Press release

PROFIBUS Diagnostics now with improved error detection and GSD support

Trebing + Himstedt introduces new version of the PROFIBUS Diagnostics solution TH SCOPE and TH LINKSchwerin, April 23, 2014 - Trebing + Himstedt, international supplier of products and services for the optimal use of IT in the production environment, is now releasing new versions of the proven PROFIBUS diagnostics solutions TH SCOPE and TH LINK. New functions for threshold monitoring and expanded GSD support simplify maintenance requirements and the diagnostics of PROFIBUS production networks, while reducing the risk of production downtime.

The new threshold monitoring function further improves error detection in PROFIBUS networks. TH LINK PROFIBUS now also reveals critical telegram repetitions in the production network. As soon as a critical value for telegram repetitions is reached (the so-called threshold), users are automatically informed via email of possible error sources. The height of the threshold can be adapted and configured according to local conditions. Error messages can also be forwarded to higher-level systems (such as process control systems) via OPC or SNMP. As a result of this improved error detection, corrective measures in PROFIBUS can be initiated sooner, and planned production system maintenance intervals can be better utilized. Telegram repetitions are considered an important indicator for errors in a PROFIBUS network.

The PROFIBUS Diagnostics software TH SCOPE now presents error messages from PROFIBUS devices in a user-friendly manner based on GSD files (electronic device data sheets). Device-specific diagnostic messages now contain specific information from the respective device manufacturer on correcting the error, eliminating the time-consuming look-up of error codes in device technical manuals. In case of errors, this makes it even easier for users, particularly those from maintenance, to take rapid action and keep production systems permanently available.

Further information on PROFIBUS Diagnostics and downloads of the new versions of TH SCOPE and TH LINK are available here:

www.en.t-h.de/th-scope

www.en.t-h.de/th-link-profibus

About Trebing + Himstedt

Trebing + Himstedt is an international supplier of products and services for the optimal use of IT in the production environment. With easy-to-use concepts, we support our customers in their manufacturing processes and allow targeted access to production and process information. Our core competence is the continuous integration across different communication levels – from automation level to the ERP system. In the business unit “Industrial Communication” our products ensure the availability of industrial networks. The "Manufacturing Integration" business unit offers solutions for production IT, particularly for MES in SAP environments.

Contact

Trebing & Himstedt Prozeßautomation GmbH & Co. KG

Wilhelm-Hennemann-Str.13

19061 Schwerin

Web: www.t-h.de | Email: info@t-h.de

Phone: +49 385 39572 0 | Fax: +49 385 39572 22

Press contact representative

Katja Große (Marketing Assistant Industrial Communication)

Phone: +49 0385 39572 17 | Mail: kgrosse@t-h.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release PROFIBUS Diagnostics now with improved error detection and GSD support here

News-ID: 286464 • Views: …

More Releases from Trebing & Himstedt Prozeßautomation GmbH & Co. KG

Hannover Messe: START digital Production

Trebing + Himstedt offers timetable and toolbox for digital transformation in manufacturing

Schwerin, March 14, 2018 - Trebing + Himstedt, SAP MES and IoT expert for consulting, implementation and licensing of SAP solutions in the production environment, presents individual schedules for digital transformation and offers standardized SAP services in the new online service shop.

Something with industry 4.0, but what exactly? Or I know what it should look like, but what…

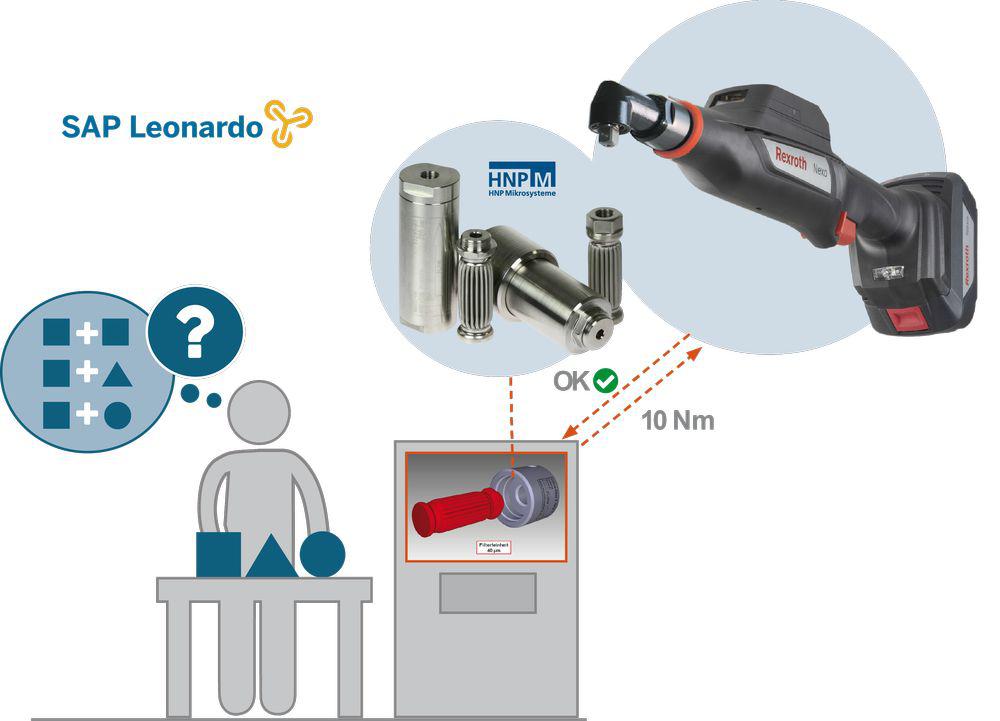

Assembly 4.0 with SAP

Live demo of assembly activities in the smart factory with SAP Leonardo at the Hannover Trade Fair

Schwerin, March 15, 2017 – Trebing + Himstedt, expert for SAP-based MES and IoT solutions, presents concrete use cases demonstrating connected production can be implemented using the SAP Leonardo portfolio. The many live demos can be seen at the Hannover Trade Fair from April 24–28, 2017, in Hall 7 at the Trebing + Himstedt…

Experience intelligent connected manufacturing

Trebing + Himstedt will present numerous live demos, from 3-D worker instructions, to shop floor analytics, to predictive maintenance, at the Hannover Trade Fair 2016

Schwerin, March 8, 2016 – Trebing + Himstedt, SAP MES expert for consulting, implementation and licensing of SAP solutions in the production environment, presents practical example applications for intelligently connected production based on SAP MES and IoT solutions. Visitors to the Hannover Trade Fair can experience…

Trebing + Himstedt opening Stuttgart Location

SAP MES expert now with a location in Southern Germany

Schwerin, April 9th - Trebing + Himstedt, SAP MES expert for consulting, implementation and licensing of SAP solutions in the production environment, is now even more accessible for Southern Germany with its own location in Stuttgart.

In order to better serve its customers in Southern Germany and to react with even greater agility, the SAP consultancy for manufacturing companies has opened…

More Releases for PROFIBUS

Industrial PROFIBUS Market Analysis and Future Prospects for 2030

The world of the industrial profibus market is a complex and ever-evolving landscape, shaped by consumer demands and technological advancements. In this report, we delve into the depths of this market to provide a profound and comprehensive analysis, catering to a diverse audience that includes manufacturers, suppliers, distributors, and investors. Our primary goal is to empower industry stakeholders with invaluable insights to make informed decisions in a rapidly changing environment.…

Industrial PROFIBUS Market Size, Status and Forecast 2025

Industrial PROFIBUS Market provides a basic overview of the markets including definitions, classifications, applications and industry chain structure. The Industrial PROFIBUS Market analysis is provided for the international Industry including development trends, competitive landscape analysis, and key regions development status.

For Free Sample report@ https://www.reportsandmarkets.com/sample-request/global-industrial-profibus-market-size-status-and-forecast-2025

The provincial analysis of the worldwide Industrial PROFIBUS Industry splits the global market area into key areas that include both continents as well as specific countries…

Industrial Profibus Market-Growing Acceptance Of Smart Manufacturing Techniques

Profibus is one of the new generations of fieldbus I/O bus networks. Profibus is a fieldbus used to connect field devices at the plant level and communicate data between field devices and control systems at the enterprise level. Profibus also helps to attain better yield and higher product quality through the delivery of better and up-to-date data to operations. Profibus uses a multi drop single cable to connect the…

Complete PROFIBUS DP Slave in FPGA

Haar, April, 29, 2015 – Softing Industrial Automation is introducing a new PROFIBUS Slave subsystem that can be fully loaded into an FPGA. The solution consists of a VHDL-designed PROFIBUS controller and processor on which runs the entire protocol software.

With Softing's new PROFIBUS Slave architecture, device developers can take advantage of a subsystem which is immediately executable, since the protocol software has already been ported to the processor. The integration…

Profibus Communication Added to Absolute Encoders

Terryville, CT – Advanced Micro Controls Inc. (AMCI), adds Profibus-DP communication to their lineup of NR25 series encoders. These heavy duty rotary sensors provide an overall measuring range of 16 bits (single-turn resolution) plus 12 or 14 bits (number of revolutions), up to 30 bits total. With both single-turn and multi-turn versions available, AMCI’s Profibus encoders are ready for any application. AMCI NR25 Profibus-DP encoders are compatible…

Dunkermotor Introduces CANopen, Profibus, Modbus Enabled Solar Tracker Motors

Embedded intelligence reduces bus traffic and can take over mission critical motion control functions when network is down.

Elgin, IL - September 13, 2011 -- Based on 20 years experience in solar industry motion control with over 150,000 units in the field, Dunkermotor's new line of brushless dc Solar Tracker Motors (STM) with integral fieldbus-enabled motion controllers are optimized to reduce development time, lower installation costs and provide lowest total cost…