Press release

Guyson Export Success with Environment Friendly PCB Cleaning Equipment

As one of the world's largest manufacturers of technical cleaning and surface finishing equipment, Guyson International is experiencing unprecedented export success in China and Mainland South East Asia with its 'Kerry' brand Microsolve Mono and Co-Solvent 'vapour cleaning' systems. Typically, these systems are used to clean medium to high volume PCB assemblies, such as insulated-gate bipolar transistor (IGBT) power module packaging for electric vehicles (EV), produced by local indigenous manufacturers as well as by subsidiaries of Western-owned companies.This export growth is not a coincidence. A significant part of this has to do with Guyson's Shanghai-based China team, who even during a troubled 2020 and 2021, have continued to attend and exhibit at a series of nationwide electronics seminars with the support from Guyson's Malaysian staff. These regional sales efforts have also been supported by an updated Chinese language website - www.guyson.cn - that highlights the wide range of cleaning and finishing products available from Guyson.

Microsolve Co-Solvent systems achieve cleanliness standards to specifications including BS, IPC [Institute for Printed Circuits], ESA [European Space Agency] and MIL SPEC. The Co-Solvent process defluxes all types of PCBs, assembled and reworked, removes no-clean solder flux residues and eliminates the white deposits associated with traditional single solvent and water-based detergent processes.

There are increasing concerns over the environment and personal health with the current worldwide climate change issue, leading to an increased demand for the Co-Solvent cleaning process. The Co-Solvent process replaces all VOC solvents (Volatile Organic Compounds) which impact global warming and are also classified as CMRs (Carcinogens, Mutagens & Reproductive Toxins).

Furthermore, Microsolve owners enjoy low, predictable running costs, thanks to intelligent machine design - a highly efficient reflux cooling system, a vapour break, and a deep freeboard zone all cut OEL (Occupational Exposure Limits) for operators while minimising costly solvent loss. With an optional automatic HFE (hydrofluoroether) top-up system, you can log the rate of solvent usage. In a 7-day test of a high capacity co-solvent unit, the device showed a total consumption of only 2.4 litres. A typical HFE solvent use per week for PCB cleaning customers is less than 2%, and the solvating solution is typically changed every four to six months.

Automation of the cleaning process also reduces operating costs by ensuring consistently high quality, reducing reject rates and increasing throughput. Both Mono and Co-Solvent Microsolve systems achieve this by controlling the speed at which the basket enters and exits the vapour zone, thus reducing solvent drag-out and losses to the atmosphere that can occur when the vapour blanket is disturbed.

In this regard, Guyson offers a variety of automated handling systems, including the Autotrans Single Axis Lift, which provides vertical movement for loads up to 10 kg, as well as the recently introduced Autotrans iDrive, which offers lifting capacities between 30-80 kg, depending on the model.

In addition to being supplied with guarding to comply with CE regulations for moving parts, Autotrans handling transporters can be integrated with feed conveyors or loading and unloading tables for fully automatic operation. Options to suit machine location, factory layout and operating procedures can also be selected.

Guyson can arrange free 'try before you buy' ultrasonic cleaning trials for your PCB components, prove the process and make recommendations on the most suitable cleaning systems for you - call +44 (0)1756 799911 or email info@guyson.co.uk today.

Guyson International Limited

Snaygill Industrial Estate, Keighley Road,

SKIPTON, North Yorkshire, England BD23 2QR

Privately owned, Guyson International Limited is a worldwide leader in the design and manufacture of blast finishing, spray washing and ultrasonic cleaning equipment. The company, which was founded more than eight decades ago, holds ISO certifications 9001:2015 and ISO 45001:2018 and its head office is located at Skipton, North Yorkshire, in the north of England. Guyson has four international subsidiary companies: Guyson Corporation of the USA, located in Saratoga Springs, New York State; Guyson SA, situated near Paris, France; Guyson Sdn Bhd in Penang, Malaysia; and Guyson CN, in Wuxi, Jiangsu Province, China.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Guyson Export Success with Environment Friendly PCB Cleaning Equipment here

News-ID: 2395416 • Views: …

More Releases from Guyson International Ltd

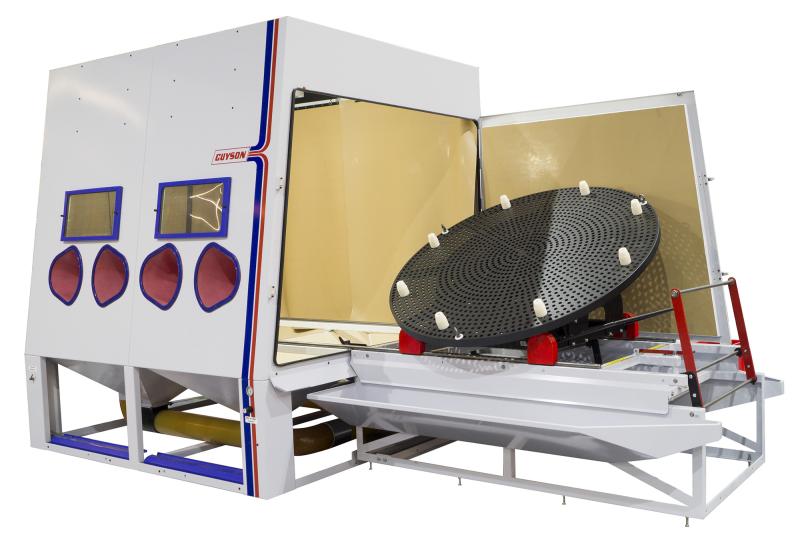

Extra-Large Blast Machine for Blast Etching Aerospace Rings

Guyson International, the UK's foremost industrial finishing equipment manufacturer, has installed a Guyson Euroblast® 2-metre PF (Pressure Fed) blast system into a division of a leading European aerospace company. The extra-large blast cabinet is used to deliver a uniform etched key surface on a range of machined circular aluminium rings prior to bonding.

After blast trails performed at the company's Skipton demonstration centre, a Euroblast 2-metre PF blast system (2.1…

Guyson Twin Spindle Blast Machine for Etching Tubular Components

Guyson International, the UK's leading manufacturer of industrial finishing equipment, has recently manufactured and installed into a UK manufacturing company an automated Multiblast RSB twin spindle blast system for externally blast etching various sizes of tubular components. This new blast system incorporates two rotating blast stations with matching top clamps, to hold the product securely, whilst two vertically traversing blast guns produce a uniform blast etch finish over the length…

Guyson Staff Clock-Up 180 Years!

At Guyson International's Skipton headquarters, Monday 15th August saw rain, much needed, and celebrations, much deserved. Employees from the company's blast and wash division gathered outside to congratulate seven employees who were awarded long service awards. And between them amassed a total of 180 years of service at Guyson, with one, Keith Miller celebrating 50 years of service.

In typical unpredictable UK weather, after so many days of bright hot sunshine,…

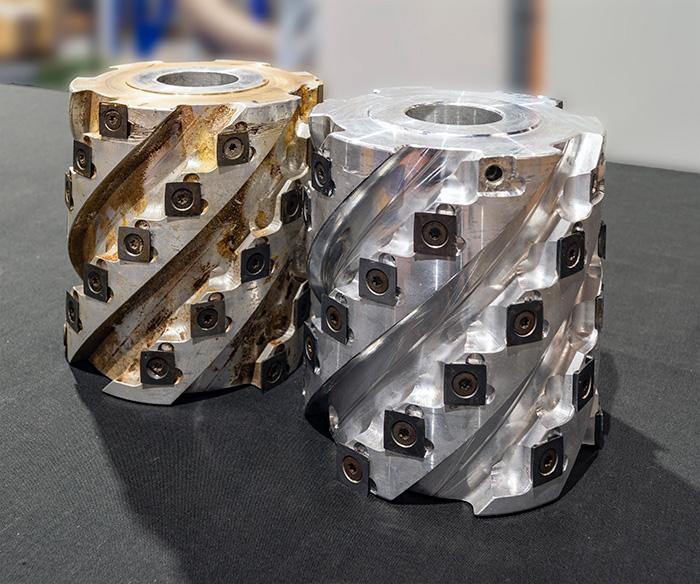

Guyson Equipment Cleans and Maintains Planing and Woodcutting Tools

Guyson International, one of the UK's leading manufacturers of industrial finishing equipment, recently delivered a KS450 ultrasonic cleaning tank and a Formula 1200 benchtop bead blast cabinet to RHW (R H Wilson (Lakes) Ltd.) of Kirkby Stephen, a leading timber importer and supplier, for cleaning and maintaining their wood cutting and planing tools.

The problem was how best to clean 'helical planer blocks' to remove a build-up of pitch, sap, resin…

More Releases for Microsolve

Guyson Embracing Technology to Remotely Pass Off Export Machines

Due to the Covid pandemic and the inability of customers to travel; Guyson International, the UK’s foremost industrial finishing equipment manufacturer, has had to remotely pass off a number of machines destined for export markets. But with the cooperation of their customers and usage of the latest video conferencing software and hardware, the pass off trials were still able to successfully take place on time.

So, through a combination of Microsoft…

Guyson Delivers Further Cleaning Machines for VentilatorChallengeUK Consortium

Guyson International Ltd, the UK's foremost industrial finishing equipment manufacturer, based in Skipton, North Yorkshire, has recently installed a further precision cleaning machine to Rolls-Royce Filton in Bristol, for the VentilatorChallengeUK Consortium. A consortium of significant UK industrial, technology and engineering businesses from across the aerospace, automotive and medical sectors, has come together to produce medical ventilators for the UK.

This latest Guyson 'Kerry' branded Microsolve 250, which was built in…