Press release

How to Setup an AAC Block Adhesive Manufacturing Plant

Setting up an AAC block adhesive manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "AAC Block Adhesive Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a AAC block adhesive manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

AAC block adhesive is a specially formulated high-strength bonding material used for joining Autoclaved Aerated Concrete (AAC) blocks in construction. This adhesive is a ready-mix, polymer-modified, and cement-based material that provides superior bonding strength, ensuring durable and seamless masonry work. It is designed to replace traditional mortar, offering faster application, reduced material consumption, and enhanced thermal insulation properties. AAC block adhesive is widely used in residential, commercial, and industrial construction for wall assemblies, ensuring structural stability and longevity. Its benefits include reduced shrinkage, improved workability, and minimal wastage, making it an efficient and cost-effective solution. Additionally, its quick setting time enhances construction efficiency while contributing to sustainable building practices by reducing cement and sand usage.

The increasing adoption of Autoclaved Aerated Concrete (AAC) blocks in modern construction is primarily driving the demand for AAC block adhesive. Construction companies and builders are increasingly preferring this adhesive due to its superior bonding strength, reduced material wastage, and ease of application. Additionally, the rising focus on sustainable and energy-efficient construction practices is encouraging the use of AAC blocks, thereby propelling the demand for compatible adhesives. Governments and regulatory bodies are continuously implementing stringent building codes and promoting eco-friendly materials, further supporting the adoption of AAC block adhesive. Moreover, the ongoing urbanization and rapid infrastructural development across residential, commercial, and industrial sectors are significantly contributing to the growing demand for this adhesive.

Furthermore, the increasing emphasis on faster construction processes and cost-efficient building materials is accelerating the widespread use of AAC block adhesive. Construction professionals are continuously shifting towards this adhesive as it enhances work efficiency by eliminating the need for conventional cement mortar, reducing construction timelines. Additionally, the rising labor costs and the need for minimal material handling are prompting builders to adopt AAC block adhesive, which simplifies the masonry process. The ongoing research and development in construction chemicals are also leading to the formulation of advanced adhesives with improved strength, thermal insulation, and water resistance. Moreover, the expansion of smart cities and sustainable housing projects is further fostering the demand for AAC block adhesive. As infrastructure projects continue expanding globally, the reliance on high-performance adhesives is steadily increasing, making AAC block adhesive an essential component in modern construction methodologies.

Request for a Sample Report: https://www.imarcgroup.com/aac-block-adhesive-manufacturing-plant-project-report/requestsample

Key Steps Required to Set Up an AAC Block Adhesive Plant.

1. Market Analysis

The report provides insights into the landscape of the AAC block adhesive industry at the global level. The report also provides a segment-wise and region-wise breakup of the global AAC block adhesive industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of AAC block adhesive, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the AAC block adhesive manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=14984&flag=C

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for the AAC block adhesive manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for AAC block adhesive production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up an AAC block adhesive manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Setup an AAC Block Adhesive Manufacturing Plant here

News-ID: 3914501 • Views: …

More Releases from IMARC Group

Fantasy Sports Market in India 2026: Size, Share, Growth Rate & Industry Forecas …

India Fantasy Sports Market Overview

According to IMARC Group's report titled "India Fantasy Sports Market Size, Share, Trends and Forecast by Sports Type, Platform, Demographics, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

The India fantasy sports market size was valued at USD 27.0 Billion in 2025. IMARC Group estimates that the market will expand to reach USD 519.8 Billion…

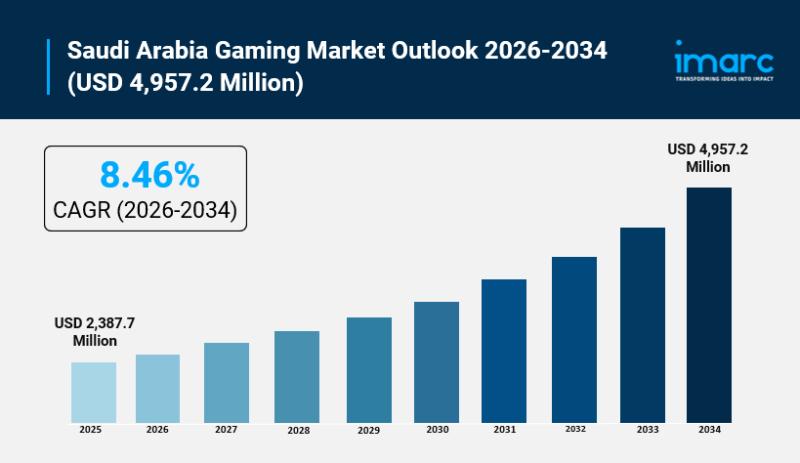

Saudi Arabia Gaming Market is Set For Strong Growth, Projected to Reach USD 4,95 …

Saudi Arabia Gaming Market Overview

Market Size in 2025: USD 2,387.7 Million

Market Forecast in 2034: USD 4,957.2 Million

Market Growth Rate 2026-2034: 8.46%

According to IMARC Group's latest research publication, "Saudi Arabia Gaming Market Report by Device Type (Consoles, Mobiles and Tablets, Computers), Platform (Online, Offline), Revenue (In-Game Purchase, Game Purchase, Advertising), Type (Adventure/Role Playing Games, Puzzles, Social Games, Strategy, Simulation, and Others), Age Group (Adult, Children), and Region 2026-2034", the Saudi Arabia…

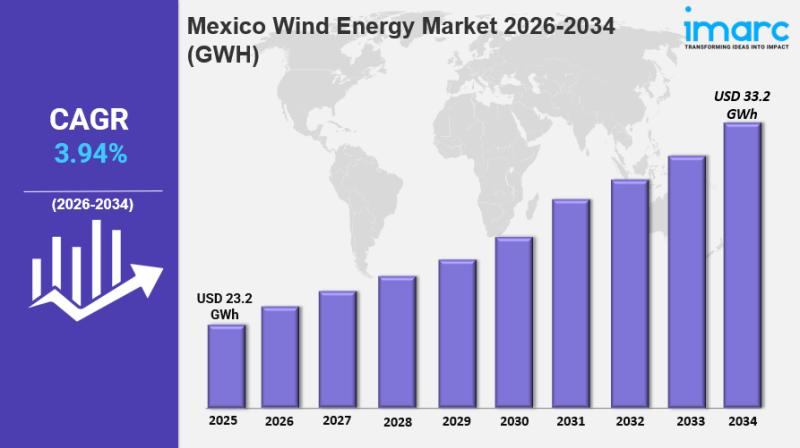

Mexico Wind Energy Market Size, Share, Industry Overview, Trends and Forecast 20 …

IMARC Group has recently released a new research study titled "Mexico Wind Energy Market Report by Component (Turbine, Support Structure, Electrical Infrastructure, and Others), Rating (≤ 2 MW, >2 ≤ 5 MW, >5 ≤ 8 MW, >8 ≤ 10 MW, >10 ≤ 12 MW, >12 MW), Installation (Offshore, Onshore), Turbine Type (Horizontal Axis, Vertical Axis), Application (Utility, Industrial, Commercial, Residential), and Region 2026-2034", offers a detailed analysis of the market…

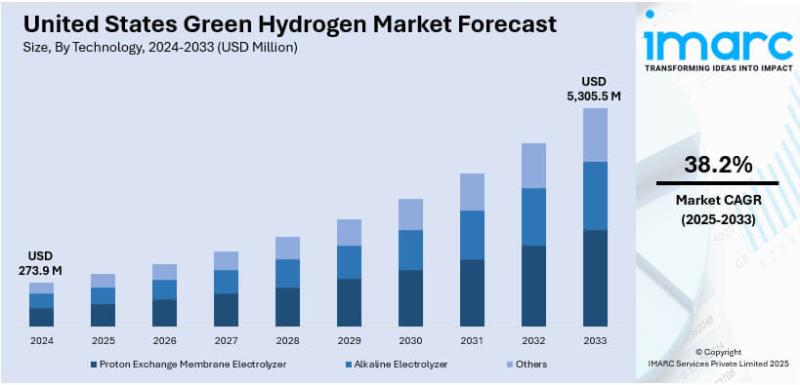

U.S. Green Hydrogen Market to Reach USD 5,305.5 Million by 2033 | CAGR 38.2%

Market Overview

The United States green hydrogen market size was valued at USD 273.9 Million in 2024 and is expected to reach USD 5,305.5 Million by 2033, exhibiting a CAGR of 38.2% during the forecast period 2025-2033. Growth is primarily driven by supportive government policies including the Bipartisan Infrastructure Law and Inflation Reduction Act, rapid technological advancements in electrolyzer efficiency, expanding applications in transportation and heavy industry, growing private-sector investments, and…

More Releases for AAC

Autoclaved Aerated Concrete (AAC) Blocks Market: 2029 Vision: Consumption, Sales …

"This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global Autoclaved Aerated Concrete (AAC) Blocks industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this Autoclaved Aerated Concrete…

Autoclaved Aerated Concrete (AAC) Market Insights 2023 - Xella Group, Aercon AAC …

Global Autoclaved Aerated Concrete (AAC) Market analysis with precise estimates and predictions by MarketsandResearch.biz gives you complete research solutions for strategic decision-making targeted at giving maximum industry clarity. This study provides ideas for rational decisions to deliver optimum market insight, including Autoclaved Aerated Concrete (AAC) market analysis with precise estimates and forecasts. Along with these, the changing industry trends and other key market factors have been thoroughly explored. Furthermore, the…

Autoclaved Aerated Concrete (AAC) Market to Flourish With An Impressive CAGR of …

Los Angeles, (United States) - The Autoclaved Aerated Concrete (AAC) market report includes an in-depth survey of market size, market share, and market segmentation at the national and international levels. The competitive landscape, value chain optimization, trade procedures, recent advances, and identified results of global market businesses are all included in the research. Autoclaved Aerated Concrete (AAC) industry studies highlight major key competitors' industrial revolutions, product launches,…

Investigation announced for Investors in shares of AAC Holdings, Inc. (NYSE: AAC …

An investigation was announced for investors in shares of AAC Holdings, Inc. (NYSE: AAC) concerning potential breaches of fiduciary duties by certain directors of AAC Holdings, Inc.

Investors who are current long term investors in AAC Holdings, Inc. (NYSE: AAC) shares, have certain options and should contact the Shareholders Foundation at mail@shareholdersfoundation.com or call +1(858) 779 - 1554.

The investigation by a law firm for current long term investors in NYSE: AAC…

Autoclaved Aerated Concrete (AAC) Global Market 2019: Key Players – AERCON AAC …

Autoclaved Aerated Concrete (AAC) Industry

Description

Wiseguyreports.Com Adds “Autoclaved Aerated Concrete (AAC) -Market Demand, Growth, Opportunities and Analysis Of Top Key Player Forecast To 2023” To Its Research Database

Global Autoclaved Aerated Concrete (AAC) market is estimated at $6.32 billion in 2016 and is expected to reach $10.98 billion by 2023 growing at a CAGR of 8.2% from 2016 to 2023. Advanced characteristics of autoclaved aerated concrete and rising importance of green buildings…

Global AAC Device Market Report 2018 Companies included Gus Communication Device …

We have recently published market research report on AAC Device. For inquiry email us at: sales@marketreportscompany.com

Report includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR. The report also provides detailed segmentation on the basis of product type, applications and regional segmentation. The regional segment is further…