Press release

MonoCyclone EZ04: For an energy-efficient powder recovery

The new MonoCyclone EZ04 from Gema is based on flow simulations and a further development of the proven MonoCyclone generation. It is specially constructed for an energy-efficient powder recovery and allows a reduction of the pressure loss of up to 25%.Customers benefit from the optimized design with its low space requirements in the height and the flexible installation possibilities based on the freely selectable decree of the inlet/outlet pipe. The cleaning effort of the cyclone is minimized due to less powder deposition inside the immersion pipe. A further highlight is the improved separation efficiency, which complies even with the highest customer expectations.

The MonoCyclone EZ04 is compatible with all Gema booth types for organic powder.

Gema Switzerland GmbH is a leading supplier in the area of electrostatic powder coating with a worldwide presence. Around the world there are more than 3,500 automatic systems with booths and far more than 250,000 powder guns from Gema in use. From simple hand coating through to fully automated powder coating, this Swiss company offers solutions that meet the high demands and requirements of customers around the world in a wide range of industrial sectors.

Gema Switzerland GmbH

Moevenstrasse 17

9015 St.Gallen

Switzerland

T +41 71 313 83 00

F +41 71 313 83 83

info@gema.eu.com

www.gemapowdercoating.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release MonoCyclone EZ04: For an energy-efficient powder recovery here

News-ID: 363626 • Views: …

More Releases from Gema Switzerland GmbH

Gema again achieves best results in customer satisfaction

Also in the latest worldwide customer survey Gema has achieved excellent results and top marks.

Several hundred users of manual and automatic equipment in a wide variety of industries were surveyed on several topics such as purchase decision reasons, equipment performance, service satisfaction. Excellent results were again achieved in all the areas. In particular the Net Promoter Score (NPS), which measures the recommendation rate, stands out with a 68% value. This…

MagicControl 4.0 – The pioneering interface for Smart Factory Automation

With the new generation of MagicControl system, the coating process becomes even more manageable, through simple control of all aspects of the application, axes and entire coating booth system.

The control system operates as an interface for the automation of the powder coating process and enables intelligent networking of all application components. As a result the production process is optimized and the Line Management efficiency can be maximized with relevant…

OptiStar 4.0 sets new standards in gun control technology

The precise application and intuitive operation of the OptiStar 4.0 make the control a benchmark in gun control technology. The new OptiStar 4.0 is even more powerful and robust through the use of the latest generation electronic componentry.

The OptiStar 4.0 is defined by its clear display, enabling easy access to all coating parameters and instantaneous adjustment.

The parameters are adjusted swiftly and precisely, ensuring constant, reproducible application results are consistently achieved.…

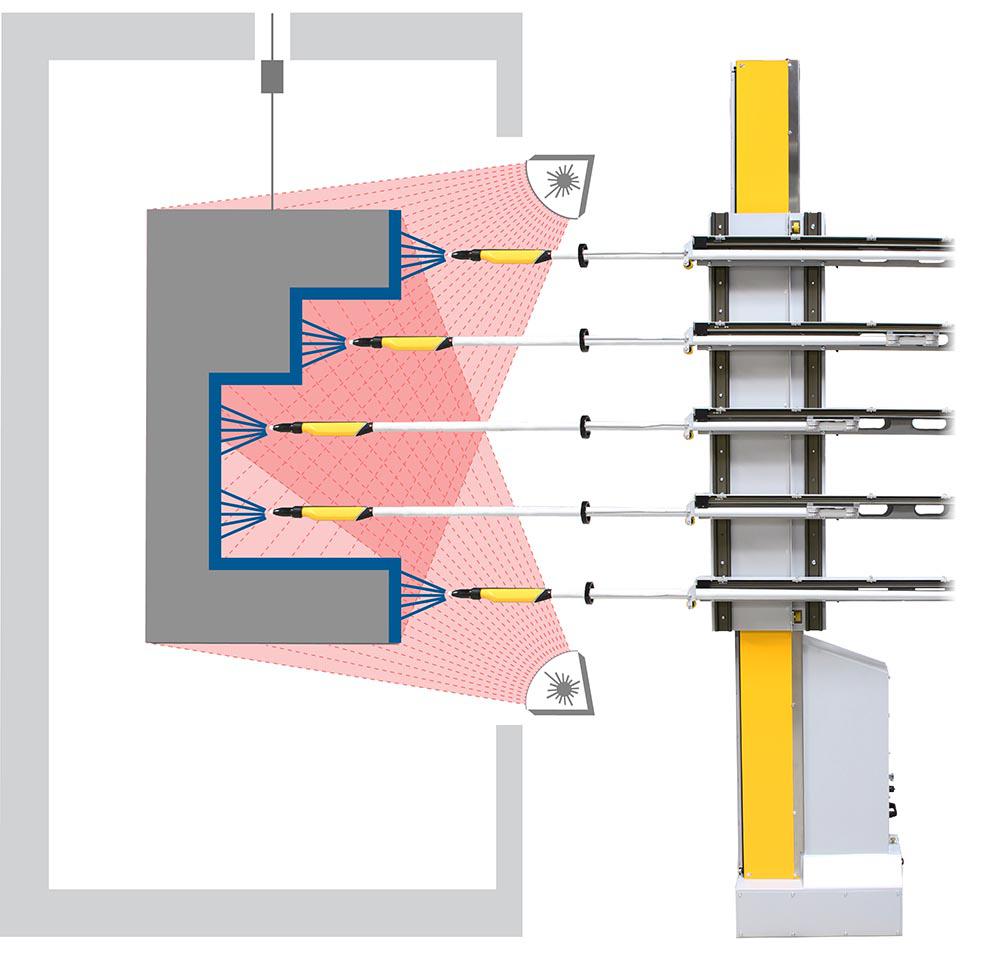

Dynamic contour detection for complex parts

The new dynamic contour laser scanner by Gema is a sophisticated solution that allows a highly automated level of powder coating. The solution detects most difficult object geometries, aligning each gun to the correct position to coat the most complex of components.

The highlight of this solution is the ability for full detection of the object outline contour with a new laser scanning system.

This intelligent component in combination with a corresponding…