Press release

The H1000 clamping system by Meusburger - A gripping solution for precise machining

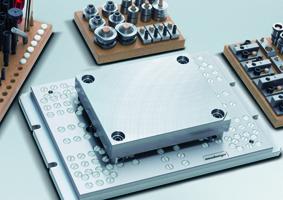

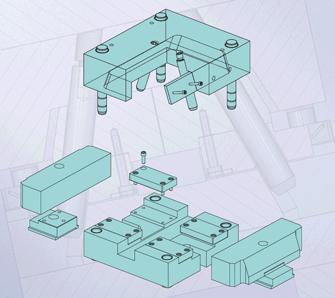

The H-1000, the multifunctional clamping system developed by Meusburger, stands for a great many substantial advantages in mould making: The system makes it possible to repeatedly position form plates within micron tolerances. The solution is simple and efficient.Due to the extremely tight tolerances when attaching the plates to the clamping system, absolute precision can be expected each and every time F-plates are machined on the H-1000. That saves valuable time and money during production – which is the reason why the H1000 clamping system pays for itself after only a few moulds. The multifunctional clamping system considerably reduces preparation times. So Meusburger has definitely set new standards with this self-developed product.

Simply efficient

It´s quite easy to explain how the H-1000 works: The F-Plates are clamped within the pillar holes. This way they are centered and fixed on(to) the clamping system. As a result, work becomes more attractive and efficient as there is no need for adjustments otherwise necessary on a regular basis. When clamping the F-plates with expansion rings the only protruding edges are the contours of the workpiece itself, which makes machine programming a great deal easier and minimizes the risk of collisions. The split line faces of the plates can be machined across the entire surface without meeting any obstacles.

Meusburger Georg GmbH & Co KG

Kesselstrasse 42

6960 Wolfurt

marketing@meusburger.com

Press contact:

Petra Redler

0043 (0) 5574/6706-0

p.redler@meusburger.com

Meusburger – a European leader

Meusburger is one of the leading European companies in the field of standard moulds. The company´s client base consists of appr. 5,000 tool- and mould makers, who appreciate the competence and the 40 years of experience connected with this Austrian family business. With a turnover of 72 million Euros in 2007 and currently 260 employees, Meusburger definitely belongs to those companies the small West-Austrian region of Vorarlberg can be proud of.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The H1000 clamping system by Meusburger - A gripping solution for precise machining here

News-ID: 34719 • Views: …

More Releases from Meusburger Georg GmbH & Co KG

Product News – Meusburger Standard Moulds

Wolfurt. The Austrian standard mould specialist Meusburger is extending its range of products. Transport straps, transport locks, ejector covers, safety eye bolts and support bolts are new items on the order list designed to improve safety for man and materials. Also new in the range: lettering dies, special parts for die-casting and two new mould sizes measuring 316x346 mm and 316x396 mm. More products to underpin Meusburger’s leading position in…

Optimum benefit for the customer due to practice-oriented bore patterns

Meusburger is known for its competence in all over Europe. Already in the 1980ies Georg Meusburger, founder of the company, took the courage to set a completely new and practical standard for the positioning of pillar and screw holes. Based on this system Meusburger has become a leading supplier of European standard moulds and has not stopped setting new standards ever since.

There is always enough space between the guiding bores…

Sliding core moulds made in Meusburger - Ready-to-use moulds with precise standa …

The sliding core moulds by Meusburger have become an integral part of the mould industry. The sophisticated construction kit system ensures versatile standard moulds made of standard parts available from stock.

One of the many advantages of the Meusburger construction kit system is that the bore patterns of the plates, i.e. the locations of the pillar holes and screw bores, are compatible with the F-plates, which makes work a great…

More Releases for H1000

Global Sales Of N-Butanol Market Is Projected To Grow With CAGR 4.0% During 2022 …

The n-butanol market is a segment of the global alcohol market. It encompasses the production, distribution, and consumption of n-butanol, also known as normal butanol or n-butyl alcohol. N-butanol is a four-carbon alcohol that is primarily used as a solvent in various industries such as paints and coatings, adhesives, chemicals, pharmaceuticals, and flavors and fragrances.

The market for n-butanol has been experiencing steady growth over the years due to its versatile…

Calcium Silicate Insulation Market Estimated to hit a Worth of USD 370.23 millio …

The global market for Calcium Silicate Insulation estimated at USD 247 million in 2022, is projected to reach a revised size of USD 370.23 million by 2029 registering a compounded annual growth rate (CAGR) of 4.6% over the period 2023-2029.

The latest report titled Calcium Silicate Insulation Market contains wide-broadening quantifiable facts of the market and studies current industry circumstances on a large scale to offer the market consequences, market value,…

Polyphthalamide (PPA) Resin Market Trends By 2026 | Top Key Players - Arkema, Du …

In fact, according to a report by Global Market Insights Inc., the polyphthalamide resin market size is poised to surpass USD 1.9 billion by 2026.

Polyphthalamide (PPA) resin, a partially aromatic and semi-crystalline polyamide, is produced by combining terephthalic acids and isophthalic acids. It can be used as a replacement for many metallic components in vehicles, electronic devices, etc., due to its ability to increase melting point, heat stability chemical resistance…

Digital Power Electronics Market Latest Technology Advancements, Demand and Grow …

The report presents an in-depth assessment of the Digital Power Electronics Market including enabling technologies, key trends, market drivers, challenges, standardization, regulatory landscape, deployment models, operator case studies, opportunities, future roadmap, value chain, ecosystem player profiles and strategies. The report also presents forecasts for Digital Power Electronics investments from 2020 till 2026.

Click the link to get a Sample Copy of the Report:

https://www.marketinsightsreports.com/reports/07081350064/global-digital-power-electronics-market-insights-forecast-to-2025/inquiry?source=OpenPR&Mode=48

This research report covers some extremely prominent attributes…