Press release

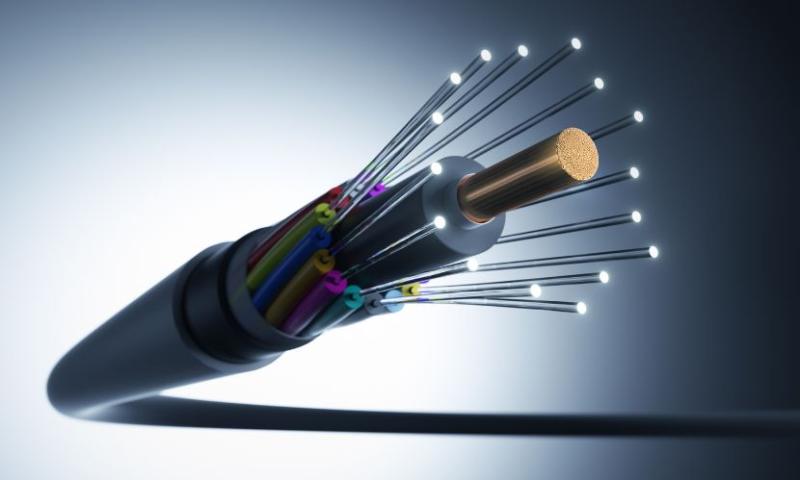

Fiber Optic Cable Manufacturing Plant Project Report 2025: Project Report and Setup Guide

The Fiber Optic Cable Manufacturing Plant Project Report provides a detailed analysis of the processes, market trends, financial projections, and other key considerations involved in setting up a manufacturing facility for producing fiber optic cables. Fiber optic cables are a critical component in the telecommunications industry, enabling high-speed data transmission over long distances. As the world continues to embrace digital transformation, the demand for fiber optic cables is rapidly increasing, driven by the expansion of high-speed internet, 5G networks, and data centers.This report aims to evaluate the feasibility of establishing a fiber optic cable manufacturing plant by focusing on the required technologies, raw materials, production processes, market dynamics, regulatory considerations, and economic factors.

Read Full Report with Table of Contents@ https://bit.ly/41N0M9y

Market Overview

Growth of the Fiber Optic Cable Industry

The fiber optic cable industry has experienced significant growth over the past few years, driven by technological advancements and the increasing need for high-speed communication networks. Fiber optic cables are widely used in telecommunications, broadband networks, and data centers, among other sectors. The global demand for fiber optic cables is expected to continue growing as more businesses and consumers rely on fast, reliable internet connections.

Telecommunications: Fiber optic cables are the backbone of modern telecommunication networks. They offer much higher bandwidth and faster speeds compared to traditional copper cables. With the rise of 5G networks, which rely heavily on fiber optic infrastructure, the demand for fiber optic cables is set to increase.

Data Centers and Cloud Services: Data centers, which store and manage vast amounts of data, are increasingly relying on fiber optic cables to meet the demands of high-speed data transfer. As businesses continue to migrate to cloud-based services, the need for faster, more reliable fiber optic networks will grow.

Broadband Internet: The rollout of fiber-to-the-home (FTTH) networks is expanding globally, as internet service providers aim to offer faster internet speeds to residential users. This trend is a significant driver of fiber optic cable demand, particularly in developed countries.

Industrial and Military Applications: Fiber optic cables are also used in industrial automation, aerospace, and defense industries, where high-speed, reliable communication is critical. These sectors value the durability and performance of fiber optic cables, especially in harsh environments.

Get a Free Sample Report with Table of Contents@ https://bit.ly/43r9CLv

Key Trends in the Fiber Optic Industry

5G Deployment: The deployment of 5G networks worldwide is a major catalyst for the growth of the fiber optic cable industry. Fiber optic cables play a vital role in delivering the high-speed, low-latency connectivity required for 5G technologies.

Fiber Optic to the Home (FTTH): The continued push for FTTH networks in both developed and emerging markets is driving the demand for fiber optic cables in residential areas. This trend is being fueled by governments, telecom companies, and private investments in infrastructure.

Increased Data Traffic: With the rise of cloud computing, IoT (Internet of Things), and data-intensive applications, data traffic continues to surge. Fiber optic cables, with their ability to handle large volumes of data at high speeds, are essential to supporting this growth.

Raw Materials and Procurement

Key Raw Materials

The primary materials required for the manufacturing of fiber optic cables include:

Glass Preforms: The core material for producing optical fibers is a high-purity silica glass. The glass preforms are the starting point for manufacturing the fiber optic cables. These preforms are heated and drawn into long, thin fibers that form the core of the cable.

Polymer Materials: For the outer cladding and jacket of the fiber optic cable, various polymer materials such as PVC (Polyvinyl Chloride), LSZH (Low Smoke Zero Halogen), and other flame-retardant compounds are used. These materials provide protection and insulation for the optical fibers.

Metallic Components: Metallic wires such as steel and aluminum are used for reinforcing the fiber optic cables, especially in cables that are intended for underground or industrial applications. These metals add strength and durability to the cables.

Coloring Materials: Dyes or pigments are used in fiber optic cables to color the fibers for identification purposes. These materials are applied during the manufacturing process to differentiate between different optical fibers in the same cable.

Procurement Strategy

Establishing a reliable procurement strategy for raw materials is essential for the smooth operation of a fiber optic cable manufacturing plant. Key considerations include:

Supplier Relationships: Strong relationships with suppliers of high-quality glass preforms, polymers, and metallic materials are crucial for ensuring consistent production quality.

Price Volatility: The prices of raw materials such as glass and polymers can fluctuate based on global supply and demand. A good procurement strategy should account for potential price volatility and include long-term contracts or partnerships with suppliers.

Logistics and Storage: Efficient logistics and proper storage facilities are required to handle and store raw materials safely. Fiber optic cables are sensitive to moisture and environmental factors, so appropriate measures must be taken to protect the materials during transportation and storage.

Manufacturing Process

The manufacturing process for fiber optic cables involves several stages that require precision and advanced technology. Below is a detailed overview of the process:

Step 1: Manufacturing of Optical Fibers

The first step in the manufacturing process is the production of optical fibers, which are the core component of fiber optic cables. This process begins with the creation of a glass preform, which is made by depositing layers of silica onto a mandrel. The preform is then heated and drawn into long, thin fibers. These fibers are coated with a thin layer of polymer to protect them and maintain their optical properties.

Drawing: The preform is heated to a high temperature in a furnace, and the glass is drawn into long fibers. The fibers are then coated with a polymer material to protect them and enhance their performance.

Testing: After drawing, the optical fibers are tested for key properties such as attenuation (signal loss), bandwidth, and strength. Fibers that do not meet quality standards are discarded.

Step 2: Fiber Stranding and Jacketing

Once the optical fibers are produced, they are grouped together to form a cable. The fibers are arranged into bundles, and additional protective layers are added. This step involves:

Fiber Bundling: The optical fibers are arranged in a specific pattern depending on the cable design. The fibers are bundled together using various techniques such as twisting or braiding.

Jacketing: The fiber bundle is then covered with an outer jacket made of polymer material. This jacket provides protection against environmental factors such as moisture, UV rays, and physical damage.

Strength Members: In some cable designs, additional strength members, such as metallic wires or aramid yarns (Kevlar), are added to reinforce the cable and ensure its durability.

Step 3: Final Testing and Quality Control

After the fiber optic cables are manufactured, they undergo a series of quality control tests to ensure they meet industry standards and customer requirements. These tests may include:

Tensile Strength Test: To measure the mechanical strength of the cable and ensure it can withstand stress during installation.

Optical Performance Test: To check for any signal loss (attenuation) or defects in the fibers.

Environmental Testing: To assess the cable's ability to withstand temperature extremes, moisture, and other environmental factors.

Step 4: Packaging and Distribution

Once the fiber optic cables have passed all quality control tests, they are packaged in drums or reels and prepared for distribution. Packaging is done carefully to avoid damaging the cables during transport, and the cables are labeled with important information such as type, length, and specifications.

Regulatory Compliance and Safety

Regulatory Standards

Manufacturers of fiber optic cables must comply with various industry standards and regulations to ensure the safety and quality of their products. Some of the key standards include:

IEC 60794: An international standard for the construction, performance, and testing of fiber optic cables.

ISO 9001: A quality management standard that ensures the manufacturing process meets consistent quality criteria.

RoHS: Restriction of Hazardous Substances (RoHS) regulations that limit the use of certain hazardous materials in electrical and electronic products.

Environmental and Safety Considerations

The manufacturing process for fiber optic cables involves handling chemicals and high-temperature equipment, so ensuring a safe working environment is crucial. Key safety measures include:

Fire Safety: Due to the high-temperature processes and the use of flammable materials, fire safety measures must be in place.

Ventilation: Adequate ventilation systems must be installed to manage the release of fumes and gases from the manufacturing process.

Waste Management: Proper disposal of chemical waste and by-products is essential to prevent environmental contamination.

Financial Projections and Cost Analysis

Capital Expenditure (CAPEX)

The capital investment required to set up a fiber optic cable manufacturing plant includes:

Land and Infrastructure: The cost of land, building construction, and plant setup.

Machinery and Equipment: Investment in specialized equipment for drawing fibers, bundling, and jacketing.

Testing and Quality Control: Setting up labs and testing equipment for quality assurance.

Operating Expenses (OPEX)

Ongoing operating expenses include:

Raw Materials: The cost of glass preforms, polymers, and metals.

Labor Costs: Salaries for plant workers, technicians, and management.

Utilities: Costs for electricity, water, and other utilities needed for the manufacturing process.

Revenue Generation

The revenue for a fiber optic cable manufacturing plant comes from the sale of fiber optic cables to telecommunications companies, data centers, and other industrial clients. The market demand for fiber optic cables is strong, and the plant can expect a steady flow of orders as global infrastructure projects and 5G deployments continue to drive demand.

Read More Reports:

Top Gaming Console Companies: https://bit.ly/3F5cHqI

Top Honey Companies: https://bit.ly/3DiYRAj

Top Automotive Airbag Inflator Manufacturers in the World:

https://bit.ly/3F0KL7c

Top Industrial Sewing Machines Manufacturers Companies: https://bit.ly/3QKA7UN

Top Merino Wool Companies: https://bit.ly/4kpPZJO

Media Contact:

Company Name: Claight Corporation

Contact Person: Peter Fernandas, Corporate Sales Specialist

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Acquire unparalleled access to critical industry insights with our comprehensive market research reports, meticulously prepared by a team of seasoned experts. These reports are designed to equip decision-makers with an in-depth understanding of prevailing market trends, competitive landscapes, and growth opportunities.

Our high-quality, data-driven analysis provides the essential framework for organisations seeking to make informed and strategic decisions in an increasingly complex and rapidly evolving business environment. By investing in our market research reports, you can ensure your organisation remains agile, proactive, and poised for success in today's competitive market.

Don't miss the opportunity to elevate your business intelligence and strengthen your strategic planning. Secure your organisation's future success by acquiring one of our Expert Market Research reports today.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fiber Optic Cable Manufacturing Plant Project Report 2025: Project Report and Setup Guide here

News-ID: 3904135 • Views: …

More Releases from Expert Market Research

AI in Mental Health Market to Reach USD 8.38B by 2035

How Is Artificial Intelligence Transforming Mental Healthcare?

The Artificial Intelligence in Mental Health Market is rapidly emerging as a transformative force in global healthcare, addressing long-standing challenges such as access, affordability, stigma, and workforce shortages. With more than 970 million people worldwide affected by mental health conditions, the need for scalable, personalized, and data-driven mental health solutions has never been more urgent.

The global artificial intelligence in mental health market was valued…

Brazil Clinical Microbiology Market USD 390.12M | 5.8% CAGR

Why is the Brazil Clinical Microbiology Market gaining strategic importance within Latin America's healthcare ecosystem?

Brazil has one of the largest and most complex healthcare systems in the region, with a growing focus on early disease detection, antimicrobial resistance monitoring, and laboratory automation. Clinical microbiology plays a critical role in identifying infectious diseases, guiding targeted therapies, and supporting public health surveillance.

The Brazil clinical microbiology market was valued at USD 390.12 Million…

Battery Recycling Market Size, Trends and Forecast 2026-2035

The battery recycling market is gaining steady traction as industries and governments focus more on resource efficiency, environmental compliance, and supply chain security for critical metals. With the rising use of lithium-ion, lead-acid, and nickel-based batteries across electric vehicles, consumer electronics, industrial equipment, and energy storage systems, recycling has moved from being a regulatory requirement to a strategic necessity. Battery recycling helps recover valuable materials like lithium, cobalt, nickel, and…

Biometrics Technology Market Size, Trends & Forecast 2026-2035

The biometrics technology market is witnessing robust growth and is expected to continue expanding at a significant pace. Valued at approximately USD 27.78 billion in 2025, the market is projected to grow at a compound annual growth rate (CAGR) of 10.20% between 2026 and 2035. By 2035, the market is expected to reach USD 73.38 billion. This growth is driven by the increasing need for advanced security solutions, innovations in…

More Releases for Fiber

Fiber Laser Market Forecast to 2028 COVID-19 Impact and Global Analysis By Type …

The fiber laser market was valued at US$ 2286.16 million in 2021 and is projected to reach US$ 4,765.43 million by 2028; it is expected to grow at a CAGR of 11.1% from 2021 to 2028.

Automotive production is constantly rising across the world, particularly in Asian and European countries, which is driving the demand for fiber lasers. Most automotive manufacturers are rapidly turning to fiber lasers to resolve their manufacturing…

Pea Fiber Market Inclinations Exhibit Growing Demand during the Period until 202 …

The new report on the pea fiber market provides estimations of the size of the global market and share and size of key regional markets during the historical period of 2014 – 2018. This highly favorable growth of the pea protein creates a highly conducive environment for the associated pea fiber market, which is expected to exhibit a promising CAGR of ~8% during the forecast period (2019-2029. The business intelligence…

Optical Fiber and Optical Fiber Cables Market

Optical Fibers and Optical Fiber Cables Market describes its growth, size, share, Forecast and trends to 2025

Optical Fibers and Optical Fiber Cables Market Production and Demand Analysis 2019 to 2025

Optical Fibers and Optical Fiber Cables Market 2019 Manufacturing Analysis and Development Forecast to 2025

Optical Fibers and Optical Fiber Cables Market 2019: Recent Study Including Growth Factors, Regional Drivers, Forecast 2025

Optical Fibers and Optical Fiber Cables Market Insights 2019, Global and…

Aramid Fiber Market (Para-Aramid Fiber, Meta-Aramid Fiber) by Type, Application …

The aramid fiber market (http://www.rnrmarketresearch.com/aramid-fiber-market-by-type-para-aramid-fiber-meta-aramid-fiber-and-application-security-protection-frictional-material-tire-rubber-reinforcement-optical-fiber-electrical-insulation-aeros-market-report.html) is projected to grow from USD 3.28 billion in 2018 to USD 5.78 billion by 2024, at a CAGR of 9.9%. The increasing demand for lightweight materials for automotive components owing to stringent environmental and emission regulations is expected to drive the market in the automotive industry. In addition, the demand for lightweight and flexible materials for body armor, firefighting equipment, bulletproof vests, helmets, and…

Fiber-optic couplers Market Segmentation By Type Y Fiber-optic Couplers, T Fiber …

Fiber-optic couplers market: Market Overview

Due to increasing reliance of organizations on IT, the demand for robust, agile and cost effective IT infrastructure is growing rapidly and supporting the Fiber-optic couplers market. The fabric-optic couplers market is expanding rapidly as the telecom services providers in this modern era are moving towards fiber based networking services. Increasing advancements in the telecom industry are one of the major factors driving the growth of…

Fiber Laser Market 2025 - Global Analysis and Forecasts by Type (Infrared Fiber …

The "Global Fiber Laser Market Analysis to 2025" is a specialized and in-depth study of the fiber laser industry with a focus on the global market trend. The report aims to provide an overview of global fiber laser market with detailed market segmentation by type, application and geography. The global fiber laser market is expected to witness high growth during the forecast period. The report provides key statistics on the…