Press release

The Difference Between PCB Potting Compound And PCB Conformal Coating

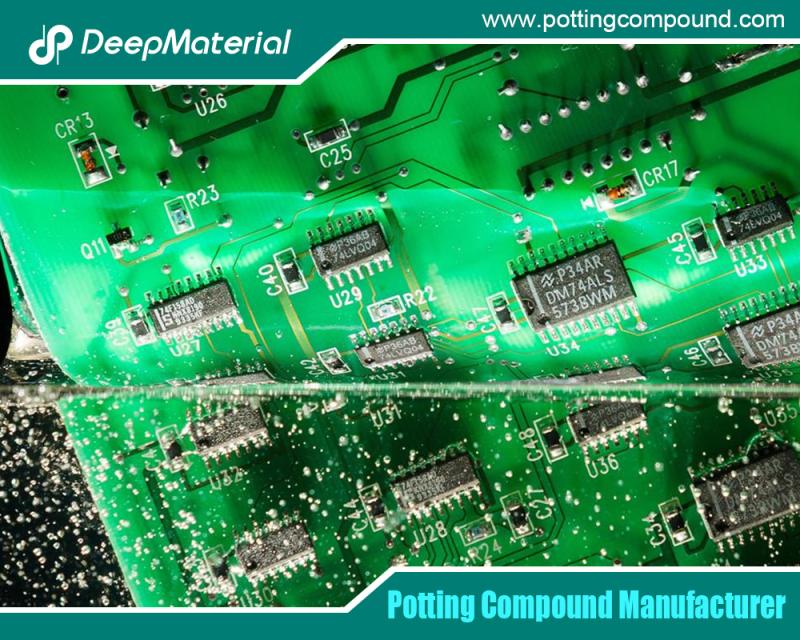

The Difference Between PCB Potting Compound And PCB Conformal CoatingPrinted circuit boards, commonly referred to as PCBs, contain the most critical components for electronic devices. When exposed to elements like dust, moisture, humidity, and chemicals, the components can damage, leading to device malfunction or destruction. Electrical engineers used different methods to protect the components even as they grew smaller and smaller in size with technological development. PCB potting and conformal coating are the two main protection methods used in different applications.

The two methods use polymers to create a protective layer on the PCBs. The electrical components have varying requirements, and it is, therefore, important to start by understanding the differences and similarities of the protection methods to decide which one is most suited for what application.

PCB Potting

Potting is a protective method for circuit boards involving filling PCB enclosures with a liquid compound or resin to create a layer that keeps the components safe from harm. The PCB potting compound fills the housing and covers the entire circuit board and the components or just the part that requires protection. Individual components can also be potted; it all depends on the requirements.

Potting gives circuit boards resistance to heat, chemicals, abrasion, and other environmental hazards. The potting material will usually determine the protection levels achieved and their functionality. The most commonly used materials for PCB potting are silicone, epoxy, and polyurethane.

Epoxy is a durable potting material offering circuit boards with excellent chemical resistance. This rigid compound also has high adhesion properties, among other features making it one of the most popular in different sectors. Its curing takes time and requires enough time to set, but when it is fully cured, the PCB protection results are amazing.

Polyurethane is another potting material that you can use for printed circuit boards. This material is softer than epoxy and makes a great choice for boards with sensitive connectors that would otherwise get damaged from epoxy rigidity. However, the heat and moisture resistance of this material is not as impressive as the other potting options.

Silicone is very popular among engineers and fabricators because it is flexible and durable. This material withstands extreme temperatures but is relatively higher in cost.

Conformal coating

Conformal coating is a protective method for PCBs that involves using a thin polymeric film to cover the boards. The layer used in this method is lighter and takes up little space but also offers protection from corrosion and other hazards. The conformal coating also has waterproofing properties, thus protecting the boards from moisture and water damage.

This method employs dip coating, brushing, and spraying as the main application methods depending on the project requirements. Different conformal materials achieve the desired results, including acrylic, epoxy, silicon, urethane, and parylene.

Acrylic is a basic material for consumer electronics and mass-production appliances. The conformal coating is easy to apply and remove.

Parylene polymer is applied in gas form and creates a thin but durable film with excellent dielectric strength and other qualities. It is hard to remove, and repairs are complicated as a result.

Silicone resin performs well in varying conditions making it one of the best in conformal coating for PCBs.

Epoxy is suitable for demanding applications because it is rigid and hard. Even with the thin layer in conformal coating, it is not the best for sensitive components.

Urethane, on the other hand, is resistant to solvents and abrasion. It is loved because it is cost-effective compared with the other conformal coatings.

DeepMaterial is a reputable and reliable manufacturer of potting compounds, conformal resins, and adhesives. The company experts can go the extra mile to formulate a product to suit your application's special requirements.

For more about the difference between pcb potting compound and pcb conformal coating,you can pay a visit to DeepMaterial at https://www.deepmaterialcn.com/ for more info.

Name:James Yuan

Email:info@deepmaterialcn.com

Web: https://www.deepmaterialcn.com

Organization: Shenzhen Deepmaterial Technologies Co., Ltd

Address: Building C, Comlong Science & Technology Park, Guanlan High-tech Park, Long- hua District, Shenzhen, Guangdong, China

Phone:+86-13352636504

Shenzhen DeepMaterial Technologies Co., Ltd is a professional epoxy adhesive glue manufacturer and supplier in china. DeepMaterial mainly offering one component epoxy adhesive,two component epoxy adhesive,epoxy encapsulant,UV Curing optical adhesives,epoxy conformal coating,smt epoxy adhesives,epoxy potting compound,waterproof epoxy and so on.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Difference Between PCB Potting Compound And PCB Conformal Coating here

News-ID: 3306469 • Views: …

More Releases from Shenzhen DeepMaterial Technologies Co., Ltd

Why Are Silicone Potting Compounds Used In Electronics Products?

Potting compounds are one of the key materials used to safeguard sensitive as well as critical electronics components from a variety of threats. Silicone-based potting compounds offer the maximum levels of elasticity and the least levels of mechanical strength. The global silicone potting compounds market is obtaining massive growth as they are one of the prime components of the electronics as well as automobile industries.

From tiny personal devices to huge…

Choosing The Best Electronic Epoxy Encapsulant Potting Compounds For Your Needs

Choosing The Best Electronic Epoxy Encapsulant Potting Compounds For Your Needs

Electronic epoxy encapsulant potting compounds are essential for protecting electronic components from harsh environmental factors. However, with so many options available on the market today, choosing the right compound for your specific needs can be a daunting task.

In this article, we will explore the key factors to consider when selecting the best electronic epoxy encapsulant potting compound. By the…

The Benefits of Working with Leading Industrial Electronic Component Adhesive Ma …

The Benefits of Working with Leading Industrial Electronic Component Adhesive Manufacturers

Industrial electronic component adhesive manufacturers play a crucial role in the manufacturing process of electronic components. These adhesives are used to bond and seal various components, ensuring their durability and longevity. With the increasing demand for high-quality electronic components, the need for reliable and consistent adhesive products has become more important than ever. In this article, we will explore the…

What Is The Market For UV Curable Adhesive?

UV curable adhesive is a type of adhesive that cures, or hardens, when exposed to ultraviolet (UV) light. It is used in a wide range of industries, including automotive, electronics, medical devices, packaging, and more. It tends to several advantages over traditional adhesives, such as faster curing times, higher bond strength, and improved environmental friendliness.

In this article, we will take a closer look at the market for UV curable…

More Releases for PCB

Victory PCB Showcases High-Quality Double-Sided PCB Solutions for Modern Electro …

Victory PCB highlights the performance, flexibility, and cost-effectiveness of its double-sided printed circuit boards, designed to meet the demands of mid-complexity electronic systems.

Victory PCB, a professional printed circuit board manufacturer, continues to support modern electronics development through its high-quality double-sided PCB manufacturing solutions [https://www.victorypcb.com/products-category/double-sided-pcbs.html]. Designed to balance performance, reliability, and cost efficiency, Victory PCB's double-sided printed circuit boards are widely used across industries that require greater circuit density without the…

Victory PCB Expands Global Reach with Industry-Leading PCB Manufacturing & Assem …

Image: https://www.abnewswire.com/upload/2025/06/aa56d146ab76e34a4f335137dad3dd49.jpg

Victory PCB [https://www.victorypcb.com/], a global leader in printed circuit board (PCB) manufacturing and assembly, continues to set new benchmarks in high-quality PCB production, fast delivery, and customer service excellence. With a legacy of 19 years of innovation and precision manufacturing, Victory PCB is powering the next generation of industries, from automotive and medical equipment to aerospace and advanced communication devices.

Located in the heart of Shenzhen's modern Industrial Park, Victory…

Victory PCB: Pioneering Excellence in Global PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/fabf105f8930f331e50cb1ca439637fe.jpg

Victory PCB [https://www.victorypcb.com/] is a renowned global manufacturer of PCBs and assembly services, recognized worldwide for its exceptional precision, innovation, and commitment to quality. With a client base exceeding thousands across various sectors, including automotive, aerospace, medical, industrial automation, and communication technologies, PCB solutions are tailored to meet each client's needs.

With centers covering as much as 30,000 square meters, Victory PCB employs over 450 staff dedicated to producing high-quality…

Victory PCB: Redefining Global Excellence in PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/986e29984b844645f2a99a0a5e93a4c8.jpg

Having almost 20 years of expertise in producing and assembling printed circuit boards (PCBs), Victory PCB has established a solid reputation for providing high quality products, creative solutions, and consistent customer satisfaction. Victory PCB [https://www.victorypcb.com/], located in a contemporary 30,000-square-meter facility within Shenzhen's tech district, merges deep expertise with cutting-edge technology to manufacture products that bolster top industries worldwide. Relying on more than 1,000 clients and 80% of its…

Victory PCB Emerges as a Global Leader in PCB Manufacturing

Victory PCB has been delivering custom PCB solutions to global customers since 2005.

Image: https://www.abnewswire.com/uploads/3daf3e2d61300e7406f7fb61c56726fc.png

Victory PCB [https://www.victorypcb.com/], a professional printed circuit board (PCB) manufacturer established in 2005, is setting new standards in the global electronics industry with its commitment to top-quality, high-precision, and high-density PCB solutions. The solutions offered by Victory PCB, which exports 80% of its products worldwide, bridge the gap between concept and reality for clients in a variety…

PCB Ceramic Substrate Market Size, Share and Forecast By Key Players-Panda PCB T …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global PCB Ceramic Substrate market is anticipated to grow at a compound annual growth rate (CAGR) of 13.62% between 2024 and 2031. The market is expected to grow to USD 21.58 Billion by 2024. The valuation is expected to reach USD 52.73 Billion by 2031.

The PCB ceramic substrate market is experiencing robust growth, fueled by the rising demand…