Press release

How To Setup a Wet Wipe Manufacturing Plant

Setting up a wet wipe manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Wet Wipe Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a prestressed concrete sleeper's manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Request for a Sample Report: https://www.imarcgroup.com/wet-wipe-manufacturing-plant-project-report/requestsample

The wet wipe industry is currently experiencing significant growth and innovation, driven by several key trends and factors. A major driver is the increasing consumer focus on hygiene and convenience, a trend that has been amplified by recent global health events. This has led to a surge in demand for sanitizing wipes for hands and surfaces, becoming a staple in personal care routines and public health practices. Furthermore, the rising awareness regarding personal hygiene across various demographics, coupled with busier lifestyles, fuels the need for quick and easy cleaning solutions that wet wipes offer. The versatility of wet wipes, spanning from baby care and personal hygiene to household cleaning and industrial applications, contributes significantly to their widespread adoption.

Innovation in materials and formulations is another crucial trend shaping the industry. There's a growing emphasis on sustainability, with manufacturers increasingly exploring biodegradable and plant-based materials to address environmental concerns associated with traditional non-woven fabrics. This push for eco-friendly options resonates with environmentally conscious consumers and aligns with stricter regulations regarding single-use plastics. Additionally, advancements in formulations are leading to specialized wipes with added benefits, such as moisturizing agents, antibacterial properties, and specific cleaning solutions tailored for different surfaces and applications. The baby care segment remains a dominant force, with continuous innovation focused on gentle and skin-friendly formulations. Moreover, the cosmetic and personal care sectors are witnessing a rise in specialized wipes for makeup removal, exfoliation, and on-the-go skincare. The convenience and portability of these products cater to the fast-paced lifestyles of modern consumers. The industry is also seeing a rise in e-commerce and online retail channels, making wet wipes more accessible to a wider consumer base. Marketing and branding efforts are increasingly emphasizing specific benefits, such as natural ingredients, dermatological testing, and targeted solutions for niche markets, further driving market growth and segmentation.

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=9725&flag=C

Key Steps Required to Set Up a Wood Adhesive Plant.

1. Market Analysis

The report provides insights into the landscape of the wood adhesive industry at the global level. The report also provides a segment-wise and region-wise breakup of the global wood adhesive industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of wood adhesive, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the wet wipe manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Buy Now: https://www.imarcgroup.com/checkout?id=9725&method=1911

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for wet wipe manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for wood adhesive production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a wet wipe manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How To Setup a Wet Wipe Manufacturing Plant here

News-ID: 3980623 • Views: …

More Releases from IMARC Group

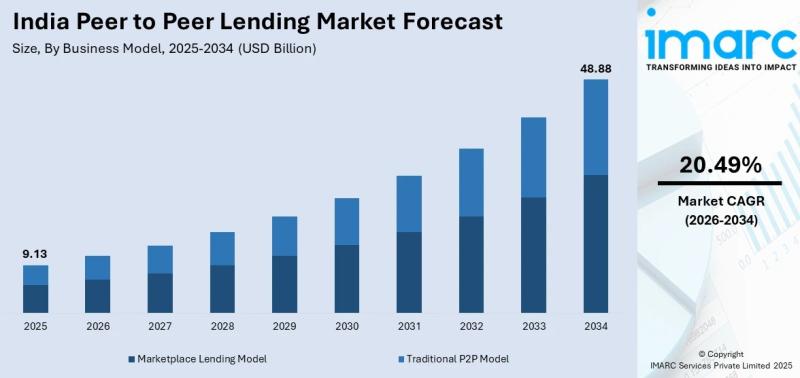

India Peer To Peer Lending Market Outlook 2026-2034: Digital Lending Trends and …

According to IMARC Group's report titled "India Peer To Peer Lending Market Size, Share, Trends and Forecast by Business Model, End User, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Peer To Peer Lending Market Analysis

The India peer to peer lending market size was valued at USD 9.13 Billion in 2025 and is projected to reach USD 48.88…

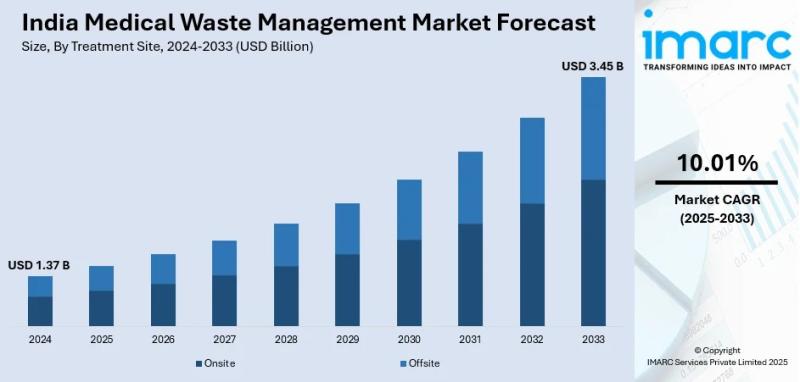

India Medical Waste Management Market to Reach USD 3.45 Billion by 2033, Growing …

Source: IMARC Group | Category: Healthcare | Author Name: Gaurav

Report Introduction

According to IMARC Group's latest report titled "India Medical Waste Management Market Size, Share, Trends and Forecast by Treatment Site, Treatment, and Region, 2025-2033", the market is growing rapidly due to the expansion of healthcare infrastructure and increasing volumes of biomedical waste. The study offers a profound analysis of the industry, encompassing market share, size, growth factors, key trends, and…

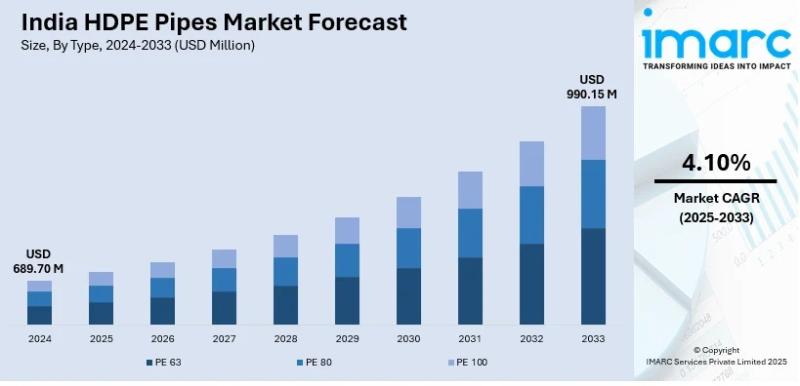

India HDPE Pipes Market to Reach USD 990.15 Million by 2033, Growing at 4.10% CA …

Source: IMARC Group | Category: Industrial Materials | Author Name: Gaurav

Report Introduction

According to IMARC Group's latest report titled "India HDPE Pipes Market Size, Share, Trends, and Forecast by Type, Application, and Region, 2025-2033", the market is growing steadily due to government-led infrastructure initiatives, agricultural modernization, and the increasing adoption of sustainable piping solutions. The study offers a profound analysis of the industry, encompassing market share, size, growth factors, key trends,…

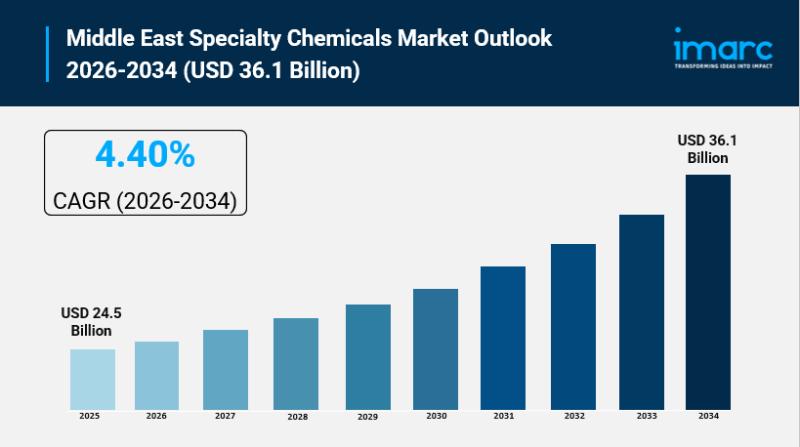

Middle East Specialty Chemicals Market Size to Surpass USD 36.1 Billion by 2034 …

Middle East Specialty Chemicals Market Overview

Market Size in 2025: USD 24.5 Billion

Market Size in 2034: USD 36.1 Billion

Market Growth Rate 2026-2034: 4.40%

According to IMARC Group's latest research publication, "Middle East Specialty Chemicals Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Middle East specialty chemicals market size was valued at USD 24.5 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 36.1 Billion by…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…