Press release

New efficient transformer lamination cutting lines: the ecolines of GEORG transformer division

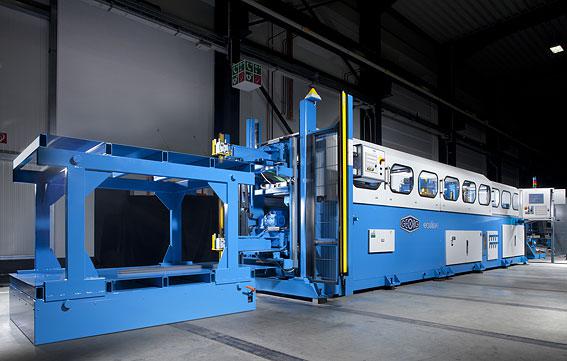

High ROI by consequent standardisation - for economic production of low-loss transformer cores enabling “step-lap” sequenceParticularly in Asia, Africa, South and Middle America, a new period of promoterism for a comprehensive energy supply is heralded. The efficient transformer lamination cutting line TBA400 ecoline and the new TBA600 ecoline for economic production of low-loss transformer cores enabling “step-lap” sequence are GEORG transformer division’s reaction to the worldwide changing energy market. With the new ecolines, GEORG transformer division offers the transformer manufacturers a robust and reliable transformer lamination cutting line at a very favourable lump sum price. A return on investment is guaranteed within a very short period of time. This was reached by consequent standardisation of the line configurations, which are done in batch production and by using optimised working processes.

Reducing installation costs

The manufacturer passes on the cost savings completely to the customers in order to enable them entering a rational, automated transformer production. The TBA400 ecoline is capable to cut laminations with a strip width between 40 and 440 mm; the TBA600 ecoline is capable to cut 50 to 640 mm. The lengths of the laminations go up to 2500 mm worked on the TBA400 ecoline and 3500 mm worked on the TBA600 ecoline. For the cost-saving ecolines, neither any special foundation nor any loop pit are necessary. Thus, the installation efforts are down to a minimum.

Advance technology as standard

The standardised lines are equipped with a 2-head decoiler, a hole punch as well as a V-notch. Additionally, two fixed shears are available. The TBA400 ecoline is optionally equipped with two stacking systems for simple stacking (RS or HS/T); for the TBA600 the customer can choose between HS/T or PB/T stacking system. “The power requirements all over the world are changing and the ecolines are our answer. The economic overall costs of the precise lamination cutting lines were already well-received on the target markets with our TBA400 ecoline. Our new TBA600 ecoline now offers further possibilities”, explains Bernd Peter Schmidt, authorized representative and Managing Director of GEORG transformer division. International service support and optimum advice is done on site by a number of own representations all over the world. For quick and personal assistance in any service case, GEORG experts are also able to give online support.

GEORG transformer division delivered more than 900 production lines, machines and devices world-wide which emphasises the exceptional position and the experience headstart of the German family company from South Westphalia. “We are always searching to break new grounds in order to create technically superior solutions. This is our incentive, our passion. With the ecolines, we have turned over a new leaf”, explicates Mark GEORG, CEO of Heinrich GEORG GmbH Maschinenfabrik. As global thinking medium-sized company, GEORG sticks up for the future.

Further informations: http://www.georg.com/cms/en/products-transformer-systems/tba400-ecoline.html

GEORG transformer division

As the leading producer worldwide we create innovative solutions with the help of our creativity and scientific head start, while maintaining relentless focus on our customers" requirements and needs. Over 900 systems produced and delivered to date say something about our customers" deep trust in pioneering GEORG technology.

The portfolio of GEORG transformer division:

- TBA lamination lines for cutting of "step lap" core sheets

- Slitting lines (TKS) for slitting of grain-oriented and non-grain-oriented electrical steel

- Reactor core cutting lines (TRKA) for manufacturing toroidal reactor cores

- Wound core production lines (SWA) with eccentric shear for the manufacture of single and three phase transformer cores

- Cutting machines (AMC) for amorphous material

- KLT stacking tables for the rational core assembly

- TKWA finfolding lines for the manufacture of corrugated tanks

- Radiator lines (RAD) for the manufacture of cooling radiators

With their extendable, modular design and intelligent, upgradable control systems, GEORG technologies are more than a match for the challenges of today. And tomorrow.

http://www.georg.com/cms/georg-transformer-lines.html

GEORG

Thomas Weber

Siegener Strasse 73-83

57223 Kreuztal

Germany

Tel. +49 (0) 2732 779-0

Fax +49 (0) 2732 779-340

marketing@georg.com

trafo@georg.com

www.georg.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release New efficient transformer lamination cutting lines: the ecolines of GEORG transformer division here

News-ID: 233251 • Views: …

More Releases from GEORG transformer division

TBA400 highspeed: Lamination cutting at highest speed

GEORG technology enables extremely high output of more than 180 transformer laminations per minute

Special requirements within the international transformer industry ask for special solutions. After successful introduction of the economic TBA400 ecoline the technology and world market leader GEORG transformer division has launched a further high efficient transformer lamination cut-to-length line: theTBA400 highspeed.

More than 180 sheets can be produced per minute. For comparison: The GEORG TBA400 ecoline cuts 42…

New cutting line: GEORG transformer division offers technological advantage

First line for cutting of transformer laminations of up to 1250 mm width

Where creativity and technically leading knowledge push the progress, the eye for new solutions improving the quality of result counts notably. According to this principle, the GEORG transformer division engineering teams have considerably pushed the state of the transformer lamination cutting line technology with their new developed TBA1200. Up to now, it was necessary to use two…

More Releases for TBA

tert-Butyl Acrylate (TBA) Market Share Driven by Expanding Demand in Coatings an …

tert-Butyl Acrylate (TBA) Market Size

The global market for tert-Butyl Acrylate (TBA) was valued at US$ 84.1 million in the year 2024 and is projected to reach a revised size of US$ 123 million by 2031, growing at a CAGR of 5.7% during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-30R573/Global_tert_Butyl_Acrylate_TBA_Market_Research_Report_2020

Overall Market Overview:

The tert-Butyl Acrylate (TBA) Market is witnessing significant market growth, fueled by its wide-ranging applications in coatings, adhesives, and specialty chemical synthesis.…

Tert-butyl Alcohol (TBA) Market Analysis and Future Prospects for 2030

The world of the tert-butyl alcohol (tba) market is a complex and ever-evolving landscape, shaped by consumer demands and technological advancements. In this report, we delve into the depths of this market to provide a profound and comprehensive analysis, catering to a diverse audience that includes manufacturers, suppliers, distributors, and investors. Our primary goal is to empower industry stakeholders with invaluable insights to make informed decisions in a rapidly changing…

Terminal Operating Systems (TOS) Market 2023-2030 is Booming Worldwide | Navis, …

Detailed analysis of the report "Terminal Operating Systems (TOS) Market" helps to understand the various types of Terminal Operating Systems (TOS) products that are currently in use, along with the variants that would gain prominence in the future by Infinitybusinessinsights.com. This report will help the viewer in Better Decision Making.

Market Overview: Terminal Operating Systems (TOS) are specialized software solutions used in the management and optimization of container terminals and port…

Tert-Butylamine (tBA) Market Revenue, Major Players, Consumer Trends, Analysis & …

The global Tert-Butylamine (tBA) market research report published by Reports and Data is a comprehensive assessment of the Tert-Butylamine (tBA) industry with regards to key companies in the market, market size, share, revenue, demand, drivers, restraints, regional bifurcation, segments and sub-segments of the market. The study evaluates the market from various dimensions to deliver an end-product that is accurate, reliable, informative, and elaborate and includes detailed market segmentation, regional analysis,…

Basmati Rice Market Size 2020-26, HBI, ESTRACO, EAST END FOODS, TBA SUNTRA

The latest study on the Global Basmati Rice market report represents a deep appraisal of the international industry. The research report on the worldwide Basmati Rice market 2020-2026 sheds light on qualitative as well as quantitative insights, historical Basmati Rice industry status and authorized projection related to the Basmati Rice market size. Each and every segment exhibited in this report are discovered through verifiable research methods and techniques. It also…

Tert-butyl Alcohol (TBA) Market: Competitive Dynamics & Global Outlook 2024

LP INFORMATION offers a latest published report on Tert-butyl Alcohol (TBA) Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Tert-butyl Alcohol (TBA) market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019.…