Press release

How To Setup a DRI Sponge Iron Manufacturing Plant: Machinery Requirement

Setting up a DRI sponge iron manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "DRI Sponge Iron Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a DRI sponge iron manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Request for a Sample Report: https://www.imarcgroup.com/dri-sponge-iron-manufacturing-plant-project-report/requestsample

DRI (Direct Reduced Iron) Sponge Iron is a high-quality iron product obtained by reducing iron ore in its solid state without melting. This process, known as direct reduction, typically uses natural gas or non-coking coal as a reducing agent. The resulting sponge iron has a high iron content and is primarily used in electric arc furnaces (EAF) and induction furnaces for steel production. Unlike traditional blast furnace methods, DRI production emits lower carbon dioxide levels, making it a more environmentally friendly alternative. The material's porosity and purity make it an efficient feedstock for steel manufacturing, helping reduce dependence metal. DRI sponge iron is widely used in the steel industry, especially in regions with limited access to high-quality particle.

The growing demand for sustainable steel production is a key driver of the DRI sponge iron market. With increasing pressure to reduce carbon emissions, steel manufacturers are adopting DRI as a cleaner alternative to traditional blast furnace methods. The shift toward electric arc furnaces (EAF) and the rise in infrastructure projects worldwide are fueling demand for high-purity iron. Additionally, government policies promoting green steel and the availability of natural gas-based reduction technologies are further boosting market growth. As the global steel industry prioritizes sustainability, the adoption of DRI sponge iron is expected to rise, particularly in emerging economies with expanding construction and manufacturing sectors.

Buy Full Report: https://www.imarcgroup.com/checkout?id=30549&method=1911

Key Steps Required to Set Up a DRI Sponge Iron Plant

1. Market Analysis

The report provides insights into the landscape of the DRI sponge iron industry at the global level. The report also provides a segment-wise and region-wise breakup of the global DRI sponge iron industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of DRI sponge iron, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the DRI sponge iron manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for DRI sponge iron manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for DRI sponge iron production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a DRI sponge iron manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=30549&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How To Setup a DRI Sponge Iron Manufacturing Plant: Machinery Requirement here

News-ID: 3948580 • Views: …

More Releases from IMARC Group

India Fungicide Market Expected to Reach USD 976.70 Million by 2034, Industry Gr …

IMARC Group's latest research publication "India Fungicide Market Size, Share, Trends and Forecast by Type, Form, Crop Type, Mode of Action, Application, and Region, 2026-2034" the India fungicide market size was valued at USD 695.79 Million in 2025. The market is projected to reach USD 976.70 Million by 2034, growing at a compound annual growth rate of 3.84% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-fungicide-market/requestsample

What is Fungicide?

Fungicides are chemical or biological…

HVAC Equipment Market to Reach USD 364.2 Billion by 2034, Growing at a CAGR of 4 …

Market Overview:

The HVAC equipment market is experiencing strong growth, driven by rapid urbanization and smart infrastructure development, intensifying focus on energy efficiency and decarbonization, and transition to low-GWP refrigerants and advanced technology. According to IMARC Group's latest research publication, "HVAC Equipment Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The global HVAC equipment market size reached USD 242.7 Billion in 2025. The market is projected to…

Cloud Gaming Market Size to Reach USD 77,711.9 Million by 2033 | Exhibiting CAGR …

Market Overview:

The cloud gaming market is experiencing rapid growth, driven by global expansion of 5g infrastructure and connectivity, democratization of high-performance gaming hardware, and adoption of value-driven subscription and monetization models. According to IMARC Group's latest research publication, "Cloud Gaming Market Size, Share, Trends and Forecast by Type, Genre, Technology, Gamers, and Region 2025-2033", the global cloud gaming market size was valued at USD 2,705.9 Million in 2024. Looking forward,…

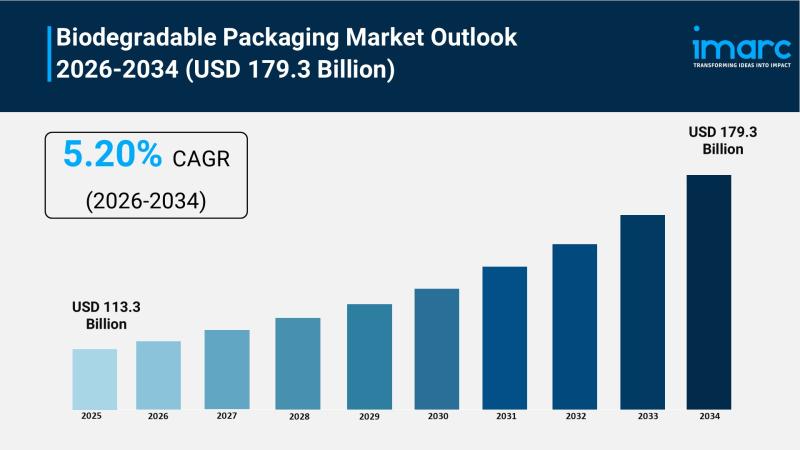

Biodegradable Packaging Market to Reach USD 179.3 Billion by 2034, Growing at a …

Market Overview:

The Biodegradable Packaging Market is experiencing rapid growth, driven by breakthroughs in biopolymer material science, rapid expansion of the organic food and beverage sector, and significant capital inflows from private equity into green tech. According to IMARC Group's latest research publication, "Biodegradable Packaging Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The global biodegradable packaging market size reached USD 113.3 Billion in 2025. Looking forward, IMARC…

More Releases for DRI

Direct Reduced Iron (DRI) Market Status, Share, Growth & Outlook | 2025 - 2032

Global Direct Reduced Iron (DRI) Market Report Summary

According to industry estimates the Direct Reduced Iron (DRI) market growth is projected to expand 5.2% CAGR during the 2025 to 2032 assessment period.

The Latest Market Research report on "Global Direct Reduced Iron (DRI) Market Report 2025 - Future Opportunities, Latest Trends, In-depth Analysis, and Forecast To 2032" offers strategic visions into the global Direct Reduced Iron (DRI) market along with the market…

Direct Reduced Iron (DRI) Market to Set Phenomenal Growth by 2031

𝐃𝐢𝐫𝐞𝐜𝐭 𝐑𝐞𝐝𝐮𝐜𝐞𝐝 𝐈𝐫𝐨𝐧 𝐌𝐚𝐫𝐤𝐞𝐭: 𝐈𝐧𝐭𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧

Transparency Market Research delivers key insights on the global direct reduced iron market. In terms of revenue, the global direct reduced iron market is estimated to expand at a CAGR of 8% during the forecast period, owing to numerous factors regarding which TMR offers thorough insights and forecast in its report on the global direct reduced iron market.

The global direct reduced iron market is broadly affected by several factors…

Direct Reduced Iron (DRI) Market Promising Growth Opportunities over 2020-2030

A recent market study published by FMI on the DRI market includes the global industry analysis of 2015-2019 & opportunity assessment for 2020-2030, and delivers a comprehensive assessment of the most important market dynamics. Our analysts conduct thorough research on the historical as well as current growth parameters of the market to obtain growth prospects with maximum precision.

Request Report Sample@ https://www.futuremarketinsights.com/reports/sample/rep-gb-11635

Direct Reduced Iron (DRI) Market: Segmentation

Production Process

• Coal-based

• Gas-based

Application

• Steel Production

• Construction

Form

• Lumps

• Pellets

Region

• North America

• Latin America

• Europe

• South…

Global Cat Litter Market 2019 - Nestle, Clorox, Church & Dwight, Oil-Dri

This new report by Eon Market Research, titled “Global Cat Litter Market 2019 Research Report, 2015 – 2025” offers a comprehensive analysis of Cat Litter industry at a global as well as regional and country level. Key facts analyzed in this report include the Cat Litter market size by players, regions, product types and end industries, history data 2014-2018 and forecast data 2019-2025. This report primarily focuses on the study…

Global Soda Crystals Market 2019 - Solvay, Tata Chemicals, Bexters, Dri-Pak

A new market research study by Apex Market Research has projected that Soda Crystalsrevenues will exceed $XX Billion by 2023 at a CAGR of XX%. Market statistics is published in Global Soda Crystals Market 2019-2026 report.

The Global Soda Crystals Market 2019-2026 report delivers comprehensive information about the Soda Crystals industry including valuable facts and figures, important aspects, and skilled opinions providing businesses with decisive information. The report covers global perspective…

Global Soda Crystals Market 2018 - FMC, Bexters, Dri-Pak

Apex Market Research, recently published a detailed market research study focused on the "Soda Crystals Market" across the global, regional and country level. The report provides 360° analysis of "Soda Crystals Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Soda Crystals Market industry, and estimates the future trend of Soda Crystals…