Press release

Liquid Thermal Interface Materials Market Professional Survey Report to 2028 | 3M, Indium Corporation, DowDuPont, Laird Technology, Boyd Corporation

According to a recent study by Fact.MR, demand for liquid thermal interface materials is estimated to grow at 4.5% in 2019 over 2018. Gains are likely to be driven by development of novel liquid thermal interface materials and their widespread adoption in electrical and automotive industries.According to the study, as adoption of artificial intelligence and machine learning technology grows, the demand for high-performance computing solutions is on the rise. With consumers increasingly preferring compact high-processing laptops and PCs, integrated circuit manufacturers are focusing on the production of high-density circuits with smaller sizes. Demand for high-performance computing continues to surge with incremental growth in the sales of high-performance gaming laptops and Alienware.

Browse Full Report, visit at https://www.factmr.com/report/3085/liquid-thermal-interface-materials-market

The study finds that liquid thermal interface materials are gaining increasing traction in the market providing microprocessor manufacturers an efficient and lightweight solution for the production of miniature electronic components.

Growing demand for wearable technology such as smartwatches and virtual reality headsets is also likely to fuel the demand for small-sized electronic components which, in turn, is estimated to benefit the liquid thermal interface materials market. Additionally, burgeoning demand for compact high-performance processors in smartphones is further estimated to bolster liquid thermal interface material market growth.

Request a Report Sample to Gain Valuable Insights at https://www.factmr.com/connectus/sample?flag=S&rep_id=3085

Challenges with Silicone Thermal Management Creating Opportunities

Silicone-based thermal interface materials are the conventional thermal management systems being used in LEDs since their inception. However, recent studies have linked silicone-based thermal interface materials to be a vital cause for the decreased output of LEDs over time. According to the Fact.MR study, manufacturers are making a shift towards other alternatives due to these challenges. These shifts have also been complemented by the rising cost of producing silicone.

The gradual shift to non-silicone-based thermal interface material is likely to open up lucrative opportunities for liquid thermal interface material manufacturers with LEDs finding growing adoption in households and automobile industry owing to its cost-effectiveness and eco-friendly nature. Companies are launching new products to leverage the growing demand for non-silicone based thermal interface material in the LED industry, a recent example being Electrolube’s launch of two non-silicone thermal pastes in Heat Transfer Compound Plus and Heat Transfer Compound.

Additionally, liquid alloys offer promising prospects to explore in the liquid thermal interface material market with the substances offering the superior thermal conductivity of metals while allowing greater control over consistent application on surfaces, unlike liquid metals.

For More Detailed Information about Methodology at https://www.factmr.com/connectus/sample?flag=RM&rep_id=3085

Europe Remains the Largest Market for Liquid Thermal Interface Materials

According to Fact.MR’s research, Europe is expected to remain at the forefront of liquid thermal interface material market growth. Burgeoning investments in the electric vehicle market, coupled with numerous initiatives popularizing the adoption of the eco-friendly alternatives are likely to present lucrative opportunities for liquid thermal interface material manufacturers with thermal management occupying the primal focus of electric vehicle battery manufacturers.

Numerous companies are expanding their production facilities or setting up new manufacturing sites to capitalize on the growing demand for thermal interface materials in Europe. For instance, Sekisui Chemicals Ltd., a leading manufacturer of thermal interface material, announced it would be setting up a production facility in the Netherlands specifically to meet the burgeoning demand for thermal interface material in the electronic vehicle industry in Europe. Due to these factors, Europe is estimated to account for the production of more than 20% of liquid thermal interface materials in 2019.

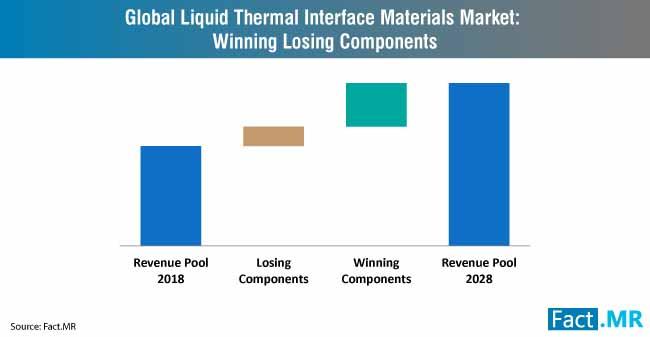

The Fact.MR report tracks the liquid thermal interface materials market for the period 2018-2028. According to the report, the liquid thermal interface materials market is projected to grow at 5.2% CAGR through 2028.

Schedule a FREE Consultation Call with Our Analysts/Industry Experts to Find Solution for Your Business at https://www.factmr.com/connectus/sample?flag=AE&rep_id=3085

Contact:

US Sales Office:

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

E: sales@factmr.com

Corporate Headquarter:

Unit No: AU-01-H Gold Tower (AU),

Plot No: JLT-PH1-I3A,

Jumeirah Lakes Towers,

Dubai, United Arab Emirates

About Fact.MR

Market research and consulting agency with a difference! That’s why 80% of Fortune 1,000 companies trust us for making their most critical decisions. While our experienced consultants employ the latest technologies to extract hard-to-find insights, we believe our USP is the trust clients have on our expertise. Spanning a wide range – from automotive & industry 4.0 to healthcare & retail, our coverage is expansive, but we ensure even the most niche categories are analyzed. We are headquartered in Dubai, and operate from our sales office in Dublin, Ireland. Reach out to us with your goals, and we’ll be an able research partner.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Liquid Thermal Interface Materials Market Professional Survey Report to 2028 | 3M, Indium Corporation, DowDuPont, Laird Technology, Boyd Corporation here

News-ID: 2262913 • Views: …

More Releases from Fact.MR

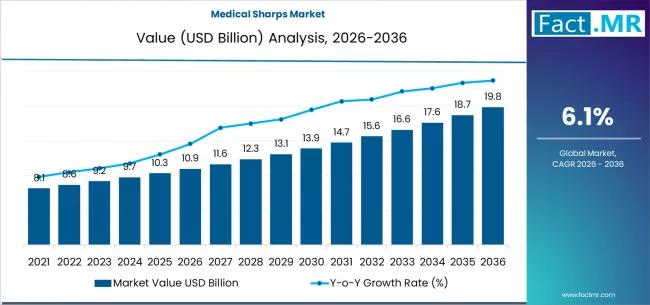

Medical Sharps Market Forecast CAGR 2026 to 2036 is 6.1% | Fact.MR Report

The global medical sharps market is projected to grow from USD 12.1 billion in 2026 to approximately USD 21.4 billion by 2036. This steady expansion represents a compound annual growth rate (CAGR) of 5.9% over the ten-year forecast period.

The market is being propelled by the global increase in surgical procedures, the rising prevalence of chronic diseases requiring self-injection, and a heightened focus on safety-engineered devices to prevent needlestick injuries.

Get…

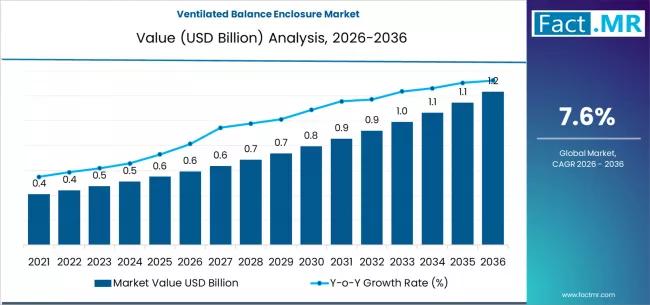

Ventilated Balance Enclosure Market achieving a compound annual growth rate of 7 …

The global ventilated balance enclosure (VBE) market is projected to grow from USD 564.2 million in 2026 to approximately USD 1.26 billion by 2036. This growth reflects a compound annual growth rate (CAGR) of 7.1% over the ten-year forecast period.

The market is being propelled by the expansion of pharmaceutical quality control, chemical research, and materials testing facilities where the handling of fine powders and potent compounds necessitates high-precision weighing…

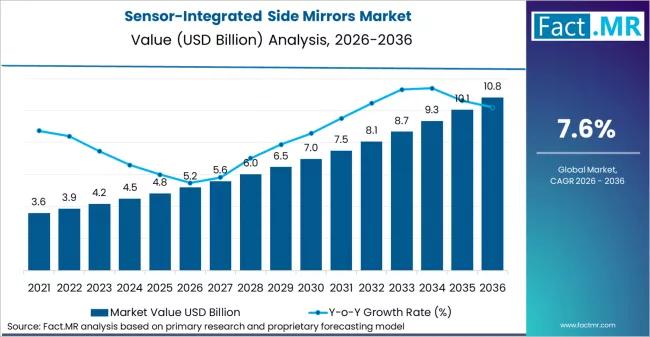

Sensor-Integrated Side Mirrors Market is Valued USD 5.2 billion in 2026 | Fact.M …

The global sensor-integrated side mirrors market is projected to grow from USD 1.6 billion in 2026 to approximately USD 3.1 billion by 2036. This growth represents a compound annual growth rate (CAGR) of 6.8% over the forecast period.

The market is being driven by the rapid integration of Advanced Driver Assistance Systems (ADAS) and the transition toward "intelligent" exterior components that enhance vehicle safety and automated parking capabilities.

Get Access of Report…

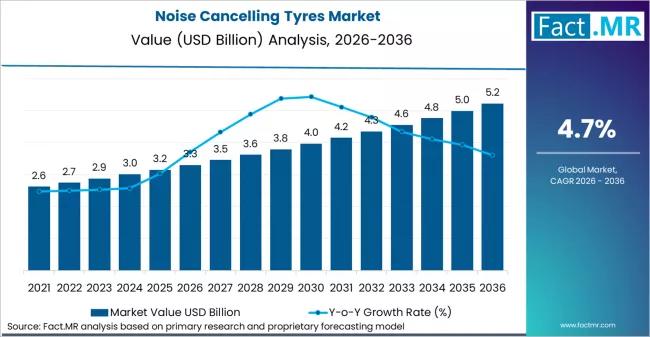

Noise Cancelling Tyres Market Will Reach USD 5.2 billion by 2036 | Research Repo …

The global noise-cancelling tyres market is projected to grow from USD 1.2 billion in 2026 to approximately USD 3.1 billion by 2036. This represents a robust compound annual growth rate (CAGR) of 9.9% over the ten-year forecast period.

The market is being fundamentally transformed by the "Silent Revolution" in the automotive industry, as the transition to Electric Vehicles (EVs) makes tyre-to-road noise the most prominent sound in the cabin.

Get Access…

More Releases for Thermal

Thermal Weeder Market

Thermal Weeder Market Value is Anticipated to Increase at a Stable CAGR over the Forecast Period (2023 to 2029). It provides an in-depth analysis of the market segments which include products, applications, and competitor analysis.

Important changes in the business allow key players to attain larger profits. This Thermal WeederMarket study report is the best way to make changes with the help of entire market condition and metrics provided here. These…

Rising Demand for Thermal Analysis Techniques to Boost Differential thermal anal …

[San Francisco, USA] - Market research firm Trouve360Reports has added a latest report on the global differential thermal analysis market. The report offers a comprehensive analysis of the market, providing insights into key trends, growth drivers, and challenges that are shaping the industry.

The report presents a detailed market introduction, highlighting the definition of differential thermal analysis and its applications in various industries. The market overview section of the report offers…

Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market …

According to Market Study Report, Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market provides a comprehensive analysis of the Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC,…

What is the Difference Between Direct Thermal and Thermal Transfer Labels?

Northern Label Systems, specialists in supplying high quality labels explain the differences between Direct Thermal https://www.northern-label-systems.co.uk/labels-by-type/direct-thermal-labels and Thermal Transfer Labels https://www.northern-label-systems.co.uk/labels-by-type/thermal-transfer-labels

Thermal Transfer printing uses an ink ribbon to transfer the printed image from the heated printhead of the label printer onto the surface of the label while Direct Thermal printing transfers the image directly onto a heat sensitive material.

There are advantages and disadvantages to both methods. Direct Thermal label…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) …

Qyresearchreports include new market research report "Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Sales Market Report 2018" to its huge collection of research reports.

This report studies the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market status and forecast, categorizes the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market size (value & volume) by key players, type, application, and…