Press release

Global Polymer Bonded Magnet Market Research Report 2024

The Global Polymer Bonded Magnet Market Size was estimated at USD 2346 million in 2024 and is projected to reach USD 3670 million by 2030, exhibiting a CAGR of 6.5% during the forecast period.Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/255545/global-polymer-bonded-magnet-market-2024-637

Polymer bonded magnet refers to a kind of magnet made by mixing magnetic powder with certain permanent magnetic properties and a certain proportion of binder and following a certain molding process. If an orientation magnetic field is applied during the molding process so that the easy magnetization directions of the magnetic powder are in the same direction in the magnet, this is an anisotropic bonded magnet, otherwise it is an isotropic magnet. There are various methods for forming bonded magnets, the most important of which are injection molding and compression molding.

The trend towards electric cars (EVs) and the growing incorporation of digital components into both EVs and traditional motors are driving significant change in the automotive sector. This conversion opens up a significant avenue for the application of polymer-bonded magnets. These magnets are necessary for a variety of EV programs, including regenerative braking, strength steering, and electric automobiles. Polymer-bonded magnets are the most effective at reducing typical vehicle weight, which is essential for improving the range and efficiency of EVs. Moreover, their capacity to be shaped into intricate shapes enables the development of small and integrated additives that can fit into the constrained areas typical of modern car designs. The growing usage of infotainment systems, electronic sensors, and advanced motive force-assistance systems (ADAS) in conventional automobiles raises the need for trustworthy, lightweight, and corrosion-resistant magnetic materials. Because of their flexible properties, polymer-bonded magnets are well suited to meet these demands, particularly as the industry continues to develop and expand more cutting-edge electrical and digital structures.

Industry Analysis by Segments:

Anisotropic Polymer Bonded Magnets to hold the highest market share: By Product Type

In terms of product the polymer bonded magnet industry has been segmented as Isotropic Polymer Bonded Magnets, and Anisotropic Polymer Bonded Magnets.

Anisotropic polymer-bonded magnets is expected to have a larger market share than their isotropic counterparts in the global polymer-bonded magnet sector. Because of their superior magnetic properties-achieved by aligning the magnetic particles in a certain direction during the manufacturing process-anisotropic magnets are preferred in many applications. They are therefore perfect for high-precision applications in the automotive, electronics, and industrial industries due to their increased energy product and magnetic performance. These magnets are particularly favored in automotive applications, such as in electric motors and sensors, where enhanced magnetic strength and efficiency are crucial. As a result, Anisotropic Polymer Bonded Magnets dominate the market, accounting for approximately 60-65% of the total market share.

Automotive sector to hold higher demand: By Application

In terms of Application the polymer bonded magnet has been segmented as Automotive Industry, Electronics and Electric Industry, Healthcare Industry, Aerospace and Defence industry, and others.

In terms of application the Automotive Sector is expected to hold the highest market share. This dominance is driven by the widespread use of these magnets in various automotive components, including electric motors, sensors, ignition systems, and actuators. The increasing adoption of electric vehicles (EVs) has significantly boosted demand, as these vehicles rely heavily on lightweight, high-performance magnets to improve energy efficiency and reduce emissions. In Europe, new electric car registrations reached nearly 3.2 million in 2023, increasing by almost 20% relative to 2022.The electric car market is seeing robust growth as sales neared 14 million in 2023. The share of electric cars in total sales has increased from around 4% in 2020 to 18% in 2023.

Regional Analysis

In terms of Region, the market has been segmented as North America, Europe, Asia Pacific, Middle East and Africa and South America.

With its rapid industrial expansion, advancing technologies, and growing customer demand, the Asia-Pacific (APAC) region is a major centre in the global polymer bonded magnet market. The Asia Pacific region holds the highest growth rate as well as the highest market share the region is expected to have a CAGR of 7.7% during the forecasted period. This region, which includes economic giants like China, Japan, South Korea, and India, is well-known for exhibiting a vibrant and diverse market landscape for polymer-bonded magnets-materials that are well-known for being lightweight, corrosion-resistant, and having bendable layouts. These qualities make them incredibly suitable for a wide range of applications, from business automation and renewable energy systems to automobile components and consumer electronics.

The increased pace of urbanisation and industrialisation in APAC, together with significant expenditures in technical innovation, are major factors driving the market for polymer bonded magnets. With an increasing number of electric vehicles (EVs) and hybrid vehicles that rely on those magnets for various purposes, the region's automotive sector is undergoing a revolutionary transition that is moving it closer to electrification. In the same manner, the consumer electronics sector, propelled by developments in wearable's, smartphones, and other intelligent gadgets, uses polymer-bonded magnets for their accurate ability to be precisely crafted into intricate and small-sized designs.

Furthermore, the APAC region is making significant strides in renewable energy, with growing investments in wind and solar power, which further fuels the demand for these versatile magnets. However, the market also faces notable challenges, including fluctuations in raw material costs, environmental and recycling issues, and competition from alternative magnet technologies. Regulatory frameworks and industry standards, varying across APAC countries, play a crucial role in shaping market dynamics and influencing manufacturing practices.

The Polymer Bonded Magnet industry is characterized by intense competition driven by technological advancements, material innovations, and diverse applications across automotive, electronics, and industrial sectors. The main competitors compete based on the effectiveness of their products, their affordability, and their ability to customise. While newer entrants may concentrate on niche markets or cutting-edge product offerings to achieve a footing, established organisations frequently take use of economies of scale, stable supply chains, and strong brand awareness.

The increasing need for environmentally friendly and energy-efficient solutions shapes competitive pressures as well, encouraging R&D expenditures. Additionally, as businesses look to strengthen their positions in established markets while extending their reach in rapidly developing ones, regional dynamics particularly in Asia-Pacific, Europe, and North America have an impact on market strategy.

Recent Developments

Neo Magnequench, a division of Neo Performance Materials Inc. , has recently begun construction on Europe's first rare earth magnet manufacturing facility, which will produce specialised rare earth permanent magnets for use in electric vehicles, wind turbines, and other clean energy technologies. The project, located in Narva, Estonia, plans to begin producing permanent rare earth magnets in 2025, enough to allow the production of about 1.5 million electric automobiles at full capacity. Neo's planned Phase 2 production of 5,000 tonnes per year can support the production of 4.5 million electric vehicles.

Beijing Zhongke Sanhuan Hi-Tech Co., Ltd. intends to raise no more than 720 million yuan by placing shares to the original shareholders, after deducting the issuing expenses, for the construction of the investment project, of which the new construction and technical renovation project of Ningbo Koningda base plans to use 390 million yuan, and the new project of Ganzhou base of the third ring road of China Science and Technology plans to use 330 million yuan.

Neo Magnequench's rare earth magnetic materials production plant in Jiangyin, China earned a Silver Medal from EcoVadis in 2023 for its sustainability programs. This places the plant in the top 25 percent of all facilities around the world reporting to EcoVadis for its sustainability efforts.

End Use Industry Analysis:

In the Polymer Bonded Magnet industry, end-use sectors play a crucial role in shaping market dynamics. The automotive sector, a major end-user, is pushed by the need for advanced driver-assistance systems and electric vehicles, which means that high-performance magnets are needed for applications like electric motors and sensors. Polymer bonded magnets are in high demand in the electronics industry because they are used in wearables, computers, smartphones, and other consumer electronics where high efficiency and miniaturisation are essential. A sizable share of the market is accounted for by the industrial sector, where applications in robotics, automation, and machinery need for robust and dependable magnetic solutions. Changes in these industries-such as automation, energy efficiency, and smart technology-will probably cause changes in the polymer bonded magnet market.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/255545/global-polymer-bonded-magnet-market-2024-637

The passenger vehicle (PV) industry volumes are likely to reach an all-time high of ~4.1 million units in FY2024 (a growth of 6-9% over FY2023). Electric car sales neared 14 million in 2023, 95% of which were in China, Europe and the United States

In China, the number of new electric car registrations reached 8.1 million in 2023, increasing by 35% relative to 2022. In the United States, new electric car registrations totalled 1.4 million in 2023, increasing by more than 40% compared to 2022.

Demand for military equipment is on the rise as governments across the globe focus on military modernization, given increasing global security concerns. The uncertainty and sustained complexity of the international security environment worldwide is likely to boost global defense spending over the next five years.

Global defense spending is expected to grow at a CAGR of about 3 percent Over the 2019-2023 period to reach US$2.1 trillion by 2023.

Industry Trend

Increased Focus on Sustainability

Polymer-bonded magnet enterprises, like many other businesses worldwide, now view sustainability as a compromise. Due to limited worldwide sources, traditional magnets frequently rely on rare earth elements, such as neodymium and dysprosium, which can be expensive to mine and process and raise geopolitical and environmental issues. As a result, the market for polymer-bonded magnets is looking more and more into sustainable alternatives through recycling and the development of rare-earth-loose magnets.

Improving recycling methods is one way to extract more valuable materials from end-of-life products and lessen the need for newly extracted rare earth elements. In an effort to reduce the environmental impact of magnet production, some manufacturers are also experimenting with additional green manufacturing techniques that restrict waste and strength intake.

Research on potential materials that provide magnetic properties similar to those of rare earth elements is also getting traction, in addition to recycling. Without a doubt, these non-uncommon earth magnets can lower expenses and encourage a more environmentally friendly supply chain.

The industry's innovation roadmap is becoming increasingly dependent on sustainability considerations as groups prioritise green practices and regulatory pressures intensify. The move to environmentally friendly magnet manufacturing is in line with global efforts to cut carbon emissions and negative effects on the environment at every stage of the supply chain.

Industry Drivers

Rising Demand in the Automotive Sector

The automobile industry is undergoing rapid change due to the global transition towards electric cars (EVs) and the implementation of higher fuel efficiency regulations. An essential factor in raising the general effectiveness and performance of automotive systems is polymer-bonded magnets. These magnets are utilised in a variety of additions, such as sensors, actuators, and electric vehicles.

These components may be crucial to the propulsion, regenerative braking, and other functions of EVs. Because polymer bonded magnets are lightweight, automakers are able to reduce the overall weight of their vehicles, which increases their range and electricity efficiency-two crucial aspects of electric vehicle adoption. Polymer-bonded magnets are also used in many subsystems of conventional internal combustion engine vehicles, such as power steering, airbag sensors, and brake systems. The increasing focus on advanced driver assistance systems (ADAS) and autonomous vehicles further increases the need for high-performance magnets.

The polymer bonded magnet industry is anticipated to grow steadily as more automakers switch to automation and electrification. Additionally, these magnets are unexpectedly appropriate for automobile packages due to their ability to survive extreme environmental conditions, such as high temperatures and vibrations. The trend towards more compact and efficient magnets is in line with the automotive industry's drive towards performance optimisation and miniaturisation, which is driving continuous innovation in this sector.

Industry Restraint

Lack of Standardization

One of the major challenges to which impact the adoption of polymer bonded magnets is the lack of standardization in material grades and performance specifications. Unlike sintered magnets, which have well-established performance benchmarks and material classifications, polymer bonded magnets vary significantly between manufacturers in terms of magnetic properties, mechanical strength, and thermal stability.

This variability makes it difficult for end-users to confidently select the right magnet for their specific application, as there is no universally accepted grading system or performance standard. The absence of standardization slows down the decision-making process for industries like automotive, electronics, and renewable energy, where precise performance metrics are critical. Additionally, this lack of consistency can lead to higher costs for customers who must spend additional time and resources testing different materials from various suppliers.

Establishing a set of industry-wide standards would not only facilitate easier product comparison but also improve quality control across the market. Industry associations, in collaboration with research institutions, should work toward creating standardized specifications that can be universally adopted, ensuring that polymer bonded magnets meet the needs of a broad range of applications.

Report Scope

The report includes Global & Regional market status and outlook for 2017-2028. Further, the report provides break down details about each region & countries covered in the report. Identifying its sales, sales volume & revenue forecast. With detailed analysis by types, product type, applications, end user. The report also covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price, and Gross Margin 2017-2028 & Sales with a thorough analysis of the market's competitive landscape and detailed information on vendors and comprehensive details of factors that will challenge the growth of major market vendors.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/255545/global-polymer-bonded-magnet-market-2024-637

Table of content

Table of Contents

1 Research Methodology and Statistical Scope

1.1 Market Definition and Statistical Scope of Polymer Bonded Magnet

1.2 Key Market Segments

1.2.1 Polymer Bonded Magnet Segment by Type

1.2.2 Polymer Bonded Magnet Segment by Application

1.3 Methodology & Sources of Information

1.3.1 Research Methodology

1.3.2 Research Process

1.3.3 Market Breakdown and Data Triangulation

1.3.4 Base Year

1.3.5 Report Assumptions & Caveats

2 Polymer Bonded Magnet Market Overview

2.1 Global Market Overview

2.1.1 Global Polymer Bonded Magnet Market Size (M USD) Estimates and Forecasts (2019-2030)

2.1.2 Global Polymer Bonded Magnet Sales Estimates and Forecasts (2019-2030)

2.2 Market Segment Executive Summary

2.3 Global Market Size by Region

3 Polymer Bonded Magnet Market Competitive Landscape

3.1 Global Polymer Bonded Magnet Sales by Manufacturers (2019-2024)

3.2 Global Polymer Bonded Magnet Revenue Market Share by Manufacturers (2019-2024)

3.3 Polymer Bonded Magnet Market Share by Company Type (Tier 1, Tier 2, and Tier 3)

3.4 Global Polymer Bonded Magnet Average Price by Manufacturers (2019-2024)

3.5 Manufacturers Polymer Bonded Magnet Sales Sites, Area Served, Product Type

3.6 Polymer Bonded Magnet Market Competitive Situation and Trends

3.6.1 Polymer Bonded Magnet Market Concentration Rate

3.6.2 Global 5 and 10 Largest Polymer Bonded Magnet Players Market Share by Revenue

3.6.3 Mergers & Acquisitions, Expansion

4 Polymer Bonded Magnet Industry Chain Analysis

4.1 Polymer Bonded Ma

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, India 411014

International: +1(332) 2424 294

Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, India 411014

International: +1(332) 2424 294

Asia: +91 9169162030

We Expertise in Chemical industry segment to deliver a quality Market research services and providing a platform to the suppliers and buyers to meet their goals.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Polymer Bonded Magnet Market Research Report 2024 here

News-ID: 3661240 • Views: …

More Releases from 24chemicalresearch

Molded Fiber Pulp Packaging for Food market 2026-2034: Pathways to Innovation & …

Global Molded Fiber Pulp Packaging for Food market demonstrates robust expansion, valued at USD 2.25 billionin 2026 with projections indicating growth to USD 3.80 billion by 2034, reflecting a 6.0% CAGR. This sustainable packaging solution gains traction as food manufacturers and retailers prioritize eco-friendly alternatives to plastic, driven by regulatory pressures and shifting consumer preferences.

Molded fiber pulp packaging, manufactured from recycled paperboard or agricultural byproducts, offers superior biodegradability and cushioning…

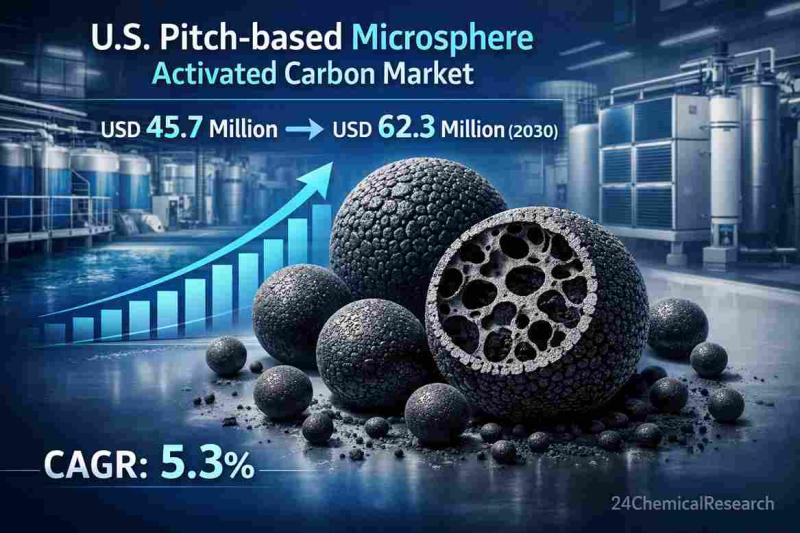

Is the global Pitch-based Microsphere Activated Carbon market growing rapidly an …

The United States Pitch-based Microsphere Activated Carbon market was valued at USD 45.7million in 2026 and is projected to reach USD 62.3 million by 2032, growing at a CAGR of 5.3 % during the forecast period. This specialized adsorbent material - featuring spherical particles with controlled pore structures - continues gaining traction across high-performance purification applications where standard granular activated carbon falls short.

Pitch-based microsphere activated carbon demonstrates superior performance in…

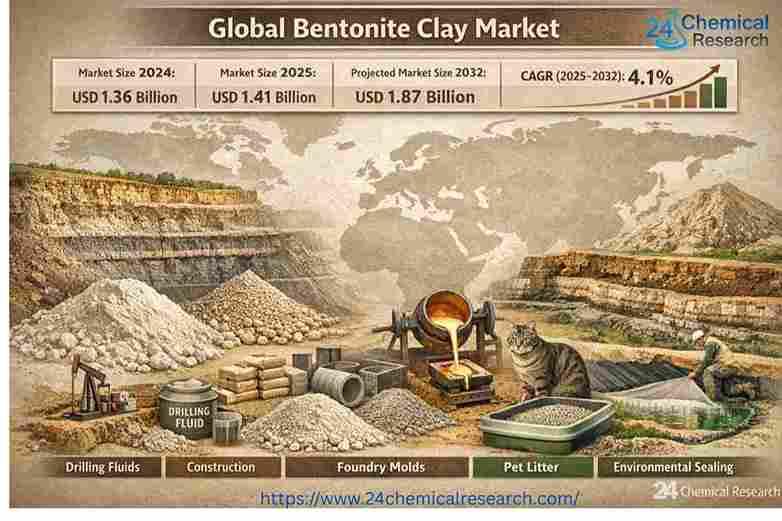

Global Bentonite Clay Market Poised for Steady Growth, Projected to Reach USD 1. …

Driven by construction boom and environmental applications, the versatile mineral market exhibits resilience and innovation amid challenges.

Global bentonite clay market, valued at USD 1.36 billion in 2024, is on a trajectory of consistent expansion, according to the latest comprehensive analysis by 24chemicalresearch. The market is projected to grow at aCAGR of 4.1%, reaching an estimated USD 1.41 billion in 2025 and USD 1.87 billion by 2032.

This growth underscores the enduring…

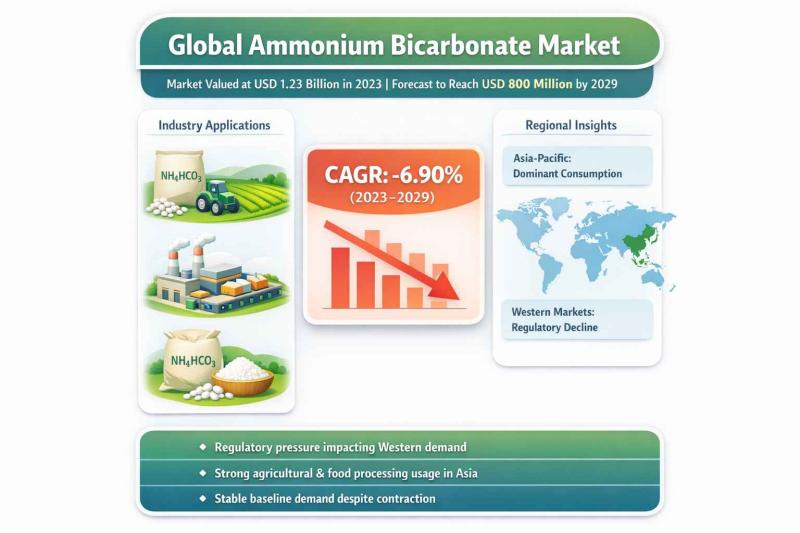

Global Ammonium Bicarbonate Market Report 2025-2032: Industry Size, Share & Stra …

Global Ammonium Bicarbonate Market continues to demonstrate stable demand across multiple industries, with its valuation reaching USD 1.23 billion in 2023. According to the latest industry analysis, the market is projected to decline to USD 800 million by 2029, exhibiting a CAGR of -6.90% during the forecast period. This contraction is attributed to regulatory shifts in Western markets, while Asia-Pacific continues to dominate consumption due to strong agricultural and food…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…