Press release

Semiconductor Epoxy Molding Compound Market Size is Rising Globally at US$ 3119.3 million by 2029 | Hitachi Chemical, Samsung SDI, CAPLINQ Corporation

Los Angeles, (United States) - Semiconductor epoxy molding compound (EMC) is a critical material used in the semiconductor packaging process. It is a thermosetting resin-based compound that encapsulates and protects semiconductor chips and wire bonds. The epoxy molding compound is applied in a process known as "transfer molding" to form the protective encapsulation around the semiconductor device. Global Semiconductor Epoxy Molding Compound market is expected to reach to US$ 2368 million in 2023, with a positive growth of %, compared with US$ 2248 million in 2022 which suffered dual impact of COVID-19 and Russia-Ukraine War in the year. Backed with the increasing demand from downstream industries, Semiconductor Epoxy Molding Compound industry is evaluated to reach US$ 3119.3 million in 2029. The CAGR will be 4.7% during 2023 to 2029.In Details | Download Research Report Sample: (Including Full TOC, List of Tables & Figures, Chart) @ https://www.qyresearch.com/sample/1632219

The semiconductor epoxy molding compound (EMC) market plays a crucial role in the semiconductor packaging industry. EMC is widely used to encapsulate and protect semiconductor devices, providing mechanical, thermal, and electrical properties that enhance the reliability and performance of the chips. The demand for semiconductor devices across various industries, such as consumer electronics, automotive, industrial, and telecommunications, has been a significant driver for the growth of the EMC market. The demand for semiconductor epoxy molding compounds is spread across regions, with Asia-Pacific being a dominant market due to the presence of major semiconductor manufacturers in countries like China, Taiwan, South Korea, and Japan. North America and Europe also contribute significantly to the global market, owing to the strong presence of semiconductor and electronics industries in these regions. The semiconductor epoxy molding compound market is expected to witness continued growth in the coming years, driven by the expansion of semiconductor applications, advancements in packaging technologies, and the increasing need for reliable and efficient semiconductor devices in various industries.

Semiconductor Epoxy Molding Compound Market Report Scope and Research Methodology :

Before delving into the scope of Semiconductor Epoxy Molding Compound market reports, it is crucial to comprehend the vastness of the Semiconductor Epoxy Molding Compound industry. This sector encompasses an extensive array of products, from basic chemicals like acids, alkalis, and polymers to specialty chemicals used in various industries such as pharmaceuticals, agriculture, and cosmetics. Moreover, materials range from metals, plastics, and ceramics to composites, nanomaterials, and biomaterials. This diversity makes the Semiconductor Epoxy Molding Compound industry highly dynamic and adaptable.

A Research Methodology is a comprehensive document that analyzes and presents the current and future trends, opportunities, challenges, and advancements in research methods, tools, and technologies. It encompasses a wide range of topics related to research, including data collection, analysis, interpretation, and reporting. These reports serve as a valuable resource for researchers, businesses, and academic institutions, helping them stay up-to-date with the latest developments in the field.

Semiconductor Epoxy Molding Compound Market Segmentation:

Segment by Type

Bulk Molding Compounds

Sheet Molding Compounds

Segment by Application

Semiconductor Packaging

Electronic Component

Others

Competitive Landscape: -

Analyze the competitive dynamics of the Semiconductor Epoxy Molding Compound market by identifying key players, their market shares, and strategies. Highlight their strengths and weaknesses, recent developments, partnerships, mergers, and acquisitions.

Hitachi Chemical

Sumitomo Bakelite Company

Panasonic

Kyocera

Samsung SDI

KCC Corporation

Chang Chun Group

Hysol Huawei Electronics

Nepes

PhiChem Materials

Jiangsu Zhongpeng New Material

Shin-Etsu Chemical

CAPLINQ Corporation

Scienchem

Regional Insights

Asia-Pacific: The Asia-Pacific region dominates the Semiconductor Epoxy Molding Compound market, driven by rapid industrialization in countries like China and India. The region benefits from low-cost labor, favourable government policies, and rising consumer demand.

North America: The North American Semiconductor Epoxy Molding Compound market is characterized by technological advancements, a focus on sustainability, and the presence of key players. The United States leads in chemical production, with a strong emphasis on research and development.

Europe: Europe has a mature Semiconductor Epoxy Molding Compound industry, with a focus on eco-friendly and sustainable practices. The region's stringent regulations drive innovation in green chemistry and bio-based materials.

Latin America and Middle East/Africa: These regions offer significant growth opportunities due to expanding industrial sectors, favorable investment policies, and increasing consumer demand.

Semiconductor Epoxy Molding Compound Market Drivers and Challenges:

Identify and elaborate on the factors that are propelling Semiconductor Epoxy Molding Compound market growth. These could include technological advancements, rising demand from various industries, regulatory changes, and shifting consumer preferences. Discuss the obstacles and challenges hindering the Semiconductor Epoxy Molding Compound market's growth potential. This could encompass regulatory hurdles, environmental concerns, economic fluctuations, and supply chain disruptions.

Semiconductor Epoxy Molding Compound Market Trends and Opportunities:

Highlight the latest trends shaping the Semiconductor Epoxy Molding Compound market. This might encompass sustainable and eco-friendly materials, digitization and automation, and evolving R&D practices. Identify untapped opportunities within the Semiconductor Epoxy Molding Compound sector. This could involve niche markets, emerging applications, or gaps in the current product offerings.

Emerging Markets:

Emerging markets, such as Southeast Asia, Eastern Europe, and parts of Africa, offer immense growth opportunities for Semiconductor Epoxy Molding Compound companies. These regions are witnessing rapid industrialization, urbanization, and a rising middle class. To tap into these markets successfully, companies must navigate diverse regulatory landscapes and adapt to local preferences and practices.

Importance of a Market Synopsis:

Decision Making: A well-prepared Semiconductor Epoxy Molding Compound market synopsis helps businesses, investors, and professionals make informed decisions. It provides a comprehensive understanding of the Semiconductor Epoxy Molding Compound market landscape, enabling stakeholders to identify potential risks and opportunities.

Competitive Analysis: By examining the competitive landscape, a Semiconductor Epoxy Molding Compound market synopsis allows businesses to benchmark themselves against industry leaders and identify areas for improvement or differentiation. It facilitates strategic planning and Semiconductor Epoxy Molding Compound market positioning.

Market Entry: For companies considering entering a new market or launching a new product, a Semiconductor Epoxy Molding Compound market synopsis provides valuable insights into market size, customer needs, and competitive factors. It guides businesses in developing effective market entry strategies.

Investment Decisions: Investors rely on Semiconductor Epoxy Molding Compound market synopses to evaluate the feasibility and potential returns of investment opportunities. The synopsis helps them assess the market's growth prospects, competitive intensity, and long-term viability.

Knowledge Sharing: Semiconductor Epoxy Molding Compound Market synopses serve as valuable resources for industry research, academic studies, and knowledge sharing among professionals. They provide a concise summary of Semiconductor Epoxy Molding Compound market dynamics, making complex information accessible to a broader audience.

In summary, a market synopsis is a concise yet comprehensive summary of a Semiconductor Epoxy Molding Compound market's current state, trends, and future outlook. It helps stakeholders gain a holistic understanding of the Semiconductor Epoxy Molding Compound market, make informed decisions, and capitalize on emerging opportunities.

Request for Pre-Order Enquiry On This Report @ https://www.qyresearch.com/enquiry/1632219

Table of Content

1 Study Coverage

1.1 Semiconductor Epoxy Molding Compound Product Introduction

1.2 Market by Type

1.2.1 Global Semiconductor Epoxy Molding Compound Market Size by Type, 2018 VS 2022 VS 2029

1.2.2 Bulk Molding Compounds

1.2.3 Sheet Molding Compounds

1.3 Market by Application

1.3.1 Global Semiconductor Epoxy Molding Compound Market Size by Application, 2018 VS 2022 VS 2029

1.3.2 Semiconductor Packaging

1.3.3 Electronic Component

1.3.4 Others

1.4 Assumptions and Limitations

1.5 Study Objectives

1.6 Years Considered

2 Global Semiconductor Epoxy Molding Compound Production

2.1 Global Semiconductor Epoxy Molding Compound Production Capacity (2018-2029)

2.2 Global Semiconductor Epoxy Molding Compound Production by Region: 2018 VS 2022 VS 2029

2.3 Global Semiconductor Epoxy Molding Compound Production by Region

2.3.1 Global Semiconductor Epoxy Molding Compound Historic Production by Region (2018-2023)

2.3.2 Global Semiconductor Epoxy Molding Compound Forecasted Production by Region (2024-2029)

2.3.3 Global Semiconductor Epoxy Molding Compound Production Market Share by Region (2018-2029)

2.4 North America

2.5 Europe

2.6 China

2.7 Japan

3 Executive Summary

3.1 Global Semiconductor Epoxy Molding Compound Revenue Estimates and Forecasts 2018-2029

3.2 Global Semiconductor Epoxy Molding Compound Revenue by Region

3.2.1 Global Semiconductor Epoxy Molding Compound Revenue by Region: 2018 VS 2022 VS 2029

3.2.2 Global Semiconductor Epoxy Molding Compound Revenue by Region (2018-2023)

3.2.3 Global Semiconductor Epoxy Molding Compound Revenue by Region (2024-2029)

3.2.4 Global Semiconductor Epoxy Molding Compound Revenue Market Share by Region (2018-2029)

3.3 Global Semiconductor Epoxy Molding Compound Sales Estimates and Forecasts 2018-2029

3.4 Global Semiconductor Epoxy Molding Compound Sales by Region

3.4.1 Global Semiconductor Epoxy Molding Compound Sales by Region: 2018 VS 2022 VS 2029

3.4.2 Global Semiconductor Epoxy Molding Compound Sales by Region (2018-2023)

3.4.3 Global Semiconductor Epoxy Molding Compound Sales by Region (2024-2029)

3.4.4 Global Semiconductor Epoxy Molding Compound Sales Market Share by Region (2018-2029)

3.5 US & Canada

3.6 Europe

3.7 China

3.8 Asia (excluding China)

3.9 Middle East, Africa and Latin America

4 Competition by Manufactures

4.1 Global Semiconductor Epoxy Molding Compound Sales by Manufacturers

4.1.1 Global Semiconductor Epoxy Molding Compound Sales by Manufacturers (2018-2023)

4.1.2 Global Semiconductor Epoxy Molding Compound Sales Market Share by Manufacturers (2018-2023)

4.1.3 Global Top 10 and Top 5 Largest Manufacturers of Semiconductor Epoxy Molding Compound in 2022

4.2 Global Semiconductor Epoxy Molding Compound Revenue by Manufacturers

4.2.1 Global Semiconductor Epoxy Molding Compound Revenue by Manufacturers (2018-2023)

4.2.2 Global Semiconductor Epoxy Molding Compound Revenue Market Share by Manufacturers (2018-2023)

4.2.3 Global Top 10 and Top 5 Companies by Semiconductor Epoxy Molding Compound Revenue in 2022

4.3 Global Semiconductor Epoxy Molding Compound Sales Price by Manufacturers

4.4 Global Key Players of Semiconductor Epoxy Molding Compound, Industry Ranking, 2021 VS 2022 VS 2023

4.5 Analysis of Competitive Landscape

4.5.1 Manufacturers Market Concentration Ratio (CR5 and HHI)

4.5.2 Global Semiconductor Epoxy Molding Compound Market Share by Company Type (Tier 1, Tier 2, and Tier 3)

4.6 Global Key Manufacturers of Semiconductor Epoxy Molding Compound, Manufacturing Base Distribution and Headquarters

4.7 Global Key Manufacturers of Semiconductor Epoxy Molding Compound, Product Offered and Application

4.8 Global Key Manufacturers of Semiconductor Epoxy Molding Compound, Date of Enter into This Industry

4.9 Mergers & Acquisitions, Expansion Plans

5 Market Size by Type

5.1 Global Semiconductor Epoxy Molding Compound Sales by Type

5.1.1 Global Semiconductor Epoxy Molding Compound Historical Sales by Type (2018-2023)

5.1.2 Global Semiconductor Epoxy Molding Compound Forecasted Sales by Type (2024-2029)

5.1.3 Global Semiconductor Epoxy Molding Compound Sales Market Share by Type (2018-2029)

5.2 Global Semiconductor Epoxy Molding Compound Revenue by Type

5.2.1 Global Semiconductor Epoxy Molding Compound Historical Revenue by Type (2018-2023)

5.2.2 Global Semiconductor Epoxy Molding Compound Forecasted Revenue by Type (2024-2029)

5.2.3 Global Semiconductor Epoxy Molding Compound Revenue Market Share by Type (2018-2029)

5.3 Global Semiconductor Epoxy Molding Compound Price by Type

5.3.1 Global Semiconductor Epoxy Molding Compound Price by Type (2018-2023)

5.3.2 Global Semiconductor Epoxy Molding Compound Price Forecast by Type (2024-2029)

6 Market Size by Application

6.1 Global Semiconductor Epoxy Molding Compound Sales by Application

6.1.1 Global Semiconductor Epoxy Molding Compound Historical Sales by Application (2018-2023)

6.1.2 Global Semiconductor Epoxy Molding Compound Forecasted Sales by Application (2024-2029)

6.1.3 Global Semiconductor Epoxy Molding Compound Sales Market Share by Application (2018-2029)

6.2 Global Semiconductor Epoxy Molding Compound Revenue by Application

6.2.1 Global Semiconductor Epoxy Molding Compound Historical Revenue by Application (2018-2023)

6.2.2 Global Semiconductor Epoxy Molding Compound Forecasted Revenue by Application (2024-2029)

6.2.3 Global Semiconductor Epoxy Molding Compound Revenue Market Share by Application (2018-2029)

6.3 Global Semiconductor Epoxy Molding Compound Price by Application

6.3.1 Global Semiconductor Epoxy Molding Compound Price by Application (2018-2023)

6.3.2 Global Semiconductor Epoxy Molding Compound Price Forecast by Application (2024-2029)

7 US & Canada

7.1 US & Canada Semiconductor Epoxy Molding Compound Market Size by Type

7.1.1 US & Canada Semiconductor Epoxy Molding Compound Sales by Type (2018-2029)

7.1.2 US & Canada Semiconductor Epoxy Molding Compound Revenue by Type (2018-2029)

7.2 US & Canada Semiconductor Epoxy Molding Compound Market Size by Application

7.2.1 US & Canada Semiconductor Epoxy Molding Compound Sales by Application (2018-2029)

7.2.2 US & Canada Semiconductor Epoxy Molding Compound Revenue by Application (2018-2029)

7.3 US & Canada Semiconductor Epoxy Molding Compound Sales by Country

7.3.1 US & Canada Semiconductor Epoxy Molding Compound Revenue by Country: 2018 VS 2022 VS 2029

7.3.2 US & Canada Semiconductor Epoxy Molding Compound Sales by Country (2018-2029)

7.3.3 US & Canada Semiconductor Epoxy Molding Compound Revenue by Country (2018-2029)

7.3.4 United States

7.3.5 Canada

8 Europe

8.1 Europe Semiconductor Epoxy Molding Compound Market Size by Type

8.1.1 Europe Semiconductor Epoxy Molding Compound Sales by Type (2018-2029)

8.1.2 Europe Semiconductor Epoxy Molding Compound Revenue by Type (2018-2029)

8.2 Europe Semiconductor Epoxy Molding Compound Market Size by Application

8.2.1 Europe Semiconductor Epoxy Molding Compound Sales by Application (2018-2029)

8.2.2 Europe Semiconductor Epoxy Molding Compound Revenue by Application (2018-2029)

8.3 Europe Semiconductor Epoxy Molding Compound Sales by Country

8.3.1 Europe Semiconductor Epoxy Molding Compound Revenue by Country: 2018 VS 2022 VS 2029

8.3.2 Europe Semiconductor Epoxy Molding Compound Sales by Country (2018-2029)

8.3.3 Europe Semiconductor Epoxy Molding Compound Revenue by Country (2018-2029)

8.3.4 Germany

8.3.5 France

8.3.6 U.K.

8.3.7 Italy

8.3.8 Russia

9 China

9.1 China Semiconductor Epoxy Molding Compound Market Size by Type

9.1.1 China Semiconductor Epoxy Molding Compound Sales by Type (2018-2029)

9.1.2 China Semiconductor Epoxy Molding Compound Revenue by Type (2018-2029)

9.2 China Semiconductor Epoxy Molding Compound Market Size by Application

9.2.1 China Semiconductor Epoxy Molding Compound Sales by Application (2018-2029)

9.2.2 China Semiconductor Epoxy Molding Compound Revenue by Application (2018-2029)

10 Asia (excluding China)

10.1 Asia Semiconductor Epoxy Molding Compound Market Size by Type

10.1.1 Asia Semiconductor Epoxy Molding Compound Sales by Type (2018-2029)

10.1.2 Asia Semiconductor Epoxy Molding Compound Revenue by Type (2018-2029)

10.2 Asia Semiconductor Epoxy Molding Compound Market Size by Application

10.2.1 Asia Semiconductor Epoxy Molding Compound Sales by Application (2018-2029)

10.2.2 Asia Semiconductor Epoxy Molding Compound Revenue by Application (2018-2029)

10.3 Asia Semiconductor Epoxy Molding Compound Sales by Region

10.3.1 Asia Semiconductor Epoxy Molding Compound Revenue by Region: 2018 VS 2022 VS 2029

10.3.2 Asia Semiconductor Epoxy Molding Compound Revenue by Region (2018-2029)

10.3.3 Asia Semiconductor Epoxy Molding Compound Sales by Region (2018-2029)

10.3.4 Japan

10.3.5 South Korea

10.3.6 China Taiwan

10.3.7 Southeast Asia

10.3.8 India

11 Middle East, Africa and Latin America

11.1 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Market Size by Type

11.1.1 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Sales by Type (2018-2029)

11.1.2 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Revenue by Type (2018-2029)

11.2 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Market Size by Application

11.2.1 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Sales by Application (2018-2029)

11.2.2 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Revenue by Application (2018-2029)

11.3 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Sales by Country

11.3.1 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Revenue by Country: 2018 VS 2022 VS 2029

11.3.2 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Revenue by Country (2018-2029)

11.3.3 Middle East, Africa and Latin America Semiconductor Epoxy Molding Compound Sales by Country (2018-2029)

11.3.4 Brazil

11.3.5 Mexico

11.3.6 Turkey

11.3.7 Israel

11.3.8 GCC Countries

12 Corporate Profiles

12.1 Hitachi Chemical

12.1.1 Hitachi Chemical Company Information

12.1.2 Hitachi Chemical Overview

12.1.3 Hitachi Chemical Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.1.4 Hitachi Chemical Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.1.5 Hitachi Chemical Recent Developments

12.2 Sumitomo Bakelite Company

12.2.1 Sumitomo Bakelite Company Company Information

12.2.2 Sumitomo Bakelite Company Overview

12.2.3 Sumitomo Bakelite Company Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.2.4 Sumitomo Bakelite Company Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.2.5 Sumitomo Bakelite Company Recent Developments

12.3 Panasonic

12.3.1 Panasonic Company Information

12.3.2 Panasonic Overview

12.3.3 Panasonic Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.3.4 Panasonic Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.3.5 Panasonic Recent Developments

12.4 Kyocera

12.4.1 Kyocera Company Information

12.4.2 Kyocera Overview

12.4.3 Kyocera Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.4.4 Kyocera Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.4.5 Kyocera Recent Developments

12.5 Samsung SDI

12.5.1 Samsung SDI Company Information

12.5.2 Samsung SDI Overview

12.5.3 Samsung SDI Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.5.4 Samsung SDI Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.5.5 Samsung SDI Recent Developments

12.6 KCC Corporation

12.6.1 KCC Corporation Company Information

12.6.2 KCC Corporation Overview

12.6.3 KCC Corporation Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.6.4 KCC Corporation Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.6.5 KCC Corporation Recent Developments

12.7 Chang Chun Group

12.7.1 Chang Chun Group Company Information

12.7.2 Chang Chun Group Overview

12.7.3 Chang Chun Group Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.7.4 Chang Chun Group Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.7.5 Chang Chun Group Recent Developments

12.8 Hysol Huawei Electronics

12.8.1 Hysol Huawei Electronics Company Information

12.8.2 Hysol Huawei Electronics Overview

12.8.3 Hysol Huawei Electronics Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.8.4 Hysol Huawei Electronics Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.8.5 Hysol Huawei Electronics Recent Developments

12.9 Nepes

12.9.1 Nepes Company Information

12.9.2 Nepes Overview

12.9.3 Nepes Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.9.4 Nepes Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.9.5 Nepes Recent Developments

12.10 PhiChem Materials

12.10.1 PhiChem Materials Company Information

12.10.2 PhiChem Materials Overview

12.10.3 PhiChem Materials Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.10.4 PhiChem Materials Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.10.5 PhiChem Materials Recent Developments

12.11 Jiangsu Zhongpeng New Material

12.11.1 Jiangsu Zhongpeng New Material Company Information

12.11.2 Jiangsu Zhongpeng New Material Overview

12.11.3 Jiangsu Zhongpeng New Material Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.11.4 Jiangsu Zhongpeng New Material Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.11.5 Jiangsu Zhongpeng New Material Recent Developments

12.12 Shin-Etsu Chemical

12.12.1 Shin-Etsu Chemical Company Information

12.12.2 Shin-Etsu Chemical Overview

12.12.3 Shin-Etsu Chemical Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.12.4 Shin-Etsu Chemical Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.12.5 Shin-Etsu Chemical Recent Developments

12.13 CAPLINQ Corporation

12.13.1 CAPLINQ Corporation Company Information

12.13.2 CAPLINQ Corporation Overview

12.13.3 CAPLINQ Corporation Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.13.4 CAPLINQ Corporation Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.13.5 CAPLINQ Corporation Recent Developments

12.14 Scienchem

12.14.1 Scienchem Company Information

12.14.2 Scienchem Overview

12.14.3 Scienchem Semiconductor Epoxy Molding Compound Capacity, Sales, Price, Revenue and Gross Margin (2018-2023)

12.14.4 Scienchem Semiconductor Epoxy Molding Compound Product Model Numbers, Pictures, Descriptions and Specifications

12.14.5 Scienchem Recent Developments

13 Industry Chain and Sales Channels Analysis

13.1 Semiconductor Epoxy Molding Compound Industry Chain Analysis

13.2 Semiconductor Epoxy Molding Compound Key Raw Materials

13.2.1 Key Raw Materials

13.2.2 Raw Materials Key Suppliers

13.3 Semiconductor Epoxy Molding Compound Production Mode & Process

13.4 Semiconductor Epoxy Molding Compound Sales and Marketing

13.4.1 Semiconductor Epoxy Molding Compound Sales Channels

13.4.2 Semiconductor Epoxy Molding Compound Distributors

13.5 Semiconductor Epoxy Molding Compound Customers

14 Semiconductor Epoxy Molding Compound Market Dynamics

14.1 Semiconductor Epoxy Molding Compound Industry Trends

14.2 Semiconductor Epoxy Molding Compound Market Drivers

14.3 Semiconductor Epoxy Molding Compound Market Challenges

14.4 Semiconductor Epoxy Molding Compound Market Restraints

15 Key Finding in The Global Semiconductor Epoxy Molding Compound Study

16 Appendix

16.1 Research Methodology

16.1.1 Methodology/Research Approach

16.1.2 Data Source

16.2 Author Details

Contact Us:

QY Research, INC.

17890 Castleton, Suite 369,

Los Angeles, CA - 91748

USA: +1 626 539 9760

India: +91 9766 478 224

Emails - hitesh@qyresearch.com / enquiry@qyresearch.com

About US

QYResearch is a leading global market research and consulting company established in 2007. With over 16 years' experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Semiconductor Epoxy Molding Compound Market Size is Rising Globally at US$ 3119.3 million by 2029 | Hitachi Chemical, Samsung SDI, CAPLINQ Corporation here

News-ID: 3241581 • Views: …

More Releases from QYResearch.Inc

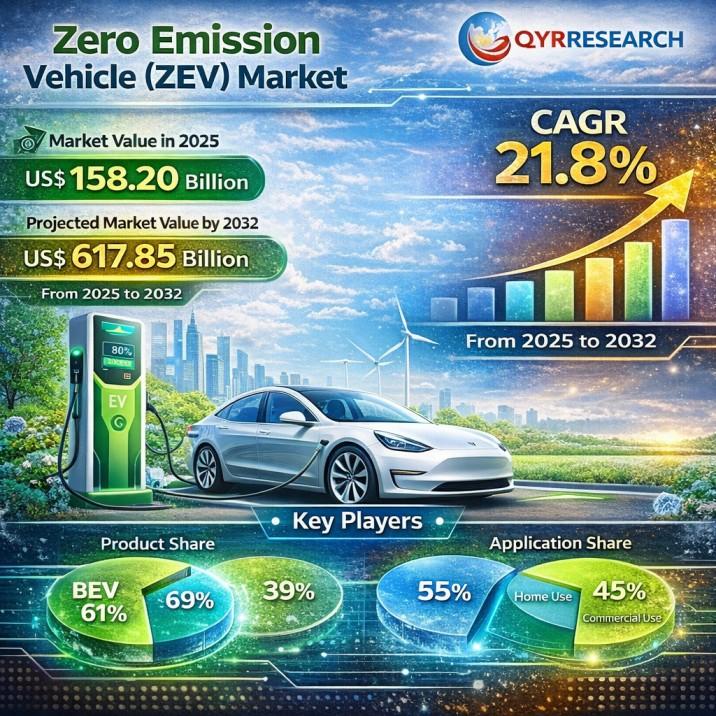

Zero Emission Vehicle (ZEV) Market Size Worth US$ 617.85 Billion by 2032, Growin …

Market Overview and Research Scope -

QY Research Inc., A global market research and consulting firm, has announced the release of its latest 2026 report titled "Zero Emission Vehicle (ZEV) - Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032." The report provides a data-driven analysis of the global Zero Emission Vehicle (ZEV) market, integrating historical insights from 2020-2025 with forward-looking forecasts through 2032. It covers market size, competitive…

Marine Electronics Market to Reach US$ 20.6 Billion by 2032 as Smart Shipping an …

Market Overview and Research Scope -

QY Research Inc., A global market research and consulting firm, has announced the release of its latest 2026 report titled "Marine Electronics - Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032." The report provides a data-driven analysis of the global Marine Electronics market, integrating historical insights from 2020-2025 with forward-looking forecasts through 2032. It covers market size, competitive landscape, demand trends, and…

Dry Etching Equipment Market Rising Demand, Trends, Growth, Competitive And Futu …

Market Overview and Research Scope -

QY Research Inc., A global market research and consulting firm, has announced the release of its latest 2026 report titled "Dry Etching Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032." The report provides a data-driven analysis of the global Dry Etching Equipment market, integrating historical insights from 2020-2025 with forward-looking forecasts through 2032. It covers market size, competitive landscape, demand…

Non-Volatile Dual In-Line Memory Module (NVDIMM) Market 2026 : Report, Market Si …

Market Overview and Research Scope -

QY Research Inc., A global market research and consulting firm, has announced the release of its latest 2026 report titled "Non-Volatile Dual In-Line Memory Module (NVDIMM) - Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032." The report provides a data-driven analysis of the global Non-Volatile Dual In-Line Memory Module (NVDIMM) market, integrating historical insights from 2020-2025 with forward-looking forecasts through 2032. It…

More Releases for Molding

Differences Between Flaskless Molding Machines and Flask Molding Machines

Flaskless molding machines [https://www.junengmachinery.com/servo-molding-machine-products/] and flask molding machines are two primary types of equipment used in foundry production for making sand molds (castings molds). Their core distinction lies in whether they use a flask to contain and support the molding sand. This fundamental difference leads to significant variations in their processes, efficiency, cost, and applications.

Key Differences

Core Concept:

Flask Molding Machine: Requires the use of a flask during mold making. A flask…

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.

• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into…

HDPE Blow Molding and Injection Molding Containers Market

Persistence Market Research (PMR) has published a new research report on HDPE blow molding and injection molding containers. The report has been titled "HDPE Blow Molding and Injection Molding Containers Market: Global Industry Analysis 2013-2017 and Forecast 2018-2026." The proliferating demand for HDPE blow molding and injection molding containers is largely from the beverage, chemical & petrochemicals, and pharmaceuticals industries, owing to the barrier properties of HDPE and convenience in…

Sheet Molding Compound and Bulk Molding Compound Market - Growth Prophesy 2025 | …

Global Sheet Molding Compound and Bulk Molding Compound Market: Snapshot

The global market for sheet molding compound and bulk molding compound is expected to advance with the launch of superior quality, lightweight, and more durable bulk molding and sheet molding compounds. By virtue of their higher line throughputs and lower production costs, these compounds are increasingly preferred by several leading manufacturers. As an augmenting number of advanced automobiles and luxury brands…

HDPE Blow Molding and Injection Molding Containers Market 2026

Due to its intrinsic physical and mechanical properties, high density polyethylene (HDPE) is highly used as packaging materials in different industries including food, beverages, pharmaceuticals, cosmetics, homecare, chemicals, and petrochemicals. Urbanization, changing consumer preferences, and expanding middle class have significantly contributed to the rising demand for consumer goods. Increased demand for consumer goods has, in turn, revolutionized the packaging industry, especially plastic packaging.

Polyethylene is most commonly used in the packaging…

Sheet Molding Compound and Bulk Molding Compound Market 2017-2025 : Polynt S.P.A …

Global Sheet Molding Compound and Bulk Molding Compound Market: Snapshot

The global market for sheet molding compound and bulk molding compound is expected to advance with the launch of superior quality, lightweight, and more durable bulk molding and sheet molding compounds. By virtue of their higher line throughputs and lower production costs, these compounds are increasingly preferred by several leading manufacturers. As an augmenting number of advanced automobiles and luxury brands…