Press release

New cutting line: GEORG transformer division offers technological advantage

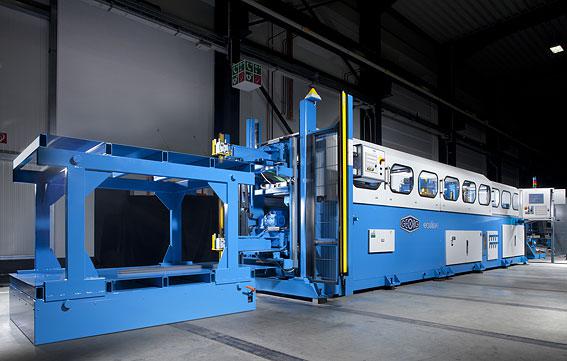

For the first time, the new developed GEORG TBA1200 enables for the cutting of transformer sheets up to 1250 mm width.

Where creativity and technically leading knowledge push the progress, the eye for new solutions improving the quality of result counts notably. According to this principle, the GEORG transformer division engineering teams have considerably pushed the state of the transformer lamination cutting line technology with their new developed TBA1200. Up to now, it was necessary to use two narrow laminations side by side for an optimum transformer construction with sheet widths of 1020 up to 1250 mm. For the first time, the new line with swing shear allows for the cutting of the required sheet width of up to 1250 mm from the coil. As it is no longer necessary to place single laminations side by side, the new development also persuades with regard to economy. At the same time, the new production process also leads to a considerable reduction of personnel.

New dimensions with regard to quality and economy

“By means of the precise cutting results of our TBA1200, we enabled a considerable quality improvement during the production of low-loss transformer cores”, emphasises Bernd Peter Schmidt, GEORG transformer division Managing Director.

The TBA1200 cuts electrical sheet of 800 to 6000 mm length and 120 to 1250 mm width and is equipped with a decoiler containing 2 hydraulic decoiler shafts and optionally with a coil turnstile and a coil car. The line is capable to run up to 240 m/min. and has an STA(2) BH stacking system. The following servo-electrically driven tools are installed: V-notches (1 or 2 pieces), hole punches (up to 4, capable for slitting and manual or CNC cut-to-length), slot punching unit, tip cutting shear and swing shear. Optionally, an automatic strip tongue feeding unit can be ordered.

“With or TBA1200, our customers have a technical advantage for their transformer production compared to our competitors”, clarifies Schmidt. “From our decades of experience as world market and technology leader, we know that a high quality and fast reacting production is very important for our customers. Head start needs a good launch which we now offer with our new line - because our technology pays off through success.” The demand that GEORG transformer division observes by now shows the needs and confidence with regard to the new technology. Two customers are already convinced by the impressive advantages of the TBA1200 and have ordered the line for optimisation of their production processes.

GEORG transformer division

With their creative knowledge, the technology and world market leader creates efficient and progressive machines, lines and devices for the transformer production. More than 900 lines delivered for well-respected transformer producer underline the trust in GEORG’s pathbreaking technology.

www.georg.com

http://www.georg.com/cms/georg-transformer-lines.html

GEORG

Thomas Weber

Siegener Strasse 73-83

57223 Kreuztal

Germany

Tel. +49 (0) 2732 779-0

Fax +49 (0) 2732 779-340

marketing@georg.com

trafo@georg.com

www.georg.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release New cutting line: GEORG transformer division offers technological advantage here

News-ID: 230068 • Views: …

More Releases from GEORG transformer division

TBA400 highspeed: Lamination cutting at highest speed

GEORG technology enables extremely high output of more than 180 transformer laminations per minute

Special requirements within the international transformer industry ask for special solutions. After successful introduction of the economic TBA400 ecoline the technology and world market leader GEORG transformer division has launched a further high efficient transformer lamination cut-to-length line: theTBA400 highspeed.

More than 180 sheets can be produced per minute. For comparison: The GEORG TBA400 ecoline cuts 42…

New efficient transformer lamination cutting lines: the ecolines of GEORG transf …

High ROI by consequent standardisation - for economic production of low-loss transformer cores enabling “step-lap” sequence

Particularly in Asia, Africa, South and Middle America, a new period of promoterism for a comprehensive energy supply is heralded. The efficient transformer lamination cutting line TBA400 ecoline and the new TBA600 ecoline for economic production of low-loss transformer cores enabling “step-lap” sequence are GEORG transformer division’s reaction to the worldwide changing energy market. With…