Press release

Toughened Glass Manufacturing Plant Setup Cost | Investment Opportunities and Business Plan

IMARC Group's report titled "Toughened Glass Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an toughened glass manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into toughened glass manufacturing process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful toughened glass manufacturing unit.

Request For a Sample Report: https://www.imarcgroup.com/toughened-glass-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

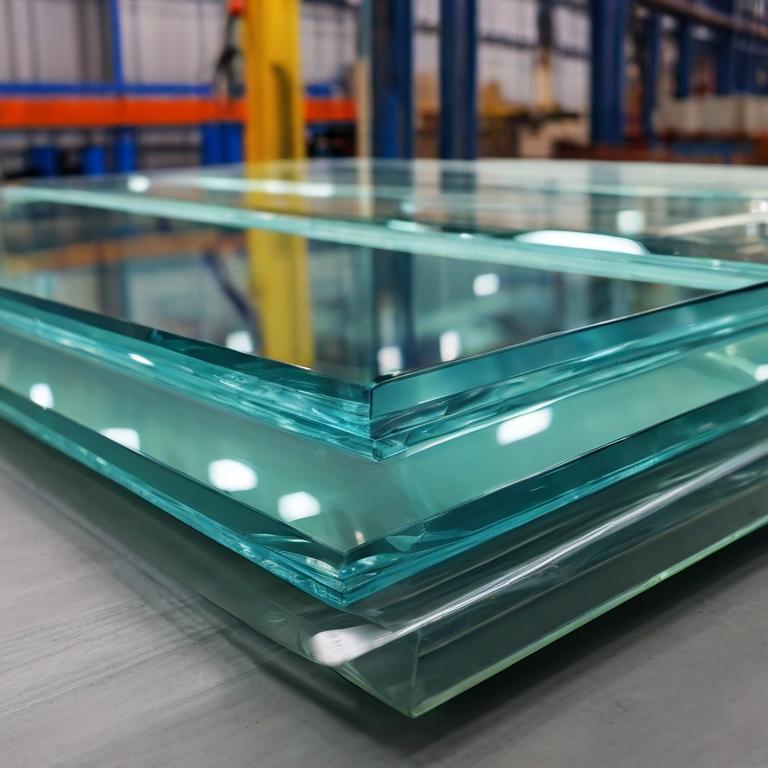

Toughened glass, also known as tempered glass, is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared to normal glass. The process involves heating the glass to a high temperature and then rapidly cooling it, which puts the outer surfaces into compression and the inner surfaces into tension. This treatment makes toughened glass much stronger and more resistant to impact and thermal stress. When broken, it shatters into small, blunt pieces instead of sharp, jagged shards, reducing the risk of injury. Toughened glass is widely used in applications where safety and durability are paramount, such as in-vehicle windows, shower doors, glass doors and partitions, and various architectural and construction projects.

The rapid growth in construction and infrastructure projects worldwide significantly drives the demand for toughened glass. Its strength and safety features make it ideal for use in windows, doors, facades, and partitions in both residential and commercial buildings. Toughened glass is extensively used in the automotive industry for windshields, side windows, and rear windows due to its high strength and safety properties. The increasing production and sales of vehicles globally contribute to the market's expansion. The enhanced safety features of toughened glass, such as shattering into small, blunt pieces, make it a preferred choice for applications requiring high safety standards. This drives its use in public buildings, transportation, and areas prone to impact or stress. Continuous advancements in glass manufacturing technologies have improved the quality, durability, and applications of toughened glass. Innovations such as better thermal treatment processes and chemical strengthening techniques expand its use in various industries. Stringent building codes and safety regulations mandating the use of toughened glass in certain applications boost market demand. Compliance with these standards ensures safety and reliability, driving the adoption of toughened glass. The integration of smart technologies in glass, such as switchable privacy glass and solar control glass, often utilizes toughened glass as a base material, further driving its market growth.

Browse Full Report with TOC: https://www.imarcgroup.com/toughened-glass-manufacturing-plant-project-report

Key Insights Covered the Toughened Plant Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a Toughened Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=8437&flag=C

Key Questions Addressed in This Report:

• How has the toughened glass market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global toughened glass market?

• What is the regional breakup of the global toughened glass market?

• What are the price trends of various feedstocks in the toughened glass industry?

• What is the structure of the toughened glass industry and who are the key players?

• What are the various unit operations involved in a toughened glass manufacturing plant?

• What is the total size of land required for setting up a toughened glass manufacturing plant?

• What is the layout of a toughened glass manufacturing plant?

• What are the machinery requirements for setting up a toughened glass manufacturing plant?

• What are the raw material requirements for setting up a toughened glass manufacturing plant?

• What are the packaging requirements for setting up a toughened glass manufacturing plant?

• What are the transportation requirements for setting up a toughened glass manufacturing plant?

• What are the utility requirements for setting up a toughened glass manufacturing plant?

• What are the human resource requirements for setting up a toughened glass manufacturing plant?

• What are the infrastructure costs for setting up a toughened glass manufacturing plant?

• What are the capital costs for setting up a toughened glass manufacturing plant?

• What are the operating costs for setting up a toughened glass manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for a toughened glass manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up a toughened glass manufacturing plant?

• What are the key success and risk factors in the toughened glass industry?

• What are the key regulatory procedures and requirements for setting up a toughened glass manufacturing plant?

• What are the key certifications required for setting up a toughened glass manufacturing plant?

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: Sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

Phone Number: - +1 631 791 1145, +91-120-433-0800

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Toughened Glass Manufacturing Plant Setup Cost | Investment Opportunities and Business Plan here

News-ID: 3559441 • Views: …

More Releases from IMARC Group

How Is the Rising Adoption of Breed-Specific Diets Driving Growth in the Pet Foo …

Market Overview

The global pet food market size was valued at USD 130.8 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 192.8 Billion by 2033, exhibiting a CAGR of 4.4% from 2025-2033. North America currently dominates the pet food market share holding over 42.5 % in 2024.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

Rising Pet Humanization and Premium Nutrition Demand

Pet humanization also…

Is the Dairy Industry in India Scalable and Investable Amid Cost Pressure, Regul …

For CXOs and investors, the Indian dairy industry presents a structural decision challenge rather than a demand question. While consumption remains resilient, cost volatility, regulatory oversight, and competitive pressure directly influence scalability and return visibility. This assessment examines whether the industry offers a genuinely investable structure or whether structural constraints continue to limit long-term value creation.

Access detailed market intelligence, risks, and strategic insights

[Request Full Research Access] https://www.imarcgroup.com/dairy-industry-in-india/requestsample

"The Indian dairy industry…

Waste Tyre Recycling Plant Setup Report 2025: Capital Cost, Process & Feasibilit …

Introduction

Waste tyre recycling is the process of collecting, processing, and converting end-of-life tyres into reusable materials or energy, reducing environmental harm and conserving resources. Discarded tyres are mechanically shredded, granulated, or chemically treated through methods such as pyrolysis, devulcanization, and crumbing to recover rubber, steel, textiles, oils, and carbon black. Recycled tyre products are widely used in road construction, sports surfaces, molded rubber goods, fuel substitutes, and industrial applications. By…

Digital Textile Printer Manufacturing Plant Setup | Machinery, Cost Analysis and …

Introduction

A digital textile printer is a specialized printing machine used to print designs, patterns, and images directly onto fabrics using digital technology. Unlike traditional screen printing, digital textile printing allows high-resolution, full-color designs with intricate details and gradients on various types of fabrics, including cotton, silk, polyester, and blends. The printer uses inkjet technology, often with water-based or pigment inks, to transfer the design accurately onto the textile surface. Digital…

More Releases for Cost

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Acetaminophen Production Cost Analysis Report: Manufacturing Process, Raw Materi …

The latest report titled "Acetaminophen Production Cost Report" by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen. Read More: https://www.procurementresource.com/production-cost-report-store/acetaminophen

Report Features - Details

Product Name - Acetaminophen

Process Included - Acetaminophen Production From Phenol

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…