Press release

With high speed in the concrete

With the sensor BBS 10_DS from IBJ technology, surface pressure in concrete components can be determined also afterwards. The applications range from the direct stress measurement in the component to the measurement and monitoring of dynamic loads in real time..

Ultrasonic captures the stress in the structure directly and in real time. All changes can be transferred online via the Internet or satellite radio. The sensors are either placed directly in the building, or subsequently attached to exposed to. Construction elements or bridges bearing may be easily monitored. The sensors are constantly active on or in the building. The simple design and small size allow the full application of all structures made of steel or concrete. All civil engineering works are static loads and measure voltages and small dynamic changes.

After the procedure, many important civil engineering works could be monitored worldwide. The costs of such controls are minimal.

The collapse of buildings goes hand in hand with a measurable change of stresses and loads. These are correlated with the stove data of seismic events worldwide available and checked for plausibility. This surveillance of buildings of all kinds on damage caused by disasters (soil landslides, earthquake, mudslide, etc.) also is possible.

Retrofitting the 1 inch borehole sensors are built into the concrete parts. With swelling mortar we a force-fit composite with concrete part achieved.

A low overall height of the sensors was elected to allow installation in boreholes for many different applications. The installation of the sensors is diameter holes approximately 1 inch.

Each sensor is clearly identifiable with the encoding of sensor in Rome.

Approx. up to 50,000 measurements per second can be made with a suitable control and evaluation unit.

The monitoring of all possible curtails and structural parameters during the construction and operation of buildings is the basis for the State and safety analysis of the building. On-line measuring method with the sensors from IBJ technology force and load measurement, especially stress measurements in concrete, are not to replace their validity and relevance.

Ibj technology as a partner of the industry for the interests of process measurement technology was founded in January 2003.

Owner of the Engineering Office for innovative measuring technology is Mr. Dipl.-ing. (TH), Dipl-ing.-Ök. Frank-Michael Jaeger.

IBJ Technology

Colkwitzer Weg 7

04416 Markkleeberg

Germany

fmj@ibj-technology.com

www.ibj-technology.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release With high speed in the concrete here

News-ID: 265184 • Views: …

More Releases from IBJ Technology

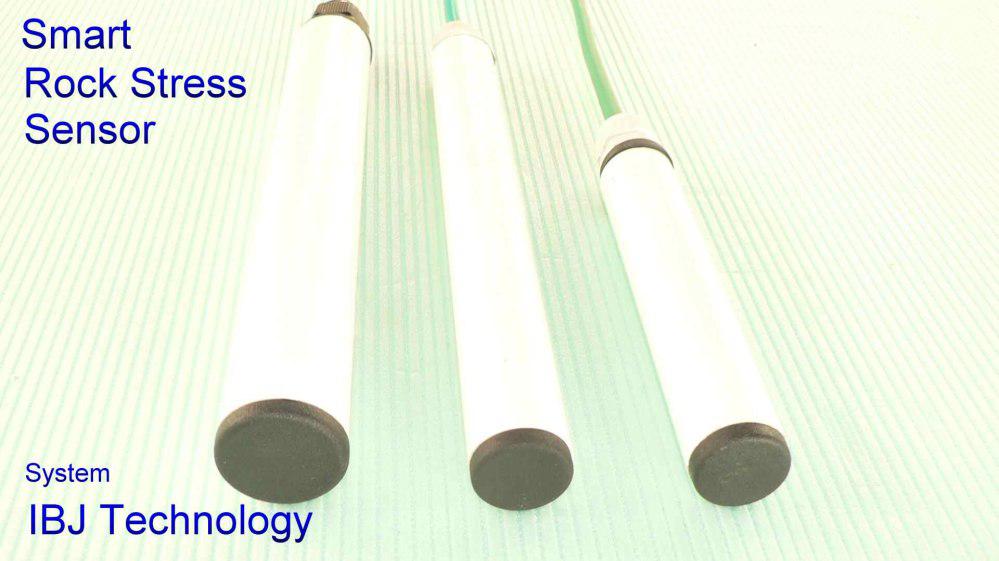

.Smart Rock Stress Sensor with MEMS

The RSS-X series of acousto elastic sensors from IBJ Techhnology is used to measure variations in compressive stress and load, which allows stress evaluation when the material’s modulus of elasticity is unknown or anisotropic and inhomogeneous. Typical examples are concretes and drill holes in the rocks, where these instruments can be used include:

• Mining

• Tunnel supports

• Deformations of pillars

• Dams and nuclear power plants

• Structural members of buildings and bridges

•…

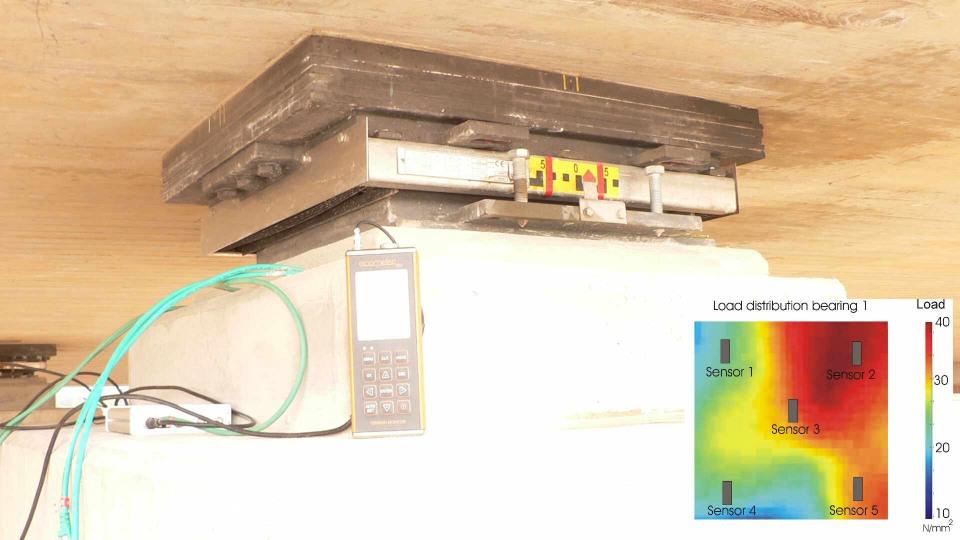

Smart Bridge - bridge bearings load control

The distribution can be determined of the load under bridge bearing load-bearing pillars or foundations with multiple sensors BBS 10_DS from IBJ technology. Uneven load entry can detect but also subsequently through still attached directly with sensors built into the bearing plate in the concrete.

The applications range from the direct voltage measurement in the component to the measurement and monitoring of dynamic loads in real time.

With the sensors is the…

Acousto-elastic concrete strain sensors for heavy duty applications

Acousto elastic concrete strain sensors are used to detect the metrological

Expansion or compression of steel building components as well as for measurements in reinforced and unreinforced concrete bodies used. The thickness of the susceptor (diameter of the bars) may be selected according to the strength reinforcement.

The acousto elastic concrete strain sensors can also be mounted on the outside parts of the structure of steel. With flanges or angle mounting is…

With high speed in the concrete

With the sensor BBS 10_DS from IBJ Technology, surface pressure in concrete components can be determined also afterwards. The applications range from the direct stress measurement in the component to the measurement and monitoring of dynamic loads in real time.

Ultrasonic captures the stress in the structure directly and in real time. All changes can be transferred online via the Internet or satellite radio. The sensors are either placed directly in…

More Releases for Sensor

Ultrasonic Oxygen Sensor Market, Ultrasonic Oxygen Sensor Market Size, Ultrasoni …

Fairfield Market Research offers a complete understanding of the Global Ultrasonic Oxygen Sensor Market in its latest research report. The report includes an unbiased analysis of the market dynamics. The report covers growth prospects, market development potential, product profitability, supply and demand curves and predictions, and government policies. The report has been put together using reliable tools to assess the primary and secondary data. The data is represented in the…

Wheel Speed Sensor Market Growing Up By Sensor Type: Passive Sensor, Active Sens …

Acumen Research and Consulting has announced the addition of the "Wheel Speed Sensor Market” report to their offering.

The Wheel Speed Sensor Market Report 2018 is an in depth study analyzing the current state of the Wheel Speed Sensor Market. It provides brief overview of the market focusing on definitions, market segmentation, end-use applications and industry chain analysis. The study on Wheel Speed Sensor Market provides analysis of China market covering…

Smart Sensor Market - Transportation System Infrastructure & Aerospace Industrie …

Smart sensor market is expected to reach $15,840 million in 2023 from $4,805 million in 2016, growing at a CAGR of 18.4% from 2017 to 2023. Smart sensor have become an integral part of the aerospace and transportation industry. The robust growth in automobile sector, inclination of society towards IoT, development of smart cities, and surge in security threats are some of the major factors that drive the demand for…

Global Body Sensor Market - By Type (EEG Sensor, Visual Sensor, Respiration Sens …

Market Research Reports Search Engine (MRRSE) has recently updated its massive report catalog by adding a fresh study titled “Global Body Sensor Market - Assessment Covering Growth Factors and Upcoming Trends by 2022 End”. This business intelligence study encapsulates vital details about the market current as well as future status during the mentioned forecast period of 2022. The report also targets important facets such as market drivers, challenges, latest trends,…

Biochemical Sensor Market Report 2018: Segmentation by Product (Electrochemical …

Global Biochemical Sensor market research report provides company profile for GE Healthcare (U.S.), Thermo Fisher Scientific. (U.S.), Honeywell International Inc. (U.S.), Bio-Rad Laboratories Inc. (U.S.), Polestar Technologies Inc. (U.S.), Microchip Technology Inc. (U.S.) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and…

Smart Wearable Fitness Devices Sensors Market to 2025 Temperature Sensor, Pressu …

The report begins from overview of Industry Chain structure, and describes industry environment, then analyses market size and forecast of Smart Wearable Fitness Devices Sensors by product, region and application, in addition, this report introduces market competition situation among the vendors and company profile, besides, market price analysis and value chain features are covered in this report.

This research report is equipped with the information categorizing Smart Wearable Fitness Devices…