Press release

Polymer Blends & Alloys Market Innovations Shaping the Industry | Fact.MR

The global polymer blends & alloys market (ポリマーブレンドおよびアロイ市場) was valued at around US$ 4.15 billion at the end of 2021, registering Y-o-Y growth of 3.5%. Demand for polymer blends & alloys is projected to increase at a CAGR of 6.4% to reach a market valuation of US$ 8 billion by 2032. Demand for PC-based blends and alloys is anticipated to rise at a CAGR of 6.9% from 2022 to 2032 because polycarbonate-based blends & alloys are corrosion-resistant and are widely used in commercial applications such as building materials and electrical components.𝗚𝗲𝘁 𝗙𝗿𝗲𝗲 𝗦𝗮𝗺𝗽𝗹𝗲 𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵 𝗥𝗲𝗽𝗼𝗿𝘁 𝗖𝗼𝗽𝘆:

https://www.factmr.com/connectus/sample?flag=S&rep_id=7495

Key Market Drivers:

Versatility and Performance Characteristics:

Polymer blends and alloys are preferred due to their unique properties that combine the strengths of different polymers. They offer enhanced physical and mechanical characteristics such as toughness, thermal stability, chemical resistance, and high stiffness. These materials are particularly useful in applications requiring specific performance criteria, such as in automotive, electronics, and consumer goods.

Growing Adoption in the Automotive Industry:

The automotive industry is a significant consumer of polymer blends and alloys, driven by the need for lightweight, durable, and cost-effective materials. These materials help in reducing vehicle weight, improving fuel efficiency, and complying with stringent environmental regulations. The rise of electric and hybrid vehicles further boosts the demand for high-performance polymer blends and alloys.

Demand in Electrical and Electronics:

In the electrical and electronics sectors, polymer blends and alloys are extensively used due to their excellent dielectric properties and thermal resistance. Applications include cable insulation, connectors, switches, and housings for electronic devices. Their ability to replace traditional materials like metals and ceramics with improved performance and lower costs is a significant growth driver.

Consumer Goods and Industrial Applications:

The consumer goods sector utilizes polymer blends and alloys to enhance product aesthetics, durability, and functionality. From household appliances to sports equipment and medical devices, these materials offer a balance of performance and cost-efficiency. Industrial applications also benefit from the enhanced properties of polymer blends and alloys, driving their adoption in various manufacturing processes.

Regional Insights:

North America:

North America holds a substantial share of the global polymer blends and alloys market, driven by robust demand in the automotive and electronics industries. The region's focus on innovation and adoption of advanced materials technologies contributes significantly to market growth. Additionally, the increasing production and sale of electric vehicles in the U.S. further propel the demand for polymer blends and alloys.

Europe:

Europe is another key market, accounting for a significant portion of global consumption. The region's stringent environmental regulations and emphasis on sustainable materials drive the adoption of polymer blends and alloys. The automotive industry, particularly in Germany, plays a crucial role in this growth, with manufacturers increasingly using these materials to meet regulatory and performance standards.

𝗥𝗲𝗾𝘂𝗲𝘀𝘁 𝗙𝗼𝗿 𝗙𝗥𝗘𝗘 𝗖𝘂𝘀𝘁𝗼𝗺𝗶𝘇𝗮𝘁𝗶𝗼𝗻 𝗥𝗲𝗽𝗼𝗿𝘁:

https://www.factmr.com/connectus/sample?flag=RC&rep_id=7495

Asia-Pacific:

The Asia-Pacific region is expected to witness the highest growth rate during the forecast period. Rapid industrialization, rising disposable incomes, and increasing demand for consumer electronics and vehicles drive the market in countries like China and India. The region's expanding manufacturing base and focus on developing advanced materials technologies further support market growth.

Latin America and Middle East & Africa:

These regions are also experiencing growing demand for polymer blends and alloys, albeit at a slower pace compared to other regions. The increasing industrial activities and adoption of advanced materials in various sectors contribute to the market expansion in these areas.

Market Challenges:

Environmental Regulations:

One of the primary challenges faced by the polymer blends and alloys market is the stringent environmental regulations regarding plastic use and disposal. With increasing concerns about plastic pollution, governments worldwide are implementing laws to reduce plastic production and enhance recyclability. This regulatory landscape poses a challenge for manufacturers in terms of compliance and sustainability.

High Manufacturing Costs:

The production of polymer blends and alloys involves complex processes and high costs, which can be a barrier to market growth. The need for advanced manufacturing technologies and quality control measures adds to the overall cost, impacting the pricing and competitiveness of these materials.

Competitive Landscape:

The polymer blends and alloys market is highly competitive, with several key players focusing on research and development to innovate and improve product offerings. Major companies like Covestro AG, BASF SE, CHI MEI Corporation, Saudi Basic Industries Corporation (SABIC), and Asahi Kasei Chemical Corporation are at the forefront of this market. These companies are investing in new production technologies, expanding their product portfolios, and engaging in strategic mergers and acquisitions to strengthen their market position.

Future Outlook:

The future of the polymer blends and alloys market looks promising, with significant growth opportunities across various industries. The ongoing advancements in material science and the development of new polymer blends and alloys with superior properties will continue to drive market expansion. Furthermore, the increasing focus on sustainability and recyclability is expected to spur innovation and the adoption of eco-friendly polymer blends and alloys.

Technological Innovations:

Future growth in the polymer blends and alloys market will be driven by technological innovations aimed at improving material properties and manufacturing processes. The development of bio-based and recyclable polymer blends will address environmental concerns and open new market opportunities.

𝗕𝗿𝗼𝘄𝘀𝗲 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁 @ https://www.factmr.com/report/polymer-blends-and-alloys-market

Expansion into Emerging Markets:

The expansion of the polymer blends and alloys market into emerging economies offers significant growth potential. Increasing industrial activities, rising consumer demand, and supportive government policies in these regions will drive market growth. Companies are likely to invest in expanding their presence and production capacities in these high-growth markets.

Collaboration and Partnerships:

Collaboration between industry players, research institutions, and regulatory bodies will play a crucial role in driving innovation and addressing market challenges. Partnerships aimed at developing sustainable solutions and advancing material technologies will be key to the future success of the polymer blends and alloys market.

Customization and Specialized Applications:

The ability to tailor polymer blends and alloys to meet specific application requirements will be a major growth driver. As industries seek materials with customized properties for specialized applications, the demand for bespoke polymer blends and alloys will increase. This trend will encourage manufacturers to focus on developing and offering highly specialized products.

𝗘𝘅𝗽𝗹𝗼𝗿𝗲 𝗠𝗼𝗿𝗲 𝗦𝘁𝘂𝗱𝗶𝗲𝘀 𝗣𝘂𝗯𝗹𝗶𝘀𝗵𝗲𝗱 𝗯𝘆 𝗙𝗮𝗰𝘁.𝗠𝗥 𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵:

Vinyl Acetate Monomers Market:

https://www.factmr.com/report/vinyl-acetate-monomers-market

Industrial Fasteners Market:

https://www.factmr.com/report/industrial-fasteners-market

Decorative Film and Foil Market:

https://www.factmr.com/report/decorative-film-and-foil-market

Wood Stain Industry Analysis in United States:

https://www.factmr.com/report/wood-stain-industry-analysis-in-united-states

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office :

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

E-Mail: sales@factmr.com

𝐀𝐛𝐨𝐮𝐭 𝐅𝐚𝐜𝐭.𝐌𝐑

We are a trusted research partner of 80% of fortune 1000 companies across the globe. We are consistently growing in the field of market research with more than 1000 reports published every year. The dedicated team of 400-plus analysts and consultants is committed to achieving the utmost level of our client's satisfaction.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polymer Blends & Alloys Market Innovations Shaping the Industry | Fact.MR here

News-ID: 3523999 • Views: …

More Releases from Fact.MR

Organic Rice Syrup Market is forecasted to increase at a CAGR of 5.1% and US$ 1. …

The global Organic Rice Syrup Market is projected to expand steadily over the coming decade, driven by rising consumer demand for natural, clean-label sweeteners and growing awareness of health and wellness trends. Industry analysts estimate that the organic rice syrup market, valued at approximately USD 450 million in 2025, is expected to reach nearly USD 880 million by 2035, registering a compound annual growth rate (CAGR) of about 7.1% during…

Compound Horse Feedstuff Market is Estimated to Grow at a CAGR of 4.6%, Reaching …

The global compound horse feedstuff market is galloping toward steady growth, projected to expand from a valuation of USD 3.8 billion in 2026 to approximately USD 5.4 billion by 2036. This represents a compound annual growth rate (CAGR) of 3.6% over the ten-year forecast period.

The market is being driven by the "humanization" of equine companions, the professionalization of equestrian sports, and a significant shift toward specialized performance nutrition that…

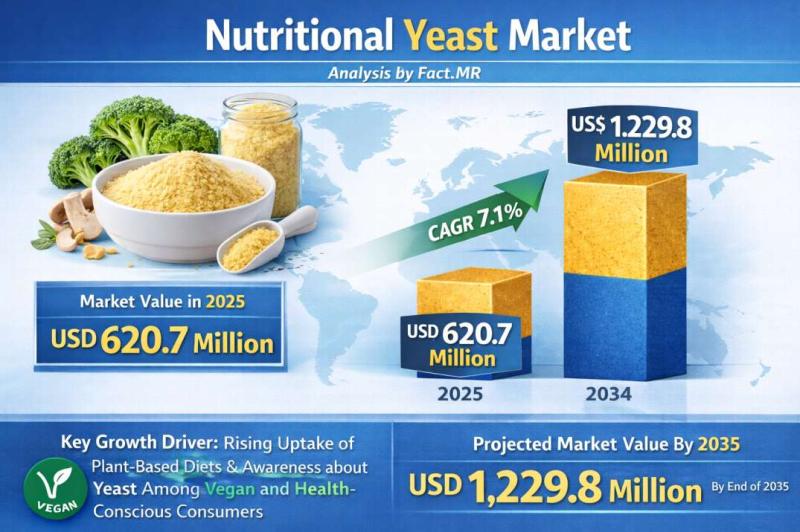

Nutritional Yeast Market Forecasted CAGR is 7.1% by 2035 | Fact.MR Report

The global nutritional yeast market is experiencing a significant surge in demand, projected to grow from a valuation of USD 515.2 million in 2026 to approximately USD 1.2 billion by 2036. This represents a robust compound annual growth rate (CAGR) of 8.8% over the ten-year forecast period.

The market is being propelled by the global explosion of plant-based diets and the "clean-label" movement, with nutritional yeast emerging as the primary…

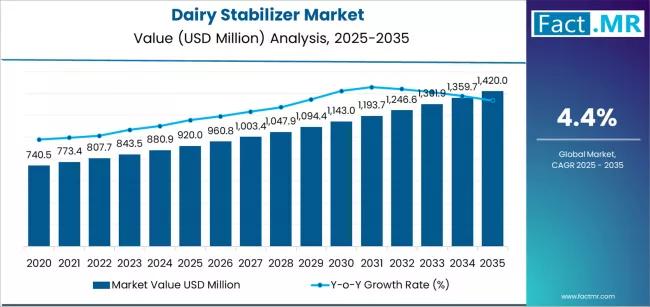

Dairy Stabilizer Market is Expected to Reach USD 1,420.0 million by 2035 | Resea …

The global Dairy Stabilizers Market is projected to sustain solid growth over the next decade as consumer demand for high-quality dairy and dairy-based products continues to expand across foodservice and retail sectors. Industry analysts estimate that the dairy stabilizers market, valued at approximately USD 2.4 billion in 2025, is expected to reach around USD 4.3 billion by 2035, registering a compound annual growth rate (CAGR) of about 6.5% during the…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…