications. It is valued for its high nitrogen content and strong oxidizing properties. Due to its energy-intensive manufacturing process and dependence on upstream raw materials, understanding the ammonium nitrate production cost structure is essential for chemical manufacturers, fertilizer producers, regulators, and procurement professionals.

Request a Free Sample:- https://www.procurementresource.com/production-cost-report-store/ammonium-nitrate/request-sample

Overview of Ammonium Nitrate Production

Ammonium nitrate is produced…

Evolving Market Trends In The Quaternary Ammonium Compounds Industry: Innovative …

The Quaternary Ammonium Compounds Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Expected Quaternary Ammonium Compounds Market Size During the Forecast Period?

The quaternary ammonium compounds market size will grow from $1.07 billion in 2024 to $1.13 billion in 2025 at a compound…

Transforming the Quaternary Ammonium Compounds Market in 2025: Industrial Growth …

What Is the Expected Size and Growth Rate of the Quaternary Ammonium Compounds Market?

There has been a robust expansion of the quaternary ammonium compounds market in the past few years. The market size is expected to rise from $1.07 billion in 2024 to $1.13 billion in 2025, registering a compound annual growth rate (CAGR) of 5.2%. The previous growth curve was primarily driven by factors such as the escalating demand…

Ammonium Sulfate Market Trends, 2021-2031

Ammonium Sulfate Market: Introduction

Transparency Market Research delivers key insights on the global ammonium sulfate market. In terms of revenue, the global ammonium sulfate market is estimated to expand at a CAGR of ~5% during the forecast period, owing to numerous factors regarding which TMR offers thorough insights and forecasts in its report on the global ammonium sulfate market.

Read report Overview -https://www.transparencymarketresearch.com/ammonium-sulfate-market.html

The emergence of biofertilizers is likely to hamper the global…

Ammonium Acetate Market Industry Analysis - Ammonium Acetate Market Size Driven …

The most recent study offered by Acumen Research and Consulting focuses Ammonium Acetate Market size, share, growth rate, and market trends, as well as the parameters and factors influencing it in both the long term and short term. The report investigates the Ammonium Acetate Market trends in order to assess its current and future potential. Our Ammonium Acetate Market analysis also provides market participants and new entrants with a comprehensive…