Press release

High Demand for Medical Polymer Due Wide Scale Healthcare Applications

Medical polymers can be defined as polymers used in the healthcare sector for medicinal purposes. Medical polymers must be stabilizability, processability, biocompatibility, fluid compatibility, and other mechanical properties that suit their specific application.There are three major types of sterilization methods considered in the selection of medical polymers. These are autoclave (heat, steam, and pressure), gamma irradiation, and ethylene oxide. Sterilization is majorly used in polymer selection. Solvent, hydrolytic, and radiation resistance are utilized in all three methods.

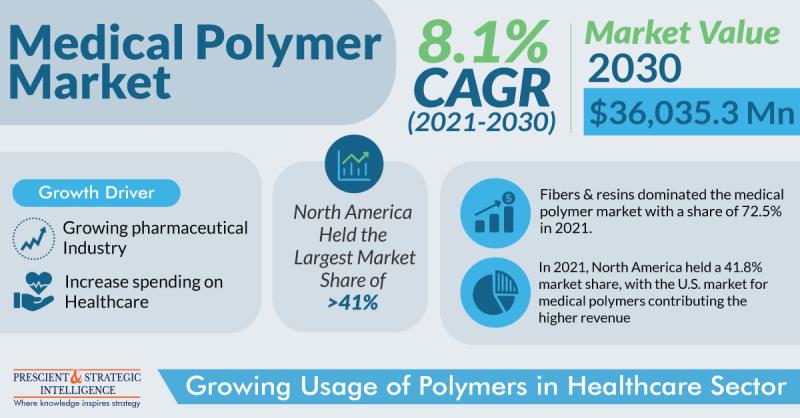

In 2021, the medical polymer industry contributes $17,842.5 million, and it is projected to generate $36,035.3 million in revenue in 2030, advancing at a rate of 8.1%, led by the expansion of the pharmaceutical industry, along with worldwide rising expenditure on healthcare.

Get the sample pages of this report: https://www.psmarketresearch.com/market-analysis/medical-polymer-market/report-sample

Types of Medical Polymers

Commodity Polymers

The foremost option for original equipment manufacturers is to determine if commodity polymers meet the application requirements, such as polyvinyl chloride, polypropylene, acrylonitrile butadiene styrene terpolymers, polyethylene, and polyesters. Their major applications include simple fluid containers, equipment housings, gown materials, masks, and tubing.

Polyvinyl chloride is inexpensive and transparent. It possesses balanced mechanical properties. In PP, it substitutes methyl group with chlorine. Plasticizers are required for acceptable processing conditions.

Moreover, the acrylonitrile butadiene styrene or ABS polymers possess complementing mechanical properties to solvent resistance due to three monomers properties. ABS is placed at the commodity engineering polymers and polyethylene terephthalate intersection.

Engineering Polymers

In the case of engineering polymers, the raw engineering resins are polybutylene terephthalate, polycarbonate, polypropylene oxide, and select polyamides (nylon 46). All of these polymers possess a high degree of thermal, wear, solvent, and electrical resistance as well as higher glass transition temperatures and melting points compared to commodity resins.

Step growth polymerization is widely used commercially by polyesters, polycarbonate, and polyamides in engineering thermoplastics. These are polymerized through diacids and diamines, diacids and diols, and bisphenol and phosgene. These polymers and their blends are utilized in the application of MD equipment housings, hemodialysis membrane housings, transparent medical packaging, and others.

Polyesters

In the case of polyesters, polyethylene, terephthalate, and polybutylene terephthalate are widely used as medical polymers. PET is highly adopted as skin-touching layers in POCT wearable sensors, and numerous other applications. PBT is highly flexible, as it has double the number of carbons in its backbone, which causes good stiffness, crystallinity, and strength. Moreover, these polyesters possess a higher melting point, and glass transition compared to PP and PE.

Polyamides

Nylon 6, and nylon 66, amide groups are widely used, among polyamides, due to their strong interchain hydrophilicity, and hydrogen bonding, coupled with high modulus, tensile strength, along with higher melting point. It enhances the stiffness and allows for higher temperature usage for internal device components.

Make inquiry before purchase of this report: https://www.psmarketresearch.com/send-enquiry?enquiry-url=medical-polymer-market

Polycarbonates

Polycarbonates possess higher aromaticity, with the absence of symmetry, which may lead to minimal transparency, crystallinity, and high glass transition, along with good dimensional stability. Such properties enable medical device applications. These polymers are widely used in fluid administration, and blood oxygenators applications in the form of intravenous connectors, controls, valves, catheters, and syringes. Alternations in the polycarbonate property enhance sterilization resistance, radiation sterilization resistance, and lipid resistance. In addition, polycarbonates are used as a crucial element in polymer blends with ABS, and PBT.

Silicones

Silicones are widely used in contact lenses, breast implants, medical tubing, and pacifiers. These polymers possess maximum oxygen permeability, electrical insulation, flexibility, transparency, and biocompatibility. Moreover, silicones are thermoset in nature and require liquid injection molding or cast molding. Silicones are polymerized through photo-initiated free radical polymerization and heat.

Therefore, medical polymers have high demand due to their vast healthcare applications.

Browse more reports:

Polymer Industry Report - https://www.psmarketresearch.com/press-release/polymer-market

Polymer Concrete Industry Report - https://www.psmarketresearch.com/press-release/polymer-concrete-market

Conductive Polymers Industry Report - https://www.psmarketresearch.com/press-release/conductive-polymer-market

Contact:

P&S Intelligence

Phone: +1-347-960-6455

Email: enquiry@psmarketresearch.com

Web: https://www.psmarketresearch.com

Blog: https://psintelligence.blogspot.com

About P&S Intelligence

P&S Intelligence provides market research and consulting services to a vast array of industries across the world. As an enterprising research and consulting company, P&S believes in providing thorough insights on the ever-changing market scenario, to empower companies to make informed decisions and base their business strategies with astuteness. P&S keeps the interest of its clients at heart, which is why the insights we provide are both honest and accurate. Our long list of satisfied clients includes entry-level firms as well as multi-million-dollar businesses and government agencies.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release High Demand for Medical Polymer Due Wide Scale Healthcare Applications here

News-ID: 2841586 • Views: …

More Releases from P&S Intelligence

Modular Automation Market Poised for Robust Growth Amid Industry 4.0 Transformat …

According to the latest market research study published by P&S Intelligence, the global modular automation market is on an impressive growth trajectory, expected to generate USD 6.3 billion in 2024 and expand at a CAGR of 8.7% to reach USD 12.1 billion by 2032. This surge is driven by rising demand for flexible, cost-efficient manufacturing solutions and the accelerating integration of Industry 4.0 technologies.

As manufacturing landscapes evolve with rapid changes…

U.S. ESG Investments Market Set to Skyrocket: $16 Trillion by 2032

According to the latest market research study published by P&S Intelligence, the U.S. Environmental, Social, and Governance (ESG) investments market is experiencing a significant surge, with projections indicating an increase from $6.5 trillion in 2024 to an estimated $16.0 trillion by 2032. This represents a robust compound annual growth rate (CAGR) of 12.1% over the forecast period.

According to a comprehensive analysis by P&S Intelligence, the market's expansion is driven…

Facility Management in the U.K. Booms with 14.1% CAGR as Demand Soars Across Sec …

According to the latest market research study published by P&S Intelligence, the U.K. facility management market is poised for significant growth, with projected revenues reaching USD 2,743.3 million in 2024 and expected to soar to USD 6,038.4 million by 2030, reflecting a robust CAGR of 14.1% during the forecast period.

This expansion is fueled by a surge in demand across both public and private sectors. According to the RICS U.K.…

Point-of-Sale Software Market in the U.S. Set to Grow by 9.7% CAGR, Boosted by O …

According to the latest market research study published by P&S Intelligence, the U.S. point-of-sale (POS) software market, valued at USD 4.7 billion in 2024, is poised for significant growth over the coming years, with projections estimating it will reach USD 9.8 billion by 2032, expanding at a compound annual growth rate (CAGR) of 9.7%. This growth is attributed to rapid technological advancements, a surge in mobile and cloud-based POS systems,…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…