Press release

Electric Motor Magnet Bonding Epoxy Adhesive Glue And How It Provides The Best Maintenance

Electric Motor Magnet Bonding Epoxy Adhesive Glue And How It Provides The Best MaintenanceElectric motors are essential components in various industries, from manufacturing and construction to transportation and healthcare. They are responsible for converting electrical energy into mechanical energy, powering machines and equipment that keep businesses running. However, to ensure their efficient and reliable operation, electric motors require regular maintenance. This includes cleaning, lubrication, and inspection of components such as bearings, brushes, and windings.

One crucial element of electric motor maintenance is the use of epoxy. Electric motor epoxy is a type of coating that provides protection and insulation to the motor components, preventing damage from environmental factors and reducing the risk of electrical arcing. In this article, we will explore what electric motor epoxy is and how it helps provide the best maintenance for electric motors.

Best Industrial Epoxy Adhesives Glue And Sealants Manufacturers In USA

What is Electric Motor Epoxy?

This is a specialized coating used to protect and insulate the components of electric motors. It is a type of adhesive that is applied to the surface of the motor windings, stator, and other components to provide a protective barrier against moisture, dust, and other environmental factors. Electric motor epoxy also helps to reduce the risk of electrical arcing, which can cause damage to the insulation system of such motor.

Types of Electric Motor Epoxy and Their Characteristics

There are various types of electric motor epoxy available, each with its own unique characteristics and properties. Some common types include:

Two-Part Epoxy

This type of electric motor epoxy is a mixture of two components - resin, and hardener. These are mixed together before application. Two-part epoxy provides excellent adhesion and resistance to chemicals and high temperatures.

Heat Cured Epoxy

Heat-cured epoxy is applied to the motor components and then cured at high temperatures. This is usually in a specialized oven. Such type of epoxy provides exceptional mechanical strength and is resistant to thermal cycling and shock.

Solventless Epoxy

Solventless epoxy does not contain any solvents and is cured at room temperature. This type of epoxy provides excellent adhesion, chemical resistance, and mechanical strength.

Importance of Using High-Quality Electric Motor Epoxy

Using high-quality electric motor epoxy is essential to ensuring the longevity and reliable operation of electric motors. It provides superior protection against environmental factors, reduces the risk of electrical arcing, and improves the mechanical strength and durability of the components. Additionally, high-quality epoxy ensures the motor maintains its efficiency and reduces the risk of downtime and repair costs.

How Electric Motor Epoxy Provides the Best Maintenance

Electric motor epoxy provides the best maintenance for electric motors in several ways, including:

Protection from Environmental Factors

Electric motor epoxy provides a protective barrier against environmental factors such as moisture, dust, and chemicals that can cause damage to components of the motor. The epoxy coating acts as a shield that prevents these factors from penetrating the motor and causing damage.

Prevention of Electrical Arcing

Electrical arcing is a phenomenon that can occur when there is a breakdown in the insulation system of the motor. It can cause damage to the motor components and even result in a complete breakdown of the motor. Electric motor epoxy helps to prevent electrical arcing by providing an additional layer of insulation that helps to maintain the integrity of the insulation system.

Improved Mechanical Strength and Durability

Electric motor epoxy also improves the mechanical strength and durability of the motor components. The epoxy coating helps to reinforce its components, making them more resistant to wear and tear, and improving their overall lifespan.

Reduction in Downtime and Repair Costs

By providing protection against environmental factors and preventing electrical arcing, electric motor epoxy helps to reduce the risk of downtime and repair costs associated with motor breakdowns. This results in increased efficiency and productivity for businesses that rely on such motors to power their operations.

Overall, electric motor epoxy is a cost-effective and efficient solution for maintaining the performance and longevity of electric motors in various industries.

Application of Electric Motor Epoxy

The application of electric motor epoxy requires a specific set of steps to ensure proper adhesion and effectiveness. The following are the steps involved in its application process:

Surface Preparation

The surface of the motor components must be thoroughly cleaned and prepared before applying the epoxy coating. This includes removing any dirt, grease, or debris that may affect adhesion.

Mixing the Epoxy

If the epoxy is a two-part system, it must be mixed thoroughly before application. It is essential to follow the manufacturer instructions for mixing the epoxy correctly.

Applying the Epoxy

The epoxy is applied to the surface of the motor components using a brush or spray gun. The thickness of such coating will depend on the manufacturer recommendations and the application requirements.

Curing

The epoxy is allowed to cure according to the instructions from manufacturers. This usually involves a specific curing time and temperature.

Best Practices for Applying Electric Motor Epoxy

To ensure optimum results when applying electric motor epoxy, the following best practices should be followed:

Use appropriate personal protective equipment such as gloves and safety goggles to protect yourself from the epoxy.

Ensure the working area is well-ventilated to prevent inhalation of fumes.

Mix the epoxy thoroughly and only apply it to a clean and dry surface.

Follow the manufacturer instructions for the appropriate thickness of the epoxy coating.

Importance of Proper Preparation and Surface Cleaning

Proper preparation and surface cleaning are critical to the effectiveness of electric motor epoxy. Any contaminants on the surface of the motor components can negatively affect the adhesion of the epoxy and reduce its protective properties. Therefore, it is essential to ensure that the surface is thoroughly cleaned and prepared before applying the epoxy coating. This can bring about maximum adhesion and protection, prolonging the life of the motor and reducing the need for repairs.

Best structural epoxy adhesive glue manufacturers in china

Summary

In conclusion, electric motor epoxy is an essential component of electric motor maintenance, providing protection against environmental factors, preventing electrical arcing, improving mechanical strength and durability, and reducing downtime and repair costs. The application of electric motor epoxy requires proper surface preparation, mixing, and curing, and following best practices can ensure the best results.

For more about electric motor magnet bonding epoxy adhesive glue,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/epoxy-adhesive-glue/ for more info.

Contact Info:

7th Floor, Building C, Comlong Science & Technology Park, Guanlan High-tech Park, Long- hua District, Shenzhen, Guangdong, China

+86-13352636504

Email: info@deepmaterialcn.com

Web: https://www.deepmaterialcn.com

Shenzhen DeepMaterial Technologies Co., Ltd is a professional epoxy adhesive glue manufacturer and supplier in china. DeepMaterial mainly offering one component epoxy adhesive,two component epoxy adhesive,epoxy encapsulant,UV Curing optical adhesives,epoxy conformal coating,smt epoxy adhesives,epoxy potting compound,waterproof epoxy and so on.DeepMaterial waterproof epoxy adhesive is for plastic,metal,glass,concrete,aluminium,composites and so on.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electric Motor Magnet Bonding Epoxy Adhesive Glue And How It Provides The Best Maintenance here

News-ID: 3003778 • Views: …

More Releases from Shenzhen DeepMaterial Technologies Co., Ltd

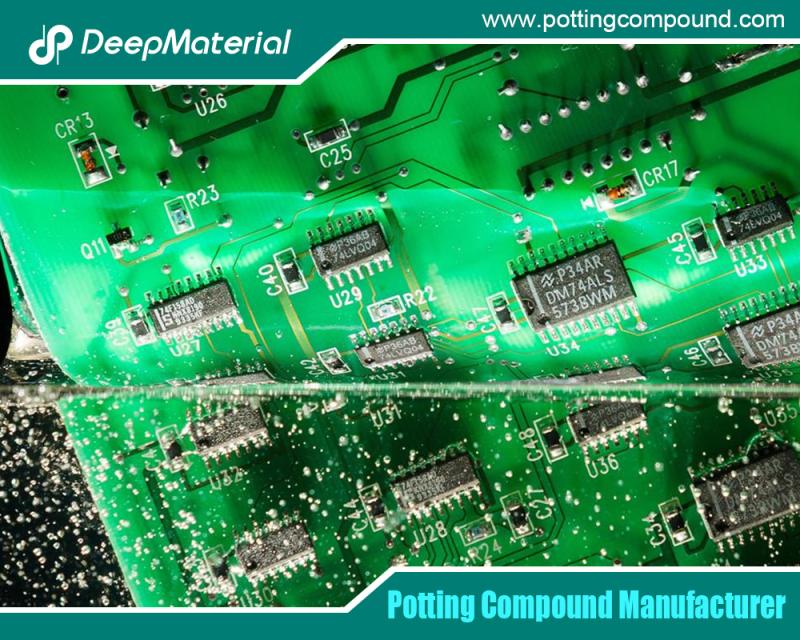

Why Are Silicone Potting Compounds Used In Electronics Products?

Potting compounds are one of the key materials used to safeguard sensitive as well as critical electronics components from a variety of threats. Silicone-based potting compounds offer the maximum levels of elasticity and the least levels of mechanical strength. The global silicone potting compounds market is obtaining massive growth as they are one of the prime components of the electronics as well as automobile industries.

From tiny personal devices to huge…

Choosing The Best Electronic Epoxy Encapsulant Potting Compounds For Your Needs

Choosing The Best Electronic Epoxy Encapsulant Potting Compounds For Your Needs

Electronic epoxy encapsulant potting compounds are essential for protecting electronic components from harsh environmental factors. However, with so many options available on the market today, choosing the right compound for your specific needs can be a daunting task.

In this article, we will explore the key factors to consider when selecting the best electronic epoxy encapsulant potting compound. By the…

The Difference Between PCB Potting Compound And PCB Conformal Coating

The Difference Between PCB Potting Compound And PCB Conformal Coating

Printed circuit boards, commonly referred to as PCBs, contain the most critical components for electronic devices. When exposed to elements like dust, moisture, humidity, and chemicals, the components can damage, leading to device malfunction or destruction. Electrical engineers used different methods to protect the components even as they grew smaller and smaller in size with technological development. PCB potting and conformal…

The Benefits of Working with Leading Industrial Electronic Component Adhesive Ma …

The Benefits of Working with Leading Industrial Electronic Component Adhesive Manufacturers

Industrial electronic component adhesive manufacturers play a crucial role in the manufacturing process of electronic components. These adhesives are used to bond and seal various components, ensuring their durability and longevity. With the increasing demand for high-quality electronic components, the need for reliable and consistent adhesive products has become more important than ever. In this article, we will explore the…

More Releases for Electric

Electrical Isolators Market 2023: Mitsubishi Electric, Orient Electric, Schneide …

The Electrical Isolators Market size (volume and value) and industry chain structure published by The Insight Partners through its high quality database which is a valuable source of guidance and direction for companies and individual interested in the industry.

An electrical isolator is a material in which electric current does not flow freely. The atoms of the insulator have tightly bound electrons which cannot readily move. Other materials, semiconductors and conductors…

Electric Motors for Electric Vehicle Market by Manufacturers: Hitachi Automotive …

Electric Motors for Electric Vehicle Market research report analyzes and studies the Electric Motors for Electric Vehicle Market's production, value, financial status, and capacity. It also provides information about market share and development plans during the projected period. Moreover, the Electric Motors for Electric Vehicle Market research report provides data about key manufacturers and focuses on the market competition landscape by analyzing the market by application, product type, and region.

Click…

Thermal Overload Relay Market 2021 Precise Outlook - ABB, Schneider Electric, Ea …

Global Thermal Overload Relay Market Size, Status and Forecast 2021

The Global Thermal Overload Relay Market report offers in-depth information and comprehensive analysis of the market. It provides a complete overview of the market with detailed insights on key aspects including the current market situation, potential size, volume, and dynamics of the market. This research report makes a thorough assessment of the COVID-19 pandemic and its impact on the current market…

Global Electric Motors for Electric Vehicles Market 2025 | MAHLE GmbH, Protean E …

Researchmoz added Most up-to-date research on "Global Electric Motors for Electric Vehicles Market Insights, Forecast to 2025" to its huge collection of research reports.

This report presents the worldwide Electric Motors for Electric Vehicles market size (value, production and consumption), splits the breakdown (data status 2013-2018 and forecast to 2025), by manufacturers, region, type and application.

This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities…

Yokogawa Electric, General Electric Profiled in Smart Factory Solutions Market 2 …

Global Smart Factory Solutions Market which focuses on effective strategies of the business framework. It highlights the recent market trends stringent energy regulations and growing pressure to conform to energy efficiency. The research methods and tools used to analyze the studies are both primary and secondary research.

This market research report on analyzes the growth prospects for the key vendors operating in this market space including Siemens, ABB, Honeywell International, Yokogawa…

Global Quartz Heat Lamps Market 2017 : Indu Electric Gerber, Schneider Electric, …

The Market Research Store report offers majority of the latest and newest industry data that covers the overall market situation along with future prospects for Quartz Heat Lamps market around the globe. The research study includes significant data and also forecasts of the global market which makes the research report a helpful resource for marketing people, analysts, industry executives, consultants, sales and product managers, and other people who are in…