Press release

Automotive Aluminum Extruded Parts Market to Reach US$ 103,953 Million by 2033

Introduction:The automotive industry has witnessed a paradigm shift in recent years, with growing emphasis on reducing vehicle weight, improving fuel efficiency, and complying with stringent environmental regulations. A key material that has emerged to address these concerns is aluminum, particularly in its extruded form. Automotive aluminum extruded parts are integral to the manufacturing of lightweight, high-performance vehicles. These parts help reduce the overall weight of automobiles, leading to improved fuel efficiency and lower carbon emissions.

The global automotive aluminum extruded parts market is expected to experience substantial growth over the next decade, driven by increasing environmental awareness, regulatory changes, and demand for more fuel-efficient vehicles. According to Persistence Market Research's projections, the market for automotive aluminum extruded parts is expected to grow from a value of US$ 58,597.3 million in 2023 to US$ 103,953.0 million by 2033, expanding at a compound annual growth rate (CAGR) of 5.9%.

This report provides an in-depth analysis of the automotive aluminum extruded parts market, exploring the key factors driving its growth, the challenges faced by the industry, emerging trends, and regional dynamics.

Market Projections and Forecast:

As per Persistence Market Research's projections, the global market for automotive aluminum extruded parts is set to experience robust growth in the coming years. The market, valued at approximately US$ 58,597.3 million in 2023, is expected to reach US$ 103,953.0 million by 2033. This represents a CAGR of 5.9% from 2023 to 2033.

The demand for automotive aluminum extruded parts is being fueled by the growing need for lightweight materials in vehicle manufacturing. As governments worldwide impose stricter fuel efficiency and emissions standards, automakers are increasingly adopting aluminum extrusions to meet these requirements. Additionally, the material's ability to be molded into complex shapes, combined with its strength and corrosion resistance, makes it an ideal choice for a wide range of automotive applications.

Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): www.persistencemarketresearch.com/samples/32625

Market Dynamics:

Drivers of Market Growth:

Environmental Regulations and Sustainability Initiatives

Stricter environmental regulations aimed at reducing automotive carbon footprints are one of the key drivers for the increased adoption of aluminum in vehicle production. Governments across regions are implementing fuel economy standards and emission regulations that demand automakers use lighter materials to improve fuel efficiency and reduce greenhouse gas emissions. Aluminum extrusions are increasingly being utilized to meet these requirements due to their lightweight properties.

Demand for Lightweight Vehicles

With the growing consumer demand for fuel-efficient and environmentally friendly vehicles, manufacturers are turning to aluminum to reduce the weight of vehicles. Lighter cars consume less fuel, which leads to improved fuel efficiency and lower carbon emissions. As a result, aluminum extruded parts are increasingly being used in critical vehicle components such as chassis, body frames, and suspension parts.

Improved Performance Characteristics

Automotive aluminum extruded parts offer high strength-to-weight ratios, making them ideal for enhancing vehicle performance. These parts are durable, resistant to corrosion, and can withstand high temperatures. This makes aluminum extrusions a preferred choice for automakers aiming to produce vehicles that offer both safety and performance without compromising on fuel efficiency.

Technological Advancements

The continuous advancements in aluminum extrusion technology have made it easier and more cost-effective for manufacturers to produce complex, lightweight, and durable automotive parts. Innovations in extrusion processes allow for better material strength, greater precision, and the ability to create more intricate designs, further fueling the demand for aluminum parts in automotive applications.

Challenges in the Market:

High Production Costs

One of the primary challenges in the automotive aluminum extruded parts market is the relatively high cost of production compared to traditional materials such as steel. The cost of aluminum itself, combined with the specialized extrusion processes required to shape the parts, can be a significant barrier to widespread adoption, especially among smaller automotive manufacturers.

Competition from Alternative Materials

While aluminum is an ideal material for lightweight vehicles, it faces competition from other materials such as advanced high-strength steel and composite materials. These alternatives often offer similar benefits, and in some cases, they may be more cost-effective or easier to process.

Supply Chain Challenges

The automotive aluminum industry is highly dependent on the availability of raw aluminum, which can be subject to supply chain disruptions and fluctuations in global aluminum prices. Variability in material costs and supply constraints can affect the overall cost structure for automotive manufacturers, impacting the growth of the market.

Market Trends and Technological Innovations:

Adoption of Advanced Manufacturing Technologies

As the demand for lightweight, high-performance parts grows, there has been a significant push toward the adoption of advanced manufacturing technologies. Techniques such as 3D printing, robotic automation, and artificial intelligence are being leveraged to improve the precision, efficiency, and scalability of aluminum extrusion processes. These innovations are helping manufacturers to optimize their production lines, reduce costs, and meet the increasing demand for complex and customized parts.

Emergence of Electric and Autonomous Vehicles

The rise of electric vehicles (EVs) and autonomous vehicles (AVs) is another major trend shaping the automotive aluminum extruded parts market. Aluminum is a preferred material for electric and autonomous vehicles due to its lightweight nature, which helps offset the weight of heavy battery packs in EVs. Additionally, the need for advanced structural components in autonomous vehicles, which often require specialized materials for safety and performance, is further driving the demand for aluminum extrusions.

Focus on Sustainability and Recycling

The automotive industry is increasingly focusing on sustainability and the circular economy. Aluminum is 100% recyclable, and recycling aluminum requires only a fraction of the energy needed to produce new aluminum. As such, the use of recycled aluminum in automotive parts is expected to grow. This trend not only reduces environmental impact but also helps automotive manufacturers reduce material costs.

Automotive Aluminum Extruded Parts Market Segmentation:

By Product Type:

Sub-structures

Door Beams

Bumpers

Pillars

Sub Frames

Seat Back Bars

Front Side Rails

Space Frames

Body Panels

Others

By Material:

5000 Series Automotive Aluminium Extruded Parts

6000 Series Automotive Aluminium Extruded Parts

7000 Series Automotive Aluminium Extruded Parts

Others

By Vehicle:

Automotive Aluminium Extruded Parts for Passenger Cars

Compact Cars

Mid-Sized Cars

Luxury Cars

SUVs

Automotive Aluminium Extruded Parts for Light Commercial Vehicles

Automotive Aluminium Extruded Parts for Heavy Commercial Vehicles

Regional Analysis:

North America

North America, particularly the United States, is a significant market for automotive aluminum extruded parts. The region has a well-established automotive industry with major automakers increasingly adopting aluminum to meet stringent fuel economy and emissions standards. The rising demand for electric vehicles in North America is also expected to drive the adoption of aluminum extrusions.

Europe

Europe is another key market, with many leading automotive manufacturers based in Germany, France, and Italy. The European Union's strict environmental regulations and the increasing adoption of electric vehicles are driving the demand for lightweight materials such as aluminum. Germany, in particular, is a major contributor to the market's growth, with the country being a hub for premium vehicle manufacturers.

Asia-Pacific

The Asia-Pacific region, particularly China and India, is experiencing rapid growth in the automotive aluminum extruded parts market. With the expansion of the automotive sector and the increasing demand for fuel-efficient vehicles, aluminum extrusions are gaining popularity in both developed and emerging markets. China is expected to lead the market in this region due to its large-scale automotive production and government incentives for environmentally friendly vehicles.

Key Companies Profiled in the Report:

Arconic Inc.

Constellium N.V.

UACJ Corporation

Kaiser Aluminum

Sapa Group (Hydro Extrusions)

Alcoa Corporation

Novelis Inc.

Future Outlook

The automotive aluminum extruded parts market is poised for significant growth in the coming decade. Factors such as environmental regulations, rising demand for lightweight vehicles, and advancements in manufacturing technologies will continue to drive the market's expansion. However, challenges such as high production costs and competition from alternative materials must be addressed for the market to reach its full potential.

As the automotive industry embraces new technologies and sustainability initiatives, the demand for aluminum extrusions is expected to increase, especially with the rise of electric and autonomous vehicles. With the continuous development of new aluminum alloys and improved manufacturing processes, the automotive aluminum extruded parts market is well-positioned to support the future of the global automotive industry.

Conclusion:

The automotive aluminum extruded parts market is set for substantial growth, driven by the need for lightweight, fuel-efficient vehicles and the growing focus on environmental sustainability. While challenges such as high production costs and competition from alternative materials exist, the market's overall outlook remains positive. As technological advancements and the shift toward electric and autonomous vehicles continue, aluminum extrusions will play a crucial role in shaping the future of the automotive industry.

Explore the Latest Trending "Exclusive Article" @

• https://www.linkedin.com/pulse/biometric-sensors-technology-transforming-security-obylf/

• https://www.linkedin.com/pulse/finance-cloud-real-time-data-analytics-technology-market-geeks-clvaf/

• https://www.linkedin.com/pulse/postal-automation-system-drives-efficiency-mail-handling-aqd3f/

• https://www.linkedin.com/pulse/mining-waste-management-reducing-carbon-footprint-ajay-patil-fjrcf/

• https://www.linkedin.com/pulse/hydroseeding-market-innovations-advancements-gmv9f

• https://www.linkedin.com/pulse/north-america-gypsum-boards-impact-construction-boom-demand-patil-tgqcf/

Contact Us:

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automotive Aluminum Extruded Parts Market to Reach US$ 103,953 Million by 2033 here

News-ID: 3732560 • Views: …

More Releases from Persistence Market Research

Aseptic Packaging Market Set to Grow to US$136.5 Bn by 2033 Driven by Rising Foo …

Introduction: Aseptic Packaging Market Overview and Industry Evolution

The aseptic packaging market has emerged as a cornerstone of modern food, beverage, and pharmaceutical preservation systems. As global consumers increasingly seek safe, long-lasting, and convenient packaged products, aseptic packaging solutions have gained substantial importance. This technology allows products to be sterilized separately from packaging materials and filled in a sterile environment, ensuring extended shelf life without refrigeration or preservatives. The rising demand…

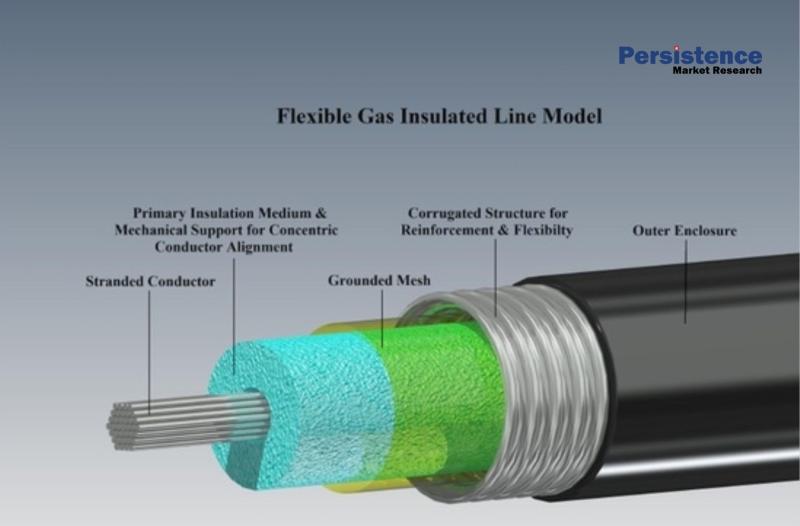

Gas-Insulated Transmission Line (GIL) Market Expected to See Growth to US$836.9 …

Introduction: Rising Demand for Advanced Power Transmission Solutions

The global energy landscape is undergoing a major transformation as nations accelerate investments in renewable energy, grid expansion, and reliable electricity distribution networks. With rapid urbanization, industrialization, and digital infrastructure growth, the demand for uninterrupted and efficient power transmission has never been higher. Traditional overhead transmission systems, while widely used, face challenges related to land constraints, environmental exposure, and transmission losses. This has…

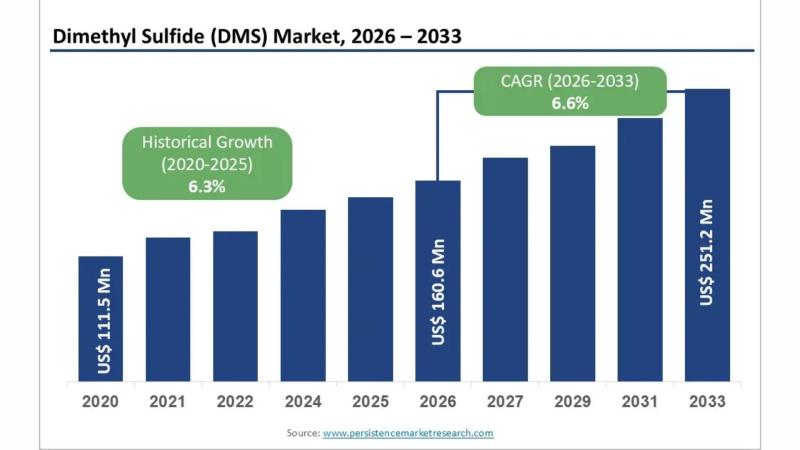

Dimethyl Sulfide (DMS) Market Anticipated to Reach US$ 251.2 Mn by 2033, Driven …

Market Overview: Expanding Demand for Dimethyl Sulfide Across Industries

The Dimethyl Sulfide (DMS) market is witnessing consistent growth due to its widespread applications across food processing, pharmaceuticals, agriculture, and chemical manufacturing. Dimethyl sulfide is an organosulfur compound known for its distinctive odor and reactive properties, making it a crucial intermediate in multiple industrial processes. In food and beverage applications, it is valued for flavor enhancement, while in chemical manufacturing, it serves…

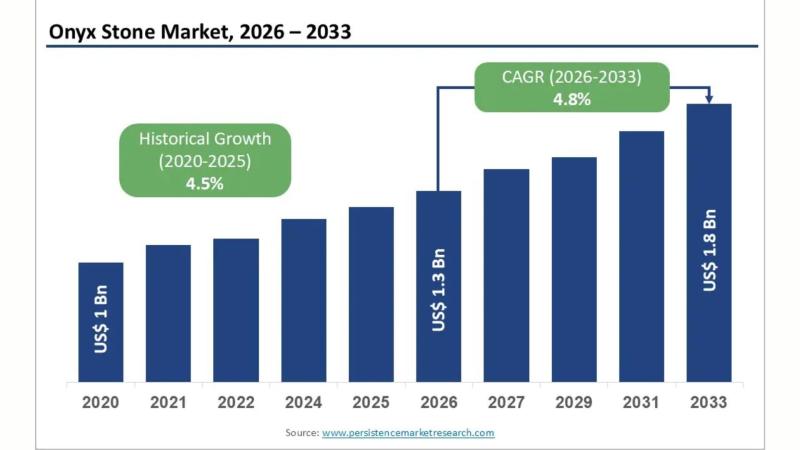

Onyx Stone Market to Surge to Reach US$ 1.8 Bn by 2033 Driven by Construction & …

Market Overview: Rising Demand for Premium Natural Stones

The onyx stone market has gained remarkable prominence in recent years, driven by increasing demand for luxury natural stones in architecture, interior décor, and artistic applications. Onyx, known for its translucent appearance and unique veining patterns, has become a preferred choice for premium residential and commercial projects. The material's ability to elevate aesthetic appeal while maintaining durability has attracted designers, architects, and homeowners…

More Releases for Automotive

Automotive Grommet Market set for explosive growth: Cooper Standard Automotive, …

According to HTF MI, "Global Automotive Grommet Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2030". The Global Automotive Grommet Market is anticipated to grow at a compound annual growth rate (CAGR) of 5.96% from 2024 to 2030, reaching USD 100 Billion in 2024 and USD 150 Billion by 2030.

Automotive grommets are protective rings or eyelets made from rubber or plastic, used to protect or cover holes in metal…

KSA Automotive Market | KSA Automotive Industry | KSA Automotive Industry Resear …

Saudi Arabia’s automotive market faced a decline in new car sales due to tripling of value-added tax (VAT) rates. Effective in July 1, 2020, Saudi Arabia hiked its VAT from 5% to 15%.

Vision 2030 trying to attract foreign investment to kick start Dammam manufacturing city to aid re-exports & fulfill domestic demand

Surge in Domestic Manufacturing to gain independence of Imports: With Vision 2030, KSA is trying to gain impendence of…

Automotive Fuel Injectors Market: Growing Automotive Sales Fueling Automotive Fu …

Automotive fuel injectors market is likely to grow at a steady pace in the long run, according to a new report by Fact.MR. The demand for automotive fuel injectors continues to remain influenced with a multitude of industry-specific and macroeconomic factors. Significant growth in the automotive sector, coupled with increasing vehicle fleet remain instrumental in driving the demand for automotive fuel injectors worldwide. Fact.MR estimates that the sales of automotive fuel injectors are expected…

Global Automotive Safety Market 2019 Worldwide Outlook By Autoliv, Delphi Automo …

Automotive safety systems are designed to comply with the standards and regulations prescribed by government agencies and transport authorities worldwide. Passive safety systems are designed to protect passengers, drivers, and pedestrians during an accident.

In terms of region, the global Automotive Passive Safety Systems market can be segmented into North America, Europe, Asia Pacific, and Middle East & Africa. Asia Pacific is likely to hold a prominent share of the global…

Global Oil Pump for Automotive Market 2018 Analysis -Bosch,Denso,Aisin Seiki,Del …

According to this study, over the next five years the Oil Pump for Automotive market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2023, from US$ xx million in 2017. In particular, this report presents the global market share (sales and revenue) of key companies in Oil Pump for Automotive business.

Get Sample Copy of this Report for more Information…

Global Automotive Body Welded Assembly Market 2018 - Daesan, Baylis Automotive, …

Accord Market, recently published a detailed market research study focused on the “Automotive Body Welded Assembly Market” across the global, regional and country level. The report provides 360° analysis of “Automotive Body Welded Assembly Market” from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global PP Pipe industry, and estimates the future trend of…