Press release

Antifungal Cream Manufacturing Plant 2024 - Detailed Project Report and Manufacturing Process

Antifungal creams are topical medications prepared to treat fungal infections on the skin and nails effectively. These creams are composed of active ingredients like clotrimazole, or miconazole that target fungal pathogens, inhibiting their growth or eradicating them. They are widely used to manage conditions such as athlete's foot, ringworm, jock itch, and yeast infections, offering a convenient and non-invasive treatment option. The benefits of antifungal creams extend to their ease of application, rapid relief of symptoms such as itching and inflammation, and suitability for use by individuals of various age groups.The rising prevalence of fungal infections worldwide is the primary driver of the antifungal cream market. Fungal infections often thrive in warm, humid climates and are exacerbated by factors like poor hygiene and increased outdoor activities, driving the demand for effective treatments. Furthermore, the growing awareness about the importance of early and proper treatment of skin infections to prevent complications is encouraging the adoption of antifungal creams. Innovations in pharmaceutical formulations, such as the introduction of water-resistant and fast-absorbing creams, are also boosting market demand. The integration of antifungal ingredients in everyday skincare and hygiene products, such as body washes and talcum powders, is further expanding the market's scope. Additionally, the increase in healthcare spending and access to online pharmacies ensures widespread availability, supporting market growth.

IMARC Group's report titled "Antifungal Cream Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for setting up an antifungal cream manufacturing plant.

Request for a Sample Report: https://www.imarcgroup.com/antifungal-cream-manufacturing-plant-project-report/requestsample

The report includes the following information:

Market Analysis:

The antifungal cream market is witnessing several notable trends, reflecting the evolving preferences of consumers and advancements in technology. One of the significant trends is the development of natural and herbal antifungal creams, catering to the rising demand for chemical-free and eco-friendly products. Another trend is the shift towards personalized skincare, with manufacturers designing creams tailored to specific fungal conditions or skin types. Future growth is anticipated to be driven by research in nanotechnology, enabling the development of creams with superior penetration and efficacy. These innovations, combined with the increasing focus on preventive healthcare and wellness, are set to propel the antifungal cream market toward sustained growth in the coming years.

Market Trends

Market Breakup by Segment

Market Breakup by Region

Price Analysis

Impact of COVID-19

Market Forecast

Buy Now: https://www.imarcgroup.com/checkout?id=9524&method=402

Project Overview

This section offers detailed information related to the process flow and several unit operations involved in an antifungal cream manufacturing plant project. Moreover, information related to raw material requirements and mass balance has further been provided in the report with a list of necessary technical tests as well as quality assurance criteria.

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Key Requirements and Costs

This section provides an analysis encompassing insights, including land location, selection criteria, location significance, environmental impact, and expenditure for antifungal cream manufacturing plant setup. Besides this, the report further offers information related to plant layout and factors influencing the same. Additionally, other expenditures and requirements related to packaging, utilities, machinery, transportation, raw materials, and human resources have also been included in the report.

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Project Economics:

This section covers a comprehensive analysis of the project economics for setting up an antifungal cream manufacturing plant. This comprises the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), taxation, depreciation, profitability analysis, payback period, NPV, income projections, liquidity analysis, uncertainty analysis, and sensitivity analysis.

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9524&flag=C

Customization Available:

Production Capacity:

Draft the machinery selection and plant layout to align with the expected scale of production, which can range from small-scale operations to large industrial setups.

Automation Levels:

Modify the level of automation based on labor availability, budget constraints, and technical expertise from semi-automated processes to fully automated systems.

Location Adaptation:

Customize the plant's location to strategically align with local market demand, ensure efficient access to raw materials, utilize available labor resources, and adhere to regional regulatory requirements, thereby maximizing operational efficiency and cost-effectiveness.

Product Flexibility:

Encompass processes and machinery that can handle numerous product variations. This, in turn, can enable the plant to cater to diverse market demands.

Sustainability Features:

Incorporate various eco-friendly options, including renewable energy integration, waste management systems, energy-efficient machinery, etc., to meet sustainability goals.

Raw Material Sourcing:

Tailor the supply chain strategy to enable cost-effective and reliable access to raw materials specific to client requirements or the region.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Antifungal Cream Manufacturing Plant 2024 - Detailed Project Report and Manufacturing Process here

News-ID: 3785120 • Views: …

More Releases from IMARC Group

Trinitrotoluene Production Plant DPR & Unit Setup 2026: Demand Analysis and Proj …

Setting up a trinitrotoluene production plant involves strategic planning, substantial capital investment, and a comprehensive understanding of production technologies. This critical explosive compound serves military and defense, mining and quarrying, construction and demolition, and industrial explosives manufacturing applications. Success requires careful site selection, efficient nitration processes, stringent safety protocols for handling hazardous materials, reliable raw material sourcing, and compliance with industrial safety regulations to ensure profitable and sustainable operations.

Market Overview…

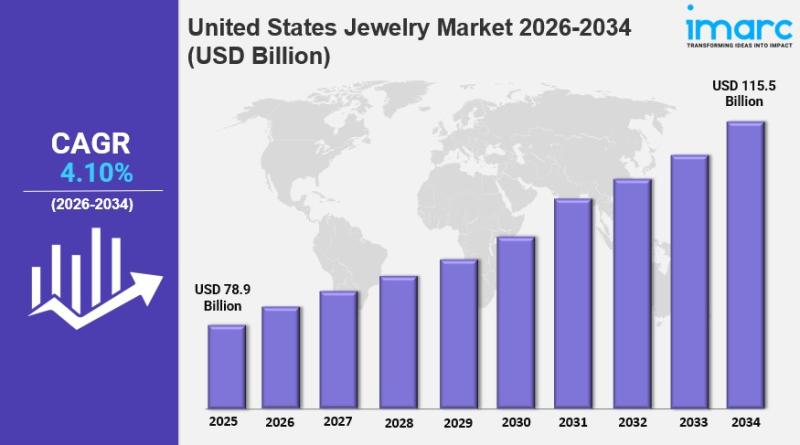

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…