Press release

APEJ to Hold 50% of Global TPU Elastomers Market Share Through 2027

The global thermoplastic polyurethane elastomers market surpassed US$ 2.5 billion in 2018, and a new study by Fact.MR estimates revenues to grow at 5.4% in 2019. According to the study, increasing demand for TPU elastomers in emerging economies of Asia Pacific excluding Japan (APEJ) continues to create sizeable opportunities for manufacturers. APEJ continues to hold over 50% share of TPU elastomers globally.For detailed insights on enhancing your product footprint, request for a sample here - https://www.factmr.com/connectus/sample?flag=S&rep_id=3445&utm_source=openpr&utm_medium=Prasad

Analyzing the key factors that are fuelling TPU elastomers demand in APEJ, the study reports that strong presence of leading chemical companies along with increasing penetration of small- and medium-scale companies remain key growth drivers. Increasing investments by top-tiered players and rapidly-growing end-user industries continue to attract investments by market leaders, finds the Fact.MR study.

The Fact.MR study also assesses the business and product strategies of key players in the TPU elastomers market. Investments and expansion in Asia Pacific continue to be a key focus for stakeholders in the TPU elastomers market. BASF’s investment in Expanded Thermoplastic Polyurethane (E-TPU) Infinergy® at Changhua, Taiwan, and The Lubrizol Corporation’s investment in Songjiang (Shanghai) China plant are indicators of the growing prominence of APEJ among stakeholders.

For critical insights on this market, request for methodology here – https://www.factmr.com/connectus/sample?flag=RM&rep_id=3445&utm_source=openpr&utm_medium=Prasad

Environmental Concerns Trigger Manufacturing Innovations

The study finds that although TPU elastomers have been witnessing incremental demand across versatile industrial applications, meeting the evolving sustainability requirements continues to be a challenge for stakeholders. Negative impacts of thermoplastics on the environment have been restricting manufacturers from exploring new niche applications. Thereby, leading stakeholders in the TPU elastomers market have been focusing on innovating their manufacturing strategies and technologies to discover biocompatible and biostable TPU elastomers.

According to the study, the focus on finding sustainable solutions is also driven by stringency in environmental regulations. In many countries of APEJ, environmental regulations have become more stringent over the years, and manufacturers have had to adapt to the changing status-quo.

For in-depth competitive analysis, buy now – https://www.factmr.com/checkout/3445?utm_source=openpr&utm_medium=Prasad

Some notable examples include,

• In March 2019, Lubrizol International, Inc. announced the launch of a new, toluene-free Pearlbond™ TPU for films and adhesives, to expand its high-melt strength Pearlbond TPU portfolio. Toluene exposure can have hazardous impact on the environment as well human health. The company announced that the new Pearlbond TPU is toluene-free and recyclable, thereby environment-friendly, and it can be used in various applications such as furniture, footwear, automotive films, and apparels.

• In February 2019, A.P.I. Applicazioni Plastiche Industriali SPA – an Italian chemical company – announced the launch of the new recyclable TPU APILONTM52 A/C-series. The company declared that the new portfolio of its TPU elastomer products reduces the production cycle time by around 70% while significantly cutting the energy consumption and production costs.

• In October 2018, Covestro AG – a German stakeholder in the TPU elastomers market – discovered a new carbon dioxide (CO2)-based technology for manufacturing environmentally-friendly TPU elastomers. With growing concerns about ecological fallout, Covestro established partnerships with research institutes and other companies to boost the use of CO2technology as a synthesis platform for the large-scale production of TPU elastomers.

Read More Trending and Similar Reports from Fact.MR – https://www.globenewswire.com/en/news-release/2020/03/31/2009290/0/en/Controlled-Release-Fertilizers-Sales-Invigorated-by-Improved-Crop-Efficiency-Polymer-Coated-NPK-Fertilizers-Significant-Contributors-Says-a-New-Fact-MR-Study.html

Fact.MR’s study tracks developments in the TPU elastomers market for the assessment period 2019-2027. According to the study, the TPU elastomers market is expected to envisage impressive growth at a CAGR of 5.9% during the assessment period.

Contact:

US Sales Office:

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

Corporate Headquarter:

Unit No: AU-01-H Gold Tower (AU),

Plot No: JLT-PH1-I3A,

Jumeirah Lakes Towers,

Dubai, United Arab Emirates

E: sales@factmr.com

Website: https://www.factmr.com

Content Source: https://www.factmr.com/media-release/972/global-tpu-elastomers-market

About Us:

Market research and consulting agency with a difference! That’s why 80% of Fortune 1,000 companies trust us for making their most critical decisions. While our experienced consultants employ the latest technologies to extract hard-to-find insights, we believe our USP is the trust clients have on our expertise. Spanning a wide range – from automotive & industry 4.0 to healthcare & retail, our coverage is expansive, but we ensure even the most niche categories are analyzed. Our sales offices in United States and Dublin, Ireland. Headquarter based in Dubai, UAE. Reach out to us with your goals, and we’ll be an able research partner.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release APEJ to Hold 50% of Global TPU Elastomers Market Share Through 2027 here

News-ID: 2334204 • Views: …

More Releases from Fact.MR

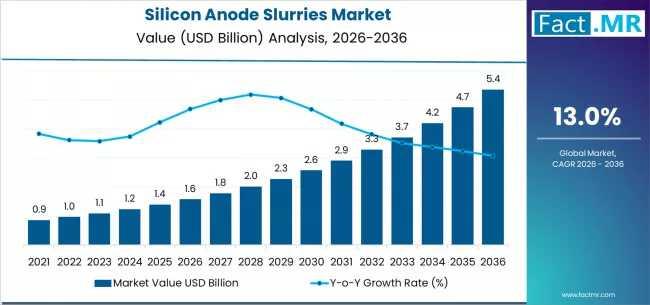

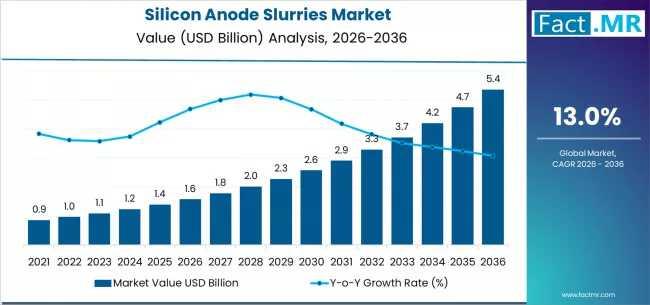

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

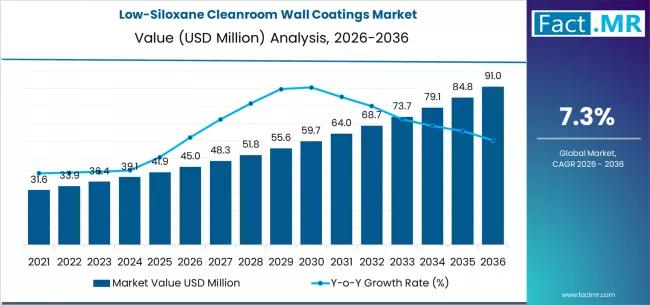

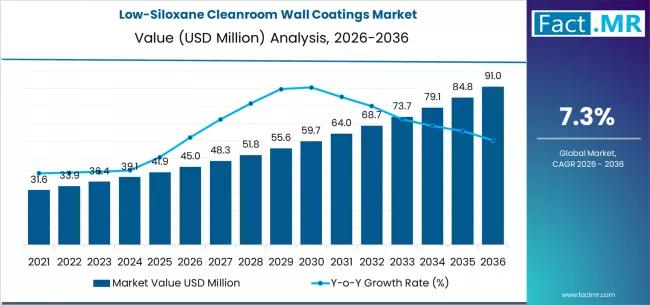

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

More Releases for TPU

High-Performance Soft TPU Modifier for Matte TPU Films | Soft-Touch, Non-Sticky, …

You've adjusted the formulation, slowed the cooling rate, and even changed the resin grade - but the TPU film still ends up sticky, not soft enough, and prone to color loss after aging. These persistent drawbacks limit design freedom, reduce visual appeal, and undermine performance stability. What if the solution didn't require redesigning your entire process, and instead came from enhancing the TPU material itself? SILIKE Soft TPU Modifier particles(https://www.si-tpv.com/soft-modified-tpu-particle-series/)…

Global Demand for TPU Filament From China Spurs New TPU Filament Manufacturer In …

The global movement towards additive manufacturing is revolutionizing supply chains and product development cycles across multiple industrial sectors, leading to rapid adoption of high-performance materials like Thermoplastic Polyurethane (TPU). TPU filament in particular is notable for its combination of elasticity, durability and chemical resistance - something which Chinese producers are taking advantage of by investing heavily and diversifying into flexible polymers manufacturing as part of a competitive edge they possess…

Application of TPU Material in Humanoid Robots

TPU (Thermoplastic Polyurethane) [https://www.ytlinghua.com/polyether-tpu/] has outstanding properties such as flexibility, elasticity, and wear resistance, making it widely used in key components of humanoid robots like exterior covers, robotic hands, and tactile sensors. Below are detailed English materials sorted out from authoritative academic papers and technical reports:

1. Design and Development of an Anthropomorphic Robotic Hand Using TPU Material [https://www.ytlinghua.com/polyether-tpu/]The paper presented here approaches to solve the complexity of an anthropomorphic robotic…

TPU (Thermoplastic Polyurethane) Main Industry Applications

TPU (Thermoplastic Polyurethane [https://www.ytlinghua.com/t3-series-tpu/]) is a versatile material with excellent elasticity, wear resistance, and chemical resistance. Here are its main applications :

1. Footwear Industry - Used in shoe soles, heels, and upper parts for high elasticity and durability. - Commonly seen in sports shoes, outdoor footwear, and casual shoes to enhance shock absorption and grip.

2. Automotive Sector [https://www.ytlinghua.com/polyester-type-tpu-h3-series-product/] - Manufactures seals, gaskets, and weather strips for their flexibility and resistance…

Addressing the Limitations of Traditional TPU and Innovations for EV Charging Ca …

TPU is a versatile material known for its hardness and elasticity, making it popular in various applications. However, traditional TPU faces challenges in meeting the specific performance demands of industries such as automotive, consumer goods, and medical devices. These challenges include inadequate surface quality, high hardness levels limiting flexibility, and a lack of desirable tactile properties, which can impact user experience and product longevity.

Solutions: Modified TPU Technology

The modification of TPU…

Professional 3d printing manufacturer for TPU

What is TPU

TPU is a stands for Thermoplastic Polyurethane. It is a subset of TPE and is a soft polyether type polyurethane that comes in a range of hardness grades. At the same time, TPU also as the one of material be commonly used in injection industry. But today we want to show you another craft to process TPU, that is 3D Printing. Have you ever thought about 3D…