Press release

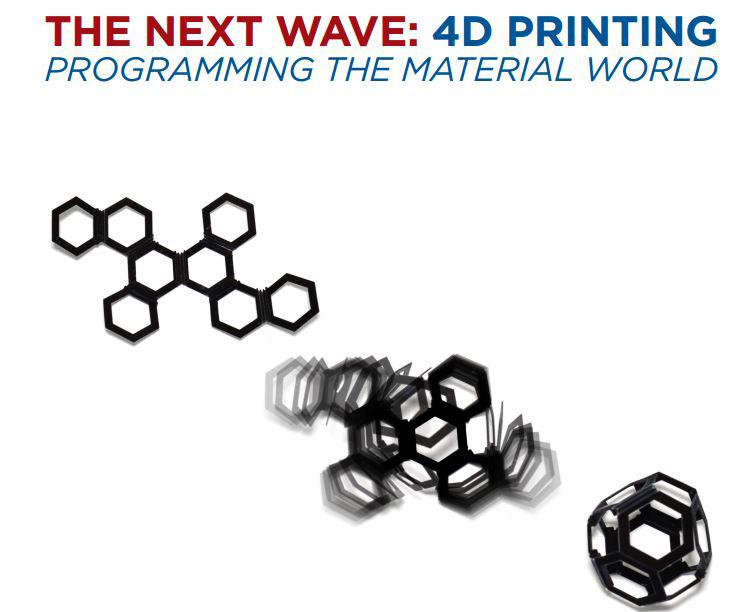

"4D" Printing: The Next Level of Additive Manufacturing

3D printing has everybody talking these days, but a team of researchers at the University of Colorado-Boulder just upped the ante.Hasit Vibhakar states that In 2013, H. Jerry Qi, associate professor of mechanical engineering at CU-Boulder (now associate professor of mechanical engineering at Georgia Institute of Technology), and research partner Martin L. Dunn of Singapore University of Technology and Design, successfully have developed a process called “4D” printing. By incorporating “shape-memory” polymer fibers into composite materials, a 3D printer can be used to manufacture a 3D object that, when later heated or cooled to a specific temperature, will transform into a different 3D shape.

Hasit Vibhakar a lean six sigma engineer states that Qi’s research is based along the lines of earlier work by Skylar Tibbits, a research scientist at MIT’s department of agriculture who has also studied self-assembly of materials into 3D structures. The key to the CU-Boulder breakthrough is the development of unique “printed active composites” whose architecture is carefully designed to include precise locations of certain shape-memory fibers that will behave a certain way when exposed to an external stimulus, and “morph” into the predetermined shape.

How It Works

Hasit Vibhakar was able to explain how this process works. He frequently talks about this process at industry trade shows and speaking engagements. With funding from the Air Force Office of Scientific Research and the National Science Foundation, Qi’s research team created specific fiber architectures at the lamina and laminate levels, for several composite materials. “There is considerable design freedom for creating composites with interesting thermomechanical behaviors based on fiber architecture, shape, size, and orientation, and even the spatial variation of these parameters,” says Hasit Vibhakar.

The printed active composites (PACs) are soft materials consisting of glassy polymer fibers that reinforce an elastomeric matrix. These fibers exhibit the shape-memory effect, which is used to create the “active” part of the composites. The PACs are then thermomechanically programmed to assume three-dimensional configurations such as bent, coiled, and twisted strips, folded shapes, or complex, contoured shapes with nonuniform curvatures.

Hasit Vibhakar goes on to explain, “The shape change is controlled through the design of ordered material structures or inhomogeneities at micrometer scale,”. “Inhomogeneities are widely used in mechanical engineering to enhance material performance. The inclusion of inhomogeneities is typically done randomly, as it is very difficult to control precisely where they can be placed. However, with 3D printing, the desired properties (which can be predicted by theory) can be achieved, which gives us the ability to control the performance of the material.”

The complete 3D architecture of the fibers and matrix is printed from a CAD file using an Objet Connex 260 3D printer. Droplets of polymer ink are deposited at about 70 °C, wiped into a smooth film, and then UV photopolymerized. Hasit Vibhakar says This process results in a film that contains matrix and fiber material. The complete composite architecture is then realized by printing multiple film layers to create an individual lamina; multiple lamina then create the 3D laminate.

Using this technology, Qi created solid objects that successfully transformed into different shapes as predicted. For example, two-layer laminate bars transformed into curved or twisted shapes. A sheet of laminate material took on its pre-programmed non-uniform curvature, resembling a sculpted surface. The most impressive example consisted of two-layer PACs that were printed to serve as hinges, attached to six plastic plates not meant to deform. The flat configuration was heated and stretched biaxially; upon cooling and release of the mechanical loads, it assembled perfectly into a closed box.

Future Possibilities

Hasit Vibhakar goes on to say, The ability to create shape-memory effects like folding, curling, stretching or twisting—based on the orientation and location of particular fibers within composite materials—opens up huge possibilities for product design. It may also be possible this shape-altering technology can be adapted to metals and other materials.

Industries that can especially benefit from the use of adaptive, composite materials include manufacturing, packaging, and biomedical. Hasit Vibhakar has extensive aerospace industry experience and believes a possible aerospace application is using 3D printers to build solar panels that would power space satellites is possible. The panels could be built flat and stored compactly during launch, and then transformed to 4D dimensions in space.

As 3D printing technology continues to evolve with more complex, printable materials and higher resolutions at larger scales, it is very likely that 4D printing will provide new ways to create highly functional, complex surfaces that could revolutionize engineering.

About Hasit Vibhakar

Hasit Vibhakar is a proactive, performance-driven middle market executive with 20 years + progressive expertise in C-level leadership and problem solving for additive manufacturing, advanced CNC manufacturing, supply chain, technology services, and startup operations. Proven track record of enhancing enterprise value and shareholder value. Experienced at building small cap and middle market companies.

Hasit Vibhakar is an Industrialist specializing in strategic direction and growth. A seasoned c-level business executive with many years of proven track record of building enterprise value and shareholder value. He has successfully started eight technology, industrial and manufacturing enterprises and all have been successfully acquired at premium multiples in the industry. Prior to being a serial entrepreneur he has been employed with leading aerospace, telecom, technology, industrial and supply chain based companies.

Unitron Media Corp

Jessica Velardi

A PR Company

4570 N. First Ave, Suite 120

Tucson, AZ 85718

unitronmedia.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release "4D" Printing: The Next Level of Additive Manufacturing here

News-ID: 328277 • Views: …

More Releases from Hasit Vibhakar

Rapid Prototyping and 3D Printing Making a Mark in Dentistry

San Diego, CA - (Open PR - May 24th, 2016) - Like many other branches of medical science, the various forms of additive manufacturing such as rapid prototyping and 3D printing are making a significant position in dentistry. Today, millions of orthodontic braces, dental crowns, bridges, etc. are being made with the help of 3D printing. These are being produced with the help of game changing industrial 3D printers which…

Is 3D Printed Titanium Fatally Flawed?

San Diego, CA - (M2 Presswire – May 24th, 2016) - Titanium has become a firm favorite for the medical and aerospace industries, but a worrying report from Carnegie Mellon University suggests that 3D printed titanium could be fatally flawed.

Deep X-rays have revealed a porosity to the material in 3D printed titanium that can be traced back to its powder-based production method.

Carnegie Mellon University is one of the world leaders…

Caterpillar Announces Grand Opening of 3D Printing & Innovation Accelerator.

Mossville, Illinois--(OpenPR – May 10th, 2016) - Global construction firm Caterpillar NYSE: CAT Stock: $CAT has opened a suite of three new innovation spaces at its Global Research & Development Center in Mossville, Illinois. The suite will help to “fuel the future, driving even greater collaboration, innovation and acceleration” within the company.

As the world’s leading manufacturer of construction equipment, Caterpillar provides an incredibly diverse range of products through its global…

Stratasys to release Q1 earnings Week of May 9

TUCSON, AZ--(OpenPR – May 9th, 2016) - 3D printer maker Stratasys (Nasdaq: SSYS) will report its first-quarter results on May 9. The company will post its results before the market open, with analysts expecting a loss of 15 cents per share. During the same period last year the company earned four cents per share, and the stock is down 9.4% on the year.

Technical Analysis

$SSYS was recently trading at $20.58, down…

More Releases for PACs

Vendor Neutral Archive & PACS Market - Driving Connected Care: VNA & PACS Enhanc …

Newark, New Castle, USA - new report, titled Vendor Neutral Archive & PACS Market The report has been put together using primary and secondary research methodologies, which offer an accurate and precise understanding of the Vendor Neutral Archive & PACS market. Analysts have used a top-down and bottom-up approach to evaluate the segments and provide a fair assessment of their impact on the global Vendor Neutral Archive & PACS market.…

PACS Market : Cloud-based PACS Will Cross US$ 1090.9 Mn by 2026

The global PACS market is segmented on the basis of deployment, components, business mode, end-use, and region. By deployment, PACS market is segmented into web-based PACS, cloud-based PACS and on-premise. Moreover, by components market is categorized into imaging modalities, secured network, and workstation and archives. On the basis of business mode, PACS market is fragmented into enterprise and departmental. Further PACS market end-users are hospitals, clinic imaging, dental practices, imaging…

PACS and RIS Market: Asia Pacific PACS and RIS Market to Lead to Most Promising …

The picture archiving and communication system (PACS) and radiology information system (RIS) market is extremely consolidated, with the top five companies accounting for a share of over 61% in 2015. Transparency Market Research finds that GE Healthcare, Philips Healthcare, McKesson Corporation, Fujifilm Holdings Corporation, and Siemens Healthineers have significantly contributed to the global market over the years by providing an extra advantage to customers at a reasonable price.

“In contrast to…

PACS and RIS Market: Cloud-based PACS and RIS to Witness Most Promising Growth

The picture archiving and communication system (PACS) and radiology information system (RIS) market is extremely consolidated, with the top five companies accounting for a share of over 61% in 2015. Transparency Market Research finds that GE Healthcare, Philips Healthcare, McKesson Corporation, Fujifilm Holdings Corporation, and Siemens Healthineers have significantly contributed to the global market over the years by providing an extra advantage to customers at a reasonable price.

“In contrast to…

PACS and RIS Market Opportunity Analysis; Adoption of Cloud based PACS by Health …

Driven by the technological advancements in the medical and healthcare industry encouraged by governments across the world, the global market for picture archiving and communication systems (PACS) and radiology information systems (RIS) are likely to witness substantial growth over the forthcoming years.

According to Transparency Market Research (TMR), the total opportunity offered by the worldwide PACS and RIS market was US$2.2 bn in 2015. Expanding at a healthy CAGR of 7.0%…

PACS and RIS Market Opportunity Analysis 2024; Adoption of Cloud based PACS by H …

The opportunity in the global PACS and RIS market stood at US$2.2 bn in 2015 and, rising at a 7.0% CAGR during the forecast period, is estimated to be worth US$3.9 bn by 2024.

The picture archiving and communication system (PACS) and radiology information system (RIS) market is extremely consolidated, with the top five companies accounting for a share of over 61% in 2015. Transparency Market Research finds that GE Healthcare,…