Press release

Wilmington Machinery Meets Needs for Molding with Recycled Materials

ABC's of Recycled MaterialsWhen considering production of products with recycled material, it is essential to understand the difference between molding with recycled resins compared to virgin. Most recycled resins present processing difficulties such as contamination, low bulk density flakes, or mixed polymers. It is naturally subject to greater batch variations than virgin material.

There are two basic sources for recycled material. The first is from consumer goods recycling (such as milk/laundry bottles), and the other is processed plastics leftover from plastic product manufacturing. Both sources can offer plastics manufacturers with quality material for a variety of products and markets.

Use of Recycled Materials for Large Part Production

Wilmington Machinery has designed LUMINA Low Pressure Injection Molding machines (LPIM) to operate on 100% recycled or co-mingled resin using either the structural foam or gas assist methods to make heavy wall parts such as pallets, bins, enclosures, etc.

By adding nitrogen gas to the melted polymer, the weight of the finished product can be reduced by up to 15% or more. Wilmington LUMINA LPIM machines also have superior mixing and compounding capabilities compared to typical injection molding machines. This is accomplished by using a 30:1 L/D extruder with two mixing stations.

The Lumina LPIM systems give plastic product producers the option for a more sustainable approach. The many benefits of this feature include:

· Ability to process recycled material

· Reduction of energy required for processing

· Products with a longer life span

· Suitability for post-production reuse and recycling.

How to Overcome Recycled Packaging Challenges

Solving recycled packaging challenges may seem overwhelming. To meet diverse and many times conflicting specifications, companies are exploring multi-layer and barrier alternatives. In that regard, working together with material suppliers and machinery manufacturers often leads to the best and fastest solutions.

For instance, Wilmington Machinery has identified numerous multi-layer options to help its customers solve packaging problems such as improving shelf appeal, reducing costs, and creating better barrier protections, including using recycled material in an internal layer.

We are often asked, "Why I should be using Wilmington's rotary blow molding systems?"

Well, the answer is straightforward. Our rotary systems are the simplest technologies to use to provide the means to produce the absolute lowest cost bottle at the highest quality level and the highest volume production.

Wilmington systems are produced with the finest commercial components and are known for their modular compact design that Wilmington pioneered in 1979 for the first 6-layer (barrier) bottle programs.

The Bottom Line: Wilmington's injection and blow molding equipment will contribute to your company's circular economy goals.

Wilmington Machinery, Incorporated

4628 Northchase Parkway NE

Wilmington, North Carolina 28405

Press:

nanette@nsgconsultinginc.com.

Wilmington Machinery has been helping customers use recycled material with our injection and blow molding equipment for over two decades from our modern 65,000 square foot facility in Wilmington, North Carolina. The company is well prepared to meet unique customers' needs for large plastics machinery products for the circular economy. International shipments are commonplace and can be arranged via the nearby deep-water Port of Wilmington. https://www.wilmingtonmachinery.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Wilmington Machinery Meets Needs for Molding with Recycled Materials here

News-ID: 2624372 • Views: …

More Releases from Wilmington Machinery

Wilmington Machinery Adds New Large Part Low Pressure Injection Machine in Resea …

Have you always wondered if Low-Pressure Injection Molding (Structural Foam) could be a better process for your application?

Wilmington Machinery may be able to help. Wilmington Machinery has recently expanded its lab/trial capabilities by adding a new Low Pressure Structural Foam machine.

Wilmington Machinery has always maintained a Low-Pressure Injection Molding machine in its research lab and made these machines available to plastics processors looking for validation of large parts or materials.…

Wilmington Machinery NEW Dual Injection LUMINA MP1200 Medium Pressure Injection …

LIKE NO OTHER …… ENGINEERED TO MAXIMIZE GAS ASSIST AND FOAM MOLDING

NEW Dual Injection LUMINA MP1200 Medium Pressure Injection Molding Machine Introducing at K' 22

The MP1200 is Wilmington Machinery's latest addition to its medium pressure large part injection molding machines first introduced at NPE 2018. It boasts dual 130mm reciprocating/compounding injection units with Wilmington's unique in-line first-in, first-out 50lb accumulators. The new machine accepts both hot runner and cold runner…

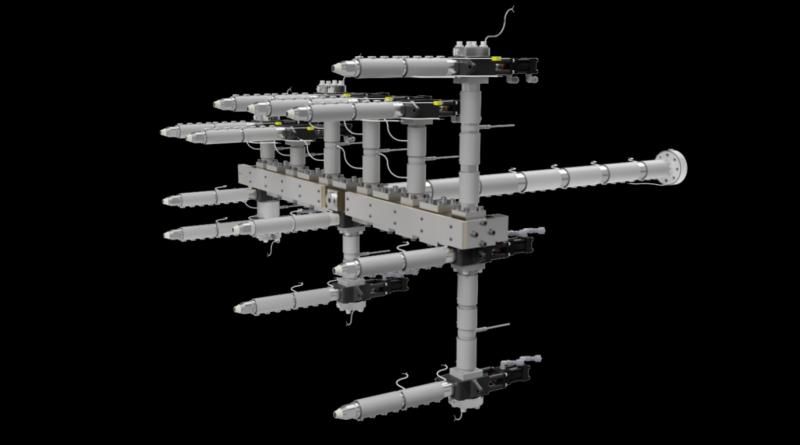

Wilmington Machinery Structural Foam Nozzle / Manifold Components are now availa …

LUMINA manifold/nozzle components are designed for interchangeability with other makes/sources. Manifolds are provided with block-off plug provision to eliminate stagnant melt buildup. Spacers (manifold extensions) are available in a variety of lengths to match the 6” x 6” grid pattern for nozzle placement.

The LUMINA Nozzle features a forged body with generous flow characteristics and variable length nozzle extensions.

Wilmington’s LUMINA Nozzle boasts a forged nozzle housing that improves plastic flow when…

More Releases for Recycled

Recycled TPEs Introduction

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report "Recycled TPEs- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032". Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2026-2032), this report provides a comprehensive analysis of the global Recycled TPEs market, including market size, share, demand, industry development status, and forecasts for the next few years.

The global market…

Top Trends Transforming the Recycled Asphalt Market Landscape in 2025: Enhancing …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

What Will the Recycled Asphalt Industry Market Size Be by 2025?

In recent times, the recycled asphalt market has been experiencing significant growth. The market, which was valued at $7.82 billion in 2024, is expected to increase to $8.25 billion in 2025, reflecting a compound annual growth rate (CAGR)…

Recycled Glass Sales Market Size Analysis by Application, Type, and Region: Fore …

USA, New Jersey- According to Market Research Intellect, the global Recycled Glass Sales market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The recycled glass sales market is showing steady growth, driven by rising environmental awareness and increasing demand for sustainable materials across various industries. With…

Recycled Plastic Market: Rising Demand for Eco-Friendly Products Driving Recycle …

[100+ Pages Report] | Global "Recycled Plastic Market" research report provides Innovative Insights on the Strategies adopted by Major Global in the worldwide industry. This valuable information offers businesses and investors a clear understanding of the market's Competitive Landscape, Growth Potential, and Impending Opportunities. The modern report highlights Latest Mergers, Achievements, Revenue Offshoring, R & D, Development Plans, Progression Growth, and Collaborations.

The global recycled plastic market is projected to grow…

Recycled Elastomers Market | J. Allcock & Sons Limited, RubberForm Recycled Prod …

Global Recycled Elastomers Market: Overview

The report details an exhaustive account of the global recycled elastomers market along with numerous associated factors. Some of these factors that are included in the report are drivers, restraints, competitive analysis, latest trends and opportunities, geographical outlook, and many other aspects. The study covered in the report spans a forecast period from 2018 to 2028. From an…

Recycled Elastomers Market - Transformation Survey 2028 | J. Allcock & Sons Limi …

Global Recycled Elastomers Market: Overview

The report details an exhaustive account of the global recycled elastomers market along with numerous associated factors. Some of these factors that are included in the report are drivers, restraints, competitive analysis, latest trends and opportunities, geographical outlook, and many other aspects. The study covered in the report spans a forecast period from 2018 to 2028. From an…