Press release

Revolutionary method for the recognition of bridges collapse

New procedure for the damage recognition at bridges of IBJ Technology. Bridges can be supervised on-line. With that new procedures of IBJ Technology for the permanent monitoring of bridges and other traffic routes could be recognized disasters as in time in Minneapolis. The world-wide only on-line procedure permits the measurement of loads and stress situations directly in the building. With ultrasonic the stress in the building directly and in real time is seized. All changes can be transferred immediately on-line by Internet Monitoring or Wireless Lan. The sensors are brought either directly into the building or later attached to endangered places. Design features such as carriers or bridge bearings can be supervised particularly simply. The sensors are constantly at or active in the building. The simple structure and the small size permit comprehensive application at all buildings from steel or concrete. In the procedure many traffic routes could be supervised world-wide. The costs of such a monitoring are small. IBJ Technology offers world-wide licenses for this new measuring procedure.IBJ Technology

Colkwitzer Weg 7

D-04416 Markkleeberg

Germany

Tel.:0341 33 80 172

mail:fmj@ibj-technology.de

web:http://www.ibj-technology.de

In January 2003 ibj technology as partner of the industry for the interests of the process measuring technique one based.

Owner of the engineer's office for innovative measuring technique is Mr. Dipl.-Ing. (TH), Dipl.-Ing.-Oek. Frank- Michael Jäger.

Our activity and thus our experiences in the process measuring technique for fastidious applications justify themselves on one over 15 years activity in the project management and development in research establishments of the chemistry, the natural gas industry and the mining industry.

The practical use of measurement principles and sensor technologies under most difficult operating conditions is supplemented by one over 12 years advisory activities to the employment and the use from process measuring technique to the benefit of the customers within all ranges of the economy.

As independent and reliable partners of the industry we offer comprehensive solutions in all questions of the process measuring technique.

Particularly with fastidious applications of the ultrasonic technology we can repair your problems with new solutions.

Many innovative solutions for measuring tasks in the most different industries were protected in a multiplicity by patents and utility models.

The satisfaction of the clients, expert quality as well as economically justifiable solutions.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Revolutionary method for the recognition of bridges collapse here

News-ID: 25251 • Views: …

More Releases from IBJ Technology

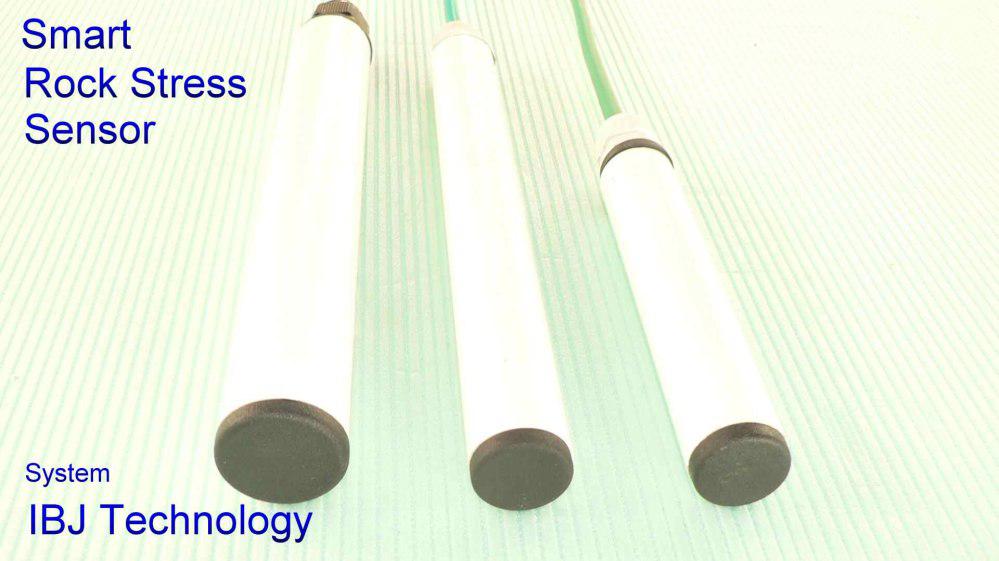

.Smart Rock Stress Sensor with MEMS

The RSS-X series of acousto elastic sensors from IBJ Techhnology is used to measure variations in compressive stress and load, which allows stress evaluation when the material’s modulus of elasticity is unknown or anisotropic and inhomogeneous. Typical examples are concretes and drill holes in the rocks, where these instruments can be used include:

• Mining

• Tunnel supports

• Deformations of pillars

• Dams and nuclear power plants

• Structural members of buildings and bridges

•…

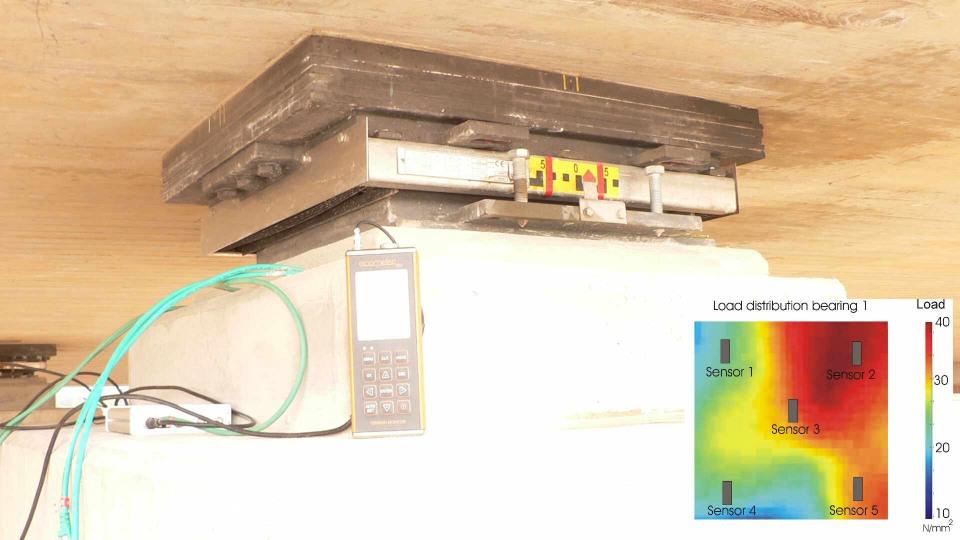

Smart Bridge - bridge bearings load control

The distribution can be determined of the load under bridge bearing load-bearing pillars or foundations with multiple sensors BBS 10_DS from IBJ technology. Uneven load entry can detect but also subsequently through still attached directly with sensors built into the bearing plate in the concrete.

The applications range from the direct voltage measurement in the component to the measurement and monitoring of dynamic loads in real time.

With the sensors is the…

Acousto-elastic concrete strain sensors for heavy duty applications

Acousto elastic concrete strain sensors are used to detect the metrological

Expansion or compression of steel building components as well as for measurements in reinforced and unreinforced concrete bodies used. The thickness of the susceptor (diameter of the bars) may be selected according to the strength reinforcement.

The acousto elastic concrete strain sensors can also be mounted on the outside parts of the structure of steel. With flanges or angle mounting is…

With high speed in the concrete

With the sensor BBS 10_DS from IBJ Technology, surface pressure in concrete components can be determined also afterwards. The applications range from the direct stress measurement in the component to the measurement and monitoring of dynamic loads in real time.

Ultrasonic captures the stress in the structure directly and in real time. All changes can be transferred online via the Internet or satellite radio. The sensors are either placed directly in…

More Releases for Dipl

Free Webinar: Unit and software integration testing in safety-critical projects …

Verifysoft Technology GmbH was founded in 2003 in Offenburg, located in the Black Forest, and has since established itself as a key player in the global software distribution market. With products such as the Code-Coverage Analyzer Testwell CTC++ and the Code Complexity Measurement tools Testwell CMT++ and CMTJava, the company has gained recognition for its ongoing commitment to the advancement of standards in software engineering.

In addition to offering innovative software…

Free Webinar: Challenges in the use of AI systems in safety-relevant systems (wi …

Verifysoft offers seminars, webinars and trainings about software development and quality. Verifysoft Technology is a worldwide leading software distribution company founded 2003 in Offenburg, Black Forest.

Register now to the free webinar on March 30th at 15:00 p.m. CET and learn more about the following topics:

- Definition of artificial intelligence

- Status of standardisation

- Comparison of AI algorithms and classical software

- Requirements engineering for AI

- System and validation tests

- Coverage measurements

For…

Round Belts Market-With the Best Scope, Trends, Benefits, Opportunities to 2028 …

"Infinity Business Insights has published a report entitled Global Round Belts Market Research Report which provides comprehensive data on emerging trends, market drivers, growth opportunities, and barriers that could change the dynamics of the industry market. It provides an in-depth analysis of market segments which includes the product, application, and competitor analysis. The analysis includes historical data from 2016 to 2021 as well as an estimate based on sales from…

Voltage Detector Pen Market is Booming Worldwide (2020-2026)-Says QYR |Top Playe …

LOS ANGELES, United States: QY Research has recently published a research report, “Impact of COVID-19 Outbreak on Voltage Detector Pen, Global Market Research Report 2020". The report has offered exhaustive analysis of the global Voltage Detector Pen, Global market taking into consideration all the crucial aspects like growth factors, constraints, market developments, future prospects, and trends. Market researchers and industry experts have pointed out the key market trends and prospects…

How Faulted Circuit Indicator Market Will Dominate In Coming Years? Key Players: …

The rising awareness about green energy sources across the world is transforming the energy and power industry. The trend of green energy is emerging on account of increasing environmental pollution from traditional energy resources. Governments are playing a significant role on conducting awareness programs about clean energy. Fortune Business Insights in a report, titled “Faulted Circuit Indicator Market Size, Share & Industry Analysis, By Type (Overhead Line Fault Indicator, Cable…

How Faulted Circuit Indicator Market Will Dominate In Coming Years? Key Players: …

The rising awareness about green energy sources across the world is transforming the energy and power industry. The trend of green energy is emerging on account of increasing environmental pollution from traditional energy resources. Governments are playing a significant role on conducting awareness programs about clean energy. Fortune Business Insights in a report, titled “Faulted Circuit Indicator Market Size, Share & Industry Analysis, By Type (Overhead Line Fault Indicator, Cable…