Press release

The Growing Dominance of Plastic in the Returnable Transport Packaging Market

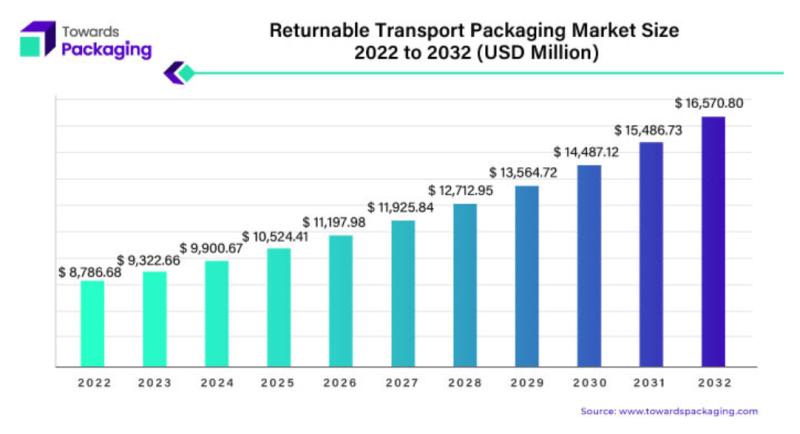

The global returnable transport packaging (RTP) market is poised for significant growth, with the market size projected to increase from USD 8.79 billion in 2022 to an estimated USD 16.57 billion by 2032. This robust growth trajectory reflects a compound annual growth rate (CAGR) of 6.6% from 2023 to 2032. The escalating adoption of RTP solutions highlights a transformation within industries that prioritize sustainability, cost-efficiency, and operational optimization.Download a Brochure of Returnable Transport Packaging Market: https://www.towardspackaging.com/download-brochure/5134

The Financial and Operational Benefits of Returnable Transport Packaging

One of the key drivers behind the widespread adoption of RTP solutions is the substantial cost savings they offer. Traditionally, businesses have relied on single-use packaging materials for the transportation of goods. However, RTP offers a more sustainable and economically viable alternative. By reusing durable containers, businesses can minimize the need for frequent repurchasing of packaging materials, which can add up over time. This not only reduces operational costs but also contributes to improved cash flow management for companies across diverse sectors.

Moreover, RTP significantly enhances supply chain efficiency. The use of standardized, reusable packaging reduces the complexity of logistics and transportation operations, offering a streamlined approach to moving goods. With RTP, companies can reduce the amount of packaging waste generated, which is a critical consideration for organizations striving to meet their sustainability goals. The reduction in waste translates to less landfill use, contributing to a lower environmental footprint.

Additionally, RTP systems help in mitigating the risk of product damage during transit. Since RTP containers are typically designed to be more durable and protective than single-use packaging, products are less likely to be compromised during transportation. This not only improves the overall quality of the goods delivered but also enhances customer satisfaction by ensuring items arrive in pristine condition.

Technological Advancements Shaping the Future of RTP

The integration of advanced tracking and tracing technologies is a game-changer for the returnable transport packaging sector. Technologies such as Radio Frequency Identification (RFID) tags, barcodes, and GPS tracking systems are being increasingly employed to enhance the visibility and accountability of RTP systems. These innovations enable real-time tracking of packaging assets, ensuring efficient management and minimizing the risk of lost or misplaced items in the supply chain.

The use of RFID and GPS systems offers valuable insights into the movement of goods, allowing businesses to better manage their packaging inventory and improve the flow of operations. By knowing the exact location of packaging units at any given moment, companies can optimize routing, reduce delays, and further improve the efficiency of their logistics.

Sustainability at the Core: RTP and Environmental Impact

The growing emphasis on sustainability within the packaging industry is another critical factor driving the adoption of returnable transport packaging solutions. As environmental concerns continue to rise, companies across the globe are searching for ways to reduce their carbon footprints. RTP offers a highly effective solution by minimizing the consumption of raw materials and reducing the volume of waste generated by traditional, single-use packaging. With increasing pressure from both regulatory bodies and consumers to adopt eco-friendly practices, RTP serves as an essential tool for companies striving to meet these expectations.

Incorporating RTP into the supply chain also aligns with global initiatives to move toward a circular economy. Rather than relying on disposable packaging that ends up in landfills, RTP encourages the reuse of materials, promoting sustainability and helping to close the loop in packaging systems.

The Road Ahead: Market Prospects and Future Growth

Looking ahead, the returnable transport packaging market is set to experience substantial growth driven by these factors. As more industries embrace the cost-saving, logistical, and environmental benefits of RTP solutions, the demand for these packaging systems is expected to rise. Key industries that will continue to drive this growth include automotive, retail, electronics, and food and beverage, where large-scale transportation of goods is a daily necessity.

Furthermore, the increasing integration of smart technology in RTP solutions, including AI-powered analytics and automated systems, will continue to shape the landscape of the market. These innovations will further streamline the logistics process, improve efficiency, and provide businesses with actionable insights to refine their operations.

Plastic's Dominance in the Returnable Transport Packaging (RTP) Industry: A Closer Look at Growth and Innovation

In recent years, plastic has solidified its position as the fastest-growing material in the Returnable Transport Packaging (RTP) industry. This shift towards plastic is not just a passing trend but a reflection of the material's numerous advantages, which cater to the evolving demands of modern supply chains. As industries seek more efficient, sustainable, and cost-effective packaging solutions, plastic has emerged as a clear frontrunner, revolutionizing RTP with its unmatched versatility and durability.

The Rise of Plastic-Corrugated Packaging

One of the standout innovations driving plastic's rapid growth in RTP is plastic-corrugated packaging. This packaging material, made from extruded twin-wall plastic sheets crafted from high-impact polypropylene, polyethylene, and other robust plastic resins, mimics the structure of corrugated fiberboard. With fluted ribs supporting the upper and lower surfaces, the design provides enhanced strength and durability, making it ideal for the transportation of goods across various industries.

Plastic-corrugated packaging can be used to create a wide array of returnable product types, including handheld boxes and bulk bins. These containers are highly versatile and adaptable to different sizes and forms, allowing businesses to optimize their logistics operations effectively. The lightweight, yet sturdy design is particularly appealing for companies looking to reduce shipping costs and improve operational efficiency.

Market Trends: Growing Popularity of Plastic Packaging

In 2023, a survey revealed that 44% of primary users in the RTP market predicted an increase in their companies' use of plastic-corrugated packaging over the next five years. This forecast underscores the material's growing dominance in the industry. The combination of lightweight construction, recyclability, and long-lasting durability makes plastic a highly attractive option for businesses seeking packaging that can stand up to the rigors of multiple uses.

Plastic packaging is not only easier to handle but also more efficient in terms of logistics. For instance, plastic pallets are much lighter compared to their wooden or metal counterparts. This reduction in weight makes transportation and handling more convenient, which translates into significant savings for companies involved in the supply chain. Furthermore, plastic pallets are designed to withstand repeated use, making them a cost-effective choice for long-term operations.

Plastic Trays in the Fresh Produce Supply Chain

Another area where plastic packaging has made significant strides is in the fresh produce supply chain. Plastic trays, such as those offered by Euro Pool System, have gained popularity for their lightweight design, which allows for easy mobility. These trays are perfect for use in the transportation of fresh fruits, vegetables, and other perishable items. Their high-quality plastic composition ensures a long lifespan, making them a reliable solution for businesses that require durable and reusable packaging.

In addition to being lightweight and durable, these plastic trays are designed for efficiency in the fresh produce supply chain. Their standardized size and shape facilitate stacking and storage, optimizing space in warehouses and transportation vehicles. This streamlining of logistics operations not only helps reduce costs but also enhances the overall flow of goods through the supply chain.

The Role of Recyclability and Sustainability

As sustainability becomes a primary focus for businesses across various sectors, the recyclability of plastic packaging is a key factor in its increasing adoption. Recyclable plastic is a critical element in the move toward a circular economy, where products and materials are reused and recycled rather than disposed of. Plastic RTP solutions, which can be returned and reused multiple times, align perfectly with these sustainable goals.

The RTP industry's embrace of recyclable plastic reflects a broader shift in the packaging sector, where environmental impact is becoming an increasingly important consideration. By opting for reusable plastic packaging, businesses can significantly reduce their reliance on single-use materials, contributing to waste reduction and a more sustainable future.

Industry Innovation: IFCO's Introduction of the Dora Plastic Pallet

A recent development further exemplifying plastic's role in the RTP industry is the launch of the Dora plastic pallet by IFCO, a global leader in returnable packaging containers (RPCs). In January 2024, IFCO announced the introduction of Dora throughout Europe, a state-of-the-art returnable plastic pallet specifically designed for compatibility with RPCs.

The Dora pallet integrates seamlessly into the existing fresh food supply chain operations, offering significant improvements in logistical efficiency and sustainability. As part of IFCO's circular model pooling system, the Dora pallet is intended to be reused multiple times, further enhancing the sustainability of the supply chain. This innovation showcases the growing importance of plastic in revolutionizing packaging solutions, particularly in industries that require reliable, cost-effective, and sustainable materials.

Source: https://www.towardspackaging.com/insights/returnable-transport-packaging-market-sizing

Baner

Buy Premium Global Insight: https://www.towardspackaging.com/price/5134

Review the Full TOC for the Returnable Transport Packaging Market Report: https://www.towardspackaging.com/table-of-content/returnable-transport-packaging-market-sizing

Get the latest insights on packaging industry segmentation with our Annual Membership - https://www.towardspackaging.com/get-an-annual-membership

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

Towards Healthcare: https://www.towardshealthcare.com

Towards Automotive: https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Growing Dominance of Plastic in the Returnable Transport Packaging Market here

News-ID: 3819353 • Views: …

More Releases from Towards Packaging

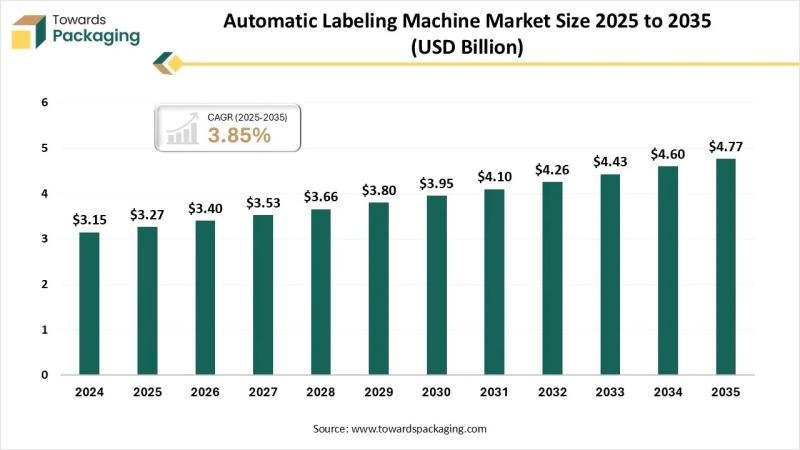

Automatic Labeling Machine Market Set for Strong Growth Through 2035

The global automatic labeling machine market is poised for steady expansion, rising from USD 3.4 billion in 2026 to USD 4.77 billion by 2035 at a CAGR of 3.85%. Demand is being driven by rapid automation in packaging lines, stringent labeling regulations, and the shift toward high-speed, error-free production across industries.

Download Sample: https://www.towardspackaging.com/download-sample/5882

Self-adhesive labeling systems currently hold the largest share at 39%, supported by their versatility and cost efficiency. Meanwhile,…

Unleashing Growth in the Liquid Packaging Market with Strategic Innovations

The liquid packaging industry is experiencing remarkable growth, with projections indicating an increase from USD 397.36 billion in 2025 to USD 645.43 billion by 2034. This growth, at a compound annual growth rate (CAGR) of 5.7%, signifies the expanding demand for liquid packaging solutions across a variety of sectors. As we delve into the market dynamics, it becomes clear that the liquid packaging sector is evolving rapidly, with several key…

Advancements in Hot-Fill Food Packaging Paving the Way for a Sustainable Future

The global hot-fill food packaging market is experiencing a steady rise, with an expected market value of USD 71.26 billion by 2033, up from USD 49.85 billion in 2023. This growth is projected to follow a compound annual growth rate (CAGR) of 3.76% from 2024 to 2033, reflecting the increasing demand for innovative packaging solutions in the food and beverage sector.

Download a Brochure of Hot-fill Food Packaging Market: https://www.towardspackaging.com/download-brochure/5266

Hot-Fill…

Driving Growth and Innovation in the Plastic Bag Market

The plastic bag market is undergoing significant growth, with its value reaching an estimated US$ 25.10 billion in 2023. Projections suggest that this market could hit a substantial US$ 35.41 billion by 2033, marking a steady compound annual growth rate (CAGR) of 3.5% from 2024 to 2034. This growth is largely driven by the expanding needs of various industries for efficient and cost-effective packaging solutions.

Download a Brochure of Plastic Bag…

More Releases for RTP

Plastic Compounding Market Comprehensive study by Key Players: Solvay, DowDuPont …

HTF MI Analyst have added a new research study on Title Global Plastic Compounding Market Growth 2021-2026 with detailed information of Product Types [PP Compounds, PE Compounds, PVC Compounds, PA Compounds & Others], Applications [Automotive, Building & Construction, Electronics & Appliances, Consumer Goods, Packaging & Others] & Key Players Such as LyondellBasell, SABIC, BASF, Solvay, DowDuPont, RTP, Mitsui Chemicals, ExxonMobil, Mexichem, Westlake Chemical, Chevron Phillips Chemical, Ineos Styrolution, Total Petrochemicals,…

Molded Interconnect Devices Market Trend, Revenue & Regional Analysis 2024 By To …

With the advent of an increasing number of consumer device applications, the global molded interconnect devices market is expected to experience a substantial growth rate in the forthcoming years. The primary factor driving the industry would undeniably be the ability of the molded interconnect devices' to integrate several mechanical & electrical functions in consumer devices while also enabling the reduction of circuit density & facilitating product miniaturization. Moreover, the devices…

What’s Driving the Molded Interconnect Devices Market Trends? Key Companies - …

The Molded Interconnect Devices market has witnessed growth from USD XX million to USD XX million from 2014 to 2019. With the CAGR of X.X%, this market is estimated to reach USD XX million in 2026.

The report mainly studies the size, recent trends and development status of the Molded Interconnect Devices market, as well as investment opportunities, government policy, market dynamics (drivers, restraints, opportunities), supply chain and competitive landscape. Technological…

What’s Driving the Molded Interconnect Devices Market Trends? Key Companies - …

Molded Interconnect Devices Market is expected to reach USD 840 million by 2024. The proliferation of the smart & connected wearable devices across the globe is driving the industry growth. These components allow lesser energy consumption and help in enhancing the battery life of the wearable devices, which is beneficial to the users. Moreover, these components further help in reducing the overall of the wearable devices. The wearables are increasingly…

Global Polyetherimide(PEI) Market 2019 - SABIC, RTP, Ensinger, Mitsuichemicals

This new report by Eon Market Research, titled “Global Polyetherimide(PEI) Market 2019 Research Report, 2015 – 2025” offers a comprehensive analysis of Polyetherimide(PEI) industry at a global as well as regional and country level. Key facts analyzed in this report include the Polyetherimide(PEI) market size by players, regions, product types and end industries, history data 2014-2018 and forecast data 2019-2025. This report primarily focuses on the study of the competitive…

Polyetherimide(PEI) Market 2017- SABIC, RTP, Ensinger, Mitsuichemicals

Apex Research, recently published a detailed market research study focused on the "Polyetherimide(PEI) Market" across the global, regional and country level. The report provides 360° analysis of "Polyetherimide(PEI) Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Polyetherimide(PEI) industry, and estimates the future trend of Polyetherimide(PEI) market on the basis of…