Press release

EDTMP Manufacturing Plant Report: Cost Model, Top Manufacturers, Outline, Feedstocks, Market Drivers, Manufacturing Process, Key Insights

In the modern world, the demand for chemicals and specialty materials has been on the rise, and one such key player in the sector.

EDTMP Manufacturing Plant Report: https://www.procurementresource.com/reports/edtmp-manufacturing-plant-project-report

1. Cost Model for EDTMP Production

Understanding the cost structure is critical for any manufacturer or investor in the EDTMP industry. The cost model for EDTMP production is influenced by several key factors, including raw material prices, labor costs, energy consumption, and technology used in the manufacturing process.

The primary feedstocks for EDTMP production are ethylenediamine and phosphorous compounds. These raw materials need to be sourced at competitive prices to maintain profitability. The cost model also takes into account the maintenance of sophisticated chemical plants and the implementation of quality control measures to ensure that the EDTMP produced meets industry standards. Energy costs, which include electricity and natural gas, can also play a significant role in the overall cost structure.

Request Your Free Sample Report - https://www.procurementresource.com/reports/edtmp-manufacturing-plant-project-report/request-sample

In addition to raw materials, transportation costs, labor, and facility overheads must be factored into the total manufacturing costs. Economies of scale are another factor-larger manufacturing plants often achieve cost savings by producing larger quantities of EDTMP. This is particularly true for high-output EDTMP plants that cater to a global market.

As highlighted in the Edtmp Manufacturing Plant Report, optimizing the cost model requires a balance between raw material procurement, manufacturing efficiency, and energy consumption. For businesses looking to enter the EDTMP market, understanding the cost dynamics is essential for profitability and market positioning.

2. Top Manufacturers in the EDTMP Industry

The global EDTMP market is driven by the activities of key manufacturers who have the technology, supply chain networks, and expertise required to produce high-quality EDTMP. These top manufacturers are not only focused on meeting domestic demand but are also expanding their reach to international markets where water treatment needs are growing. Some of the major manufacturers of EDTMP include:

BASF

Shandong Xinyu Chemical

Jiangsu Sopo Chemical

Jiangsu Ruiqiang Chemical

These companies have solidified their presence in the EDTMP manufacturing sector by investing in state-of-the-art production plants and establishing robust distribution channels. They also collaborate with Procurement Resource for market insights, competitive pricing strategies, and procurement practices that help reduce costs and improve profit margins.

Top manufacturers generally lead the market due to their ability to streamline operations, utilize advanced technology for more efficient production, and maintain consistent supply chains. The scalability of their operations allows them to offer competitive prices and increase market share, which is vital for businesses looking to stay ahead in the EDTMP production industry.

3. Outline of an Edtmp Manufacturing Plant

An EDTMP manufacturing plant typically operates in a multi-phase process, from the procurement of raw materials to the packaging of the final product. Below is an outline of the plant operations:

Raw Material Handling and Storage: Materials such as ethylenediamine and phosphorous acid are stored in secure containers and carefully monitored for temperature and humidity to ensure their stability.

Reaction Process: The core chemical reaction occurs in large reactors where ethylenediamine reacts with phosphonic acids to form EDTMP. The reaction is carefully controlled to maintain optimal conditions for maximum yield.

Purification: After the reaction, the mixture is subjected to purification processes like distillation, filtration, and crystallization to remove impurities and ensure the product meets industry standards.

Quality Control and Packaging: Finished EDTMP is tested for quality and packaged in drums, bags, or bulk containers. This step also involves safety checks to confirm that the product is free from contaminants and adheres to environmental standards.

4. Feedstocks for EDTMP Manufacturing

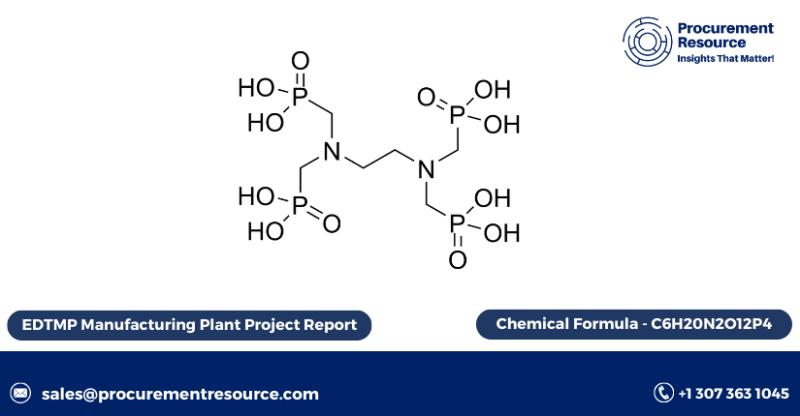

The feedstocks for EDTMP production are primarily ethylenediamine and phosphorus-based chemicals. Ethylenediamine is derived from petrochemical processes and serves as a key raw material for a range of other chemicals, including EDTMP. Phosphorus compounds are used to provide the phosphonic group that characterizes EDTMP's chemical structure.

These feedstocks are often sourced from large-scale chemical production facilities and require careful transportation and storage to maintain their quality. The sourcing of high-quality feedstocks is essential for ensuring that the final EDTMP product meets the necessary standards for use in water treatment and other applications.

5. Market Drivers for EDTMP

The EDTMP market is shaped by several key market drivers that influence production, demand, and overall industry growth:

Water Treatment Industry: As urbanization and industrialization increase, the need for water treatment solutions has grown significantly, with EDTMP playing a critical role in preventing scale buildup in water pipes and equipment.

Environmental Regulations: Growing concerns about environmental sustainability and the need for cleaner water have pushed industries to adopt more efficient chemicals like EDTMP that help prevent scaling and corrosion.

Technological Advancements: The continuous development of more efficient manufacturing technologies has allowed companies to produce EDTMP at lower costs, contributing to market growth.

Geopolitical Factors: Trade agreements and international market expansion have opened new markets for EDTMP manufacturers, leading to increased competition and demand.

6. Manufacturing Process of EDTMP

The manufacturing process of EDTMP involves several key steps to ensure that the final product meets the stringent requirements of industries such as water treatment, oilfield chemicals, and detergent manufacturing. Here's an overview of the process:

Synthesis Reaction: The synthesis of EDTMP begins with the reaction between ethylenediamine and phosphonic acids, typically under controlled temperature and pressure conditions in a chemical reactor.

Neutralization and Filtration: The reaction mixture is neutralized using appropriate acids or bases and then filtered to remove by-products and unreacted raw materials.

Crystallization and Drying: The purified EDTMP is then crystallized and dried to remove any residual moisture.

Final Product Formulation: The final EDTMP product is formulated into various grades and packaged according to market demand, ensuring it meets the specific needs of customers in different industries.

Read Full Report With Table Of Contents: https://www.procurementresource.com/reports/edtmp-manufacturing-plant-project-report/toc

7. Key Insights into the EDTMP Manufacturing Industry

The EDTMP manufacturing industry is poised for continued growth, driven by the rising demand for water treatment chemicals and advancements in manufacturing technologies. The key insights derived from an extensive Edtmp Manufacturing Plant Report include:

Cost Optimization: Efficient production techniques, such as the use of green chemistry and catalysis, are helping manufacturers reduce production costs and environmental impacts.

Sustainability: Manufacturers are increasingly adopting environmentally friendly practices, including waste reduction and energy-efficient operations, which contribute to sustainability and cost-efficiency.

Market Expansion: With the demand for EDTMP on the rise, manufacturers are expanding their production capacity and exploring new market opportunities in emerging economies where industrialization is growing.

The Edtmp Manufacturing Plant Report offers a comprehensive view of the EDTMP manufacturing industry, from production costs to the market dynamics shaping its growth. With a focus on raw materials, manufacturing processes, and market drivers, this report provides valuable insights for businesses seeking to enter or expand within the EDTMP market. Understanding the cost models, key manufacturers, and market trends is essential for stakeholders to make informed decisions and remain competitive in this ever-evolving industry. By collaborating with Procurement Resource, manufacturers can gain real-time pricing data, procurement insights, and detailed market analysis to better navigate this complex industry.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA

About Us:

Procurement Resource is a leading market research firm that specializes in providing detailed insights and analysis on the procurement and production costs of various commodities and products. With a team of seasoned industry experts, Procurement Resource offers comprehensive reports that cover all aspects of the supply chain, from raw material sourcing to final product manufacturing. Their services are designed to help businesses optimize their procurement strategies, reduce costs, and enhance efficiency. By leveraging their in-depth market intelligence and proprietary cost models, Procurement Resource enables clients to make informed decisions, stay competitive, and drive sustainable growth in an ever-evolving market landscape.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release EDTMP Manufacturing Plant Report: Cost Model, Top Manufacturers, Outline, Feedstocks, Market Drivers, Manufacturing Process, Key Insights here

News-ID: 3822066 • Views: …

More Releases from Procurement Resource

Cocoa Butter Price Trend: Market Drivers, Supply Dynamics, and Global Outlook fo …

The Cocoa Butter Price Trend has become a strategic point of attention for confectionery manufacturers, personal care brands, food processors, commodity traders, and procurement leaders across global supply chains. As cocoa butter remains one of the most essential raw materials in chocolate production and a core ingredient in cosmetics, pharmaceuticals, and nutraceuticals, fluctuations in its price directly influence cost structures, profit margins, and retail pricing strategies across multiple industries.

Inquire for…

Dichloromethane Price Trend Analysis Report By Procurement Resource

Dichloromethane (DCM), also known as methylene chloride, is a volatile, colorless liquid primarily used as a solvent in various industrial processes. It plays a critical role in paint stripping, pharmaceuticals, adhesives, and metal cleaning. With increasing demand and changing dynamics across global supply chains, the Dichloromethane price trend has become a key point of interest for stakeholders across industries.

Dichloromethane Price Trend Analysis Report: https://www.procurementresource.com/resource-center/dichloromethane-price-trends

This article explores a comprehensive overview of…

Ammonium Nitrate Production Cost Analysis

Ammonium nitrate is a widely used inorganic chemical compound with significant applications in fertilizers, explosives, mining, construction, and industrial blasting. Due to its high nitrogen content and strong oxidizing properties, ammonium nitrate plays a crucial role in global agriculture and industrial development. Understanding the ammonium nitrate production cost structure is essential for manufacturers, investors, and procurement professionals operating in fertilizer and chemical markets.

Request a Free Sample:- https://www.procurementresource.com/production-cost-report-store/ammonium-nitrate/request-sample

This article provides a…

Naphthalene Sulfonic Acid Price Trend: Cost Drivers, Supply Dynamics, and Global …

The Naphthalene Sulfonic Acid Price Trend has become an increasingly important indicator for manufacturers, procurement teams, and industrial planners operating across construction chemicals, textiles, dyes, agrochemicals, and specialty chemical segments. As a key intermediate used in the production of concrete admixtures, dispersants, dye intermediates, and surfactants, fluctuations in naphthalene sulfonic acid pricing have a direct impact on downstream cost structures and profit margins.

Inquire for Latest Market Prices :- https://www.procurementresource.com/resource-center/naphthalene-sulfonic-acid-price-trends/pricerequest

In 2025,…

More Releases for EDTMP

Setting Up a Successful Organophosphonate Manufacturing Plant: Project Report an …

Syndicated Analytics new report titled "Organophosphonate Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" offers a comprehensive overview of the process involved in establishing a manufacturing facility for organophosphonate. It methodically examines various aspects, including manufacturing requirements, project costs and economics, success and risk factors, returns on investment, and profit margins.

The study provides an in-depth analysis of the performance…

Global Organophosphonate Market Is Likely to Witness Tremendous Growth by 2025: …

Organophosphonate Market research report delivers a close watch on leading competitors with strategic analysis, micro and macro market trend and scenarios, pricing analysis and a holistic overview of the market situations in the forecast period.

Get Exclusive FREE Sample Copy Of this Report @ https://www.upmarketresearch.com/home/requested_sample/51464

UpMarketResearch offers a latest published report on “Global Organophosphonate Market Analysis and Forecast 2019- 2025” delivering key insights and providing a competitive advantage to clients through…

Organophosphonate Market- Global Industry Analysis,Trends and Forecast 2023

Organophosphonate is a chelating agent which has molecules with the ability to provide more than one bond to a metal ion, thereby augmenting the stability of the ion complex. Chelation represents a particular way of binding ions and molecules with metal ions. It involves the formation of multiple separate coordinate bonds between a polydentate ligand and single central atom. Usually, these ligands are organic compounds and are referred as sequestering…

Organophosphonate Market - Global Industry Analysis 2023

Organophosphonate is a chelating agent which has molecules with the ability to provide more than one bond to a metal ion, thereby augmenting the stability of the ion complex. Chelation represents a particular way of binding ions and molecules with metal ions. It involves the formation of multiple separate coordinate bonds between a polydentate ligand and single central atom. Usually, these ligands are organic compounds and are referred as sequestering…