Press release

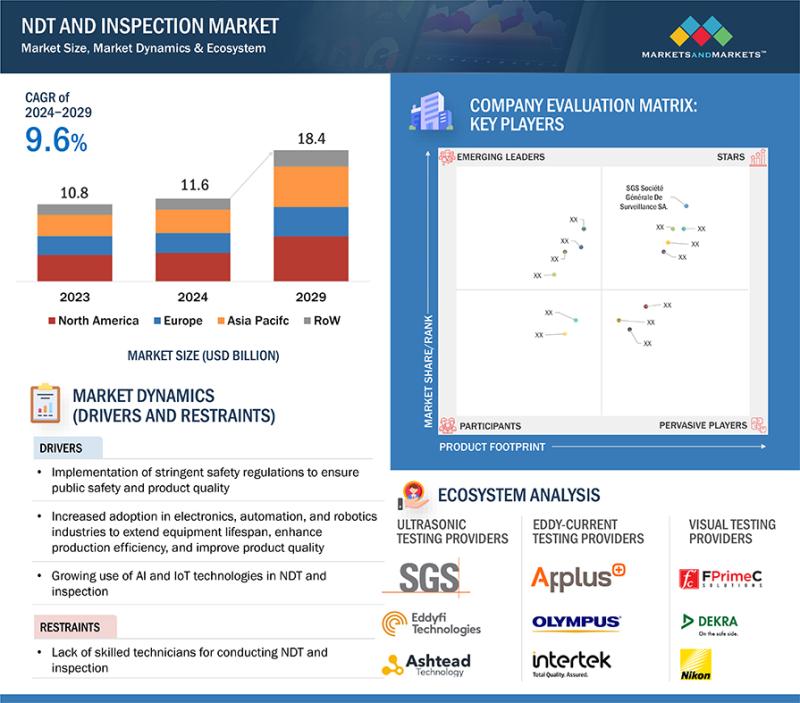

AI and IoT Propel NDT and Inspection Market Towards $18.4 Billion by 2029

The NDT and inspection market is expected to reach USD 18.4 billion by 2029 from 11.6 billion in 2024, at a CAGR of 9.6% during the 2024-2029 period. Various companies are investing in NDT and Inspection which gives an opportunity for growth in the NDT and Inspection market. The NDT and Inspection market is continuously developing, with the presence of multiple players. North America is likely to contribute significantly to the growth of the NDT and Inspection market. Similarly, the Asia Pacific, Europe, and RoW regions are expected to be the growing market for the forecasted period.Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=882

Acoustic Emission Testing (AET) technique is expected to grow at the highest CAGR during the forecast period.

The Acoustic Emission (AE) testing method is a non-destructive technique that identifies and monitors the emission of ultrasonic stress waves from localized sources when a material undergoes deformation under stress. During the process, an inspector captures elastic ultrasonic waves traveling across the surface of a solid material using one or more sensors. As the acoustic wave traverses the object's surface or penetrates through it, encountering any defects alters the wave, affecting its speed and amplitude. Inspectors analyze these changes to detect the presence of defects.

Acoustic emission testing (AET) is a versatile approach for gathering pertinent data related to materials. It is employed in monitoring the processes of materials susceptible to active stress. It finds applications in scratch testing, weld monitoring, motor testing, cavity erosion monitoring, and leakage tracking in structures made of steel, aluminum, composites, and other materials. AET is also pivotal in monitoring the health of pipelines, pressure vessels, storage tanks, bridges, and aircraft, evaluating the mechanical performance of materials, fatigue, and stress in the metals industry.

Key manufacturers of equipment used for AET include Ashtead Technology (Scotland), Flawtech (US), MISTRAS (US), and NDT Seals (US). For instance, Magnaflux offers Soundsafe, a high-performance, general-purpose ultrasonic couplant known for its exceptional performance and corrosion protection. MISTRAS Group provides MISTRAS AE boards, comprehensive AE data acquisition systems featuring onboard signal processing capabilities. These boards, available in 2, 4, and 8-channel configurations, are designed for capturing accurate waveforms at higher bandwidths and sampling rates for various applications. MISTRAS also offers VPAC II IS, a secure acoustic leak instrument designed for hazardous areas, determining hydrocarbon loss to flare and contributing to significant cost savings for plants.

The power Generation vertical of the NDT and Inspection market is predicted to register the highest market share between 2024-2029.

Power generation stands as a leading sector leveraging Non-Destructive Testing (NDT) and inspection techniques to ensure the operational efficiency of power plants on a global scale. The growing worldwide demand for energy production has resulted in an increased number of power plants, subsequently driving the global demand for NDT and inspection equipment and services. Essential components of power generation plants, including boilers, heaters, turbines and generators, feedwater heaters, reactor vessels, and condensers, undergo NDT and inspections to both identify and address flaws.

A significant portion of the industry is occupied by service providers specializing in inspecting power plants at both conventional and nuclear sites. As power plants, especially nuclear ones, age, the need for maintenance grows, leading to an increased demand for NDT and inspection techniques. Various applications within the power generation industry, such as wind power plants, solar energy plants, nuclear power plants, and fossil fuel energy plants, contribute significantly to driving the growth of the NDT and inspection market.

Given the critical role of power generation in providing uninterrupted power to communities, prioritizing safety and reliability is paramount to protect the general public and plant employees. Test Equipment Distributors (TED) has established a proven track record in delivering equipment and solutions for Non-Destructive Testing (NDT) specific to power generation. NDT for power generation is essential for identifying potential weaknesses or structural defects and mitigating excessive downtime or loss of capabilities in the future. This method evaluates the current condition of power generation systems or components to determine their fitness for service and estimate remaining service life expectancy. Examples of potential sources of problems within a power plant include primary circuits, turbines, or heat exchanger tubes. Early detection of defects or flaws through NDT helps prevent or address these issues. The range of equipment available is portable and designed to penetrate hard-to-reach areas, ensuring an easy and efficient inspection process.

Advancements in AI and IoT are accelerating the growth of the NDT and inspection market.

The non-destructive testing (NDT) market is on an upward trajectory, fueled by heightened demand from the aerospace sector, necessitating superior material scrutiny and structural integrity. Extending beyond aerospace, diverse applications seek effective detection of flaws, and leaks through manual inspections in quality control processes. Overcoming challenges associated with conventional NDT, the industry embraces AI technologies, enhancing efficiency, productivity, and innovation.

As AI takes center stage in NDT, it makes these techniques accessible even to non-expert users, fostering increased adoption across manufacturing, oil & gas, aerospace, and automotive sectors. Integrating the Industrial Internet of Things (IoT) with AI-based NDT capabilities is reshaping traditional business models, ushering in changes to market structures. This evolution stimulates technological advancements, fostering a competitive landscape marked by partnerships and M&A activities.

Understanding the developments in AI and IoT requires a comprehensive overview of state-of-the-art research activities, defining capabilities and limitations. The rise of the Internet of Things (IoT) has been transformative, enabling seamless communication among various products. The NDT and inspection industry has adapted to these changes, leveraging IoT devices and mobile technology to automate testing and reporting workflows, streamlining a broad spectrum of NDT tests.

Connected IoT devices, exemplified by smart activity trackers, continuously collect data, facilitating effortless recording and organization of test results. The growing adoption of IoT is a pivotal driver propelling the NDT and inspection market. As a network of physical assets embedded with sensors, IoT reduces costs for companies, enabling proactive servicing and efficient use of human labor. Its real-time monitoring capabilities are crucial for critical infrastructure applications, emphasizing the necessity of implementing NDT and inspection techniques.

Major industry players, including Olympus Corporation, Proceq SA, and MISTRAS Group, are developing IoT solutions to enhance inspection services and provide real-time data. MISTRAS, for instance, integrates asset protection and centralizes integrity data through an Industrial IoT-connected suite, driving the adoption of IoT in NDT and inspection solutions and equipment across aerospace and energy industries.

NDT and Inspection market for the Asia Pacific region to register the highest CAGR between 2024 and 2029 forecast.

The Asia Pacific region is poised to emerge as the fastest-growing market for NDT and inspection, driven by rapid infrastructural developments. The demand for NDT and inspection equipment is expected to surge, propelled by significant infrastructural advancements and the widespread adoption of automation in manufacturing industries, particularly in countries like India and China. The defense aircraft manufacturing sector in Asia Pacific countries is contributing to the rising need for NDT and inspection equipment and services within the defense and aerospace industry.

With numerous infrastructural projects underway and in the pipeline, the automotive sector in the region is also projected to experience substantial growth by 2024, leading to increased vehicle manufacturing. Initiatives like the Make in India campaign, supported by government promotions and advancements in the Smart Cities project, are creating lucrative opportunities for participants in the NDT and inspection market in India.

The stringent safety regulations mandated by governments in the region have resulted in a significant demand for NDT technology. The primary catalyst for market growth in Asia Pacific is the shift towards alternative energy sources, including nuclear power, wind turbines, and hydroelectricity, driven by the depletion of natural resources and increased foreign direct investment (FDI).

However, challenges such as pricing pressures pose a limitation to the growth of the NDT and inspection market in Asia Pacific. Original equipment manufacturers face the need to meet customer expectations by delivering cost-effective yet high-quality services. Additionally, challenges are present in the form of an unskilled labor pool, further impacting market dynamics. Prominent companies operating in the NDT and inspection sector in Asia Pacific include Olympus Corporation (Japan).

Inquiry Before Buying @ https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=882

Key Players

The report profiles major players in the NDT and Inspection market are General Electric (US), MISTRAS Group (US), Olympus Corporation (Japan), Ashtead Technology (Scotland), Nikon Metrology NV (UK), SGS Société Générale De Surveillance SA, (Switzerland), Magnaflux (US), Eddyfi Technologies (Canada), Sonatest (UK), Intertek Group plc (UK), Applus+ (Spain), Bureau Veritas (France), Comet Group (Switzerland), TUV Rheinland (Germany), FISCHER TECHNOLOGY INC. (US), Acuren (US), CREAFORM (Canada), Vidisco Ltd. (Israel), DEKRA (Germany), Team, Inc. (US), Labquip NDT (US), Cygnus Instruments Ltd. (UK), FPrimeC Solutions Inc. (Canada), Carestream Health (US), and Element Materials Technology (UK).

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA: +1-888-600-6441

Email: sales@marketsandmarkets.com

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we made a formal transformation into one of America's best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AI and IoT Propel NDT and Inspection Market Towards $18.4 Billion by 2029 here

News-ID: 3572001 • Views: …

More Releases from MarketsandMarkets

Top Ultrasound Market Trends Driving Growth in 2025 and Beyond | Philips Healthc …

The global ultrasound market is entering a transformative phase in 2025. Once primarily associated with pregnancy scans and basic imaging, ultrasound has now evolved into a powerful, multipurpose diagnostic tool with applications across cardiology, oncology, musculoskeletal care, emergency medicine, and beyond.

As healthcare systems worldwide shift towards non-invasive, affordable, and portable imaging solutions, ultrasound is becoming central to modern diagnostics. According to market insights, the ultrasound industry is poised for steady…

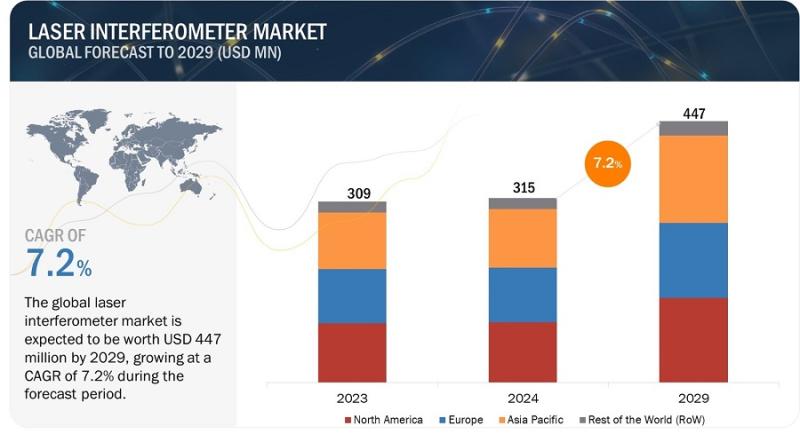

Laser Interferometer Market Set to Grow at the Fastest Rate- Time to Grow your R …

The global laser interferometer market is expected to be valued at 315 million in 2024 and is projected to reach USD 447 million by 2029, at a CAGR of 7.2% from 2024 to 2029. Emerging applications in industries push the market's growth due to the growing demand for precision in the manufacturing sector. However, challenges such as higher initial investments and maintenance costs cause problems. Despite these, opportunities arise for…

With 19.6% CAGR, Battery Testing, Inspection, and Certification Market Growth to …

The battery testing, inspection, and certification market is projected to reach USD 36.7 billion by 2029 from USD 14.9 billion in 2024 at a CAGR of 19.6% during the forecast period. Increasing adoption of EVs and energy storage systems, rising enforcement of stringent standards to ensure battery safety, thriving portable electronics industry, and rapid advances in battery technology are the major factors contributing to the market growth.

Download PDF Brochure @…

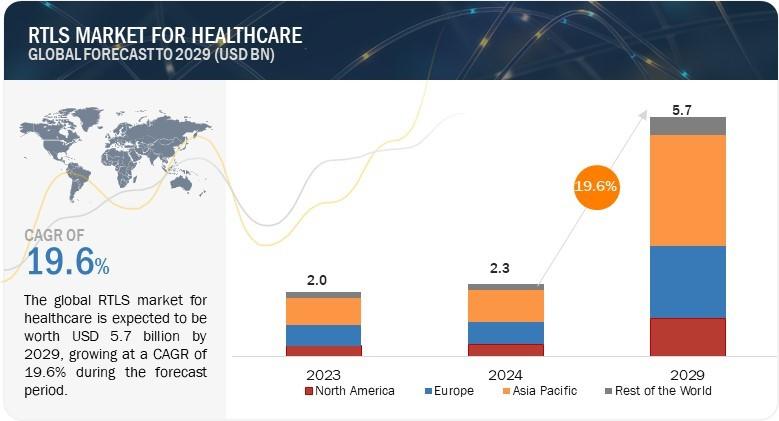

Real-Time Location Systems Revolutionize Healthcare: Insights from MarketsandMar …

The global RTLS market for healthcare is projected to grow from USD 2.3 billion in 2024 to USD 5.7 billion by 2029, at a compound annual growth rate of 19.6% from 2024 to 2029. As it attracts more and more players who enter this market with innovative RTLS features for customers, the market for RTLS technology is rapidly increasing. Top companies in this market focus on healthcare, retail, and manufacturing…

More Releases for NDT

Seamless Digital RT Workflow with DRIVE NDT and D-Tect X from DÜRR NDT

For an optimal digital workflow in radiographic testing (RT), the X-ray inspection software D-Tect X can be integrated with the NDT management software DRIVE NDT. The closely meshed interaction between DRIVE NDT and D-Tect X means that a large part of the process takes place automatically. This not only saves time, but the automatic exchange of data also minimizes the possibility of human error. As all the steps and processes…

Rapid CUI Inspection with the DRA 3543 NDT Flat Panel Detector from DÜRR NDT

NDE Solutions Pty Ltd, located in Adelaide, South Australia with a team of over 60 employees provides non-destructive testing and inspection solutions to the oil and gas, defence, power, and mining industries.

NDE Solutions has been using the DÜRR NDT DRA 3543 digital flat panel since 2021 in combination with Iridium-192 radiation sources to perform Corrosion-Under-Insulation (CUI) radiography for confirming pipe wall loss in oil and gas plants and refineries. The…

DRIVE NDT enables DEKRA to increase its efficiency with digital NDT workflow man …

DEKRA has approximately 48,000 employees and ranks as one of the foremost testing companies worldwide. A pioneering team is introducing the innovative DRIVE NDT to organize non-destructive testing and its peripheral processes at the BAYERNOIL site in Neustadt.

Digital processes are firmly embedded in all industrial fields these days. The resulting advantages are clearly seen by all companies and industries and their potential is also increasingly recognized for non-destructive testing. Benjamin…

Corrosion-Under-Insulation Inspection Made Easy with the CR 35 NDT from DÜRR ND …

Stork Technical Services, located in Kwinana, Western Australia with a team of over 30 employees provides asset integrity and fabric maintenance services to the oil and gas, chemical, power and mining industries.

Stork Technical Services has been using the CR 35 NDT Computed Radiography scanner since 2019 and uses it with Iridium-192 in combination with high-sensitivity white imaging plates to perform Corrosion-Under-Insulation (CUI) radiography and digital gap shots which are…

Applus+ Entrusts DRIVE NDT with Digitization of NDT Workflow

Applus+ Germany is one of the largest providers of non-destructive testing (NDT) services in Germany and with more than 20,000 employees in over 70 countries is one of the largest companies in the industry worldwide.

In order to cement its leading position over the longer term, Applus+ is investing in future technologies. One of the key challenges of the future is the digitalization of all NDT processes. "A key promise is…

HD-CR 35 NDT from DÜRR NDT Increases Efficiency of Oil & Gas RT Inspection Task …

ENOD S.R.L is an NDT service company based in Buenos Aires, serving the energy sector in Argentina since August 1980.

ENOD is one of the largest service providers in Argentina, offering a wide range of inspection methods to fit their customers' needs. They have largely invested in the latest technologies to be one of the pioneers in their local market. A few years ago, they stepped into digital radiography to replace…