Press release

How to Setup a Automotive Head Lamp Manufacturing Plant

Setting up an automotive head lamp manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Automotive Head Lamp Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a automotive head lamp manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Automotive head lamps are crucial components of a vehicle's lighting system, made to illuminate the road ahead during low visibility conditions like nighttime, fog, or heavy rainfall. These advanced lighting solutions ensure safety by improving visibility and signaling the vehicle's presence to other road users. Modern automotive head lamps incorporate sophisticated technologies, including halogen, LED, high-intensity discharge (HID), and laser lighting, each giving unique advantages in terms of brightness, energy efficiency, and lifespan. Beyond their functional aspects, head lamps have also become a key design element, contributing to a vehicle's aesthetics and brand identity.

The increasing emphasis on road safety and stringent vehicle lighting regulations are significant drivers propelling the automotive head lamp market. Governments worldwide mandate the integration of high-performance lighting systems to minimize accidents and ensure better visibility for drivers. Additionally, the surge in vehicle sales, particularly in emerging economies, has fueled the demand for technologically advanced head lamp solutions. The widespread adoption of electric and autonomous automobiles has further boosted the need for energy-efficient lighting systems like LEDs, which offer reduced power consumption and longer operational lifespans. Furthermore, the consumer preference for luxury vehicles featuring adaptive head lamp technologies, such as matrix LEDs and laser headlights, is another key factor driving market growth. The automotive head lamp market is experiencing rapid technological advancements, with futuristic trends reshaping its landscape. Smart head lamps with adaptive lighting systems, capable of adjusting beam patterns based on traffic conditions, are gaining traction. The integration of connected lighting systems with Internet of Things (IoT) for enhanced vehicle communication and the growing emphasis on aesthetic customization through dynamic lighting patterns are anticipated to fuel the market's evolution. These advancements underline the automotive head lamp industry's pivotal role in ensuring safety and meeting the evolving demands of modern mobility solutions.

Request for a Sample Report: https://www.imarcgroup.com/automotive-head-lamp-manufacturing-plant-project-report/requestsample

Key Steps Required to Set Up a Automotive Head Lamp Plant.

1. Market Analysis

The report provides insights into the landscape of the automotive head lamp industry at the global level. The report also provides a segment-wise and region-wise breakup of the global automotive head lamp industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of automotive head lamp, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the automotive head lamp manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=15427&flag=C

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for automotive head lamp manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for automotive head lamp production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a automotive head lamp manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Setup a Automotive Head Lamp Manufacturing Plant here

News-ID: 3887280 • Views: …

More Releases from IMARC Group

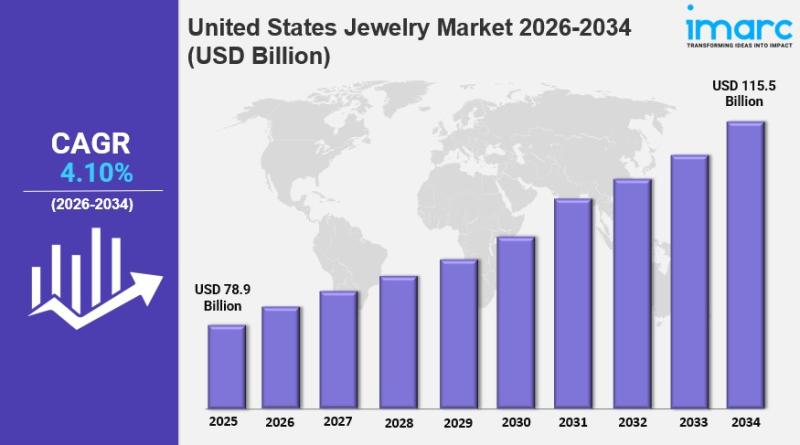

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

Saudi Arabia Pilates & Yoga Studios Market Size to Surpass USD 3.6 Billion by 20 …

Saudi Arabia Pilates & Yoga Studios Market Overview

Market Size in 2024: USD 1.6 Billion

Market Forecast in 2033: USD 3.6 Billion

Market Growth Rate 2025-2033: 8.20%

According to IMARC Group's latest research publication, "Saudi Arabia Pilates & Yoga Studios Market Size, Share, Trends and Forecast by Activity Type, Application, and Region, 2025-2033", the Saudi Arabia pilates & yoga studios market size reached USD 1.6 Billion in 2024. Looking forward, IMARC Group expects the…

More Releases for Automotive

Automotive Grommet Market set for explosive growth: Cooper Standard Automotive, …

According to HTF MI, "Global Automotive Grommet Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2030". The Global Automotive Grommet Market is anticipated to grow at a compound annual growth rate (CAGR) of 5.96% from 2024 to 2030, reaching USD 100 Billion in 2024 and USD 150 Billion by 2030.

Automotive grommets are protective rings or eyelets made from rubber or plastic, used to protect or cover holes in metal…

KSA Automotive Market | KSA Automotive Industry | KSA Automotive Industry Resear …

Saudi Arabia’s automotive market faced a decline in new car sales due to tripling of value-added tax (VAT) rates. Effective in July 1, 2020, Saudi Arabia hiked its VAT from 5% to 15%.

Vision 2030 trying to attract foreign investment to kick start Dammam manufacturing city to aid re-exports & fulfill domestic demand

Surge in Domestic Manufacturing to gain independence of Imports: With Vision 2030, KSA is trying to gain impendence of…

Automotive Fuel Injectors Market: Growing Automotive Sales Fueling Automotive Fu …

Automotive fuel injectors market is likely to grow at a steady pace in the long run, according to a new report by Fact.MR. The demand for automotive fuel injectors continues to remain influenced with a multitude of industry-specific and macroeconomic factors. Significant growth in the automotive sector, coupled with increasing vehicle fleet remain instrumental in driving the demand for automotive fuel injectors worldwide. Fact.MR estimates that the sales of automotive fuel injectors are expected…

Global Automotive Safety Market 2019 Worldwide Outlook By Autoliv, Delphi Automo …

Automotive safety systems are designed to comply with the standards and regulations prescribed by government agencies and transport authorities worldwide. Passive safety systems are designed to protect passengers, drivers, and pedestrians during an accident.

In terms of region, the global Automotive Passive Safety Systems market can be segmented into North America, Europe, Asia Pacific, and Middle East & Africa. Asia Pacific is likely to hold a prominent share of the global…

Global Oil Pump for Automotive Market 2018 Analysis -Bosch,Denso,Aisin Seiki,Del …

According to this study, over the next five years the Oil Pump for Automotive market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2023, from US$ xx million in 2017. In particular, this report presents the global market share (sales and revenue) of key companies in Oil Pump for Automotive business.

Get Sample Copy of this Report for more Information…

Global Automotive Body Welded Assembly Market 2018 - Daesan, Baylis Automotive, …

Accord Market, recently published a detailed market research study focused on the “Automotive Body Welded Assembly Market” across the global, regional and country level. The report provides 360° analysis of “Automotive Body Welded Assembly Market” from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global PP Pipe industry, and estimates the future trend of…