Press release

Control valves used for bottom outlets in dams and in hydro-power plants

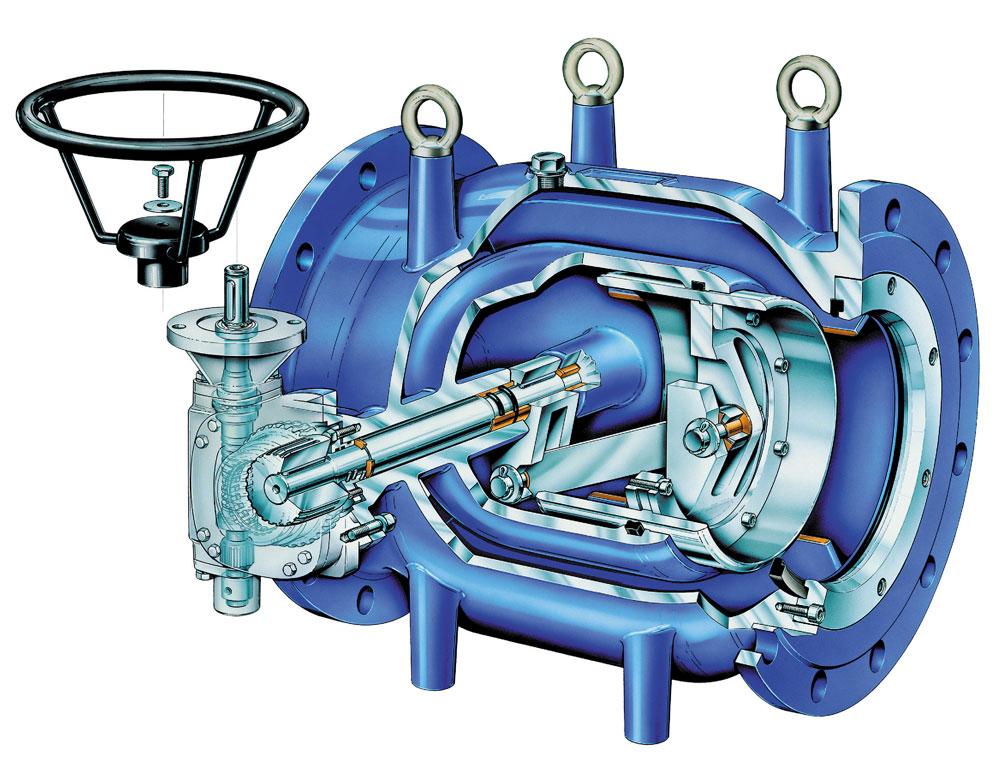

VAG-Armaturen (vag-armaturen.com/en/) - Normally butterfly valves are used as on-off valves and are usually installed in a valve chamber on the water side of bottom outlet lines in dams or in gravity lines leading to water treatment plants or hydro-power plants. In the best case the butterfly valves are assembled with brake and lift cylinders, working as pipe brake devices for emergency quick closing by lever and weight in case of pipe bursts. In dam applications, control valves such as plunger valves (or needle valves) or hollow-jet valves (or Howell Bunger valves or Fixed Cone valves) are installed after the butterfly valves on the air side. These valves always work as flow regulating or control valves. Plunger valves or hollow-jet valves are designed to perform regulating or control functions in water supply systems. Unlike butterfly valves or gate valves assuming only shut-off functions in pipeline systems, plunger valves and hollow-jet valves can meet the requirements of regulating operations.Previously, only the term of needle valve was used for valves having a controlling function. Today, the term plunger valve is very common due to the design features shown in the attached picture:

- The cross-section of the flow is annular in each position of the valve

- The axially movable closing device is shaped like a piston or a plunger

The compact and single-piece body is made of high quality ductile cast iron (GGG-40) with an inner body which is connected to the outer body by cast ribs. On the upstream side, the inner body has a spherical shape and the shape of the annular space results in a continuous narrowing towards the seat on the downstream side. Depending on the hydraulic conditions, there are different outlet parts available. The cross-section of a plunger valve is reduced in its flow, which is symmetrical to the axis, until the fully closed position of the piston is reached and the valve is absolutely drop-tight. The piston or plunger is normally made of stainless steel and is operated by an internal piston-drive made of ductile cast iron or stainless steel. An essential advantage of the new VAG RIKO Plunger valve is its piston guiding which is made as bronze welding. The piston-drive is connected by a stainless steel shaft to a gear box assembled to a connecting flange on the outside of the body. On the gearbox there can be assembled an electric actuator for automatic operation or the valve can be operated by a pneumatic actuator without gearbox. These valves are available in nominal widths ranging from DN 150 up to DN 1600, and in special versions up to pressure rates of PN 100. Plunger valves are suitable for inline installation and for installation at the end of pipelines.

For bigger dimensions and higher flow capacities, hollow-jet valves are available. Hollow-jet valves can only be installed at the end of pipelines. Due to their design and usually made of manufactured steel, these valves can be produced in nearly any dimension. As a rule, hollow-jet valves are not used for dimensions smaller than DN 400. Depending on the design of the stilling basin, hollow-jet valves can be used in a standard version or in a special version assembled with a hood pipe as a jet-guide pipe to concentrate the water flow after the valve. The advantage of using a hollow-jet valve in combination with a hood pipe is that the water flow after the valve is concentrated nearly in the same diameter of the hood pipe.

The main functions of control valves are as follows:

- control the flow capacity

- control the water level

- control the pressure in case of a following pipeline

Algeria is situated between the Atlas Mountains in the north of Africa and the Sahara desert in the south of the country. Most of the country’s water is supplied from dams. The dams are operated by the government, while the pipelines and water treatment plants are operated by the municipalities. The amount of water supplied from the dams was usually different from the amount which the municipalities received. This metering and documentation problem was solved thanks to the wide range of valves offered by VAG-Armaturen GmbH, a German company with more than 130 years of experience in the design and manufacturing of heavy-duty valves for water applications. VAG-Armaturen GmbH has been making butterfly valves and special control valves particularly for dam applications for more than 50 years. Due to their considerable experience, VAG’s technicians and engineers were closely involved in this project – a € 15 m project that is yet to be equalled in type, size and cost.

Project: Manufacturing and supply of different valves for the bottom outlets and pressure pipelines of 36 dams in

Algeria

Valves:

- VAG Plunger valves in dimensions ranging from DN 300 up to DN 1600 and with a pressure rating of PN 10

- VAG DN 800 Hollow-Jet valves with a pressure rating of PN 10

- VAG DN 2000 EKN® Butterfly valves with a pressure rating of PN 10

- VAG EKO® Gate valves ranging from DN 50 up to DN 200, with a pressure rating of PN 10

- VAG DUOJET® Air release valves ranging from DN 50 up to DN 200, with a pressure rating of PN 10

Including the necessary pipeline flanges, dismantling pieces, connecting screws and flange seals

Actuators: All control valves are equipped with electric actuators and control panels made by German supplier AUMA.

Project duration: 2003 to 2004

Executed by: VAG-Armaturen GmbH, Mannheim, Germany (hereinafter called VAG, www.vag-armaturen.com/en/ )

Contracted by: Algerian Water Enterprises (AWE)

Water was to be metered and documented at thirty-six of Algeria’s major dams. For this purpose, a tender for the equipment of the pressure pipelines with flow meters and flow control valves was drafted in 2003. In August 2003, a delegation of eight people, including engineers from VAG, visited all of the dams during a two weeks’ trip through Algeria. During this period, all the specifications required for the calculation, dimensioning and designing of the valves were collected. Working on behalf of the government, the delegation was under constant military protection. At the end of August 2003, the contract was awarded to VAG by AWE, the contracting company. A total of more than fifty plunger valves in nominal diameters between DN 300 and DN 1600 PN 10, several hollow-jet valves, butterfly valves, gate valves and air release valves were to be delivered by VAG and installed by AWE.

All the valves were calculated and dimensioned for extreme situations. To ensure the accuracy of the special valves design, VAG used its own calculation program, VAG UseCAD. Due to the hydraulic conditions, VAG had to design venting systems for some of the control valves to avoid cavitation in each operating position. VAG created flow characteristic and cavitation curves, technical data sheets with all important outer dimensions including spare parts lists, operating and maintenance instructions for each of the control valves. All these curves had been checked and approved by the contractor and by the Algerian government.

The tight schedule was particularly challenging for VAG’s design, manufacturing and logistics teams. More than fifty plunger valves, fifteen of which had nominal diameters between DN 1200 and DN 1600 and weighed between 8 to 12 tons had to be manufactured and delivered within a very short period of time. To guarantee a reliable supply of water, the valves had to be of the highest quality and reliability. This is one of the reasons why the contract was awarded to the German manufacturer VAG whose expert advice before and during the project the customer had come to have confidence in. VAG actively participated in pre-project discussions and provided solutions for problems that were not always related to valves only.

VAG delivered the complete material in six batches between December 2003 and December 2004. Everything down to the completeness check of the shipping container was meticulously planned. Each of the valves including all the connecting parts was clearly marked with the name of the dam and the place of installation of the specific parts. One missing screw would have delayed resuming the supply of water. But nothing failed in this big project.

Most of the thirty-six dams are miles away from civilization. Two mobile installation teams from AWE carried out all of the installation works. They were equipped with the necessary devices and tools, including kitchen and accommodation containers Right after the completing of one dam, the teams went on to the next. First the roller gate on the water side was closed, special tools used to cut open the dam's pipelines, and the valves were installed with cranes. The flow meters were installed at the specified distance from the control valves, and the installation was accepted and released for testing. Each building site brought new challenges for the installation teams, all of which the teams were able to deal with thanks to their know-how and experience. One of the challenges at the site consisted of bringing in bulldozers to build roads for truck-mounted cranes which were necessary to install the heavy-duty valves in the pipelines.

The operator of the dams, ANB (Agence Nationale des Barrages, Algiers) and the contracting company, AWE, highly appreciated the solution provider’s competence and excellent product quality of each of the VAG valves. The supply of water plays an important role in confirming the government’s good reputation in the Algerian population and around the world. VAG was able to fulfil each of the customer’s requirements.

Peter Oppinger

Head of Marketing at VAG-Armaturen GmbH

Carl-Reuther Strasse 1

68305 Mannheim

Germany

Phone: +49 621/ 749-2106

Fax: +49 621/ 749-292106

E-Mail: p.oppinger@vag-armaturen.com

Internet:www.vag-armaturen.com

VAG-Armaturen GmbH is an innovative and reliable partner and has defined a new standard in water and wastewater technology: dynamic, responsible and innovative.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Control valves used for bottom outlets in dams and in hydro-power plants here

News-ID: 31811 • Views: …

More Releases from VAG Armaturen

VAG Group also successful in Italy

VAG’s participation in the 9th ACCADUEO Exhibition and Conference in Ferrara (Italy) with over 10,000 visitors once again confirmed the valve manufacturer’s success in the Italian market.

The VAG Group received an overwhelmingly positive feedback from visitors for the products exhibited at the stand and the solutions provided in the areas of water, waste water and industrial applications. Besides giving various presentations on the subject of pressure management, VAG was…

New air valve for sewage applications

VAG-Armaturen GmbH (vag-armaturen.com/en/) has extended its product range by an automatic air valve for sewage applications. The VAG FLOWJET Air Valve can serve as both an aeration valve for the draining of sewage water lines and a deairing valve when sewage water lines are filled. It is also suitable for continuous ventilation under system pressure during operation.

The special features of the FLOWJET Air Valve are its corrosion-free and incrustation-free…

VAG extends its knife-gate valve range

VAG-Armaturen GmbH (vag-armaturen.com/en/) has extended its product range of resilient seated knife gate valves by nominal widths DN 800 and DN 1000, making the VAG ZETA® Knife Gate Valve available in all commonly used nominal sizes which now range from DN 50 to DN 1000. Depending on its nominal width, the new VAG ZETA® Knife-Gate Valve can now be used for working pressures of up to 10 bar.

This valve’s…

Replacement of valves in the gate valve house of the Schwammenauel dam and hydro …

The Rur dam with the Schwammenauel hydropower station is located in the Nordeifel mountains near the city of Heimbach. With its storage volume of 203 million m³ it is one of Germany's largest dams. After more than 65 years of service, the valves at the bottom outlet had to be replaced. The old plunger valves were replaced by hollow jet valves with a much higher capacity.

The Rur dam and…

More Releases for Algeria

Algeria Food Fibers Market Trends, Strategies, And Opportunities In The Algeria …

In the first class Algeria Food Fibers market report, market analysis estimates the expected rise, growth or fall of the product in the specific forecast period. Moreover, competitive analysis endows with an obvious idea about the strategies used by the major competitors in the market which perks up their penetration in the market. This promotional report is an essential document for every market enthusiast, policymaker, investor, and player. Algeria Food…

Algeria Agriculture Market, Algeria Agriculture Industry, Agriculture Grains Mar …

Agriculture in Algeria composes 25% of Algeria's budget and 12% of its GDP in 2010. Prior to Algeria’ settlement in 1830, nonindustrial agriculture providing sustenance for its population of about 2-3 million. Domestic agriculture manufacture contained within wheat, barley, citrus fruits, dates, nuts, and olives. Colonial farmers sustained harvest a diversity of fruits, nuts, wheat, and vegetables. Algeria became a large manufacturer of wine throughout the late 19th century owing to…

Pharmaceutical Market to Witness Growth Acceleration During 2018-2023 :PharmaPro …

The study methodologies used to examine the Pharmaceutical Market for the forecast period, 2019 - 2023 further classifies the industry by type, geography, end-use and end-user to add more precision and bring to light factors responsible for augmenting business development

Scope of the Report:

The researcher assessing the Pharmaceutical Market dive deep to unearth intangible facts related to the key restraints, opportunities, and threats expected to shape the progress of the industry…

Algeria: Country Intelligence Market Overview by Key Players Djezzy, Mobilis, Oo …

Country Intelligence Market research has been updated with new data and figure for better market understating. Report analysis the trend and forecast Country Intelligence Market growth outlook.

"Algeria: Country Intelligence Report", a new Country Intelligence Report by GlobalData, provides an executive-level overview of the telecommunications market in Algeria today, with detailed forecasts of key indicators up to 2022. Published annually, the report provides detailed analysis of the near-term opportunities, competitive dynamics…

Algeria: Country Intelligence Market Analysis Report Key Players Djezzy, Mobilis …

Country Intelligence Market research has been updated with new data and figure for better market understating. Report analysis the trend and forecast Country Intelligence Market growth outlook.

"Algeria: Country Intelligence Report", a new Country Intelligence Report by GlobalData, provides an executive-level overview of the telecommunications market in Algeria today, with detailed forecasts of key indicators up to 2022. Published annually, the report provides detailed analysis of the near-term opportunities, competitive dynamics…

Algeria Introduces New Regulations for Childcare Articles

Algeria’s new technical regulations for childcare articles came into effect on May 27, 2017. Originally published in November 2016 as Interministerial Order of July 11, 2016, Arrêté Interministériel du 6 Chaoual 1437, the new law contains several important provisions, including:

• Meeting physical, mechanical, flammability and chemical properties. Chemical requirements can be summarized as:

o Soluble elements – must conform to regulations

o Bisphenol A (BPA) – prohibited

o BBP, DBP and DEHP – less than or…