Press release

Momentive Electro LSR 242-1 Protecting Utility Insulators Against Harsh Climate and Pollution

Momentive Electro LSR 242-1 Protecting Utility Insulators Against Harsh Climate and Pollution in Northern Siberian City

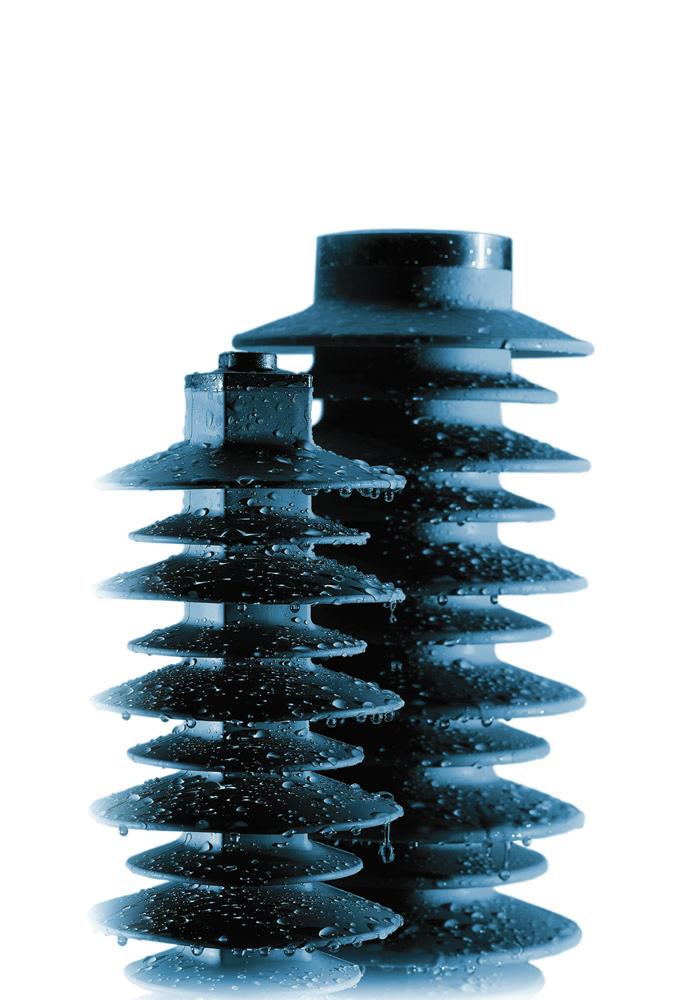

Rosizol, the first Russian producer of LSR hollow core insulators, introduced the new composite insulator based on Electro LSR 242-1 to Norsilk utility authorities in 2005. Since then, the new hollow core insulators from Rozisol have significantly outperformed the porcelain insulators in use by requiring no cleaning despite high levels of air pollution and harsh temperatures.

In addition to harsh temperatures, which average -10 degrees Celsius, the Blacksmith Institute has designated Norilsk as one of the ten most polluted places on earth. As a result, utility substations in the region are subject to heavy sedimentation of acidic highly dispersed atmospheric precipitates, conductive metallurgical dust and gas.

“The severe pollution in Norilsk means that extremely high levels of maintenance and cleaning are required to maintain the performance of porcelain insulators,” said Oliver Lebbaeus, Global Industry Manager HVI at Momentive. “By contrast, the hollow core insulators using Momentive’s Electro LSR 242-1 addition-cured LSR have required no cleaning since they were installed in 2005. The savings for the utility have been significant.”

Electro LSR 242-1 has been designed for outdoor insulating applications, delivering low viscosity, high flow-ability, fast curing and adept mechanical properties that give manufacturers new levels of design versatility for use in demanding environments. The outstanding electrical properties (Tracking Resistance: 4.5 kV) and the unique Hydrophobic properties (fast recovery and transfer through the pollution layer) make Electro LSR 242-1 an ideal material for a housing material to be used where pollution is present.

The Blacksmith Institute, a U.S.-based environmental group that works to identify and help clean up dangerously polluted sites, has reported that Norilsk’s air is polluted with particulates, including radioisotopes strontium-90, caesium-137 and heavy metals nickel copper, cobalt, lead and selenium. Air in the region also is polluted with gases, including nitrogen and carbon oxides, sulfur dioxide, phenols and hydrogen sulfide.

To find out more about Electro LSR 242-1, please call 00.800.431.1000 or +31.164.293.276 or visit www.momentive.com

Press Contact Momentive Performance Materials

Momentive Performance Materials GmbHRobert Scheib

Communications Leader EMEA & India

D-51368 Leverkusen

Germany

Phone: +49 (0) 214 30 4 05 32

Cell Phone: +49 (0) 172 2 47 53 93

E-Mail Robert.Scheib@momentive.com

Website Information: www.momentive.com

Momentive Performance Materials – Business Overview

Momentive Performance Materials was created from the sale of GE Advanced Materials and its former Joint Ventures GE Bayer Silicones and GE Toshiba Silicones to Apollo Management, L.P. in December 2006. Momentive is the world’s second-largest producer of silicones and silicone derivatives and a global leader in the development and manufacture of products derived from quartz and advanced ceramics. Silicones are a multi-functional family of materials used in thousands of products and serve as a critical ingredient in many construction, transportation, personal care, electronic, consumer and agricultural uses.

Silicones are generally used as an additive to a wide variety of end-use products in order to provide or enhance certain of their attributes, such as resistance (heat, ultraviolet light and chemical), lubrication, adhesion or viscosity. Some of the most well-known end-use product applications include bath and shower caulk, pressure sensitive adhesive labels, foam products, cosmetics and tires. Our Quartz division manufactures quartz, specialty ceramics and crystal products for use in a number of high-technology industries, which typically require products made to precise specifications.

These materials solutions are used as springboards for innovation in hundreds of consumer and industrial applications ranging from car engines to biomedical devices to integrated circuits. Industries served include aerospace, agriculture, appliances, automotive, construction, electronics, furniture and furnishings, healthcare, home care, industrial, lighting, packaging, personal care, plastics, semiconductor, telecommunications, tire, transportation, and water purification.

World Headquarters: Wilton, Connecticut

President & CEO: Jonathan Rich

Number of Employees: Approximately 5,000

Revenue in 2006: $2.5 Billion

Website information available under: www.momentive.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Momentive Electro LSR 242-1 Protecting Utility Insulators Against Harsh Climate and Pollution here

News-ID: 31490 • Views: …

More Releases from Momentive

Momentive Expanding Portfolio of Silicone Technologies to Support Growing LED Pa …

Momentive Performance Materials, a leading manufacturer of custom heat-cured elastomers, liquid silicone rubber (LSR) and RTV adhesives, today announced an expansion of its InvisiSil* LED (light emitting diode) encapsulants and Glob Top encapsulants portfolios to support the increasing need for advanced silicone technologies in LED packaging.

To facilitate enhanced transmission of light emitted from LEDs, InvisiSil LED encapsulants deliver high levels of optical efficiencies and a high-refractive index. In addition,…

Momentive Performance Materials Announces Completion of its New Addisil* HCE fam …

Momentive Performance Materials, a leading manufacturer of custom heat-cured elastomers, liquid silicone rubber (LSR) and RTV adhesives, today announced the completion of its new Addisil* elastomers family of addition- and heat-curable elastomers (HCEs). The new elastomers feature next-generation properties that offer regulatory compliance, high clarity, enhanced mechanical performance and superior productivity.

Products are now available in 40, 50, 60, 70 and 80 Shore A, covering the needs of a wide…

Momentive Performance Materials Introduces Niax* Surfactants for Microcellular P …

Momentive Performance Materials today announced an innovative family of Niax* silicone surfactants that may be cost-effective for use in low-density foam formulations for important applications such as footwear and automotive.

Generally providing improved performance over the current industry standard, Niax silicones L-1501, L-1502, L-1503 and L-1504 are “cell regulators” that may be highly useful in a variety of polyurethane systems and across a wide range of microcellular foam densities. Niax…

The Latest Generation of Liquid Silicone Rubber Delivers Excellent Properties fo …

Momentive Performance Materials announced the launch of a new product- family of liquid silicone rubber (LSR) that offers lowest compression set. Its first commercialized grade Silopren® LSR 3596/30 is self-lubricating with a nominal hardness of 30 Shore A. Based on new technology development, Momentive Performance Materials succeeded to get the compression set (22hrs at 175°C) without postcuring down to 10%, while maintaining the excellent mechanical properties of this LSR grade.…

More Releases for LSR

LSR Injection Molding Machine Market Size, Trends, Growth: Global Forecast 2025- …

The global market for LSR Injection Molding Machine was estimated to be worth US$ 284 million in 2024 and is forecast to a readjusted size of US$ 532 million by 2031 with a CAGR of 9.4% during the forecast period 2025-2031.

Global Leading Market Research Publisher QYResearch announces the release of its latest report "LSR Injection Molding Machine - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based…

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.

• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into…

Construction Aggregate Market Is Booming Worldwide : Wharehine, Hanlon Concrete, …

Latest Study on Industrial Growth of Construction Aggregate Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Construction Aggregate market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments…

Liquid Silicone Rubber (LSR) Market: Competitive Analysis and Global Outlook 202 …

The new report published by Stratview Research, titled Liquid Silicone Rubber (LSR) Market, is Segmented by Molding Technology Type (Liquid Injection Molding System), by Grade Type (Industrial Grade, Medical Grade, and Food Grade), by Application Type (Automotive, Medical, Electrical & Electronics, Consumer Goods, and Others), and by Region (North America, Europe, Asia-Pacific, and Rest of the World).

COVID-19 Impact & Recovery:

The report suggests that the Liquid Silicone Rubber (LSR) Market…

Liquid Silicone Rubber (LSR) Market Report 2018: Segmentation by Product (Indust …

Global Liquid Silicone Rubber (LSR) market research report provides company profile for ShinEtsu, KCC Corporation, Laur Silicone, Tianci Materials, Guangdong Polysil, Shenzhen SQUARE Silicone, BlueStar Xinghuo, Wynca, Dow Corning, Wacker Chemicals, Momentive and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR…

Global Liquid Silicone Rubber (LSR) Market Outlook 2016-2021

Liquid Silicone Rubber, with its low compression set, fast cure cycles, great stability and ability to resist extreme temperatures of heat and cold makes it ideally suitable for the production of parts where high quality is a must. Unlike most thermoplastic elastomers (TPRs and TPEs), LSR remains flexible and elastic down to -70o F and retains its properties up to 450o F. In addition to these qualities, the wide range…