Press release

Tank Level Monitoring System Market: Enhancing Safety and Performance in Storage Management

IntroductionTank level monitoring systems (TLMS) play a crucial role in the effective management of storage tanks in industries such as oil and gas, chemicals, water treatment, food and beverage, and pharmaceuticals. These systems allow real-time monitoring of liquid or gas levels within tanks, offering enhanced safety, performance, and efficiency in storage management. As industries continue to expand and optimize their operations, the demand for advanced tank level monitoring systems has surged, driven by the need for better operational control, cost reduction, and risk management.

This article explores the growing market for tank level monitoring systems, examining the key drivers, market dynamics, technological advancements, industry applications, and future trends that are shaping this essential technology.

Request for Sample: https://www.persistencemarketresearch.com/samples/33517

Key Drivers of Market Growth

The tank level monitoring system market is driven by several factors that reflect the evolving needs of industries seeking to enhance their storage management processes. These key drivers include:

1. Safety and Compliance Requirements

Ensuring safety is one of the primary concerns in tank storage, particularly in industries that handle hazardous materials such as chemicals, petroleum, and pharmaceuticals. Tank overflows, leaks, and underfills can lead to serious environmental hazards, financial losses, and safety incidents. Tank level monitoring systems provide continuous, real-time data on tank contents, helping companies prevent overflows, minimize environmental impact, and comply with stringent regulations. With growing regulatory pressures and safety standards, industries are increasingly turning to tank level monitoring solutions to mitigate risks and improve safety compliance.

2. Efficiency and Cost Optimization

Tank level monitoring systems enhance operational efficiency by providing accurate data on tank levels, reducing the need for manual inspections. In industries where time-sensitive operations are critical, such as oil and gas and food and beverage, these systems help streamline inventory management, reduce downtime, and optimize the supply chain. Automated monitoring allows for just-in-time ordering and ensures that tanks are neither overfilled nor underfilled, reducing operational costs related to inventory management, transportation, and storage.

3. Technological Advancements

Recent advancements in sensor technology, wireless communication, and cloud computing have significantly enhanced the capabilities of tank level monitoring systems. Modern TLMS solutions feature high-precision sensors that provide real-time, continuous monitoring of tank levels, offering improved accuracy, reliability, and ease of installation. Additionally, wireless systems allow remote monitoring from centralized control stations, reducing the need for on-site inspections and increasing operational flexibility. The integration of IoT (Internet of Things) and cloud computing further improves data accessibility, analysis, and reporting, offering greater insights into storage tank management.

4. Increasing Demand in Emerging Markets

The growth of emerging economies, particularly in regions like Asia-Pacific, Latin America, and the Middle East, is driving the demand for tank level monitoring systems. With the expansion of industries such as oil and gas, chemicals, and manufacturing, there is an increasing need for efficient storage management solutions. These regions are also witnessing investments in infrastructure development and industrial automation, further fueling the demand for advanced tank level monitoring technologies.

Market Dynamics

The market for tank level monitoring systems is influenced by several dynamic factors, which include industry-specific challenges, technological developments, and regional variations in demand.

1. Industry-Specific Applications

Tank level monitoring systems are widely used across various industries. In the oil and gas sector, TLMS is crucial for managing storage tanks that hold crude oil, refined petroleum products, and chemicals. The ability to monitor levels in real-time helps to prevent spills, optimize tank storage capacity, and ensure the efficient transfer of materials between storage and transport vessels.

In the chemical industry, accurate tank level measurement is critical to avoid the risk of spills and to ensure the proper mixing of chemicals in production processes. TLMS in these industries also help to comply with stringent safety and environmental regulations related to hazardous materials.

The water and wastewater treatment industry uses tank level monitoring systems to manage water storage tanks, ensuring a constant and adequate supply of water while preventing overflow or shortages. Similarly, the food and beverage industry uses TLMS to manage inventory levels of ingredients, prevent spoilage, and optimize production schedules.

The pharmaceutical industry also relies on tank level monitoring systems for precise inventory management of raw materials and chemicals used in the manufacturing of drugs, as well as for ensuring compliance with health and safety standards.

2. Technological Trends

The evolution of tank level monitoring systems is characterized by the integration of cutting-edge technologies such as wireless communication, IoT, and advanced sensors. Wireless tank level monitoring systems are increasingly popular due to their cost-effectiveness and ease of installation. These systems allow real-time monitoring without the need for extensive cabling, making them suitable for remote and hard-to-reach locations.

The integration of IoT enables advanced data analytics, allowing companies to monitor tank levels remotely and receive notifications or alerts when tanks reach critical levels. IoT-based systems offer features such as predictive maintenance, which helps reduce downtime and prevent costly repairs by alerting operators about potential failures before they occur.

Cloud-based tank level monitoring systems are gaining popularity for their ability to provide centralized data storage and remote access, allowing for real-time monitoring, reporting, and decision-making across multiple locations.

3. Regulatory and Environmental Pressures

Stricter environmental regulations and safety standards are a driving force in the adoption of tank level monitoring systems. Industries that handle volatile or hazardous materials are required to meet regulations related to leak detection, overfill prevention, and environmental impact. The demand for tank level monitoring solutions will continue to rise as companies seek to comply with these standards and avoid fines, penalties, or reputational damage caused by non-compliance.

Additionally, the increased focus on environmental sustainability and the reduction of carbon footprints is driving industries to adopt technologies that reduce waste, prevent spills, and improve overall operational efficiency.

Technological Advancements in Tank Level Monitoring Systems

The tank level monitoring system market has seen remarkable technological advancements in recent years, with innovations aimed at enhancing the accuracy, functionality, and scalability of these systems.

1. Advanced Sensors and Measurement Technologies

The development of high-precision sensors is transforming tank level monitoring. Traditional float-based sensors have been replaced by radar, ultrasonic, and capacitive sensors that offer greater accuracy and reliability. These advanced sensors are capable of measuring tank levels regardless of the type of material stored, offering versatility in applications across industries.

Radar sensors, for example, provide continuous level measurement without being affected by external factors such as temperature, pressure, or vapor, making them ideal for harsh environments in industries such as oil and gas. Ultrasonic sensors, on the other hand, use sound waves to measure the distance between the sensor and the tank's surface, providing highly accurate level measurements.

2. Wireless Communication and IoT Integration

Wireless communication technology has revolutionized the way tank level monitoring systems operate. Wireless systems eliminate the need for complex wiring installations, reducing installation time and costs. They allow operators to monitor tank levels remotely, making it easier to manage large storage facilities spread across different locations.

The integration of IoT in tank level monitoring systems enhances the flow of data, enabling real-time monitoring, reporting, and analytics. Operators can track inventory levels, detect potential problems, and receive alerts via mobile applications or cloud-based dashboards, allowing for quicker decision-making.

3. Cloud-Based Data Storage and Analytics

Cloud-based tank level monitoring solutions provide centralized data storage, which can be accessed from anywhere with an internet connection. This accessibility allows operators to monitor tank levels, review historical data, and generate reports in real time. Cloud-based systems also offer scalability, making them ideal for businesses with growing storage needs or multiple sites.

Advanced data analytics can be integrated into cloud-based systems to track trends, optimize tank usage, and predict maintenance needs, offering greater operational insight and enhancing decision-making.

Future Trends in the Tank Level Monitoring System Market

The tank level monitoring system market is poised for continued growth, driven by several emerging trends:

1. Growth in the Oil and Gas Sector

The oil and gas industry will remain a key driver for the tank level monitoring market. With the increasing demand for petroleum products and the need for enhanced safety and efficiency, oil and gas companies are investing in advanced tank level monitoring solutions to improve storage management and ensure regulatory compliance.

2. Focus on Predictive Maintenance

As industries continue to adopt automation, predictive maintenance is expected to become a key feature of tank level monitoring systems. By using real-time data analytics, companies can predict equipment failures before they happen, minimizing downtime and reducing maintenance costs.

3. Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) will increasingly be integrated into tank level monitoring systems to analyze data patterns, predict inventory requirements, and optimize storage management. These technologies will enable more proactive decision-making, further enhancing the efficiency and performance of storage operations.

Conclusion

The tank level monitoring system market is experiencing robust growth, fueled by advancements in technology, increasing demand across industries, and a strong focus on safety, efficiency, and compliance. As businesses seek to optimize storage operations and reduce risks, the adoption of advanced tank level monitoring systems will continue to rise. The integration of wireless communication, IoT, predictive maintenance, and AI-driven analytics will shape the future of this market, providing enhanced functionality, reliability, and operational insights. With these innovations, tank level monitoring systems will remain a cornerstone of effective storage management across a wide range of industries.

𝐀𝐛𝐨𝐮𝐭 𝐏𝐞𝐫𝐬𝐢𝐬𝐭𝐞𝐧𝐜𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

Contact Us:

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Tank Level Monitoring System Market: Enhancing Safety and Performance in Storage Management here

News-ID: 3725243 • Views: …

More Releases from Persistence Market Research

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

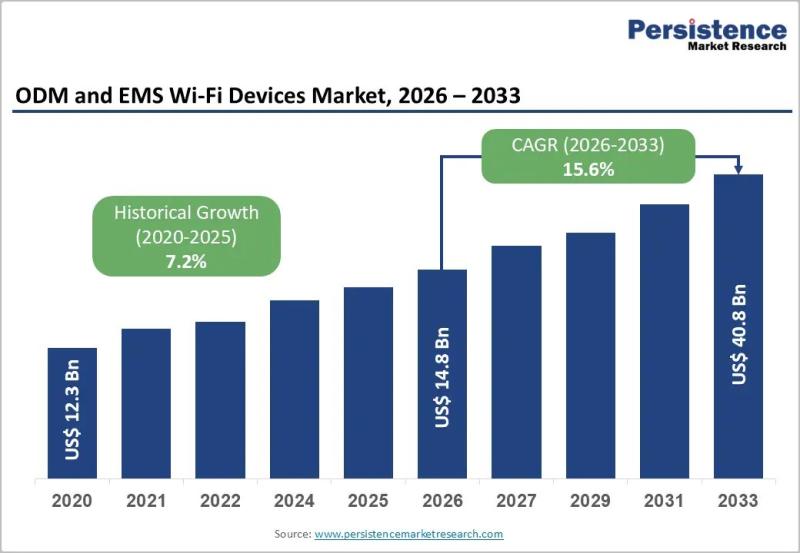

ODM and EMS Wi-Fi Devices Market to Reach US$ 40.8 Billion by 2033 at 15.6% CAGR

The global ODM and EMS Wi-Fi devices market is projected to be valued at US$ 14.8 billion in 2026 and is forecast to surge to US$ 40.8 billion by 2033, registering a robust CAGR of 15.6% between 2026 and 2033. This rapid growth reflects the accelerating demand for advanced wireless connectivity solutions across residential, enterprise, and industrial environments. The expansion of 5G infrastructure, enterprise digital transformation strategies, and large-scale IoT…

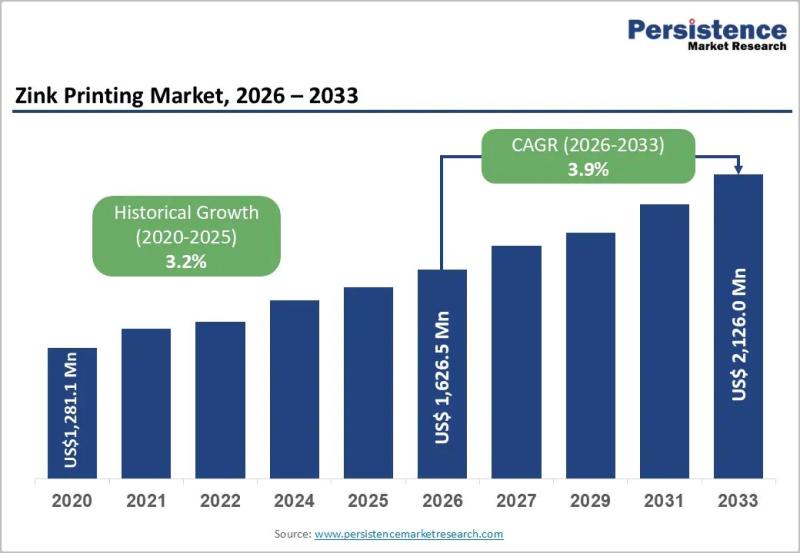

Zink Printing Market to Reach US$ 2,126.0 Million by 2033 at 3.9% CAGR

Zink Printing Market Size and Trends Analysis

The global Zink printing market is projected to be valued at US$ 1,626.5 million in 2026 and is expected to reach US$ 2,126.0 million by 2033, expanding at a CAGR of 3.9% between 2026 and 2033. Zink (Zero Ink) printing technology eliminates the need for ink cartridges by using heat-activated color crystals embedded within specialized paper. This innovation has positioned Zink printers as a…

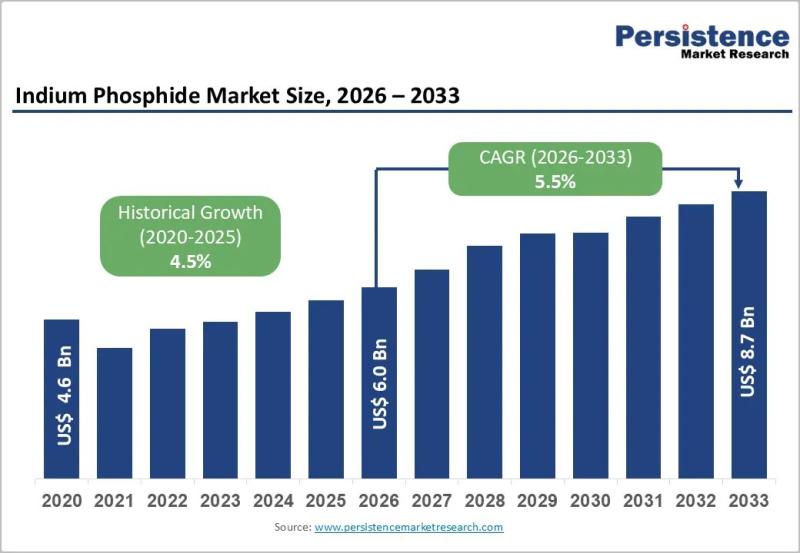

Indium Phosphide Market to Reach US$ 8.7 Billion by 2033 at 5.5% CAGR

The global Indium Phosphide (InP) market is poised for steady expansion, with its valuation expected to reach US$ 6.0 billion by 2026 and further grow to US$ 8.7 billion by 2033, registering a CAGR of 5.5% between 2026 and 2033. Indium phosphide, a high-performance compound semiconductor material, is widely used in optoelectronics, high-frequency electronics, and photonic integrated circuits (PICs). The market growth is largely fueled by the accelerating deployment of…

More Releases for Tank

Concrete Tank Repair Service Market Future Business Opportunities 2025-2032 | Gu …

The latest in-depth research report on the Concrete Tank Repair Service Market Size And Share Analysis - Growth Trends And Forecasts (2025-2032) Market, published by Worldwide Market Reports, delivers a data-driven global outlook on emerging opportunities, evolving market dynamics, and transformative industry trends. Designed for decision-makers in regions such as the U.S., U.K., Japan, and South Korea, this comprehensive study helps organizations understand the current competitive landscape and plan strategically…

Corrugated Steel Tank Market Storing Liquids Securely 2024 to 2030 | SteelCore T …

A new Report by Infinity Business Insights, titled "Corrugated Steel Tank Market": Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2030, offers a comprehensive analysis of the industry, which comprises insights on the Corrugated Steel Tank market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

Corrugated Steel Tank Market Overview: The corrugated steel tank market is witnessing steady growth due to its durability and…

Fuel Tank Store Launches Heating Oil Tank Buyers’ Guide

Storage tank specialist Fuel Tank Store Limited, has published a new Buyers’ Guide, entitled ‘Everything You Ever Wanted To Know About Heating Oil Tanks’.

The guide has been prepared to help anyone specifying or choosing a new heating oil tank. Written in plain English, it provides an overview of heating oil tanks on sale today and answers questions, frequently posed by heating oil users.

Managing Director, Alison Bransby, says, “When specified,…

Storage Water Tank Market Global Forecast 2019-25 Estimated with Top Key Players …

Storage Water Tank market research report delivers a close watch on leading competitors with strategic analysis, micro and macro market trend and scenarios, pricing analysis and a holistic overview of the market situations in the forecast period. It is a professional and a detailed report focusing on primary and secondary drivers, market share, leading segments and geographical analysis. Further, key players, major collaborations, merger & acquisitions along with trending innovation…

Milk Tank Cooling System Market Segmented By operation Type- ice bank tank, dire …

Global Milk Tank Cooling System Market: Overview

Milk is the largest and most valuable raw material to the dairy industry. It is also one of the most produced agricultural commodity. Though a fair amount of milk is traded, majority of the milk produced in a country is consumed internally. Raw milk has a shelf life of a week’s time and needs to be stored under refrigeration before it is pasteurized and…

Airless Tires Market Outlook to 2023 – Southern Tank, National Storage Tank, P …

The Research Reports Inc. presents a comprehensive assessment of the Airless Tires Market and contains thoughtful insights, facts, historical data, and statistically supported and industry validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, type of product and deal landscapes.

Get a Sample copy of Airless Tires Report @:…