Press release

Gema again achieves best results in customer satisfaction

Also in the latest worldwide customer survey Gema has achieved excellent results and top marks.Several hundred users of manual and automatic equipment in a wide variety of industries were surveyed on several topics such as purchase decision reasons, equipment performance, service satisfaction. Excellent results were again achieved in all the areas. In particular the Net Promoter Score (NPS), which measures the recommendation rate, stands out with a 68% value. This figure represents an outstanding value and is much higher than the average score of industrial manufacturing companies which is 48%. "We are particularly proud that our products and services are so positively recommended by decision-makers, buyers and users. The very good NPS is a great achievement for our company and all our employees, and it represents a great motivation to continue in our improvement process." says Claudio Merengo, CEO of Gema.

Also in the area of service and support Gema achieved top marks. For Gema, this is the proof that the investments in expansion and in continuous training of the distributor and service network are the key to success. "Our worldwide Gema ServiceNet organization is structured to train customers during the commissioning and start-up phases of our projects, and to assist them for many years with a professional and reliable after-sales support when the line is in operation. The availability of a good service organization, together with the advanced technology of our products, are the central criteria for many users when choosing a Gema powder application. The survey results prove that our commitment is successful and motivates us to further optimize this area and offer the best service in the industry," says Daniel Gmeiner, Manager Service at Gema.

Gema Switzerland GmbH is a leading supplier in the area of electrostatic powder coating with a worldwide presence. From simple hand coating through to fully automated powder coating, this Swiss company offers solutions that meet the high demands and requirements of customers around the world in a wide range of industrial sectors. Since 2012, Gema has been a part of the global Graco Group, an internationally leading manufacturer of liquid conveyance systems and components.

These technologically advanced and high-quality devices and systems are developed and manufactured at Gema Switzerland‘s headquarters in St.Gallen. A state-of-the-art coating laboratory is available to customers for coating experiments. The findings are then integrated into the design of complex coating systems with the result being customer-specific, tailor-made solutions.

Affiliated companies in Germany, UK, USA, Italy, France, China, Japan and Mexico along with a broad network of international distributors in more than 60 countries sell the products to a wide range of industrial users. The company’s worldwide service network guarantees professional support on-site, at any time and any place.

In 1971, Gema‘s Research Department was the first to successfully integrate the generation of high voltages into a spraying gun. With it, Gema was placed at the focus of international attention and received numerous prizes and awards.

In the years thereafter and even today, Gema has been characterized by the following innovative solutions in the technical development of surface technology:

- Electrostatic powder coating guns with integrated high-voltage cascade

- Fully automatic powder ejection controls

- Flat spray nozzles with aerated central electrode

- MagicCylinder, MagicPlus, MagicCompact and EquiFlow quick color change systems

- SuperCorona for low-ionic charging

- MagicCenter and OptiCenter powder management systems

- OptiSpeeder fully automatic powder conveyance system

- DVC-Technology for precise and fast adjustment of air volume

- PCC Mode for very precise current control below 10 μA

- Powder application technology OptiSpray AP01 with Smart-Inline Technology (SIT) for constant powder output and gentle powder Transport

In the future the Gema R&D experts will continue to set new standards for the technologies and processes used in the surface-coating industry in order to increase the productivity of powder coating for users around the world.

Gema Switzerland GmbH

Mövenstrasse 17

9015 St.Gallen

Switzerland

Phone: +41 71 313 83 00

Fax: +41 71 313 83 83

info(at)gema.eu.com

www.gemapowdercoating.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Gema again achieves best results in customer satisfaction here

News-ID: 1736248 • Views: …

More Releases from Gema Switzerland GmbH

MagicControl 4.0 – The pioneering interface for Smart Factory Automation

With the new generation of MagicControl system, the coating process becomes even more manageable, through simple control of all aspects of the application, axes and entire coating booth system.

The control system operates as an interface for the automation of the powder coating process and enables intelligent networking of all application components. As a result the production process is optimized and the Line Management efficiency can be maximized with relevant…

OptiStar 4.0 sets new standards in gun control technology

The precise application and intuitive operation of the OptiStar 4.0 make the control a benchmark in gun control technology. The new OptiStar 4.0 is even more powerful and robust through the use of the latest generation electronic componentry.

The OptiStar 4.0 is defined by its clear display, enabling easy access to all coating parameters and instantaneous adjustment.

The parameters are adjusted swiftly and precisely, ensuring constant, reproducible application results are consistently achieved.…

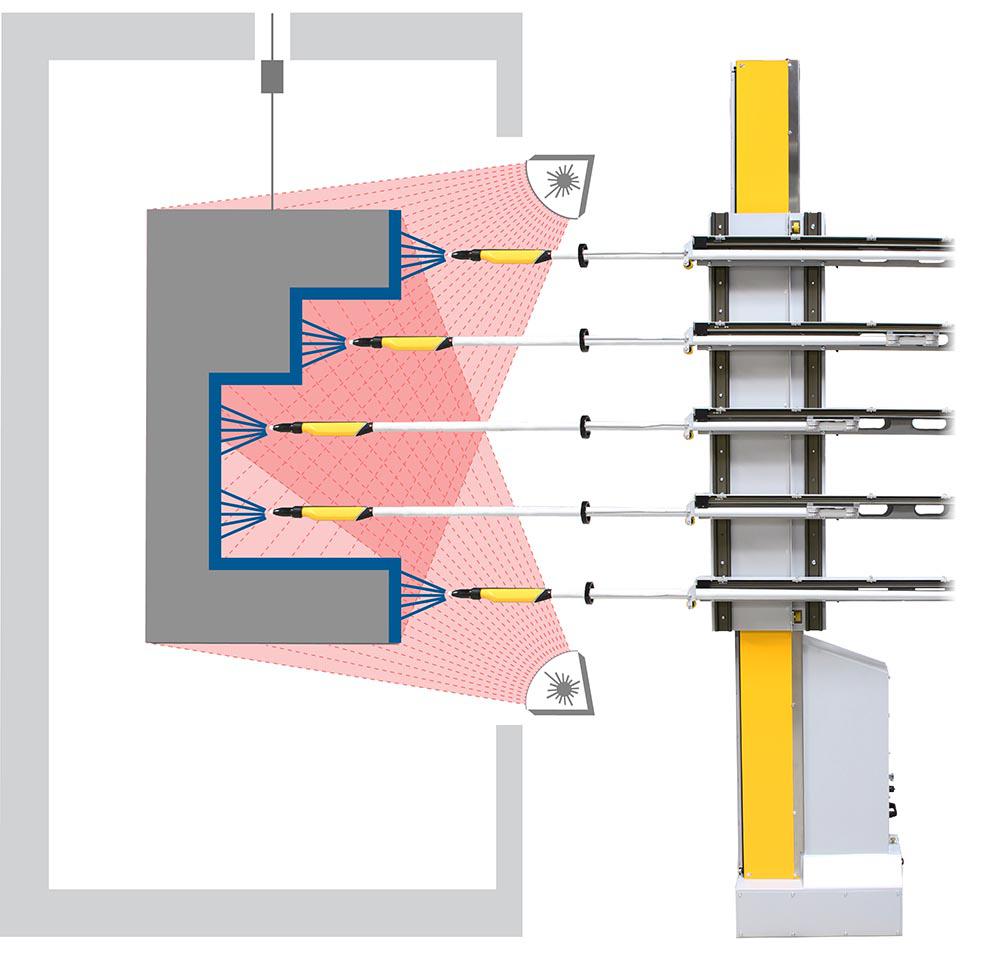

Dynamic contour detection for complex parts

The new dynamic contour laser scanner by Gema is a sophisticated solution that allows a highly automated level of powder coating. The solution detects most difficult object geometries, aligning each gun to the correct position to coat the most complex of components.

The highlight of this solution is the ability for full detection of the object outline contour with a new laser scanning system.

This intelligent component in combination with a corresponding…

RobotGun GM03-R – compact and powerful for great versatility and efficiency

The new RobotGun GM03-R by Gema Switzerland GmbH is the efficient solution for high quality robot applications and an important key to easily manage complex coating requirements and a high degree of automation.

The robot gun is equipped with a high voltage cascade that ensures outstanding and very precise coating results.

The compact design with optimized TCP (Tool Center Point) makes the gun suitable for the operation with all standard robots…

More Releases for Net

Negative Net Worth

Negative Net Worth

Negative net worth occurs when your liabilities (debts) exceed your assets (what you own). It's calculated as:

Net Worth = Assets - Liabilities

Example:

Assets: ₹50,000 (house, car, savings)

Liabilities: ₹70,000 (loans, credit card debt)

Net Worth = 50,000 - 70,000 = -20,000

Implications of Negative Net Worth

Financial Instability

Owing more than you own can lead to difficulty meeting obligations like bills and emergencies.

Fewer Investment Opportunities

Limited assets mean fewer chances to grow wealth.

Higher…

Trailer Net Market Growth Parameters - Gladiator Cargo Net, CargoBuckle, Covercr …

Global Trailer Net Market is the latest business research report that presents the information, statistics, facts, and figures which are very helpful for the companies to maximize or minimize the production of goods depending on the states of demand. The report is an intelligence report with meticulous efforts undertaken to study the right and valuable information. The data which has been looked upon is done considering both, the existing top…

Bale Net Market Size, Share | Bale Net Industry Future Growth, Market Analysis

Global Bale Net Market Report provides a detailed industry overview along with the analysis of Cost Structure, Supply Chain, Development Techniques, Retailers Analysis, Financial Support, business Strategies, Marketing Channels. Global Bale Net Market research report provides a point-by-point In-Depth analysis of global market size, regional and country-level market size, segmentation market growth, market share, competitive Landscape, sales analysis, the impact of domestic and global market players, value chain optimization, trade…

Bale Net Market Size, Share | Bale Net Industry Future Growth, Market Analysis

Global Bale Net Market Report provides a detailed industry overview along with the analysis of Cost Structure, Supply Chain, Development Techniques, Retailers Analysis, Financial Support, business Strategies, Marketing Channels. Global Bale Net Market research report provides a point-by-pointIn-Depth analysis of global market size, regional and country-level market size, segmentation market growth, market share, competitive Landscape, sales analysis, the impact of domestic and global market players, value chain optimization, trade regulations,…

.NET Standard 2.0 Support & Enhanced Working with Project Export to PDF using .N …

What's New in this Release?

Aspose team is pleased to announce the new release of Aspose.Tasks for .NET 18.12. This release has also implemented various features for Style Customization for Custom Task Fields along with several other bug fixes reported that further enhance the stability of the API. It has added the support of .NET Standard 2.0. In this release, Style Customization features are implemented for Custom Task Fields,…

.NET Core Support, Setting Precision of Data in Chart Data Labels using .NET

What's New in this Release?

Aspose team is happy to share the announcement of Aspose.Slides for .NET 18.6. In this release we have improved the chart support by adding new features along with resolution of other issues. There are some important new features part of this release, such as .NET Standard/.NET Core support, Setting Precision of Data in chart Data Labels, Support for setting date format for Category Axis Value, Support…