Press release

Wilmington Machinery Adds New Large Part Low Pressure Injection Machine in Research Lab for Testing of Parts and Materials

Have you always wondered if Low-Pressure Injection Molding (Structural Foam) could be a better process for your application?Wilmington Machinery may be able to help. Wilmington Machinery has recently expanded its lab/trial capabilities by adding a new Low Pressure Structural Foam machine.

Wilmington Machinery has always maintained a Low-Pressure Injection Molding machine in its research lab and made these machines available to plastics processors looking for validation of large parts or materials. Conducting trials at the facility also allows processors to work with Wilmington's experienced engineering team that will demonstrate how best to produce high-quality end products on this type of equipment. In addition, processors can discuss the Wilmington production-ready systems available to make their large parts reliably and cost-effectively with virgin or recycled plastics.

The low pressure machine in Wilmington's lab is available to those companies that want to trial new materials, additives, fillers, compounds, molds, or just conduct experimentation.

· LUMINA 2400HE Lab machine specs: 500 tons, 50 lb. shot capacity, 70" x 80" Platen, hydraulic ejection, 72" stroke, with the latest control package.

· High pressure molds with a cross section over .1875" running with chemical foaming agents can potentially be ran in a Low Pressure machine with multiple molds mounted to the large platens

· Material trials such as chemical foaming agents, additives, various recycled materials, compounded materials.

· Other services include customer-owned mold trials, engineering change validation, pre-production mold runoffs, low production runs, and pallet samples (Wilmington Mold or Customers).

About Wilmington's Low-Pressure Structural Foam Machines:

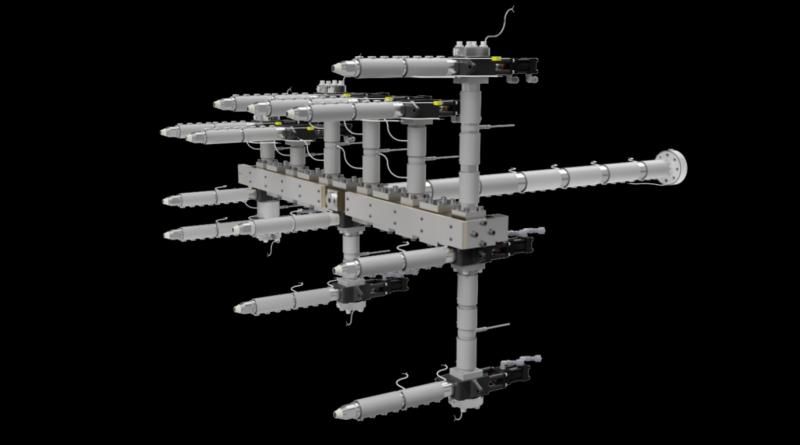

Wilmington's Low-Pressure Structural Foam machines are large platen machines with multiple nozzles capable of being arranged to fill several molds simultaneously. Platen sizes range from 54" x 54" to 108" x 186".

With low cavity pressures associated with short shooting a mold with gas, the machine can easily put multiple molds on a large platen and get multiple parts with each cycle. The parts don't have to be the same size, weight, or shape. Imagine the savings when running four molds simultaneously with one structural foam machine. Plus, reducing the need for extra floor space, lowering labor costs with only one operator and trimming utility costs as well as performing less maintenance.

Wilmington's Structural Foam machines can also run hot runner, gas assist, gas counterpressure, cold runner, stack, over molding, and molds of all sizes. Also, by utilizing Wilmington Machinery's Versafil, you can sequentially fill each mold independently with various shot sizes. The best candidates for low-pressure injection molding are parts with a thicker cross-section, .1875" or thicker.

Contact Wilmington Machinery for Lab rates and additional machine specifications at sales@wilmingtonmachinery.com

4628 Northchase Pkwy W NE, Wilmington, NC 28405

(910) 452-5090

Press Contact

Nanette Gregory

nanette@nsgconsultinginc.com

About Wilmington Machinery

Celebrating its 50th year building plastics machinery, Wilmington Machinery is a leader in Low-Pressure Structural Foam Molding Machinery. Wilmington Machines are built in the USA in our modern Wilmington, North Carolina facility. The company is well prepared to meet unique customers' needs for large plastics machinery products for the circular economy. International shipments are commonplace and can be arranged via the nearby deep-water Port of Wilmington, NC. https://wilmingtonmachinery.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Wilmington Machinery Adds New Large Part Low Pressure Injection Machine in Research Lab for Testing of Parts and Materials here

News-ID: 3149244 • Views: …

More Releases from Wilmington Machinery

Wilmington Machinery NEW Dual Injection LUMINA MP1200 Medium Pressure Injection …

LIKE NO OTHER …… ENGINEERED TO MAXIMIZE GAS ASSIST AND FOAM MOLDING

NEW Dual Injection LUMINA MP1200 Medium Pressure Injection Molding Machine Introducing at K' 22

The MP1200 is Wilmington Machinery's latest addition to its medium pressure large part injection molding machines first introduced at NPE 2018. It boasts dual 130mm reciprocating/compounding injection units with Wilmington's unique in-line first-in, first-out 50lb accumulators. The new machine accepts both hot runner and cold runner…

Wilmington Machinery Meets Needs for Molding with Recycled Materials

ABC's of Recycled Materials

When considering production of products with recycled material, it is essential to understand the difference between molding with recycled resins compared to virgin. Most recycled resins present processing difficulties such as contamination, low bulk density flakes, or mixed polymers. It is naturally subject to greater batch variations than virgin material.

There are two basic sources for recycled material. The first is from consumer goods recycling (such as milk/laundry…

Wilmington Machinery Structural Foam Nozzle / Manifold Components are now availa …

LUMINA manifold/nozzle components are designed for interchangeability with other makes/sources. Manifolds are provided with block-off plug provision to eliminate stagnant melt buildup. Spacers (manifold extensions) are available in a variety of lengths to match the 6” x 6” grid pattern for nozzle placement.

The LUMINA Nozzle features a forged body with generous flow characteristics and variable length nozzle extensions.

Wilmington’s LUMINA Nozzle boasts a forged nozzle housing that improves plastic flow when…

More Releases for Pressure

Benefits of Pressure Washing With Cen-Cal Pressure Pros

Fresno, CA - Over time, a property's exterior surfaces will collect debris, causing them to lose their visual appeal. This negative effect will become more and more noticeable over time, eventually causing property owners to seek out the best solution. In most cases, pressure washing [https://www.cencalpressurepros.com/pressure-washing-company-in-fresno-ca/] is the go-to answer to dirty exterior surfaces. Pressure washing uses high-pressure water to disturb and remove debris from these surfaces. This process has…

Ensuring Pressure Washing Safety With D4S Pressure Washing

Tampa, FL - Pressure washing [https://www.d4spressurewashing.com/pressure-washing-company-in-tampa-fl/] is an effective way of restoring a property's exterior surfaces. The process makes them cleaner, and as a result, more visually appealing. However, pressure washing does not come without its fair share of challenges. For instance, pressure washing uses highly pressurized water, and handling this force can cause significant harm or damage if the correct precautions are not taken. Learn what precautions to take…

How Midland Pressure Washing Conquers Pressure Washing Challenges

Leawood, KS - Pressure washing [https://www.midlandpressurewash.com/pressure-washing-company-in-leawood-ks/] does not go the exact same way every single time. In fact, this versatile process is used to clean a variety of different surfaces, and the precise details of pressure washing can be customized to match the job. With some knowledge of the demands of every surface that needs to be cleaned, residential and commercial property owners can harness the power of pressure washing…

Pressure Washing vs. Soft Washing With Riptide Pressure Washing

Wilmington, NC - The exterior surfaces of any property will become dirty over time. When this occurs, the owner of the property may become interested in cleaning them. However, the best way to accomplish this work may not be immediately clear. Should exterior surfaces be pressure washed, or soft washed? And what precisely is the difference between these two options? Riptide Pressure Washing [https://www.riptide-wash.com/] proudly provides pressure washing [https://www.riptide-wash.com/pressure-washing-company-in-wilmington-nc/] and…

DIY Pressure Washing Versus Professional Pressure Washing

West Hartford, CT - When a property's exterior surfaces become coated with dirt and debris, the property owner may decide the surfaces need to be pressure washed. At this point, the property owner has to make an important decision. Will they attempt to clean those exterior surfaces on their own? Or will they reach out to a professional business for the help they need? Both of these paths are valid…

Precision Under Pressure: Trends in Fluid Pressure Sensors

The Business Research Company recently released a comprehensive report on the Global Fluid Pressure Sensors Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, the fluid pressure…