Press release

Catalyst Market Report 2025 Edition: Industry Market Size, Share, Demand, and Competitor Analysis

Market Overview:The catalyst market is experiencing rapid growth, driven by environmental focus & green chemistry, process intensification in chemical manufacturing, and expanding applications & industrial growth. According to IMARC Group's latest research publication, "Catalyst Market Size, Share, Trends and Forecast by Type, Process, Raw Material, Application, and Region, 2025-2033 ", The global catalyst market size was valued at USD 41.46 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 58.68 Billion by 2033, exhibiting a CAGR of 3.74% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides a regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/catalyst-market/requestsample

Our report includes:

● Market Dynamics

● Market Trends And Market Outlook

● Competitive Analysis

● Industry Segmentation

● Strategic Recommendations

Factors Affecting the Growth of the Catalyst Industry:

● Environmental Focus & Green Chemistry:

The catalyst market shows substantial growth together with structural change because of strengthening environmental standards coupled with growing industrial interest in sustainable production. Governments around the world are enforcing stringent emission regulations on automotive sectors and chemical manufacturing and power generation plants which leads to the requirement of sophisticated catalysts to minimize pollution sources including NOx, CO and VOCs. The chemical industry now requires catalysts capable of running clean reactions while cutting down energy requirements and waste output because it actively works toward building sustainable production systems. The research field focuses on three main categories of catalysts starting with biocatalysts followed by selective heterogeneous catalysts and catalysts made from non-precious metals that are easily available. The circular economy movement guides current catalyst development because scientists concentrate on designing catalysts that simplify recovery and recycling processes. Through this development we have established an essential change in manufacturing toward environmentally sustainable and resource-efficient systems while making advanced catalysts the vital components that enable a sustainable future.

● Process Intensification in Chemical Manufacturing:

The catalyst market receives major influence from both the ongoing improvements in chemical manufacturing technology along with rising process intensification trends. The chemical industry actively pursues elevation of product yields and enhancement of manufacturing efficiency and quality through continuous advancement. The reduction of energy usage and operational costs and the promotion of both reaction speed and selectivity depend on catalysts as they allow reactions to happen at milder conditions. The development of highly active and stable catalysts stands essential to Process intensification because it allows size reduction of equipment and improves operational efficiency. Process execution requires structured catalysts along with microreactor technology and continuous flow reactors where catalysts need to meet particular performance requirements. Bio-based feedstocks have risen in chemical manufacturing which requires new biocatalysts and heterogeneous catalysts that convert renewable resources into valuable chemicals and materials. The fundamental importance of catalyst innovation drives chemical industry development because it creates manufacturing systems that produce multiple sustainable products affordably.

● Expanding Applications & Industrial Growth:

The catalyst market experiences sustained growth through its alignment with the growth of key end-use industries such as automotive and petrochemicals and pharmaceuticals together with the development of fresh applications for catalysts. The automotive sector functioning as a principal catalyst consumer for vehicle emission regulation systems continues despite the evolving electric vehicle trend because advanced catalysts designed for hybrid vehicles and EV manufacturing emission reduction present growing market opportunities. The petrochemical industry requires catalysts for both oil refining operations and chemical and polymeric substances production whereas new petrochemical complex investments sustain catalyst market demand. Pharmaceutical companies implement catalysts during drug molecule synthesis activities and mounting pharmaceutical research leads to market expansion. The catalyst market shows substantial future growth possibilities through emerging applications which involve hydrogen production by electrolysis for green hydrogen along with carbon capture and utilization methods and sustainable fuel synthesis processes. Industrial progress and environmental sustainability depend heavily on catalysts due to their widespread use in various applications throughout established and developing industries.

Buy Full Report: https://www.imarcgroup.com/checkout?id=6370&method=1670

Leading Companies Operating in the Global Catalyst Industry:

● Albemarle Corporation

● Arkema S.A.

● Axens SA

● BASF SE

● Chevron Phillips Chemical Company LLC

● Clariant AG

● Dow Inc.

● Evonik Industries AG

● Exxon Mobil Corporation

● Honeywell International Inc.

● Johnson Matthey

● Shell plc

● W. R. Grace and Co. (Standard Industries Inc.)

● Zeolyst International Inc.

Catalyst Market Report Segmentation:

By Type:

● Heterogeneous Catalyst

● Homogeneous Catalyst

Heterogeneous catalyst represents the largest segment due to their ability to be easily separated from the reaction mixture and reused, enhancing process efficiency and cost-effectiveness.

By Process:

● Recycling

● Regeneration

● Rejuvenation

Recycling exhibits a clear dominance in the market because catalysts play a crucial role in enabling efficient and sustainable recovery and reuse of valuable materials, meeting increasing environmental regulations and resource conservation needs.

By Raw Material:

● Chemical Compounds

● Peroxides

● Acids

● Amines

● Others

● Metals

● Precious Metals

● Base Metals

● Zeolites

● Others

Chemical compounds (peroxides, acids, amines, and others) account for the majority of the market share as they are essential in manufacturing various types of catalysts used across multiple industrial processes, ensuring consistent performance and high reactivity.

By Application:

● Chemical Synthesis

● Chemical Catalysts

● Adsorbents

● Syngas Production

● Others

● Petroleum Refining

● Fluid Catalytic Cracking (FCC)

● Alkylation

● Hydrotreating

● Catalytic Reforming

● Purification

● Bed Grading

● Others

● Polymers and Petrochemicals

● Ziegler Natta

● Reaction Initiator

● Chromium

● Urethane

● Solid Phosphorous Acid Catalyst

● Others

● Environmental

● Light-duty Vehicles

● Motorcycles

● Heavy-duty Vehicles

● Others

Chemical synthesis (chemical catalysts, adsorbents, syngas production, and others) holds the biggest market share owing to the extensive use of catalysts in producing pharmaceuticals, polymers, and other fine chemicals, driving demand through continuous innovation and industrial growth.

Regional Insights:

● North America (United States, Canada)

● Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

● Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

● Latin America (Brazil, Mexico, Others)

● Middle East and Africa

Asia Pacific's dominance in the catalyst market is attributed to rapid industrialization, significant investments in chemical and petrochemical industries, and a strong manufacturing base in various countries.

Ask Analyst for Sample Report: https://www.imarcgroup.com/request?type=report&id=6370&flag=C

Research Methodology:

The report employs a comprehensive research methodology , combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability .

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services. IMARC's offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Catalyst Market Report 2025 Edition: Industry Market Size, Share, Demand, and Competitor Analysis here

News-ID: 3965280 • Views: …

More Releases from IMARC Group

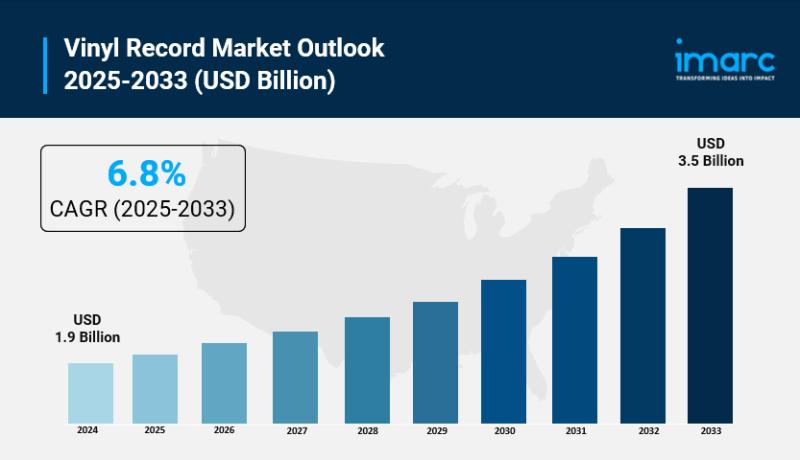

Vinyl Record Market Size to Reach USD 3.5 Billion by 2033 | With a 6.8% CAGR

Market Overview:

According to IMARC Group's latest research publication, "Vinyl Record Market Report by Product (LP/EP Vinyl Records, Single Vinyl Records), Feature (Colored, Gatefold, Picture), Gender (Men, Women), Age Group (13-17, 18-25, 26-35, 36-50, Above 50), Application (Private, Commercial), Distribution Channel (Supermarkets and Hypermarkets, Independent Retailers, Online Stores, and Others), and Region 2025-2033", The global vinyl record market size reached USD 1.9 Billion in 2024. Looking forward, IMARC Group expects the…

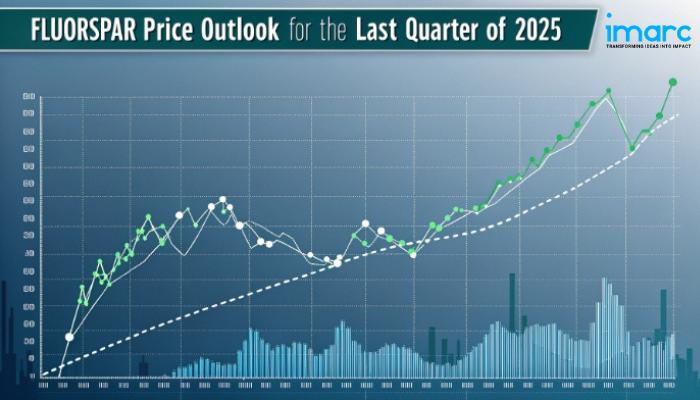

North America Fluorspar Prices Rise in Q4 2025: USA at USD 484/MT, Canada Peaks …

North America Fluorspar Prices Movement Q4 2025:

Fluorspar Prices in USA:

In Q4 2025, fluorspar prices in the USA averaged USD 484 per metric ton. Stable demand from aluminum production and chemical manufacturing supported price levels. Domestic mining operations maintained consistent output, while transportation and energy costs influenced overall supply. Moderate industrial activity and inventory management helped prevent significant price fluctuations across the regional market.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/fluorspar-pricing-report/requestsample

Note: The analysis…

Brazil Hybrid Electric Vehicle Market: Growth Dynamics, Consumer Shifts, and Com …

The Brazil hybrid electric vehicle market size was 348.75 Thousand Units in 2025 and is forecasted to reach 2,551.74 Thousand Units by 2034, reflecting a CAGR of 24.75% during 2026-2034. This robust expansion is fueled by increasing environmental awareness, rising fuel costs, and government policies aimed at emission reduction. Advances in battery technology and flex-fuel hybrid variants leveraging Brazil's ethanol resources also contribute to market growth.

Sample Request Link: https://www.imarcgroup.com/brazil-hybrid-electric-vehicle-market/requestsample

Study Assumption…

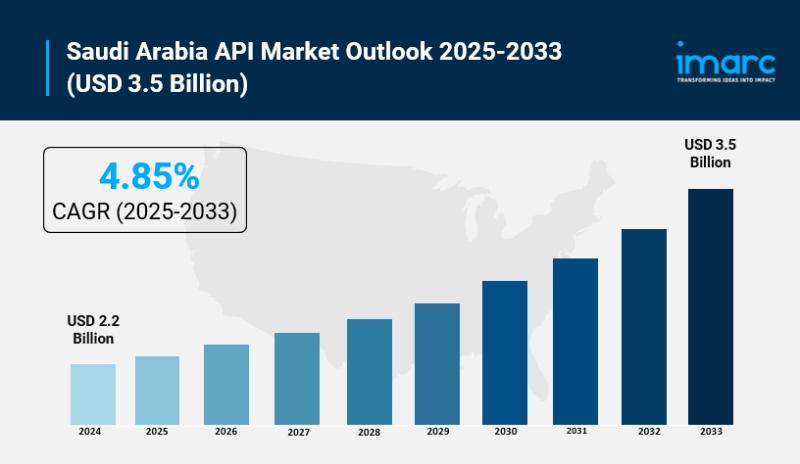

Saudi Arabia API Market Size to Expand USD 3.5 Billion by 2033 at a CAGR of 4.85 …

Saudi Arabia API Market Overview

Market Size in 2024: USD 2.2 Billion

Market Forecast in 2033: USD 3.5 Billion

Market Growth Rate 2025-2033: 4.85%

According to IMARC Group's latest research publication, "Saudi Arabia API Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Saudi Arabia API market size reached USD 2.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.5 Billion by 2033, exhibiting a growth rate…

More Releases for Catalyst

Cr-based Alkanes Dehydrogenation Catalyst Market 2025: Innovations, Trends, and …

Los Angeles-United State: QY Research has recently published a research report titled, "Cr-based Alkanes Dehydrogenation Catalyst - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031" assessing various factors impacting its trajectory. The market research report is a perfect tool for digging deep into critical aspects of the global Cr-based Alkanes Dehydrogenation Catalyst market and closely understanding factors that influence its growth. Our research analysts are experienced enough…

Catalyst Market Economic Drivers Factors Influencing Catalyst Market Expansion - …

In recent years, the global Catalyst Market has witnessed a dynamic shift, influenced by changing consumer preferences, technological advancements, and a growing emphasis on sustainability. The Research report on Catalyst Market presents a complete judgment of the market through strategic insights on future trends, growth factors, supplier landscape, demand landscape, Y-o-Y growth rate, CAGR, pricing analysis. It also provides and a lot of business matrices including Porters Five Forces Analysis,…

Diesel Engine Catalyst Market Report 2024 - Diesel Catalyst Market Size And Grow …

"The Business Research Company recently released a comprehensive report on the Global Diesel Engine Catalyst Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive…

Continuous Catalyst Regeneration (CCR) Catalyst Market Segmentation & Analysis, …

Los Angeles, USA: QY Research has recently unveiled a comprehensive report titled, "Global Continuous Catalyst Regeneration (CCR) Catalyst Market Report: Insights, Forecast to 2030." This detailed analysis examines the multiple elements shaping the future of the global Continuous Catalyst Regeneration (CCR) Catalyst market.

The Continuous Catalyst Regeneration (CCR) Catalyst report serves as an invaluable resource for industry players, providing precise and extensive research insights necessary for strategic decision-making. The analysts have…

Refinery Catalyst Market: Refinery Catalyst Market Projections: Innovations and …

Market Overview:

Refinery catalysts are used in petroleum refining operations to facilitate and accelerate chemical reactions for conversion of crude oil into useful petroleum products like gasoline, diesel, jet fuel etc. Without catalysts, refining processes would be inefficient or not commercially viable.

Get Sample Report with Global Industry Analysis @ https://www.coherentmarketinsights.com/insight/request-sample/736

Major Players Are:

✤ BP Global and Royal Dutch Shell. Other key industry participants include YARA International

✤ Foster Wheeler AG

✤ OXEA GmbH

✤ W…

Global Homogeneous Catalyst Market, Global Homogeneous Catalyst Industry, Covid- …

Homogeneous catalysts such as transition metal complexes have been utilized for the chemical reactions on the biopolymers. Homogeneous catalysts were the catalysts of choice in the early days of metathesis reactions. They entailed of a transition metal compound and a non-transition metal compound, primarily organometallic as cocatalysts. Although, the homogeneous catalysts have high probable to speed up the reaction rate, augment selectivity, conversion rate, and diminish side reactions, they cannot…