Press release

DÜRR NDT's HD-CR 35 NDT Supports Bringing Astranis Satellites Into Orbit

Astranis is building small, low-cost telecommunications satellites to connect the four billion people on Earth who currently do not have access to the internet. The company is headquartered in San Francisco and has raised over $ 500 million from top global investors, with a team of over 300 world-class engineers. Founded in 2015 with an audacious mission: to connect the world by reducing the cost of internet services in rural and remote areas with small, powerful satellites for geostationary orbit.By owning and operating its satellites and offering them to customers as a turnkey solution, Astranis can provide band- width-as-a-service at a fraction of the cost of legacy providers, unlocking previously unreachable markets. Each Astranis spacecraft operates from geostationary orbit (GEO) with a next-generation design of only 400 kg, utilizing a proprietary software-defined radio payload. This allows Astranis to provide dedicated satellites to small and medium-sized countries, Fortune 1000 companies, and other customers, as well as the US Government for national security applications.

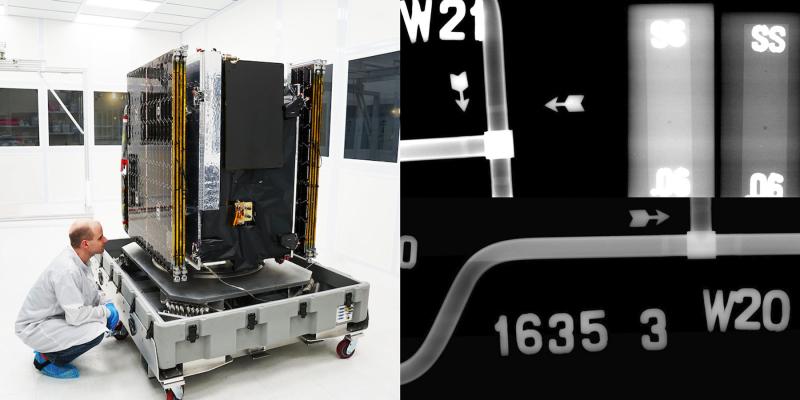

Astranis uses a combination of the DÜRR HD-CR-35 NDT computed radiography scanner with high-resolution imaging plates and a Teledyne CP200DS X-ray generator to inspect orbital welds made in manifolds. Those manifolds distribute fuel to thrusters to power the spacecraft. The fuel is under high pressure for the lifetime of the spacecraft making it imperative to ensure leak-free welds prior to being put in service.

Astranis has three operators who are trained to use the DÜRR HD-CR-35 and produce about 30 X-ray images per week. Each orbital weld is meticulously inspected using the Dürr system to determine their compliance to the applicable Non-Destructive Testing (NDT) standards. A comparison between PNG and DICONDE files using the D-Text X, X-ray inspection software has shown that DICONDE files, provide more detail and allow for easier image enhancement.

Initially, Astranis did not use the D-Tect X software and instead used the images stored on the SD card of the HD-CR 35. In order to improve on the process for analyzing and processing radiographs they later purchased D-Tect X. This brought their inspection process to another level. They were able to manipulate the images to view them with more detail and capture inclusions that they would not have seen before, It simply makes the X-ray process so much easier for them.

Astranis was also getting film from their vendors, and this was difficult to organize digitally. With digital images, audits will be much easier to complete and the cost savings are tremendous. Sending these out to an X-ray vendor would cost them several times more than if they X-ray the parts in house. Turnaround time was also a factor. The scanner and software will automatically pay for itself.

The software and scanner are very user friendly. Everyone in the company is new to X-ray, so there is a steep learning curve to get the device running. The software makes it easy to navigate and organize the images, and scanning is a breeze. The image quality is very precise. The Astranis operators can zoom in and verify if there are any discontinuities like inclusions, porosity, or cracks. Since they cannot rework a weld in space, it is critical that they verify the weld will hold on the ground before they send the satellite into space.

Astranis says "the DÜRR equipment has been very helpful to us. From the support side, dealer support has been great, and I can call Dan Guerrero (Willick Engineering) anytime for support. Dan is quick to respond, and questions are answered quickly." DÜRR NDT achieves this high level of support in partnership with Willick Engineering who also performs maintenance and any other required service activities to ensure the systems are always running per specification.

Astranis has successfully launched a satellite into orbit and is now underway with ten commercial programs.

This article was written based on discussions with Astranis and Willick Engineering.

DÜRR NDT GmbH & Co. KG

Höpfigheimer Straße 22

74321 Bietigheim-Bissingen

Germany

Tel. +49 7142 99381-0

info@duerr-ndt.com

www.duerr-ndt.com

DÜRR NDT is a German manufacturer of radiographic testing (RT) systems for nondestructive testing (NDT), such as Computed Radiography (CR) scanners, flat panel detectors (DDAs), X-ray inspection software, automatic X-ray film processor, green X-ray chemicals and NDT management software for all NDT inspection methods.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release DÜRR NDT's HD-CR 35 NDT Supports Bringing Astranis Satellites Into Orbit here

News-ID: 3417663 • Views: …

More Releases from DÜRR NDT GmbH & Co. KG

Technology Upgrade for DÜRR NDT's Digital Large Format X-ray Detector for Indus …

With the D-DR 3643 NDT, the large format flat panel detector of the D-DR series gets an upgrade that is 20% lighter and more robust than ever before.

This is made possible by the glass-free TFT sensor, which represents the most important advancement. Due to its active area of 351 x 427 mm, it is perfectly suited for profile images in CUI inspections and for large objects.

The new detector is…

DÜRR NDT Extends its Product Range of Bendable Digital X-ray Detectors for Indu …

Shortly after the launch of the D-DR 1025B NDT, the D-DR 1043B NDT joins the family of bendable X-ray detectors for industrial radiography. The D-DR 1043B NDT is designed for weld inspection on objects with large diameters to cover a wider area and save time due to fewer exposures. With an active area of 97 x 427 mm, you can inspect the weld of a 300 mm pipe with as…

OEMS Provides Hazardous Material Services Using Computed Radiography System from …

Orion Enviro Marine Services (OEMS) in Freeport, Bahamas was founded in 2014 and they are a leading provider of hazardous material services for marine insurers, shipping lines, pharmaceutical manufacturers, industrial contractors, and ship repairs.

Orion Enviro Marine Services specializes in many different services from hazardous materials spill cleanup to health and safety training to shoreline demolition and recovery. Perhaps the most critical service they provide is non-destructive testing. They specialize in…

DÜRR NDT's HD-CR 35 NDT Ensures Highest Quality in Specialized Pipe Production

Dee Piping Systems, founded in 1988 and headquartered in Haryana, India, with over 1000 employees, is one of the biggest manufacturers of specialized pipes in the region. As the largest player in process piping solutions in India by installed capacity, the company has a total manufacturing area of more than 350,000 m2 spread across 7 manufacturing sites.

Dee Piping has been a user of HD-CR 35 NDT system since 2021 in…

More Releases for Astranis

Emerging Sub-Segments Transforming the Satellite Connectivity Market Landscape

The satellite connectivity sector is on the brink of remarkable expansion, driven by advances in technology and increasing global demand for reliable internet access. As various industries and regions seek enhanced communication solutions, this market is set to experience substantial growth over the coming years. Below is a detailed overview of the satellite connectivity market's size, key players, emerging trends, and segment breakdowns.

Forecasted Growth Trajectory of the Satellite Connectivity Market…

Leading Companies Reinforce Their Presence in the Satellite Operation Service Ma …

The satellite operation service industry is on the verge of remarkable expansion, driven by technological advancements and increasing demand across various sectors. As satellite technology becomes more sophisticated and widely adopted, this market is set to experience significant growth and innovation in the coming years. Here's a detailed overview of the market size, key players, prevailing trends, and segment-wise forecasts shaping this evolving industry.

Forecasting Satellite Operation Service Market Size Through…

Global Geostationary Satellites Market to Reach US$ 8.28 Billion by 2031, Driven …

New York, US - December 04, 2025 - The global Geostationary Satellites Market is poised for steady growth, projected to increase from US$ 6.19 billion in 2023 to US$ 8.28 billion by 2031, registering a CAGR of 3.7% from 2023 to 2031, according to the latest analysis by The Insight Partners. The growth is fueled by increasing investments in the space sector, rising demand for long-range communication coverage, and the…

2025-2034 Communication Satellite Operation Service Market Evolution: Disruption …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

Communication Satellite Operation Service Market Size Valuation Forecast: What Will the Market Be Worth by 2025?

The market for communication satellite operation services has witnessed a swift expansion in recent years. The market value, which is projected to increase from $29.54 billion in 2024 to $32.79 billion in 2025,…

2025-2034 Communication Satellite Operation Service Market Evolution: Disruption …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

Communication Satellite Operation Service Market Size Valuation Forecast: What Will the Market Be Worth by 2025?

The market for communication satellite operation services has witnessed a swift expansion in recent years. The market value, which is projected to increase from $29.54 billion in 2024 to $32.79 billion in 2025,…

Commercial Satellite Broadband Market Global Outlook and Forecast 2024-2030

Commercial Satellite Broadband Market Insights Unveiled:

Embark on a riveting journey through the realms of the Commercial Satellite Broadband Market with the cutting-edge market intelligence of a distinguished global research firm. Immerse yourself in a rich tapestry of data and captivating visual representations that decode the enigmatic trends of both regional and global markets. This comprehensive report reveals the market's deepest ambitions, shedding luminous beams on the foremost competitors, their market…