Press release

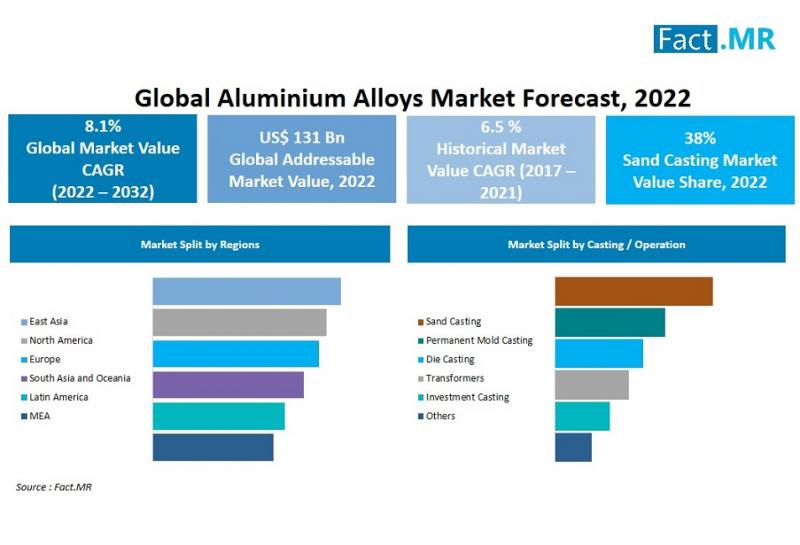

Global Aluminium Alloys Market Is Expanding At A CAGR Of 8.1% Over 2022 To 2032

Global Aluminium Alloys Industry Current Scenario and Future OutlookThe impact of the COVID-19 outbreak has compelled several manufacturers and industries to rethink their operations to gradually recover from the losses incurred for years to come. The Aluminium Alloys industry suffered a huge setback due to halted production and a limited supply of raw materials.

With the vaccination process picking up pace in countries like China, India, the U.S., the U.K., and Germany, manufacturers are gradually heading towards the road to recovery with an improved supply chain and streamlined production activities.

Request Sample- https://www.factmr.com/connectus/sample?flag=S&rep_id=7085

Key Segments Covered in Aluminium Alloys Industry Survey

Aluminium Alloys Market by Type:

Heat Treatable Aluminium Alloys

2000 Series

4000 Series

6000 Series

7000 Series

8000 Series

Non-Heat Treatable Aluminium Alloys

3000 Series

4000 Series

5000 Series

Aluminium Alloys Market by Casting / Operation:

Sand Casting Aluminium Alloys

Investment Casting Aluminium Alloys

Permanent Mold Casting Aluminium Alloys

Die Casting Aluminium Alloys

Others

Aluminium Alloys Market by Application:

Aluminium Alloys for Packaging

Aluminium Alloys for Automotive

Body Parts

Frame

Hood

Bumper Structures

Doors

Body Shells

Cabin Parts

Others

Engine Parts

Pistons

Camshafts

Crankshafts

Cylinder Heads

Engine Blocks

Others

Wheels

Powertrain

Suspension Parts

Chassis

Others

Aluminium Alloys for Marine

Ship Building

Yacht Building

Boat Building

Aluminium Alloys for Consumer Durables

Refrigerator Coolants

Cooking Utensils

Furniture

Laptop & Desktop Parts & Accessories

Tablets & Smartphone Parts

Others

Aluminium Alloys for Aerospace

Wing Skin

Fuselage

Empennage

Powerplants

Others

Aluminium Alloys for Building & Construction

Siding and Roofing

External Facades

Windows and Doors

Staircases

Railings

Others

Others

Aluminium Alloys Market by Alloy:

Cast Aluminium Alloys

Primary Foundry Alloys

Al-Si Family

AISi7Mg0

AlSi9Mg

AISi5Mg

AlSi10MnMg

AlSi9MnMoZr

AlSi9

AlSi10MnMg

AlSi10MnMgZn

Others

Al-Zn Family

AlZn10Si8Mg

AlZn3Mg3Cr

AlZn5Mg

Al-Mg Family

AlMg3

AlMg3Si

AlMg5

AlMg5Si

AlMg5Si2Mn

AlMg7Si3Mn

Al-Cu Family

AlCu4TiMg

AlCu4TiMgAg

AlCu4Ti

AlCu5NiCoSbZ

Others

Others

Secondary Foundry Alloys

Wrought Aluminium Alloys

Aluminium Alloys Market by Region:

North America Aluminium Alloys Market

Latin America Aluminium Alloys Market

Europe Aluminium Alloys Market

East Asia Aluminium Alloys Market

South Asia & Oceania Aluminium Alloys Market

Middle East & Africa Aluminium Alloys Market

Request Customization-https://www.factmr.com/connectus/sample?flag=RC&rep_id=7085

Competition Landscape

Alcoa, Aluar, Alvance, CBA, and Chalco, are some of the major aluminium alloy suppliers in the market.

In December 2021, Rusal announced investing around US$ 12 million for carrying out modernization of its alloy car wheel plant at SKAD in Russia. The company aims at expanding its business capabilities and target high-growth countries with rising demand of aluminium alloys in Germany.

In November 2021, CBA Brazil announced acquiring around 80% shares of secondary alloyed aluminium producer Alux. CBA has been involved in extensive production capacity expansions and is projected to go for the same strategy in the near future.

Fact.MR has provided detailed information about the price points of top manufacturers of aluminium alloys positioned across regions, in addition to providing sales growth information, production capacity, and speculative production expansion, in the recently published report.

Infrastructure Expansion in the U.S. is Fueling Demand for Aluminium Alloys

The Aluminium Alloys chemical industry in the U.S. suffered a huge setback due to the coronavirus outbreak in 2022, halting operations in industries such as construction, automotive, and pharmaceutical.

However, with the gradual resumption of production activities and improvements in the supply chain globally, manufacturers operating in the Aluminium Alloys chemical industry are gearing up to retain the industry's post-pandemic status.

Rising demand for Aluminium Alloys dispersants from the construction and oil & gas industry is driving the Aluminium Alloys chemical industry in the U.S. Aluminium Alloys dispersants are widely used in the construction industry, and the anticipated growth is attributable to the wide expanse of real estate in the country.

Increasing housing infrastructure projects are propelling Aluminium Alloys dispersant sales, thus augmenting the growth of the Aluminium Alloys chemical industry. The presence of leading players in the country is also driving sales and export in the Aluminium Alloys chemical industry.

U.K is Capitalizing on Aluminium Alloys Binders for Sustainable Construction Activities

The U.K. has been at the forefront in terms of technological advancements and the adoption of sustainable technology in production globally, which is a key factor augmenting the growth of the Aluminium Alloys chemical industry.

In 2022, the country suffered huge setbacks due to the adverse effects caused by the COVID-19 pandemic. However, manufacturers operating in the Aluminium Alloys chemical industry are striving to achieve the pre-pandemic status by opting for various Aluminium Alloys and inHigh Purity Quartz Sand growth strategies.

In the U.K, the growth of the Aluminium Alloys industry can be attributed to the surging demand for Aluminium Alloys binders. The environment-friendly nature, low energy consumption, and cost-effectiveness offered by Aluminium Alloys binders are key factors leading the sales and demand.

Growing urbanization and rapid increments in infrastructure activities across the country are fueling the demand for Aluminium Alloys binders, thus creating lucrative opportunities for several players operating in the Aluminium Alloys chemical industry in the upcoming decade.

Buy Now- https://www.factmr.com/checkout/7085

China is Incorporating Aluminium Alloys Pigments in Textiles and Visual Arts

The global hub for the Aluminium Alloys chemical industry, China, is picking up pace in its post-covid recovery, due to the timely eradication of the virus. With little to no restrictions, most production-related activities have resumed across the country, acting as anchors for various local and global manufacturers.

China is a lucrative ground for the Aluminium Alloys industry due to the presence of leading manufacturers and several industries such as textile, pharmaceutical, plastic, and paint. Due to the abundance of these industries, the demand for Aluminium Alloys pigments is also gaining immense traction in China.

Aluminium Alloys pigments are non-toxic, cost-effective, and offer good color strength, making them a favorable choice for usage in various end-use sectors. Increasing the use of Aluminium Alloys pigments in plastics, textiles, paints, and coatings will continue driving the growth in the Aluminium Alloys industry.

Additionally, the wide range of unique shades available in Aluminium Alloys pigments makes them a preferred choice for visual arts as well. The consumption of Aluminium Alloys pigments in high-tech applications such as photo-reprographics, optoelectronic displays, and optical data storage are fueling the demand for Aluminium Alloys pigments and creating lucrative opportunities for players operating in the Aluminium Alloys industry.

India Will Showcase High Demand for Speciality Aluminium Alloys

India is emerging as a lucrative market for the Aluminium Alloys chemical industries for players across the world. With gradual resumptions in the restrictions on movement, the country is slowly getting back on track to achieve post-pandemic status in the coming years.

The Aluminium Alloys industry in India is capitalizing on various sectors such as paints, pharmaceuticals, adhesives, pesticides, and dyes, making it one of the most important industries in the country.

Leading players operating in the Aluminium Alloys industry are focusing on enhancing their product portfolio by adding specialty chemicals such as polymer additives, water treatment chemicals, and lubricating additives, which will further drive growth and sales in the industry in the upcoming decade.

The newly discovered natural gas reserves in the country will also enable manufacturers to procure diverse Aluminium Alloys and will continue augmenting the growth of the Aluminium Alloys chemical industry.

Key Long-Term Trends

The global Aluminium Alloys industry is gradually recovering in 2021 and is expected to gain momentum in the upcoming years. With a noteworthy surge in activities in industries such as infrastructure, construction, pharmaceutical, and oil & gas, the Aluminium Alloys industry will show an upward trend in the coming years. Some new trends that are augmenting the market growth are:

Chemoinformatic

The Aluminium Alloys industry will largely benefit from chemoinformatic due to various factors such as the ease of evaluating specific properties of large compounds. The use of computational and informational techniques will help manufacturers gain insights into the new and existing chemicals and how to incorporate them into Aluminium Alloys chemical products.

For More Insights- http://www.prnewswire.com/news-releases/liquid-flux-market-expanding-at-7-cagr-digitalization-across-industries-enabling-growth-factmr-301269891.html?tc=eml_cleartime

US Sales Office :

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

E-Mail: sales@factmr.com

Corporate Headquarter:

Unit No: AU-01-H Gold Tower (AU),

Plot No: JLT-PH1-I3A,

Jumeirah Lakes Towers,

Dubai, United Arab Emirates

Visit Our Website: https://www.factmr.com

Blog URL: https://blog.factmr.com/

About Fact.MR

Market research and consulting agency with a difference! That's why 80% of Fortune 1,000 companies trust us for making their most critical decisions. We have offices in US and Dublin, whereas our global headquarter is in Dubai. While our experienced consultants employ the latest technologies to extract hard-to-find insights, we believe our USP is the trust clients have on our expertise. Spanning a wide range - from automotive & industry 4.0 to healthcare & retail, our coverage is expansive, but we ensure even the most niche categories are analyzed. Reach out to us with your goals, and we'll be an able research partner.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Aluminium Alloys Market Is Expanding At A CAGR Of 8.1% Over 2022 To 2032 here

News-ID: 2663759 • Views: …

More Releases from Fact.MR

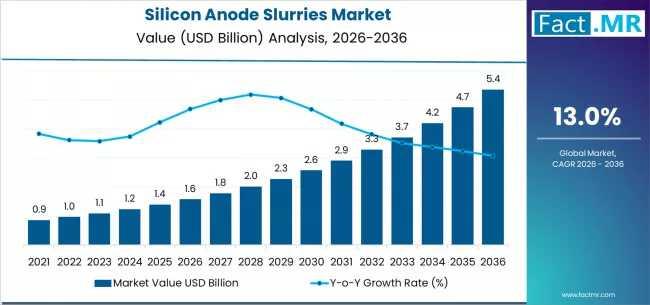

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

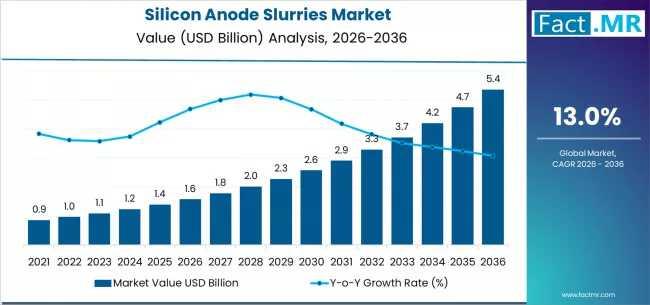

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

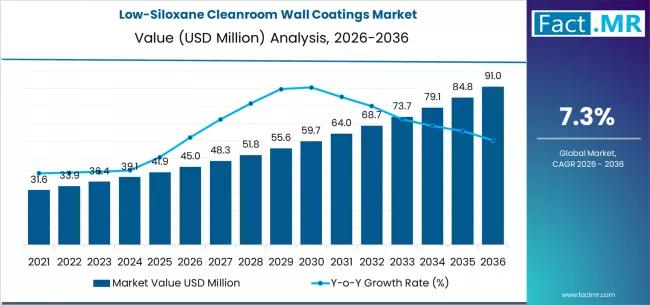

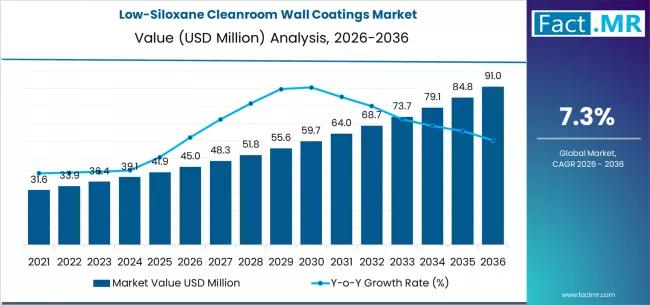

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

More Releases for Alloys

2022 Aerospace Materials Market | 2026 Forecast - by Type (Aluminium Alloys, Ste …

The Aerospace Materials research report gives a detailed examination of the worldwide Aerospace Materials market. It surveys the market through volume and information embraced on different procedures, including income evaluation and examinations of driving business sector players. Accordingly, it gives principal and unquestionable pondering the market parts. Moreover, data about market division is additionally included in the report. The market experiences and examination canvassed in the report rely upon SWOT…

Global Titanium Alloys Aluminium Alloys Aerospace Materials Market, Global Titan …

Aerospace materials are high performance alloys, which are made of aluminum, titanium, steel, and super-alloys. These materials should possess various properties including strength, heat resistance, and light weight. In addition, fatigue and corrosion resistance are must-have properties for these type materials. Aluminum is the most extensively used material during the early phase of aerospace manufacturing industry because of its exceptional light weight, inexpensive nature and state of the art. Mostly…

Global High Performance Alloy Market by product (Non-Ferrous Alloys, Super Alloy …

The global high performance alloy market was estimated at USD 2726.4 million in 2020, and is expected to reach USD 3269.6 million by 2024 growing at a CARG of 4.6% during the forecast period.

There is a high demand for super alloys from North America pertaining to the fact, that performance standards set for the products, make it mandatory for the use of high percentage of super alloys in jet engines…

Braze Alloys Market: Moving Towards Brighter Future| Aimtek Inc., Prince Izant C …

"Braze alloys market is expected to attain a good market growth by 2027, while registering this growth at a rate of 5.30% for the forecast period of 2020 to 2027. The extensive application of the alloys in the end use industry is driving the market scope of braze alloys business in the forecast period of 2020 to 2027."

This Braze Alloys Market research report contains specific segments by type and by…

Aerospace Materials Market Report 2018: Segmentation by Type (Aluminium Alloys, …

Global Aerospace Materials market research report provides company profile for Toray Industries, Inc. (Japan), Cytec Solvay group (Belgium), Alcoa Corporation (U.S.), Du Pont (U.S.), Teijin Ltd. (Japan), Kobe Steel Ltd (Japan) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…

Global Invar Market 2017: National Electronic Alloys, Eagle Alloys Corporation, …

Global Invar Market Report 2017 offers comprehensive research study on the current scenario of the Invar market globally, offering a primary overview of Invar market, consisting of definitions, classifications, a range of applications and Invar industry chain structure.

Invar Market report includes development plans and policies along with manufacturing processes and price structures. Invar market scope, share and potential users are analyzed. The Invar market is divided according to its types,…