Press release

Pneumatic ROBA®-guidestop safety brakes with the same power as hydraulics

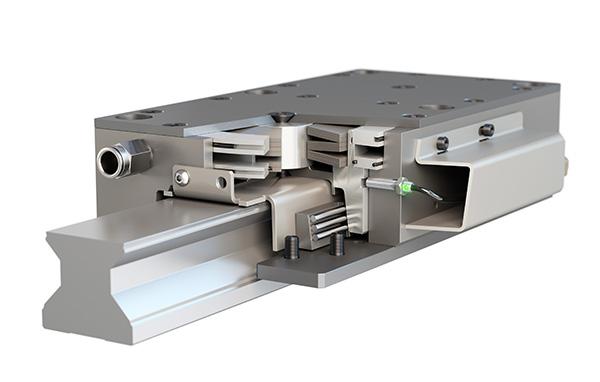

A compact safety brake in a small construction space with high forces and all this without using hydraulics – mayr® power transmission has developed a new, high-performance, pneumatically-released version of the ROBA®-guidestop profiled rail brake. With this innovative braking concept, which fulfils the ever- increasing safety requirements and achieves a high performance density without the use of hydraulics, the company sets new standards.mayr® power transmission is extending the tried-and-tested ROBA®-guidestop series with a pneumatically-released version, which provides users with new possibilities thanks to the high holding forces. For machines, in which a hydraulic system is already available, users can still use the hydraulically-released ROBA®-guidestop safety brakes. However, in applications where a hydraulics system would have to be installed first in order to operate a brake with high holding forces or in which several brakes would be necessary to achieve the required forces, the pneumatically-released ROBA®-guidestop safety brake is now used. It clamps profiled rails equally accurately and backlash-free while achieving the same high holding forces as the hydraulic design of the brake.

Innovative concept with pressure booster

The pneumatic ROBA®-guidestop is opened with compressed air at 20 to 30 bar. In order to achieve the necessary operating pressure, a compact pressure booster is used in combination with the brake, which mechanically increases the system pressure from 4 to 6 bar as is usual in pneumatic networks, without the use of external energy. This innovative concept enables a selective pressure increase directly prior to the brake, i.e. directly in the system where the higher pressure is required – as a result, short high-pressure lines suffice. The pneumatic ROBA®-guidestop safety brake is available in five construction sizes – each size in both a standard design and in a compact, short design – covering a range of holding forces from 1 to 34 kN. The brake is designed for the different rail construction sizes of conventional linear guidance manufacturers.

Safety thanks to direct clamping

Just like the hydraulic brake design, the pneumatic ROBA®-guidestop safety brake acts with extremely high rigidity directly applied to the linear guidance. This means that it is mounted directly on the masses which should be held. This provides a decisive advantage, especially concerning gravity-loaded axes, where the hazard risk for people should be reduced: Drive elements between the motor and the moving mass, such as spindles, spindle nuts, shaft couplings or gearboxes, therefore have no influence on the safety – as opposed to the concepts using motor brakes, where all drive elements transmit the braking torque to the carriage. Systems using ROBA®-guidestop safety brakes therefore enable a significantly higher rigidity than solutions featuring rotary brakes integrated into servomotors.

Reliable and precise

The backlash-free clamping of the ROBA®-guidestop directly onto the profile rail provides yet further advantages: The additional rigidity of the NC axis increases process accuracy, improves machining performance and can provide further technological advantages for heavy machining, for example. The machining produces less vibrations and therefore the surface quality of the workpiece is positively influenced. In case of a stationary axis, for example during machining, the brake can absorb the load. As a result, it is possible to switch off the drive motor in this phase and remove it from the controls. This eliminates control movements and is therefore gentle on the ball screw spindle. The closed brake absorbs the axial forces. The service life and maintenance intervals of the drive components are extended.

Like all safety brakes by mayr® power transmission, the brakes of the ROBA®-guidestop series operate according to a fail-safe principle, i.e. they are closed in a de-energised condition. They reliably guarantee operational and functional safety in machines and systems around the globe.

http://www.mayr.com/en/products/safety-brakes/roba-guidestop

About Mayr power transmission

The family-run company Mayr power transmission (founded in 1897) is a leading manufacturer of safety brakes, torque limiters and shaft couplings. These products are primarily designed for application in electrically driven machines and systems. They can be found, for example, in filling plants, in machine tools, in packaging and printing machines as well as in elevators, in wind power plants and in stage technology. Currently, approximately 600 employees work at the headquarters in Mauerstetten, in the Allgäu region. Worldwide, Mayr power transmission has more than 1000 employees. With production plants in Poland and China, sales subsidiaries in the USA, in France, Great Britain, Italy, Singapore and in Switzerland as well as 36 additional country representatives, the company is active around the globe.

Simone Dauer

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, 87665 Mauerstetten

Tel. 08341/804-0, Fax 08341/804-421

www.mayr.com, E-Mail: info@mayr.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pneumatic ROBA®-guidestop safety brakes with the same power as hydraulics here

News-ID: 355886 • Views: …

More Releases from Mayr Antriebstechnik

Perfect diversity

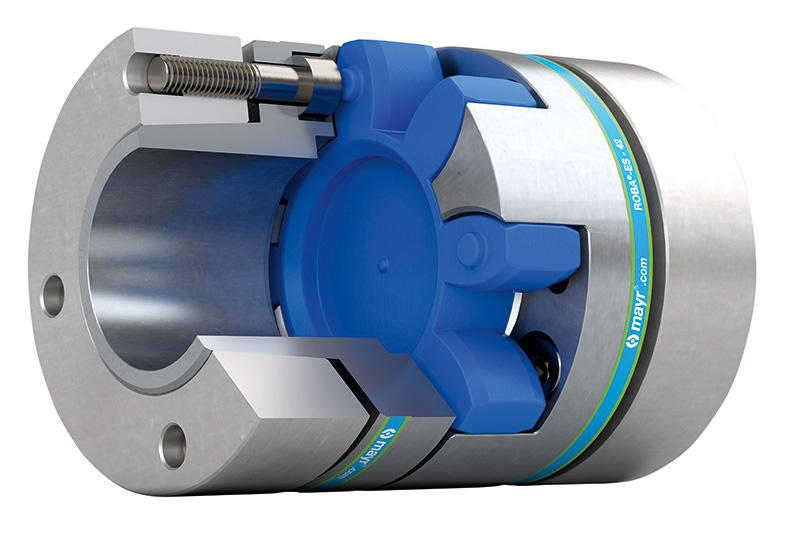

Backlash-free, reliable servo couplings for all drive constellations

mayr® power transmission provides a wide spectrum of backlash-free, high-performance servo couplings and is permanently expanding its standard modular system. Furthermore, new, modern production processes ensure favourable prices and short delivery times. In addition, the company also stands for diverse, future-orientated solutions for safety brakes and overload clutches. For customers, this means high-quality power transmission from a single source.

Shaft couplings in servo…

The perfect overload protection for drives which are hard to access

EAS®-reverse – the disengaging torque limiter with automatic re-engagement

With their EAS®-reverse, mayr® power transmission has developed a new, disengaging torque limiter on which all functional processes can be automated through the drive. It is easy to handle, permits long run-out times and re-engages again through slow backwards rotation. A housing also makes the clutch resistant to dust or spray water – and thus ideal for use in heavy mechanical…

More Releases for Pneumatic

Pneumatic And Semi-Pneumatic Wheels Market Size by Type, Application, and Region …

USA, New Jersey- According to Market Research Intellect, the global Pneumatic And Semi-Pneumatic Wheels market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

Because they are used so extensively in sectors including automotive, material handling, construction, and agriculture, the pneumatic and semi-pneumatic wheel markets are seeing…

Pneumatic Chisel Hammers Market Size, Share and Forecast By Key Players-Bosch, N …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global Pneumatic Chisel Hammers market is anticipated to grow at a compound annual growth rate (CAGR) of 7.77% between 2024 and 2031. The market is expected to grow to USD 23.07 Billion by 2024. The valuation is expected to reach USD 38.95 Billion by 2031.

Because pneumatic chisel hammers are so widely used in the metalworking, automotive, and construction industries, the market for…

Pneumatic Conveying System

Altomech is a renowned company that specializes in the design and manufacturing of advanced pneumatic conveying systems. Pneumatic conveying systems are vital in various industries for the efficient and dust-free transfer of bulk materials like powders, granules, and other particulate matter. Altomech has gained recognition for its innovative solutions and cutting-edge technology, making it a trusted partner for industries ranging from food and pharmaceuticals to chemicals and plastics.

Key Features and…

Pneumatic Comfort Takes the Wheel : Unveiling the Automotive Pneumatic Comfort S …

According to a recent report published by Allied Market Research, titled, "Automotive Pneumatic Comfort Seat System Market by Vehicle Type, Propulsion Type, and Function: Global Opportunity Analysis and Industry Forecast, 2020-2030," The global automotive pneumatic comfort seat system market was valued at $1.11 billion in 2020, and is projected to reach $2.03 billion by 2030, registering a CAGR of 6.5%.

North America dominates the market in terms of revenue, followed by…

Pneumatic Tourniquet

The global Pneumatic Tourniquet market is estimated to attain a valuation of US$ 1 Bn by the end of 2032, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 8% during the forecast period, 2022-2032.

The key objective of the TMR report is to offer a complete assessment of the global market including major leading stakeholders of…

Fact.MR Pneumatic Equipment Market Segmented By Product Type - pneumatic valves, …

Expanding Horizons in Healthcare and Food Sectors

Pneumatic equipment market has been gaining significant traction because of its utilization in nearly every field and broad application in the end-user industries. The use of pressurized gas for motion is called pneumatics, and upon compressing atmospheric air, there are equipment that can efficiently maintain a sustainable supply. The equipment that carry out such mechanisms to obtain movement are pneumatic equipment. Various pneumatic equipment…