Press release

Dynamic Warehouse Zoning for Priority Fulfillment

In today's fast-paced supply chain environment, transparency is essential for efficient operations and customer satisfaction. Modern tracking platforms have transformed the way logistics operate by providing accurate, real-time data on shipment movements. For instance, by using https://trackingpackage.com/, users can easily input a tracking number and obtain comprehensive updates on their parcel's journey-from dispatch at the warehouse to final delivery. This seamless tracking capability not only builds customer trust but also provides critical insights that feed into innovative strategies such as dynamic warehouse zoning.The Need for Dynamic Zoning in Warehousing

Traditional warehouses often operate with static layouts, where goods are stored in predetermined locations regardless of fluctuating order volumes. In an era where consumer demand can shift rapidly due to seasonal trends or marketing campaigns, this inflexibility can lead to delays and inefficiencies. Dynamic warehouse zoning addresses these challenges by reorganizing storage based on the priority and frequency of orders. In such a system, the most popular and fast-moving items are placed in easily accessible locations, while slower-moving products are stored in less critical areas. This strategic placement significantly accelerates the picking process and reduces the time required to fulfill orders, ultimately enhancing overall operational performance.

Leveraging Data for Real-Time Reconfiguration

The cornerstone of dynamic zoning is data. Advanced warehouse management systems (WMS) continuously analyze order frequency, stock turnover, and even seasonal trends to adjust the storage layout in real time. Sensors, RFID tags, and automated inventory management systems provide constant feedback, enabling managers to reposition goods swiftly. For example, if a particular product sees a sudden spike in demand, the system can automatically recommend moving it to a high-priority zone near the packing and shipping area. Conversely, items with declining order rates can be shifted to less accessible locations. This proactive approach not only reduces picking times but also minimizes human error, as employees spend less time searching for items and more time fulfilling orders.

Optimizing Picking Efficiency and Reducing Costs

One of the main benefits of dynamic zoning is the significant boost in picking efficiency. In a static system, employees often traverse long distances within the warehouse to locate products, which adds time and labor costs to the order fulfillment process. With dynamic zoning, frequently ordered items are stored in zones that are physically closer to the dispatch area. This shortens travel time for workers, leading to faster order assembly and reduced operational costs. Moreover, efficient zoning reduces congestion within the warehouse, allowing automated systems and human workers alike to operate more smoothly. As a result, companies can handle higher volumes without a proportional increase in labor or energy costs, thereby improving their bottom line.

Enhancing Flexibility and Responsiveness

Dynamic zoning also makes warehouses more adaptable to unexpected changes in demand. In traditional layouts, a sudden surge in orders can overwhelm the system, causing delays and frustrated customers. However, by continuously analyzing data and adjusting storage locations accordingly, warehouses can remain agile even during peak periods. The system's ability to reconfigure layouts on the fly ensures that high-priority items are always within reach. This adaptability is especially crucial for businesses that operate in highly competitive markets, where speed and reliability are key differentiators. In addition, real-time reconfiguration enables managers to forecast potential bottlenecks before they escalate, ensuring a smooth flow of goods through the entire supply chain.

Integrating Automation and Human Expertise

While automation plays a pivotal role in dynamic zoning, human expertise remains essential to its success. Warehouse staff must be trained to work with digital management systems that suggest real-time reconfiguration based on incoming data. Employees can then verify the suggestions and implement them with the help of automated guided vehicles (AGVs) or robotic arms. This collaborative approach between technology and human oversight not only enhances efficiency but also drives continuous improvement. The feedback from employees can be used to fine-tune algorithms, making the system increasingly accurate over time. In this way, dynamic zoning becomes a living, evolving process that constantly adapts to the needs of both the business and its customers.

Sustainability Benefits and Environmental Impact

Efficient warehouse operations not only save time and reduce costs; they also contribute to environmental sustainability. By optimizing the placement of goods, companies can minimize the energy required for moving items within a warehouse. Shorter travel distances for picking and restocking reduce the carbon footprint of operations, aligning with broader sustainability goals. Moreover, a well-organized warehouse is less likely to require excessive packaging or frequent re-handling, which further lowers waste generation. In an era where eco-friendly practices are increasingly valued by consumers, dynamic zoning represents a strategic move that supports both economic and environmental objectives.

Building a Competitive Edge in Modern Logistics

The integration of dynamic warehouse zoning into overall logistics strategy provides companies with a competitive advantage. Faster order fulfillment, lower operational costs, and increased customer satisfaction all contribute to stronger market positioning. As more businesses adopt this innovative approach, the expectations of customers evolve, further reinforcing the need for adaptable, data-driven solutions. Companies that invest in advanced warehouse management systems and train their staff accordingly will not only streamline their operations but also enhance their reputation as modern, reliable, and customer-centric organizations.

When digital tracking and dynamic reconfiguration converge to create a highly efficient, responsive, and sustainable warehouse environment, businesses can deliver faster, reduce costs, and exceed customer expectations-setting a new benchmark in global logistics excellence.

P.O Bagarji Town Bagarji Village Ghumra Thesil New Sukkur District Sukkur Province Sindh Pakistan 65200.

Wiki Blogs News always keeps careful online users to provide purposeful information and to keep belief to provide solution based information.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Dynamic Warehouse Zoning for Priority Fulfillment here

News-ID: 3889012 • Views: …

More Releases from Wikiblogsnews

Nursing School Applicants Turn to Free Online TEAS Prep Tools as Admissions Comp …

February 2026 - Anyone applying to nursing school now will tell you the same thing: the field is harsh. There just aren't enough seats, not because the coursework scares people away. More than 65,000 eligible candidates were turned down for nursing programs between 2024 and 2025; these individuals fulfilled all requirements and ticked all the boxes, but they were still told "no" since the school was already full.

And yet the…

Why ITIL Version 5 is Essential for Digital First Organisations

Are you considering an ITIL® 5 Foundation Course https://www.itil.org.uk/training/itil-foundation-level-courses/itil-version-5-foundation-certification-course because your organisation is moving towards a digital-first model? That is not surprising. Businesses today depend fully on digital platforms, data, and automation. Yet many still struggle with service gaps and poor coordination. You may also be wondering, What is ITIL Version 5 https://www.itil.org.uk/blog/itil-version-5-a-complete-guide and why does it matter now. It is more than a framework. It connects digital products, people,…

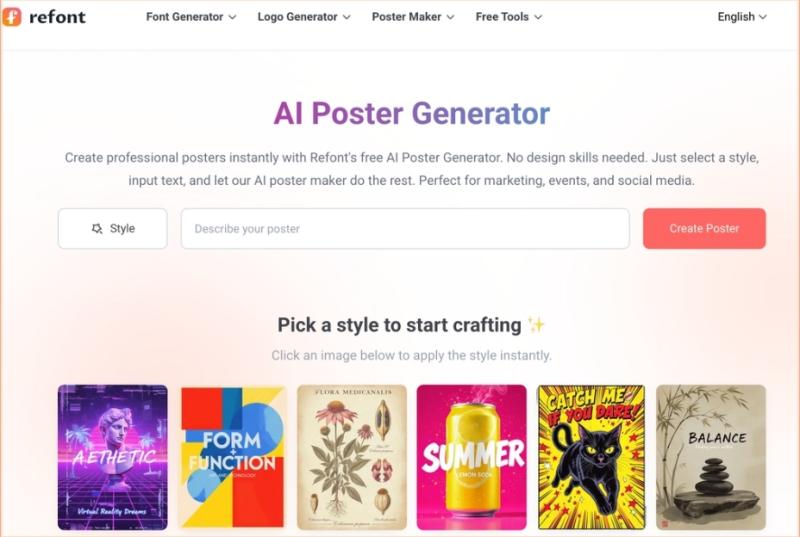

Tired of the Design Bottleneck? How I Finally Found a Practical AI Poster Genera …

If you're anything like me, you've probably spent more hours than you'd like to admit fighting with design software. We've all been there: you have a killer idea for a promotion, a social post, or a brand announcement, but by the time you've messed around with layers, alignment, and hunting for stock photos, the inspiration is gone and so is half your afternoon.

I've tried the early wave of generative AI…

Best Exotic Car Rental in Miami: Experience Luxury Without Overspending

Miami has a way of turning every drive into a cinematic experience. Picture yourself cruising down Ocean Drive at sunset with the gentle ocean breeze mixing in with the roar of your high-performance engine, smiling people looking over your car. For those who seek this experience, the best exotic car rental in Miami is your ticket to unlocking this fantasy.

But there's a catch: Miami's luxury car scene is flooded, and…

More Releases for Warehouse

Cargo Insurance Explained: Warehouse-to-Warehouse vs. Carrier Liability

A Comprehensive Analysis of Cargo Insurance: From the Fundamental Difference Between "Warehouse-to-Warehouse" and "Carrier Liability" to Setting the Most Cost-Effective Deductible

When a batch of electronic products departs from a Southeast Asian factory warehouse, transits by sea and land to a distribution warehouse in Europe, and is damaged by rain in the transit yard, the cargo owner often faces a dilemma: should they claim compensation from the carrier or file a…

How to Process Inter Warehouse & Intra Warehouse Transfers in Odoo 18

Managing inventory efficiently is a cornerstone of any successful business. Whether you're dealing with multiple warehouses or a single location, Odoo 18 offers robust tools to streamline your operations. One of the most critical aspects of inventory management is handling inter-warehouse and intra-warehouse transfers. In this article, we'll dive deep into how you can process these transfers seamlessly in Odoo 18. Plus, we'll explore how Odoo integration with WMS Warehouse…

Warehouse Management

Warehouse Management

Introduction:

In today's fast-paced business landscape, efficient warehouse management is crucial for small businesses to stay competitive and streamline their operations. A well-organized and optimized warehouse can lead to increased productivity, reduced costs, and improved customer satisfaction. In this blog post, we will explore some valuable tips and strategies to help small businesses streamline their warehouse management and achieve success.

For more information- https://krystal-group.com/blog/warehouse-management/

1. Optimize Layout and Space Utilization:

One of…

Streamlining Warehouse Operations: Choosing the Right Warehouse Management Syste …

The global market offers numerous Warehouse Management System ( https://businessprocessxperts.com/lean-warehouse-management-consulting/ ) software options, including renowned solutions such as SAP WM, Oracle WMS, Infor WMS, Odoo Inventory, Zoho Inventory, Manhattan WMS, and Microsoft Dynamics 365 Supply Chain Management. With a wide range of choices available, selecting the best-fit WMS for your business can be a daunting task. However, by considering a few essential prerequisites, you can navigate through the options and…

BPX Warehouse Specialists Redefining Warehouse Operations with Cutting-Edge Auto …

In the fast-paced world of modern logistics, warehouses play a pivotal role in ensuring efficient supply chain management. To stay ahead in the competitive landscape, businesses are turning to automation as a game-changer. Recognizing the transformative power of automation, BPX Warehouse Specialists, renowned experts in warehouse optimization, have unveiled a comprehensive suite of automation solutions that are revolutionizing the industry.

With years of experience and a deep understanding of warehouse operations,…

BPX Warehouse Specialists: Your Trusted Partner in Warehouse Setup and Optimizat …

The efficient setup of a warehouse is the foundation for smooth operations and seamless supply chain management. Recognizing the criticality of this process, BPX Warehouse Specialists, renowned experts in warehouse setup and optimization, have unveiled a comprehensive suite of services designed to help businesses establish and optimize their warehouse operations.

Setting up a warehouse involves careful planning ( https://businessprocessxperts.com/lean-warehouse-management-consulting/ ), meticulous layout design, standardized processes, and the right technology solutions. With…