Press release

Lateral Flow Strip Cutter

In the fast-evolving world of diagnostics and medical testing, lateral flow assays (LFAs) have become a game-changer. But behind every efficient LFA lies a critical piece of equipment-the lateral flow strip cutter. Without accurate cutting of these delicate strips, even the best-designed test can fail. Today, we're diving deep into the world of lateral flow strip cutters, understanding their role, features, types, and how they keep the gears of diagnostic industries turning smoothly.What is a Lateral Flow Strip Cutter?

A lateral flow strip cutter https://www.lateralflowstripcutter.com/ is a specialized machine designed to precisely cut lateral flow membranes into uniform, narrow strips. These strips are essential for producing rapid diagnostic tests like pregnancy tests, COVID-19 antigen tests, and countless others. Precision is everything in lateral flow devices-the width and consistency of the strip directly impact the test's performance and reliability.

Typically, these cutters are engineered to handle delicate materials like nitrocellulose membranes, sample pads, conjugate pads, and absorbent pads without causing damage. By ensuring clean, precise cuts, strip cutters maintain the integrity of the fluidic pathways crucial for test functionality.

Importance of Lateral Flow Strip Cutting in Diagnostic Manufacturing

You might wonder, why is cutting so critical? Well, in diagnostics, consistency is king. Every test strip must have identical dimensions to ensure fluid moves at the same rate, the reaction zones align perfectly, and results remain accurate and reproducible. Even a minor inconsistency can lead to invalid or misleading test outcomes.

Strip cutting affects not just the functionality but also the visual quality of a test. Ragged edges, uneven strips, or material deformation can destroy user confidence and damage brand reputation. Therefore, a reliable lateral flow strip cutter isn't just equipment-it's a cornerstone of quality control in test manufacturing.

How a Lateral Flow Strip Cutter Works

At its core, a lateral flow strip cutter automates the slicing process. Here's a simplified step-by-step of its function:

The membrane sheet is placed into the machine.

It's held taut, sometimes with a gentle vacuum or clamps, to prevent any wrinkles.

High-precision blades (either rotary or guillotine-style) move across the membrane, slicing it into the pre-set strip widths.

Finished strips are collected, often on a conveyor belt or into trays for immediate use.

Some advanced models even allow real-time adjustments and inspection systems to detect and correct misalignments on the fly. It's a symphony of mechanics, precision, and engineering, all tailored for an invisible yet critical job.

Key Features of a Lateral Flow Strip Cutter

When you're investing in a lateral flow strip cutter, there are some key features you should absolutely keep an eye out for. Why? Because these features determine the quality, reliability, and efficiency of your strip-cutting process-and by extension, the accuracy of your diagnostic tests.

Precision and Accuracy

Precision isn't just a luxury; it's a necessity. A minor deviation in strip width can cause huge problems in fluid flow dynamics across the membrane. The best lateral flow strip cutters use sharp, durable blades and precision mechanics to ensure every single strip is identical. Some machines offer micrometer adjustments, so you can fine-tune the width settings down to fractions of a millimeter. If you're aiming for world-class test performance, precision isn't negotiable.

Speed and Efficiency

In high-demand situations like pandemic surges or mass health campaigns, production speed matters. Modern strip cutters can process hundreds, even thousands of strips in an hour without sacrificing accuracy. Semi-automatic and fully automatic machines often integrate high-speed motors and automated feed systems to ramp up productivity. Less downtime, more output-that's the goal.

Compatibility with Various Materials

Lateral flow devices aren't made with just one type of material. You have nitrocellulose membranes, sample pads, conjugate pads, and wicking pads, each with different thicknesses and flexibilities. A good strip cutter should handle all these materials seamlessly without tearing, curling, or deforming them. Material adaptability ensures you won't need different machines for every component.

Types of Lateral Flow Strip Cutters

Depending on your production scale, budget, and required precision, you can choose among several types of strip cutters. Here's a breakdown:

Manual Strip Cutters

These are simple, cost-effective devices where operators manually feed and cut the strips. Perfect for small-scale productions or R&D labs where flexibility and hands-on control matter more than high output.

Pros: Low cost, easy to use, highly adaptable.

Cons: Lower speed, higher chance of human error, not ideal for mass production.

Semi-automatic Strip Cutters

Semi-automatic strip cutters bridge the gap between manual and fully automatic systems. Operators load the material, and the machine takes over the cutting process based on programmed settings.

Pros: Higher consistency, faster than manual, moderately priced.

Cons: Still requires operator intervention, though minimal.

Fully Automatic Strip Cutting Machines

These are the titans of the industry. Fully automated strip cutters can feed large membrane sheets, align them, cut them precisely, and even sort the strips without any human touch.

Pros: Unmatched speed and precision, best for high-volume production.

Cons: High initial cost, more maintenance, requires technical expertise to operate.

Materials Used in Lateral Flow Test Strips

Understanding the materials involved helps you appreciate why precision cutting is so important. Lateral flow tests use a sandwich of materials, including:

Nitrocellulose Membrane: The heart of the test where reactions happen.

Sample Pad: Collects and sometimes filters the sample.

Conjugate Pad: Holds dried reagents that react with the sample.

Absorbent Pad (Wicking Pad): Draws fluid through the strip.

Each layer has specific functions and material properties. Cutting them improperly can ruin the alignment and fluidic pathways, rendering the test unreliable. A top-notch lateral flow strip cutter ensures clean, perfect cuts across all these varied materials without cross-contamination or misalignment.

Applications of Lateral Flow Strip Cutters

Lateral flow tests aren't just for hospitals and doctor's offices anymore. Their portability and rapid results have opened doors across many industries. Here's where lateral flow strip cutters play an essential role:

Medical Diagnostics

From pregnancy tests to HIV, malaria, and COVID-19 diagnostics, LFAs dominate the point-of-care testing market. Strip cutters enable the mass production of these crucial tools by ensuring uniformity and reliability at the base manufacturing level.

Food Safety Testing

Contaminants like Salmonella, E. coli, and pesticide residues can be quickly detected using LFAs in the food industry. Proper strip cutting ensures these tests deliver accurate results, helping safeguard public health and protect brands from costly recalls.

Environmental Monitoring

Pollution, water quality testing, and even detecting harmful biological agents rely on LFA technology. A well-made test starts with a perfectly cut strip, making strip cutters an unsung hero in environmental safety and regulation compliance.

Advantages of Using a High-Quality Lateral Flow Strip Cutter

Investing in a high-quality lateral flow strip cutter might seem like a big decision initially, but the benefits it delivers are hard to ignore. Here's why choosing a superior machine makes a world of difference:

Consistent Quality: Every strip comes out identical, ensuring that your test results are reliable and your customers trust your brand.

Reduced Waste: Precision cutting means fewer errors, less material wastage, and lower overall production costs.

Improved Workflow: Automated features speed up production, allowing you to meet large orders without rushing and risking mistakes.

Enhanced Reputation: Accurate tests build credibility in a market where reliability is everything. Your equipment plays a direct role in building that reputation.

Long-Term Savings: Higher-quality machines are built to last, meaning fewer breakdowns, lower maintenance costs, and better ROI over time.

Cut corners on your cutter, and you could be cutting corners on your entire business.

Factors to Consider When Choosing a Lateral Flow Strip Cutter

Before purchasing a lateral flow strip cutter, take a moment to consider the following key factors:

Production Volume: Are you producing hundreds of tests a day or thousands? Choose a machine that matches your scale without overpaying for unused capacity.

Material Compatibility: Make sure the machine handles all the materials used in your specific tests.

Cutting Width Adjustability: Look for flexible width settings, especially if you plan to manufacture different types of LFAs.

Ease of Maintenance: Machines that are easy to clean and maintain will save you time and headaches in the long run.

Software Integration: Advanced models offer digital controls, allowing you to save cutting settings for different batches and improve consistency.

Cost vs. Value: Don't just look at the price tag. Consider durability, brand reputation, service support, and machine lifespan when making a decision.

Think of your lateral flow strip cutter as a long-term partner, not just a one-off purchase.

Future Trends in Lateral Flow Strip Cutting Technology

Technology doesn't sit still-and neither does the world of lateral flow strip cutting. Here are some exciting trends shaping the future:

AI and Machine Learning: Some next-gen cutters are integrating AI algorithms to adjust blade pressure and alignment in real-time for optimal cuts.

IoT Connectivity: Imagine monitoring your strip cutter's performance remotely or getting maintenance alerts via an app. It's becoming a reality!

Eco-Friendly Designs: Newer machines are being designed with energy efficiency and reduced waste in mind, helping manufacturers meet green standards.

Customization Features: Modular strip cutters are gaining popularity, allowing users to easily swap parts and configure machines for specific test types without major overhauls.

Enhanced Safety Features: As machines get faster and more powerful, built-in safety sensors and automatic shutdown features are becoming standard.

The future of lateral flow strip cutting is not just about cutting-it's about smart, sustainable, and user-friendly manufacturing solutions.

Conclusion

The humble lateral flow strip cutter https://www.lateralflowstripcutter.com/ may not get the spotlight, but it is undeniably one of the silent engines powering the success of rapid diagnostics across industries. From ensuring precision and consistency to enabling mass production with minimal waste, a quality strip cutter can elevate your entire product line.

As lateral flow technology continues to expand into new areas, the demand for better, faster, and smarter strip cutters will only grow. If you're serious about delivering reliable diagnostic tests that people can trust, then investing in a top-notch lateral flow strip cutter is a move you can't afford to overlook.

P.O Bagarji Town Bagarji Village Ghumra Thesil New Sukkur District Sukkur Province Sindh Pakistan 65200.

Wiki Blogs News always keeps careful online users to provide purposeful information and to keep belief to provide solution based information.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lateral Flow Strip Cutter here

News-ID: 3995337 • Views: …

More Releases from Wikiblogsnews

Nursing School Applicants Turn to Free Online TEAS Prep Tools as Admissions Comp …

February 2026 - Anyone applying to nursing school now will tell you the same thing: the field is harsh. There just aren't enough seats, not because the coursework scares people away. More than 65,000 eligible candidates were turned down for nursing programs between 2024 and 2025; these individuals fulfilled all requirements and ticked all the boxes, but they were still told "no" since the school was already full.

And yet the…

Why ITIL Version 5 is Essential for Digital First Organisations

Are you considering an ITIL® 5 Foundation Course https://www.itil.org.uk/training/itil-foundation-level-courses/itil-version-5-foundation-certification-course because your organisation is moving towards a digital-first model? That is not surprising. Businesses today depend fully on digital platforms, data, and automation. Yet many still struggle with service gaps and poor coordination. You may also be wondering, What is ITIL Version 5 https://www.itil.org.uk/blog/itil-version-5-a-complete-guide and why does it matter now. It is more than a framework. It connects digital products, people,…

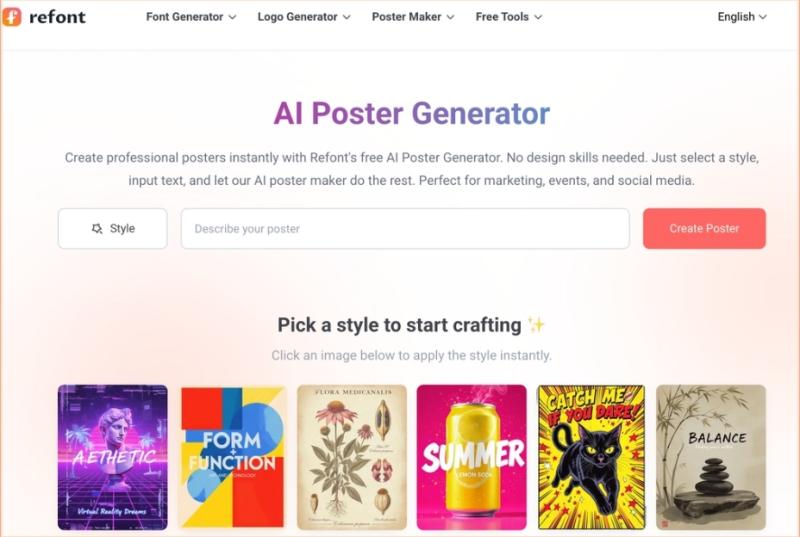

Tired of the Design Bottleneck? How I Finally Found a Practical AI Poster Genera …

If you're anything like me, you've probably spent more hours than you'd like to admit fighting with design software. We've all been there: you have a killer idea for a promotion, a social post, or a brand announcement, but by the time you've messed around with layers, alignment, and hunting for stock photos, the inspiration is gone and so is half your afternoon.

I've tried the early wave of generative AI…

Best Exotic Car Rental in Miami: Experience Luxury Without Overspending

Miami has a way of turning every drive into a cinematic experience. Picture yourself cruising down Ocean Drive at sunset with the gentle ocean breeze mixing in with the roar of your high-performance engine, smiling people looking over your car. For those who seek this experience, the best exotic car rental in Miami is your ticket to unlocking this fantasy.

But there's a catch: Miami's luxury car scene is flooded, and…

More Releases for Strip

Strip Packing Machine Market Report | Strip Packing Machine Market Analysis, Tre …

The global strip packing machine market is expected to approach US$ 431.8 million by 2030, with an annual growth rate of more than 5.6%

Global Strip Packing Machine Market was valued at US$ 295.7 million in 2023 and is expected to grow at a significant CAGR of over 5.6% over the forecast period of 2023-2030, according to the published market report by RationalStat

Market Definition, Market Scope, and Report Overview

The…

TPE Strip: Versatile Applications in Modern Industries | Toyoda Gosei, Cooper St …

TPE Strip Market 2023 Forecast: Unveiling Opportunities and Growth

TPE Strip market report presents an overview of the market on the basis of key parameters such as market size, revenue, sales analysis and key drivers. The market size of global TPE Strip market is anticipated to grow at large scale over the forecast period (2023-2029). The main purpose of the study report is to give users an extensive viewpoint of the…

Industrial Plastic Strip Curtains Market 2021-2027 Global Industry Analysis | St …

Tackling issues emerging from the initial to the final marketing process is the key factor of the Industrial Plastic Strip Curtains marker research. The market report provides details on demands of the targeted customers to help organizations do changes in the final product. It also outlines particular result, which a person sets to accomplish within particular time frame with the help of available resources. It focuses on studying dynamics of…

Strip Doors and Strip Curtains Outlook and Forecast 2020-2025

This report also researches and evaluates the impact of Covid-19 outbreak on the Strip Doors and Strip Curtains�industry, involving potential opportunity and challenges, drivers and risks. We present the impact assessment of Covid-19 effects on Strip Doors and Strip Curtains�and market growth forecast based on different scenario (optimistic, pessimistic, very optimistic, most likely etc.).

The recent�report added by GLOBAL INFO RESEARCH�gives a detailed account of the drivers and restraints in the…

Global Plastic Strip Doors Market 2017 : ALECO, Strip-Curtains, Chase Doors, Sim …

Global Plastic Strip Doors market competition by top manufacturers, with production, price, revenue (value) and market share for each manufacturer; the top players including

- ALECO

- Strip-Curtains

- Chase Doors

- Kingman Industries

- Simplex

- M.T.I. Qualos Pty Ltd

- Carona

- Premier Door Systems PTY LTD

The survey report by Market Research Store is an overview of the global Plastic Strip Doors market. It covers all the recent trends including key developments in the global market…

Global Plastic Strip Doors Market 2017- ALECO, Strip-Curtains, Chase Doors, King …

The worldwide Plastic Strip Doors Market report is an in-depth research on the current situation of the Plastic Strip Doors industry. The research study of Global Plastic Strip Doors Market 2017 offers a strategic assessment of Plastic Strip Doors market. The industry report focuses on the growth opportunities, which will help the Plastic Strip Doors industry to expand operations in the existing markets globally.

Firstly, Plastic Strip Doors Market report introduces…